Effect of tetralin on the reaction behavior of volatiles from pyrolysis of Naomaohu coal

-

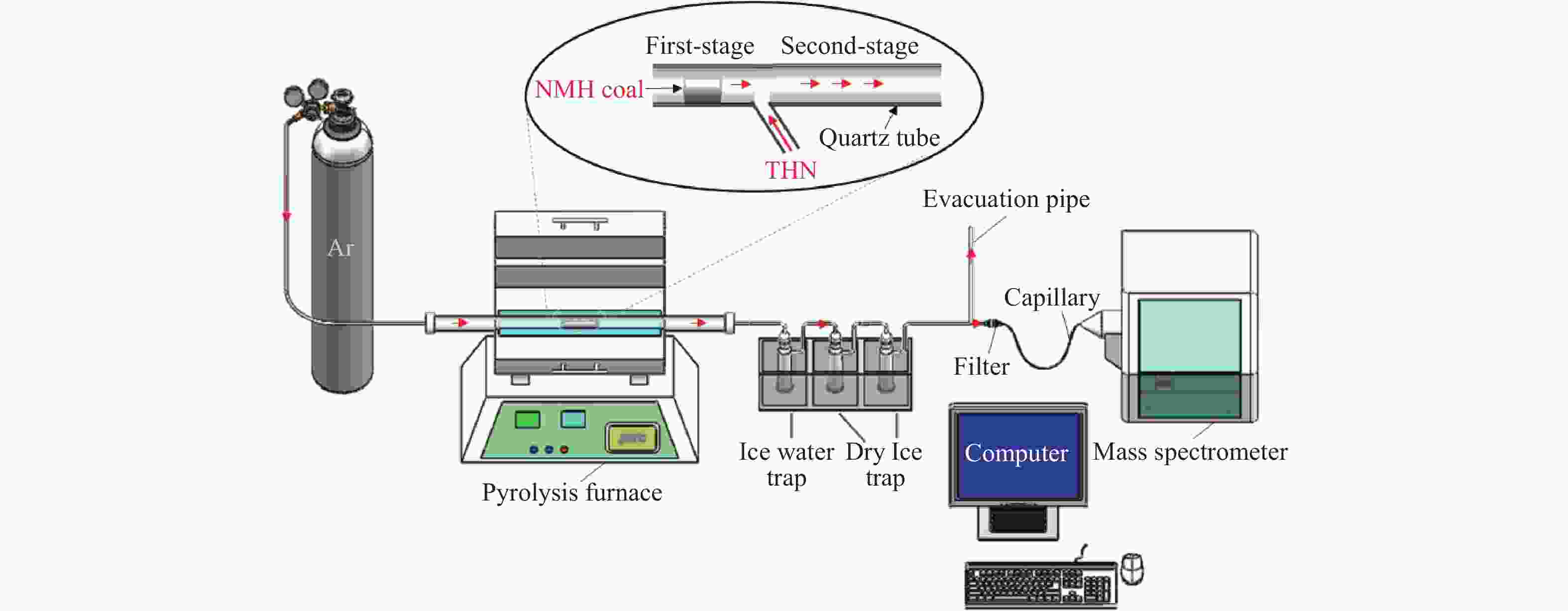

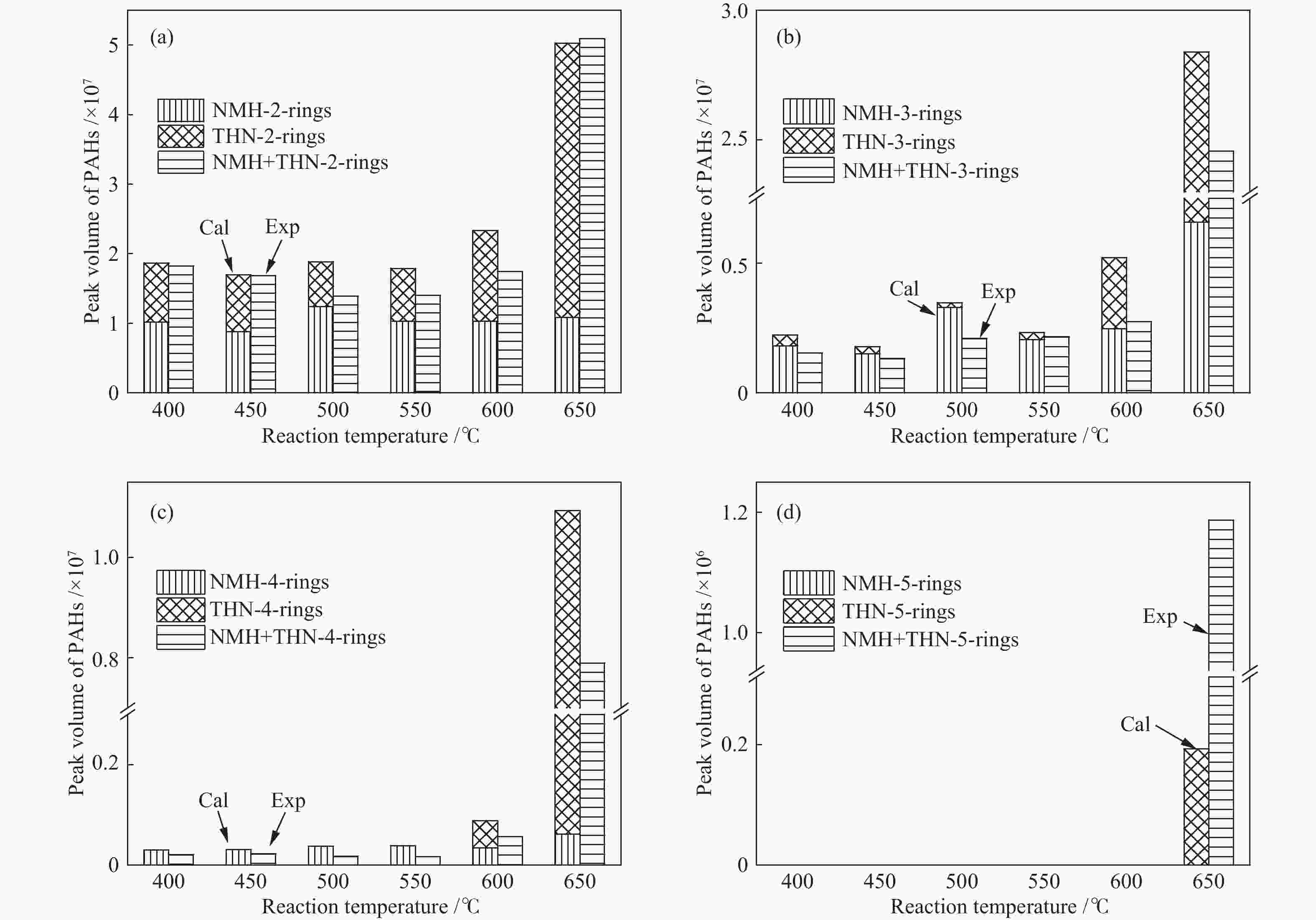

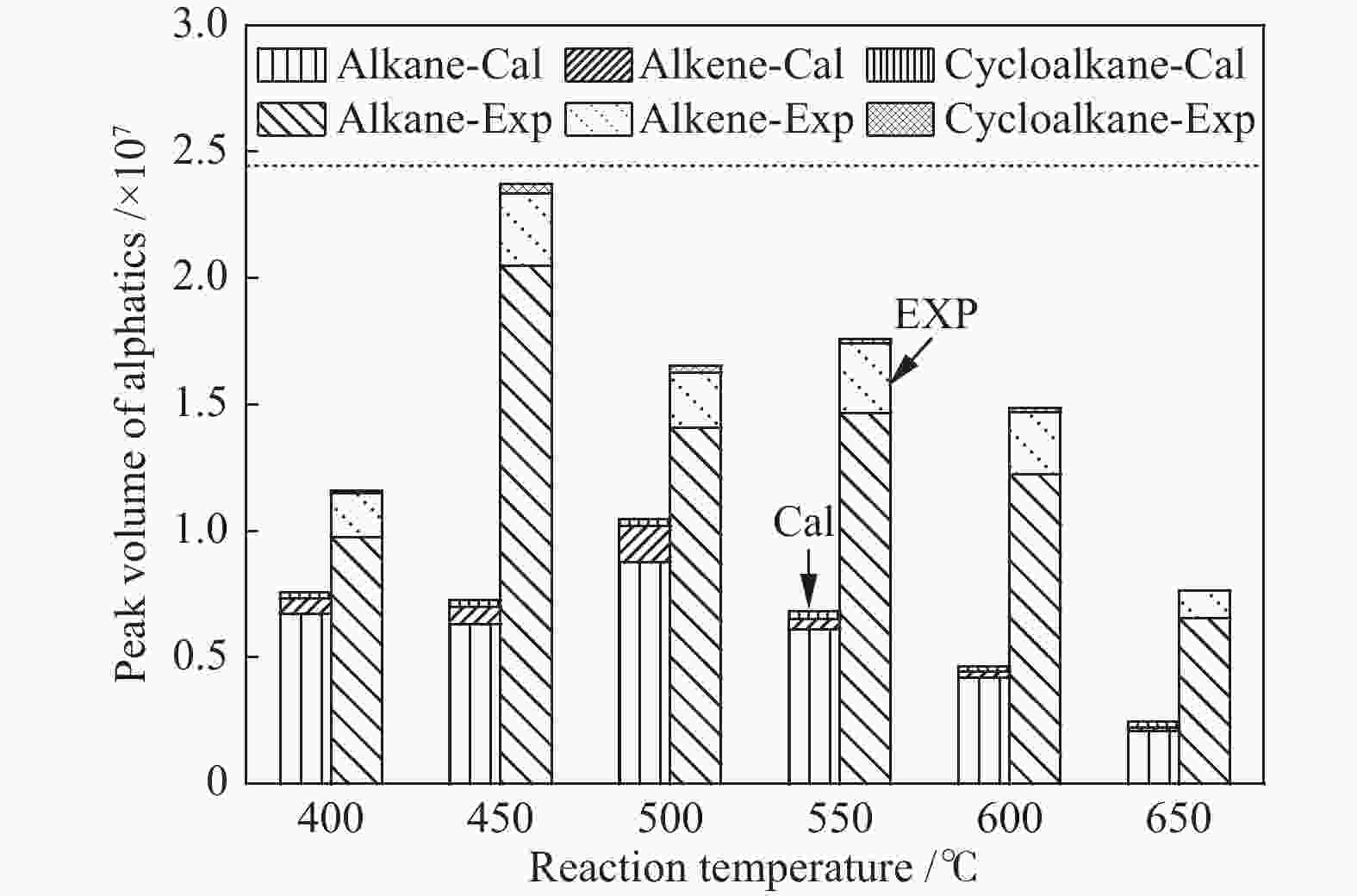

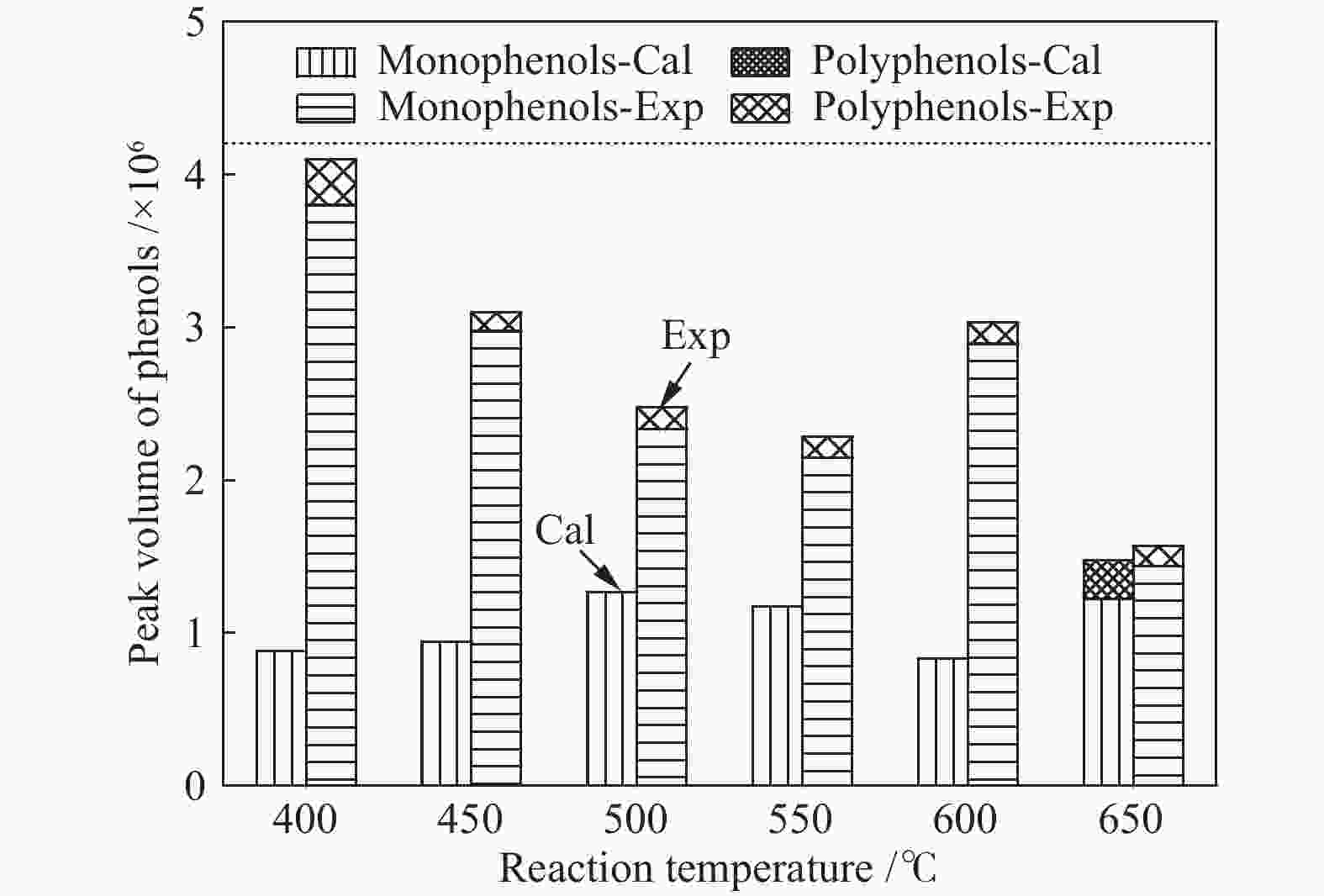

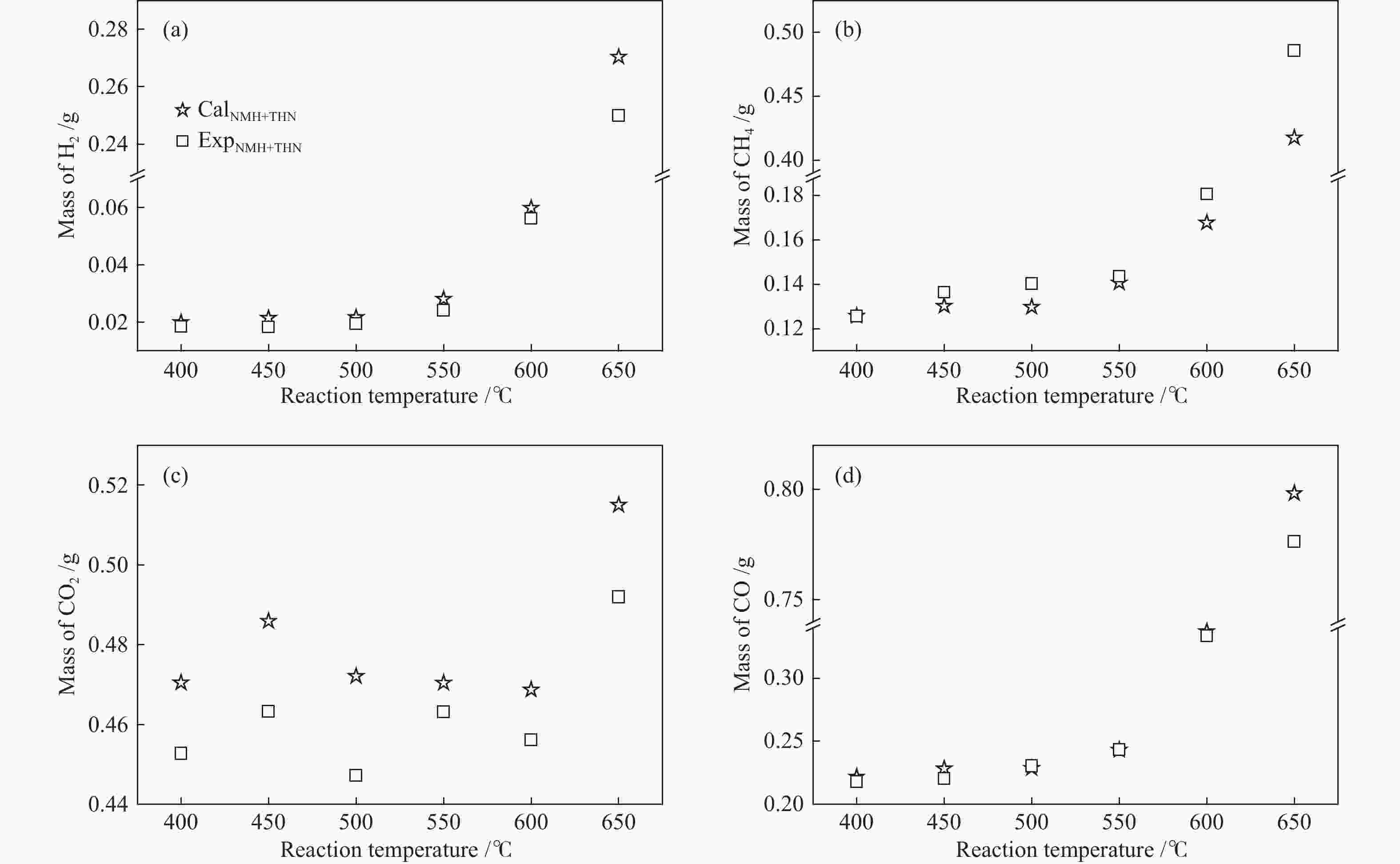

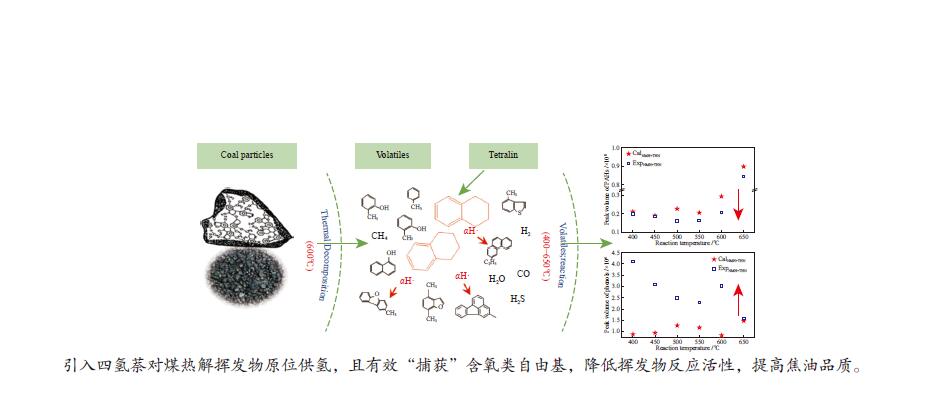

摘要: 煤在中低温热解过程中挥发物反应会显著影响焦油组成和析炭行为,这与挥发物反应活性及体系富氢组分含量有关。本文采用两段式固定床反应器,通过引入四氢萘(THN),进行淖毛湖煤热解挥发物在不同温度下的反应行为,及其对产物分布和析炭产率影响的对比研究,借助全二维气质联用仪对焦油组成进行分析。结果表明,400 °C时因挥发物与THN间的反应较弱且焦油冷凝导致析炭量较高;随着温度升高,挥发物和THN间的反应加剧,导致液体产物产量下降、气体产量增大。根据挥发物和THN反应产物分布的计算值和实验值发现,引入THN后液体产物产量增大,且2−5环芳烃和析炭量减少。表明挥发物与THN之间存在相互作用,促进了THN的α−H转移,为反应体系提供了更多H·。同时,有助于酚类化合物和其他含氧类物的形成,特别是多元酚。煤热解挥发物的反应活性与含氧类自由基有关,此类自由基对H·的键合力较强。Abstract: The volatiles’ reaction has a significant influence on composition and coking behavior of tar during low-medium temperature pyrolysis of coal, which is closely related to the activity of volatiles and the content of components rich in hydrogen in the system. By introducing tetralin, the effect of reaction of volatiles generated by pyrolysis of Naomaohu coal on the product distribution and coke yield was explored at various temperatures using a two-stage fixed bed reactor. The tar composition was analyzed by a comprehensive two-dimensional gas chromatography/mass spectrometry. The results show that the yield of coke is higher at 400 oC due to the weaker reaction between volatiles and THN and tar condensation. As the temperature increases, the reaction between volatiles and THN intensifies, resulting in the decrease of liquid products yield and the increase of gas yield. According to the calculated and experimental values of the reaction products of volatiles and THN, it is found that the liquid products yield increases after the introduction of THN. The contents of aromatic hydrocarbons with 2−5 rings and coke both decrease. This indicates that the interaction between volatiles and THN promotes the α−H transfer of THN and provides more active hydrogen for the reaction system. Besides, the interaction between volatiles and THN is also beneficial to the formation of phenolic compounds and other oxygenated compounds, especially for polyphenols. The activity of volatiles during coal pyrolysis is related to oxygen-containing radicals, which have a strong bond with active hydrogen.

-

Key words:

- Naomaohu coal /

- tetralin /

- volatiles’ reaction /

- tar /

- coke

-

表 1 淖毛湖煤的基本性质

Table 1 Basic properties of NMH coal

Proximate analysis w/% Ultimate analysis wdaf/% Gray-King wdaf/% Mad Ad Vdaf C H N S Oa tar yield water yield 19.50 5.80 50.12 74.35 5.13 0.72 0.31 19.49 15.4 11.7 note: ad: air-dry basis; daf: dry-and-ash-free basis; a: by difference -

[1] 周琦. 低阶煤提质技术现状及完善途径[J]. 洁净煤技术,2016,22(2):23−30.ZHOU Qi. Status and improvement approach of low rank coal upgrading technologies[J]. Clean Coal Technol,2016,22(2):23−30. [2] 郭树才, 罗长齐, 张代佳, 韩壮, 刘恒韫, 康锡志, 于兴国, 胡贵河. 褐煤固体热载体干馏新技术工业性试验[J]. 大连理工大学学报,1995,35(1):46−50.GUO Shu-cai, LUO Chang-qi, ZHANG Dai-jia, HAN Zhuang, LIU Heng-yun, KANG Xi-zhi, YU Xing-guo, HU Gui-he. Experiment in pilot plant of new technology for lignite retorting using solid heat carrier[J]. J Dalian Univ Technol,1995,35(1):46−50. [3] 王勤辉, 骆仲泱, 方梦祥, 倪明江, 岑可法. 12兆瓦热电气多联产装置的开发[J]. 燃料化学学报,2002,30(2):141−146. doi: 10.3969/j.issn.0253-2409.2002.02.009WANG Qin-hui, LUO Zhonng-yang, FANG Meng-xiang, NI Hong-jiang, CEN Ke-fa. Development of a 12 MW multi-generation of gas, steam and power[J]. J Fuel Chem Technol,2002,30(2):141−146. doi: 10.3969/j.issn.0253-2409.2002.02.009 [4] 戴秋菊, 唐道武, 常万林. 采用多段回转炉热解工艺综合利用年青煤[J]. 煤炭加工与综合利用,1999,(3):22−23. doi: 10.3969/j.issn.1005-8397.1999.03.008DAI Qiu-ju, TANG Dao-wu, CHANG Wan-lin. Comprehensive utilization of low rank coal in multistage rotary furnace pyrolysis technology[J]. Coal Process Compr Util,1999,(3):22−23. doi: 10.3969/j.issn.1005-8397.1999.03.008 [5] ZHANG C, WU R C, HU E F, LIU S Y, XU G W. Coal pyrolysis for high-quality tar and gas in 100 kg fixed bed enhanced with internals[J], Energy Fuels, 2014, 28: 7294–7302. [6] EDWARDS J H, SCHLUTER K, TYLER R J. Upgrading of flash pyrolysis tars to synthetic crude oil: 1. First stage hydrotreatment using a disposable catalyst[J], Fuel, 1985, 64: 594–599. [7] 曲洋, 初茉, 郝成亮, 张超, 白书霞. 固定床提质过程褐煤的热碎裂/粉化特性及其负效应分析[J]. 煤炭学报,2018,43(7):2036−2043.QU Yang, CHU Mo, HAO Cheng-liang, ZHANG Chao, BAI Shu-xia. Characteristics of lignite fragmentation/pulverization and its negative effects during upgrading in fixed-bed[J]. J China Coal Soc,2018,43(7):2036−2043. [8] PUSAT S, AKKOYUNLU M-T. A new empirical correlation to model drying characteristics of low rank coals[J]. Int J Oil Gas Coal Technol. 2017, 1: 1. [9] PATTANOTAI T, WATANABE H, OKAZAKI K. Experimental investigation of intraparticle secondary reactions of tar during wood pyrolysis[J]. Fuel,2013,104:468−475. doi: 10.1016/j.fuel.2012.08.047 [10] JIE Y Y, QIAO P J, ZONG S, QIN C B, WANG Y Y. Fast pyrolysis characteristics of two typical coastal zone biomass fuels by thermal gravimetric analyzer and down tube reactor[J]. Bioresour Technol,2019,283:96−105. [11] LIU Z Y. Advancement in coal chemistry: Structure and reactivity[J]. Sci Sin Chim,2014,44:1431−1435. doi: 10.1360/N032014-00159 [12] LIU Z Y. Origin of common problems in fast coal pyrolysis technologies for tar: The countercurrent flow of heat and volatiles[J]. CIESC J,2016,67:1−5. [13] DONG L, HAN S, YU W H, LEI Z P, KANG S G, SHUI H F. Effect of volatile reactions on the yield and quality of tar from pyrolysis of Shenhua bituminous coal[J]. J Anal Appl Pyrolysis,2019,140:321−330. doi: 10.1016/j.jaap.2019.04.009 [14] XIONG Z, WANG Y, SYED H, HU X, HAN H D, SU S, HU S, XIANG J. Effects of heating rate on the evolution of bio-oil during its pyrolysis[J]. Energy Convers Manag,2018,163:420−427. doi: 10.1016/j.enconman.2018.02.078 [15] XIONG Z, SYED H, HU X, GUO J H, CHEN Y J, LIU Q, WANG Y, SU S, XIANG J. Effects of the component interaction on the formation of aromatic structures during the pyrolysis of bio-oil at various temperatures and heating rates[J]. Fuel,2018,233:461−468. doi: 10.1016/j.fuel.2018.06.064 [16] XU K, HU S, WANG Y, ZHANG L P, SU S, JIANG L, XU J, XIANG J. Relation between char structures and formation of volatiles during the pyrolysis of Shenfu coal: further understanding on the effects of mobile phase and fixed phase[J]. Fuel Process Technol,2018,178:379−385. doi: 10.1016/j.fuproc.2018.07.022 [17] LI X R, JIN X, WANG M J, YU Y X, KONG J, XIE W, WANG J C, CHANG L P, BAO W R. Effect of volatiles' reaction on coking of tar during pyrolysis of Naomaohu coal in a downer-bed reactor[J]. Fuel Process Technol,2021,212:106623. doi: 10.1016/j.fuproc.2020.106623 [18] JIN X, LI X R, KONG J, XIE W, WANG M J, WANG J C, BAO W R, CHANG L P. Insights into coke formation during thermal reaction of six different distillates from the same coal tar[J]. Fuel Process Technol,2021,211:106592. doi: 10.1016/j.fuproc.2020.106592 [19] WANG Q, WANG M J, WANG H, KONG J, XIE W, WANG J C, CHANG L P, BAO W R. Effect of temperature and gasification gas from char on the reactions of volatiles generated from rapid pyrolysis of a low rank coal[J]. Fuel Process Technol,2021,212:106601. doi: 10.1016/j.fuproc.2020.106601 [20] JIN L J, ZHOU X, HE X F, HU H Q. Integrated coal pyrolysis with methane aromatization over Mo/HZSM-5 for improving tar yield[J]. Fuel,2013,114:l87−190. [21] DONG C, JIN L J, LI Y, ZHOU Y. Integrated process of coal pyrolysis with steam reforming of methane for improving the tar yield[J]. Energy Fuels,2014,28:7377−7384. doi: 10.1021/ef501796a [22] 陆强, 郭浩强, 叶小宁, 王昕, 周民星. 供氢剂作用下生物质快速热解的研究进展[J]. 林产化学与工业,2017,37(6):1−9. doi: 10.3969/j.issn.0253-2417.2017.06.001LU Qiang, GUO Hao-qiang, YE Xiao-ning, WANG Xin, ZHOU Ming-xing. Research Progress of Hydrogen Donor Assisted Fast Pyrolysis of Biomass[J]. Chem Ind For Prod,2017,37(6):1−9. doi: 10.3969/j.issn.0253-2417.2017.06.001 [23] XUE Y, ZHOU S, BAI X L. Role of hydrogen transfer during catalytic co-pyrolysis of lignin and tetralin over HZSM-5 and HY zeolite catalysts[J]. ACS Sustainable Chem Eng,2016,4:4237−4250. [24] 申俊, 熊奇, 武瑞涛, 刘刚, 牛艳霞. 甲烷气氛下模型化合物热解的初步研究[J]. 燃烧科学与技术,2015,21(1):47−53.SHEN Jun, XIONG Qi, WU Rui-tao, LIU Gang, NIU Yan-xia. Preliminary Research on the thermal cracking of model compounds under methane atmosphere[J]. J Combust Sci Technol,2015,21(1):47−53. [25] CONNORS W, JOHANSON L, SARKANEN K, WINSLOW P. Thermal degradation of kraft lignin in tetralin. Holzforschung. 1980, 34 (1): 29−37. [26] WU J F, LIU Q Y, WANG R X, HE W J, SHI L, GUO X J, CHEN Z Z, JI L M, LIU Z Y. Coke formation during thermal reaction of tar from pyrolysis of a subbituminous coal[J], Fuel Process Technol. 2017, 155: 68–73. [27] 杨晓林, 应立明, 覃志伟. 四氢萘热解反应机理研究[J]. 化学学报,1990,48:441−446.YANG Xiao-lin, YING Li-ming, QIN Zhi-wei. The study of mechanism for the thermolysis of tetralin[J]. Acta Chim Sin,1990,48:441−446. -

下载:

下载: