Structural features and combustion reactivity of residual carbon in fine slag from entrained-flow gasification

-

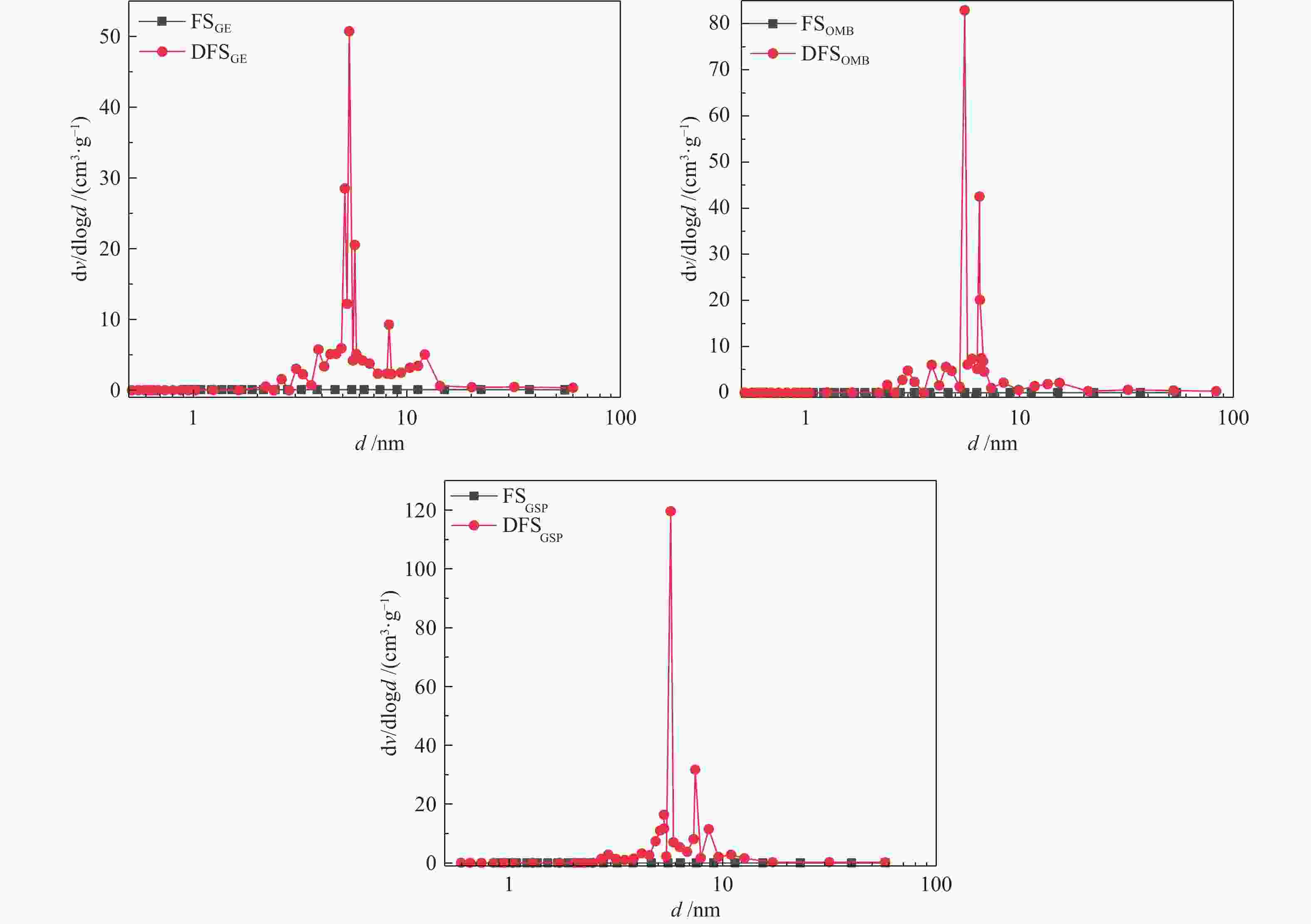

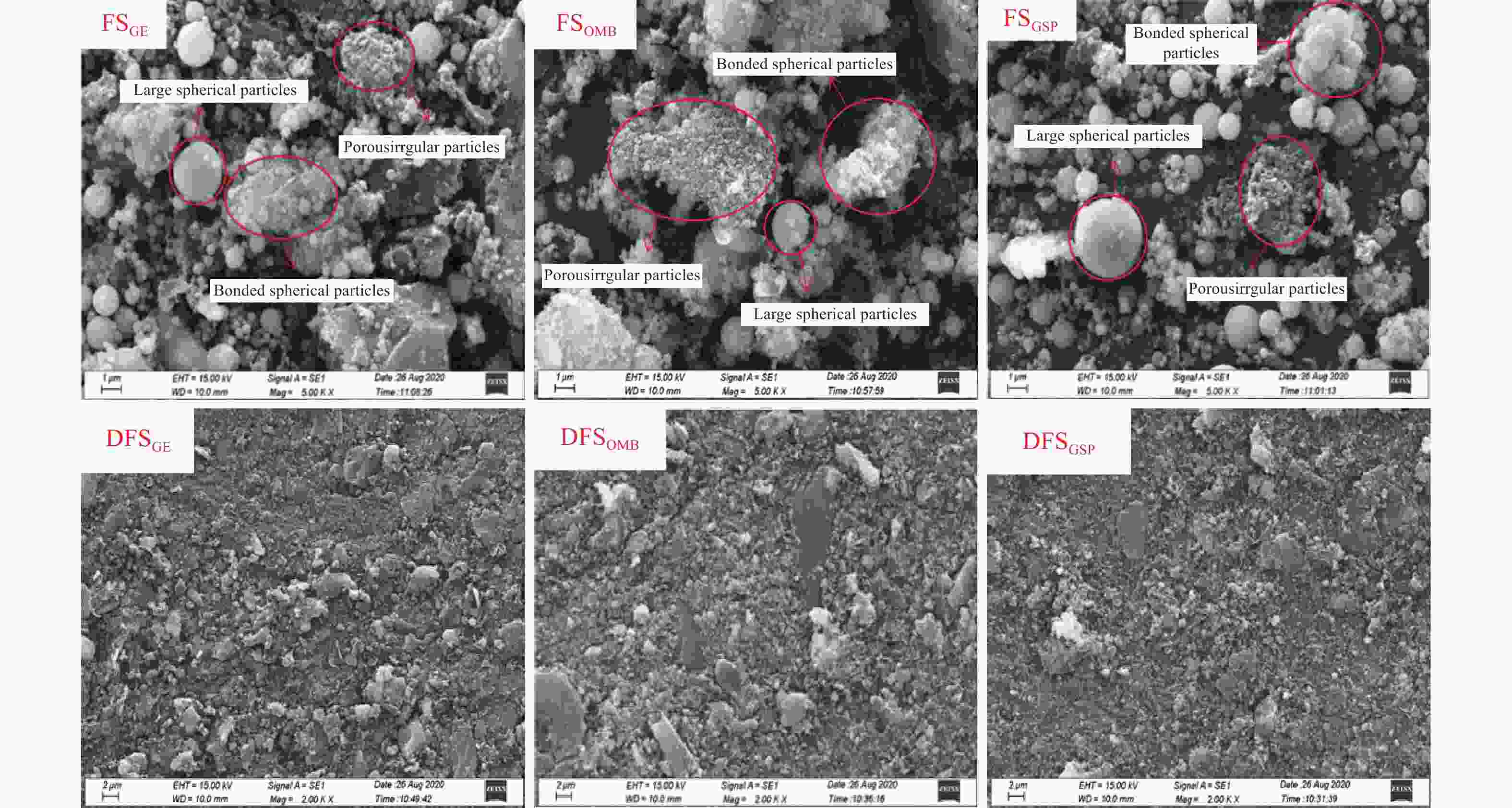

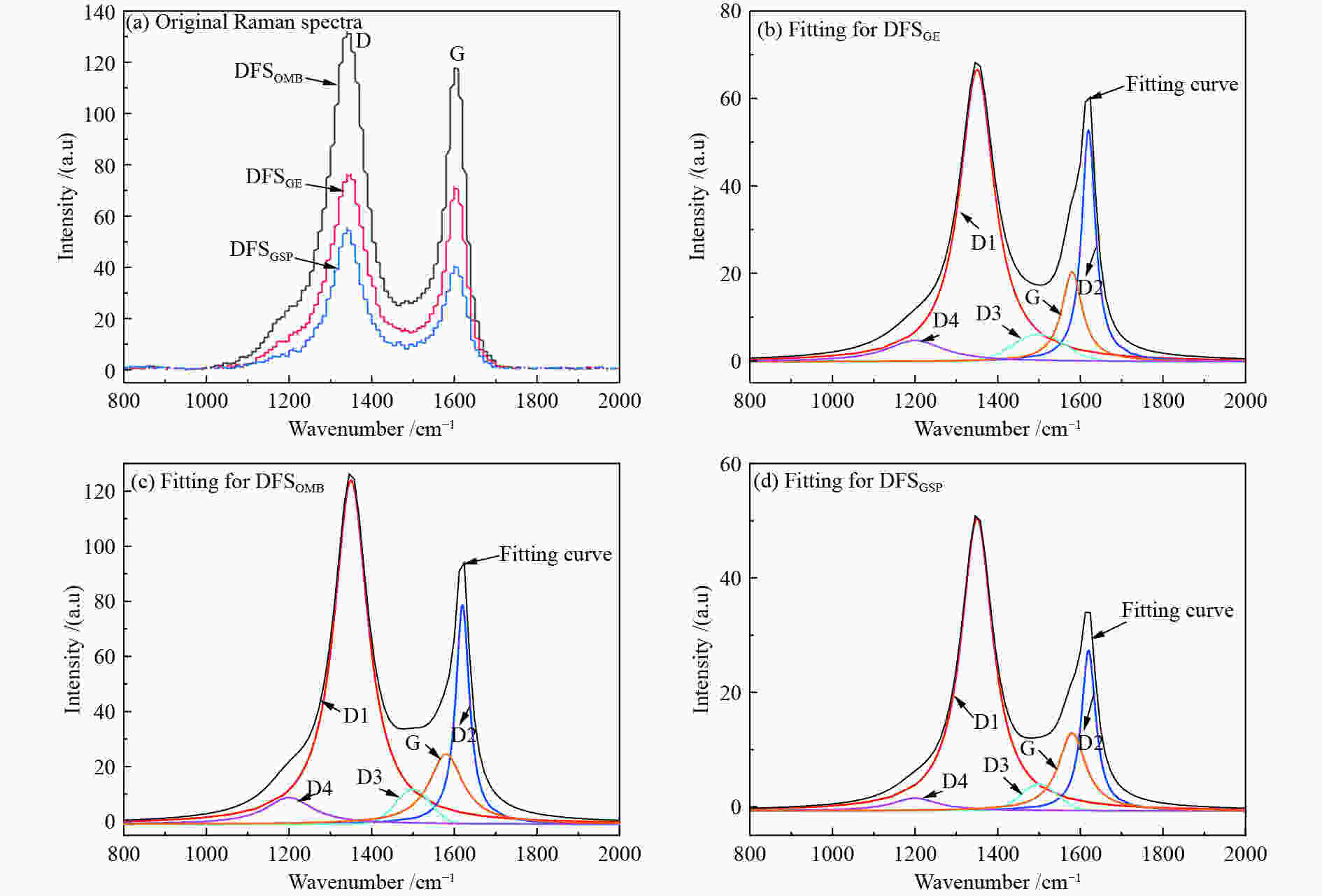

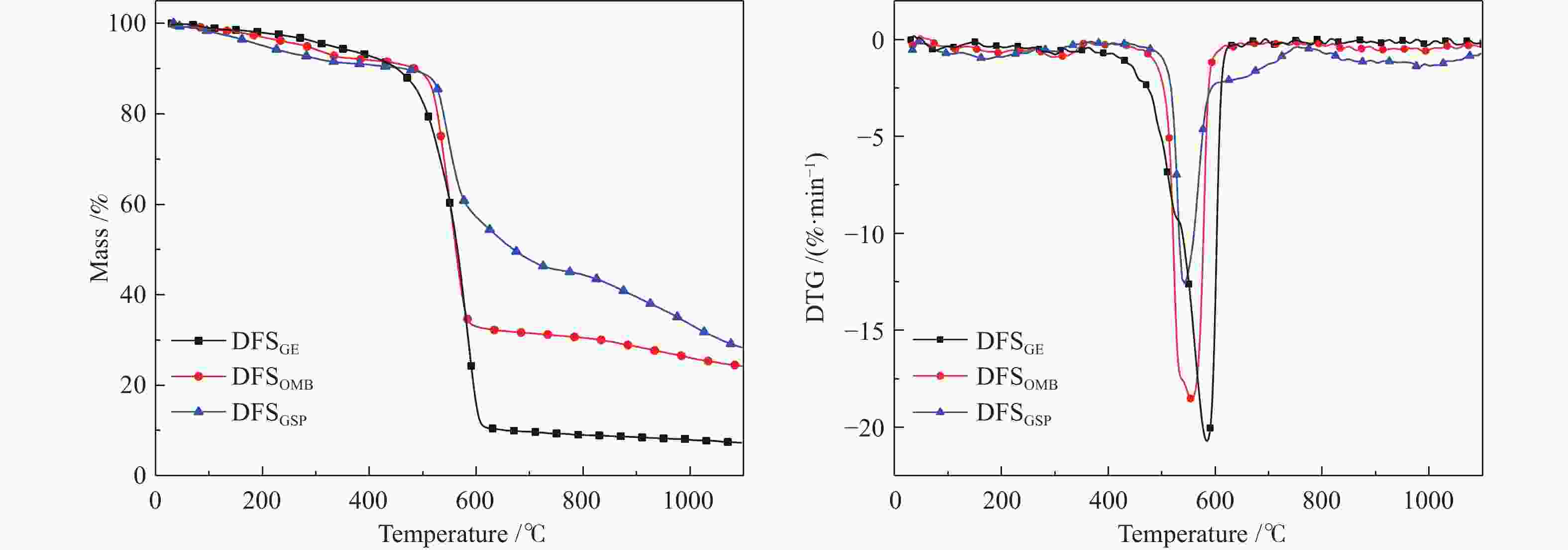

摘要: 气流床气化过程中产生的细渣含碳量很高,目前多以填埋的方式进行处理,将细渣用于循环流化床锅炉掺烧有望为细渣处理提供有利的技术。本研究选用宁东能源化工基地典型气化工艺GE、OMB及GSP产生的气化细渣为研究对象,利用物理吸附仪、激光拉曼及热重分析仪等仪器,系统研究了气化细渣中残炭的结构特征与燃烧特性。结果表明,原始气化细渣中的物质可分为黏结球形颗粒、多孔不规则颗粒与孤立的大球形颗粒,而酸洗后的气化细渣多以疏松细小的颗粒和多孔不规则块状颗粒存在;细渣中残炭的孔径尺寸主要分布在4−8 nm,且比表面积与残炭的活性位点大小顺序均为:GE > OMB > GSP;GE渣中残炭结构有序度最低,无定形炭结构最多,GSP则相反;GE渣中残炭燃烧速率最快,主要是由于GE渣中残炭有较大的比表面积、较多的无定形炭结构及较高的的活性位点,且GE渣中残炭的综合燃烧指数为5.26 × 10−7%2/(min2·℃3)。Abstract: The carbon content in fine slag during entrained-flow gasification is very high, at present, most of the fine slag was disposed by landfill. It is expected to provide a favorable technology by adding the fine slag to the circulating fluidized bed boilers to participate in combustion reaction. In this study, the gasification fine slags generated from GE, OMB and GSP gasifier, which are typical gasification processes in Ningdong energy and chemical base, was selected for investigation. The structural features and combustion reactivity of the residual carbon in the gasification fine slag were systematically studied by physical adsorption apparatus, laser Raman spectrum and thermogravimetric analyzer. The results showed that the materials in the original gasification fine slag could be divided into cohesive spherical particles, porous irregular particles and isolated large spherical particles, while the acid-washed gasification fine slag was mostly composed of loose fine particles and porous irregular massive particles. Additionally, the particle size of the residual carbon was clustered to 4–8 nm, and the specific surface area and active sites of that decreased orderly as follows: GE>OMB>GSP. The order degree of the residual carbon structure in GE slag was the lowest, and the amorphous carbon structure in it was the highest, while the case in GSP was the opposite. The combustion rate of the residual carbon in GE slag was the fastest, mainly due to its large specific surface area, more amorphous carbon structure and active site, and the comprehensive combustion index of residual carbon in GE slag was 5.26×10−7 %2/(min2·oC 3).

-

表 1 细渣的工业分析与元素分析

Table 1 Proximate and ultimate analyses of fine slags

Sample Proximate analysis wd/% Ultimate analysis wd/% V FC A C H N S O* FSGE 10.12 25.21 64.67 20.25 1.03 0.18 2.07 11.80 FSOMB 3.88 14.26 81.86 16.40 0.53 0.10 0.45 0.60 FSGSP 6.96 12.43 80.61 16.33 0.71 0.08 1.51 0.76 note: V:volatile matter; FC:fixed carbon; d:dry basis; *:calculated by difference 表 2 细渣的灰分组成

Table 2 Ash composition of fine slags

Sample Compositions w/% SiO2 Al2O3 Fe2O3 CaO Na2O K2O MgO others FSGE 44.86 19.63 9.03 9.82 5.22 2.31 6.23 2.90 FSOMB 43.72 20.06 10.63 9.74 5.08 1.98 5.51 3.28 FSGSP 59.04 16.95 7.60 6.02 2.06 2.49 3.48 2.36 表 3 脱灰前后细渣的孔隙特征参数

Table 3 Pore characteristic parameters of fine slag before and after demineralization

Sample BET surface

area/(m2·g−1)Pore volume/

(× 103 cm3·g−1)Average

pore diameter/nmFSGE 160.39 0.232 2.892 DFSGE 737.31 3.026 16.419 FSOMB 82.50 0.151 3.659 DFSOMB 716.79 2.861 15.968 FSGSP 102.61 0.133 2.591 DFSGSP 429.28 3.089 28.786 表 4 拉曼光谱峰面积比

Table 4 Raman band area ratio

Parameter DFSGE DFSOMB DFSGSP ID1/IG 5.430 4.928 4.383 IG/IAll 0.107 0.124 0.141 ID3/IG + D2 + D3 0.164 0.134 0.131 ID3/IAll 0.057 0.044 0.045 ID4/IAll 0.067 0.064 0.038 ID3 + D4/IAll 0.124 0.108 0.083 表 5 燃烧曲线的特征参数

Table 5 Characteristic parameters of combustion curve

Fuel t1/℃ th/℃ tpeak/℃ Wmax/(%·min−1) Wmean/(%·min−1) S/(%2·min−2·℃−3) DFSGE 503.7 630.2 584.1 20.71 4.06 5.26×10−7 DFSOMB 502.7 634.7 554.2 18.55 4.27 4.94×10−7 DFSGSP 502.8 745.0 543.2 12.64 1.78 1.19×10−7 -

[1] 张林民, 王焦飞, 白永辉, 苏暐光, 宋旭东, 于广锁. 宁东煤灰层/熔渣界面煤焦气化反应特性原位研究[J]. 燃料化学学报,2020,48(2):129−136. doi: 10.3969/j.issn.0253-2409.2020.02.001ZHANG Lin-min, WANG Jiao-fei, BAI Yong-hui, SU Wei-guang, SONG Xu-dong, YU Guang-suo. In-situ study of Ningdong char particles gasification characteristics on the interface of ash layer and slag[J]. J Fuel Chem Technol,2020,48(2):129−136. doi: 10.3969/j.issn.0253-2409.2020.02.001 [2] WU T, GONG M, LESTER E, WANG F, ZHOU Z, YU Z. Characterisation of residual carbon from entrained-bed coal water slurry gasifiers[J]. Fuel,2007,86(7/8):972−982. doi: 10.1016/j.fuel.2006.09.033 [3] 杨帅, 石立军. 煤气化细渣组分分析及其综合利用探讨[J]. 煤化工,2013,41(4):29−31. doi: 10.3969/j.issn.1005-9598.2013.04.009YANG Shuai, SHI Li-jun. Composition analysis of the fine slag from coal gasification and its comprehensive utilization[J]. Coal Chem Ind,2013,41(4):29−31. doi: 10.3969/j.issn.1005-9598.2013.04.009 [4] GUO, F, MIAO Z, GUO Z, LI J, ZHANG Y, WU J. Properties of flotation residual carbon from gasification fine slag[J]. Fuel,2020,267:117043. doi: 10.1016/j.fuel.2020.117043 [5] 杜杰, 戴高峰, 李帅帅, 王学斌, 孙晓伟, 谭厚章. 气化细渣基础燃烧特性试验研究[J]. 洁净煤技术,2019,25(2):83−88.DU Jie, DAI Gao-feng, LI Shuai-shuai, WANG Xue-bin, SUN Xiao-wei, TAN Hou-zhang. Experimental study on the fundamental combustion characteristics of fine slag from gasification[J]. Clean Coal Technol,2019,25(2):83−88. [6] WU S, HUANG S, JI L, WU Y, GAO J. Structure characteristics and gasification activity of residual carbon from entrained-flow coal gasification slag[J]. Fuel,2014,122:67−75. doi: 10.1016/j.fuel.2014.01.011 [7] ZHAO X, ZENG C, MAO Y, LI W, PENG Y, WANG T, EITENEER B, ZAMANSKY V, FLETCHER T. The surface characteristics and reactivity of residual carbon in coal gasification slag[J]. Energy Fuels,2010,24(1):91−94. doi: 10.1021/ef9005065 [8] XU S, ZHOU Z, GAO X, YU G, GONG X. The gasification reactivity of unburned carbon present in gasification slag from entrained-flow gasifier[J]. Fuel Process Technol,2009,90(9):1062−1070. doi: 10.1016/j.fuproc.2009.04.006 [9] HUANG S, WU S, WU Y, GAO J. Structure characteristics and gasification activity of residual carbon from updraft fixed-bed biomass gasification ash[J]. Energy Conver Manage,2017,136:108−118. doi: 10.1016/j.enconman.2016.12.091 [10] 罗海华. 循环流化床锅炉飞灰残碳燃烧特性的实验研究[D].武汉: 华中科技大学, 2007.LUO hai-hua. Experimental research on combustion characteristics of fly ash residual carbon of CFB boiler[D]. Wuhan: Huazhong University of Science and Technology, 2007. [11] DAI G, ZHENG S, WANG X, BAI Y, DONG Y, DU J, SUN X, TAN H. Combustibility analysis of high-carbon fine slags from an entrained flow gasifier[J]. J Environ Manage,2020,271:111009. doi: 10.1016/j.jenvman.2020.111009 [12] ZHANG X, BAI Y, WEI J, SONG X, WANG J, YAO M, YU G. Study on char-ash-slag-liquid transition and its effect on char reactivity[J]. Energy Fuels,2020,34(03):3941−3951. doi: 10.1021/acs.energyfuels.9b03155 [13] ZHANG L, WANG J, SONG X, BAI Y, YAO M, YU G. Influence of biomass ash additive on fusion characteristics of high-silicon-aluminum coal ash[J]. Fuel,2020,282:118876. doi: 10.1016/j.fuel.2020.118876 [14] 帅航, 尹洪峰, 袁蝴蝶, 陈金学. 煤气化炉渣的高温物相组成演变与黏温特性[J]. 煤炭转化,2015,38(3):44−48. doi: 10.3969/j.issn.1004-4248.2015.03.010SHUAI Hang, YI Hong-feng, YAUN Hu-die, CHEN Jin-xue. phase composition evolution and viscosity-temperature characteristics of gasification slags at High-temperature[J]. Coal Convers,2015,38(3):44−48. doi: 10.3969/j.issn.1004-4248.2015.03.010 [15] 张新沙, 宋旭东, 苏暐光, 卫俊涛, 白永辉, 于广锁. 宁东煤煤焦-CO2气化反应特性的原位研究[J]. 燃料化学学报,2019,47(4):385−392. doi: 10.1016/S1872-5813(19)30018-0ZHANG Xin-sha, SONG Xu-dong, SU Wei-guang, WEI Jun-tao, BAI Yong-hui, YU Guang-suo. In-situ study on gasification reaction characteristics of Ningdong coal chars with CO2[J]. J Fuel Chem Technol,2019,47(4):385−392. doi: 10.1016/S1872-5813(19)30018-0 [16] 赵永彬, 吴海骏, 张学斌, 刘洪刚, 井云环, 袁伟. 煤气化残渣基多孔陶瓷的制备研究[J]. 洁净煤技术,2016,22(5):7−11.ZHAO Yong-bin, WU Hai-jun, ZHANG Xue-bin, LIU Hong-gang, JING Yun-huan, YUAN Wei. Fabrication of porous ceramic from coal gasification residual[J]. Clean Coal Technol,2016,22(5):7−11. [17] 宋瑞领, 李静, 付亮亮, 许义, 蓝天. 多喷嘴对置式水煤浆气化炉炉渣特性研究[J]. 洁净煤技术,2018,24(5):43−49.SONG Rui-ling, LI Jing, FU Liang-liang, XU Yi, LAN Tian. Characteristics of slags generated from multi-nozzle opposed coal-water slurry gasifier[J]. Clean Coal Technol,2018,24(5):43−49. [18] SHENG C. Char structure characterised by Raman spectroscopy and its correlations with combustion reactivity[J]. Fuel,2007,86(15):2316−2324. doi: 10.1016/j.fuel.2007.01.029 [19] JAWHARI T, ROID A, CASADO J. Raman spectroscopic characterization of some commercially available carbon black materials[J]. Carbon,1995,33(11):1561−1565. doi: 10.1016/0008-6223(95)00117-V [20] DIPPEL B, JANDER H, HEINTZENBERG J. NIR FT Raman spectroscopic study of flame soot[J]. Phys Chem Chem Phys,1999,1:4707−12. doi: 10.1039/a904529e [21] SFORNA M C, ZUILEN M A V, PHILIPPOT P. Structural characterization by Raman hyperspectral mapping of organic carbon in the 3.46 billion-year-old Apex chert, Western Australia[J]. Geochim Cosmochim Acta,2014,124(1):18−33. [22] WU J, WANG B, CHENG F. Thermal and kinetic characteristics of combustion of coal sludge[J]. J Therm Anal Calorim,2017,129(3):1899−1909. doi: 10.1007/s10973-017-6341-1 [23] WANG X, LI S, ADEOSUN A, LI Y, VUJANOVIC M, TAN H, DUIC N. Effect of potassium-doping and oxygen concentration on soot oxidation in O2/CO2 atmosphere: A kinetics study by thermogravimetric analysis[J]. Energy Conver Manage,2017,149:686−697. doi: 10.1016/j.enconman.2017.01.003 [24] 周军, 张海, 吕俊复. 不同升温速率下石油焦燃烧特性的热重分析[J]. 煤炭转化,2006,29(2):39−43. doi: 10.3969/j.issn.1004-4248.2006.02.010ZHOU Jun, ZHANG Hai, LV Jun-fu. Study on combustion characteristics of petroleum coke at different heating rates by using thermogravimetry[J]. Coal Convers,2006,29(2):39−43. doi: 10.3969/j.issn.1004-4248.2006.02.010 -

下载:

下载: