Study of the dissolution performance of ferrum and calcium compounds in residue hydrogenation reaction samples

-

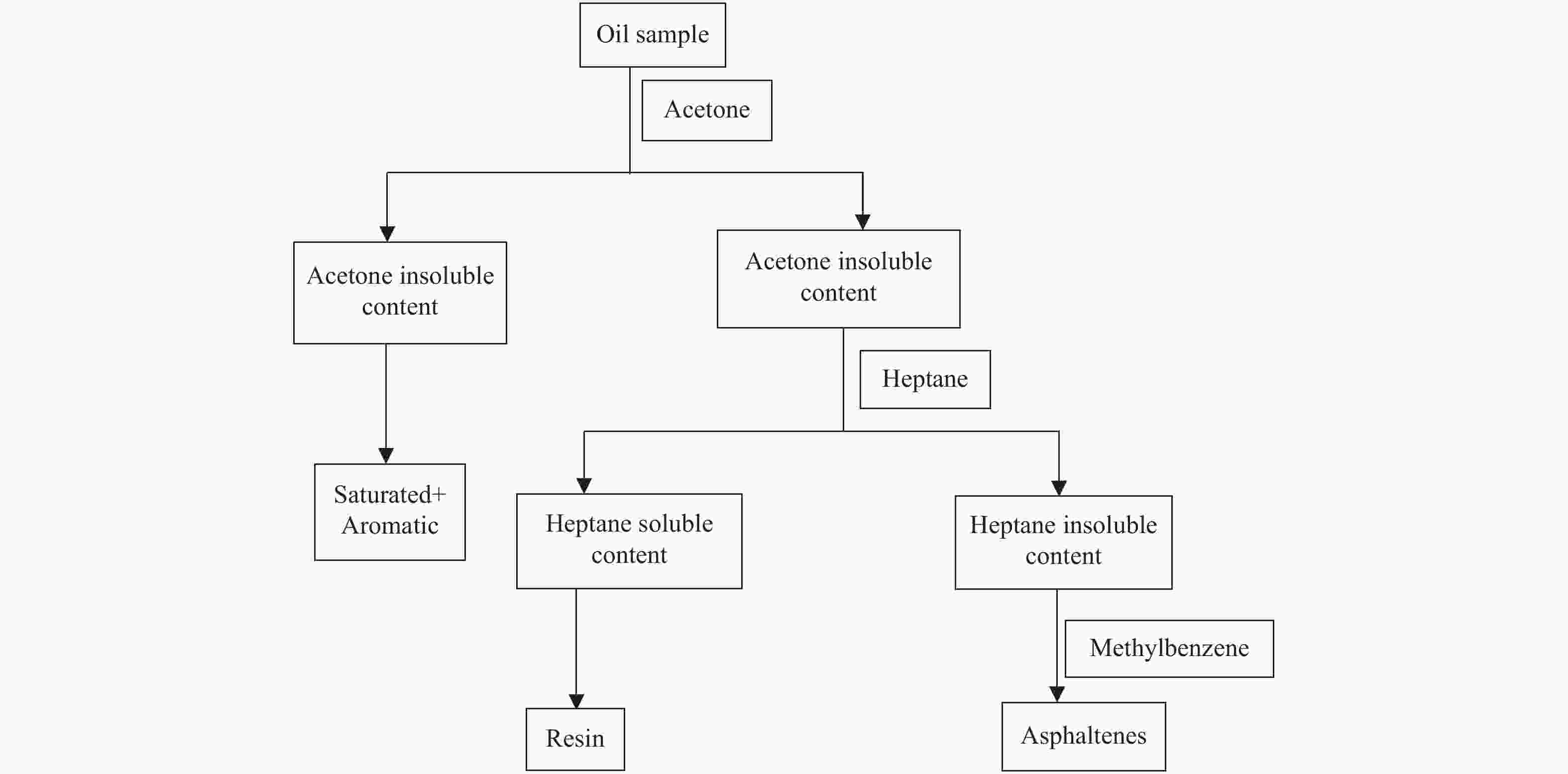

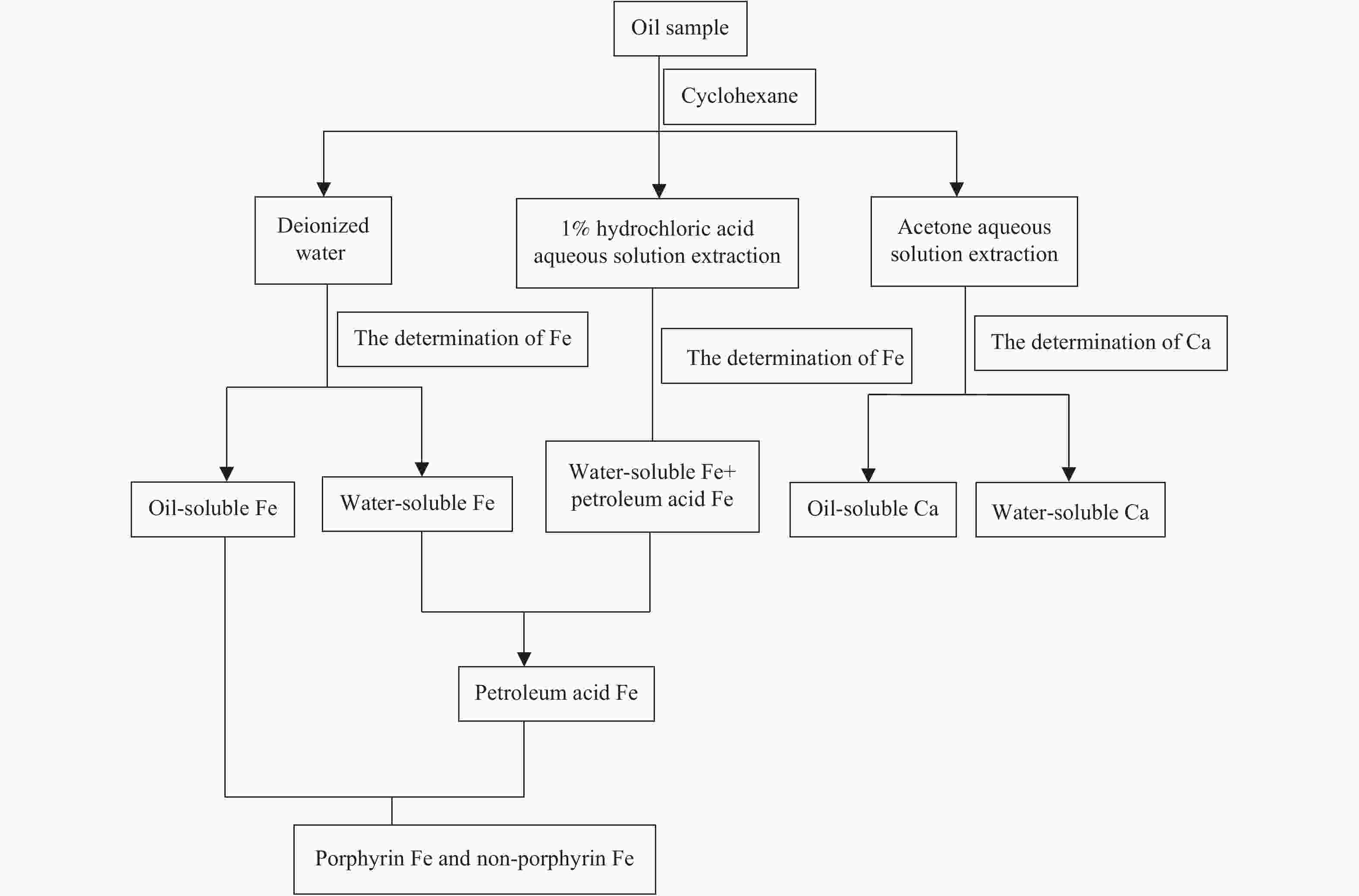

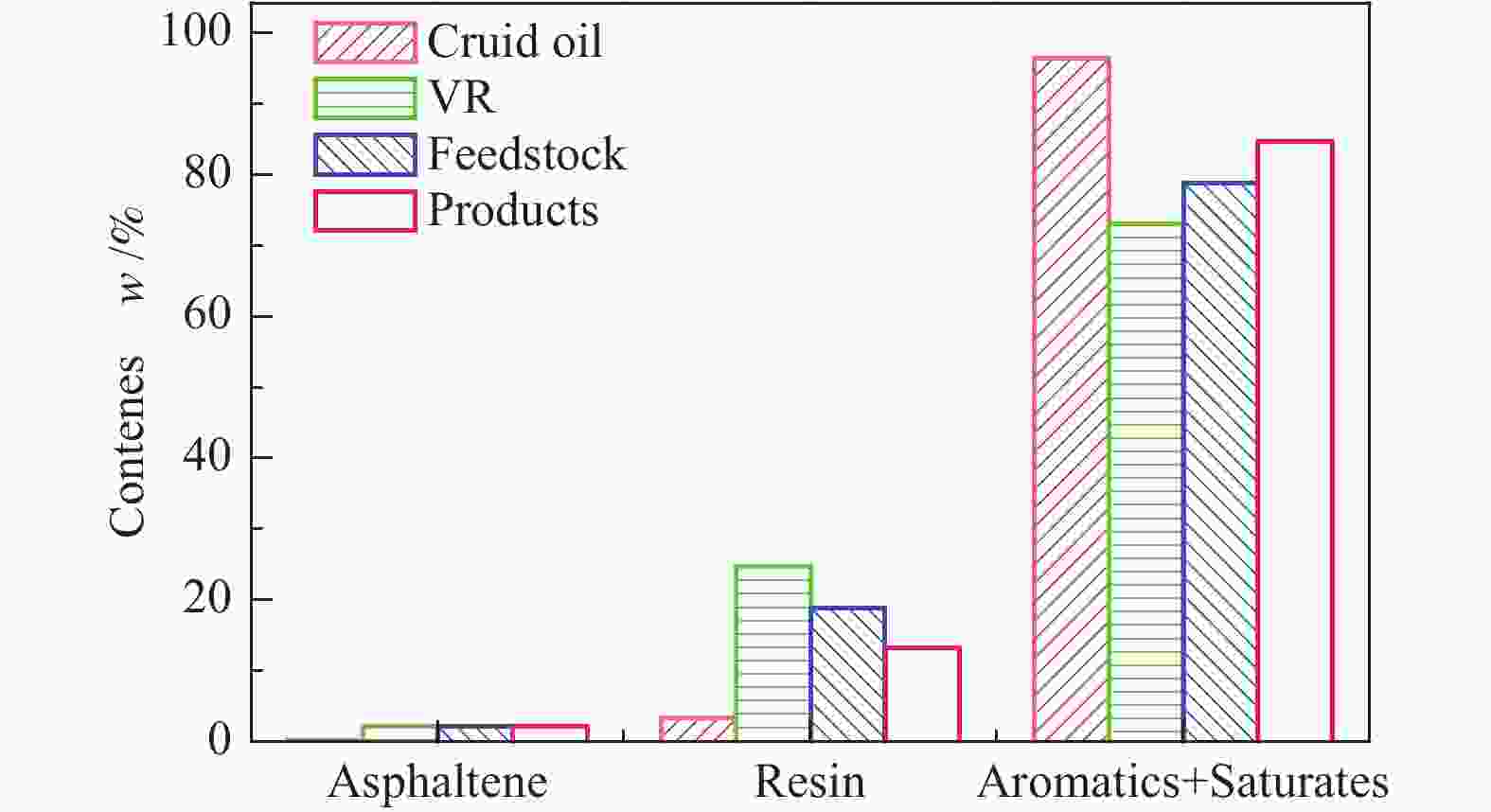

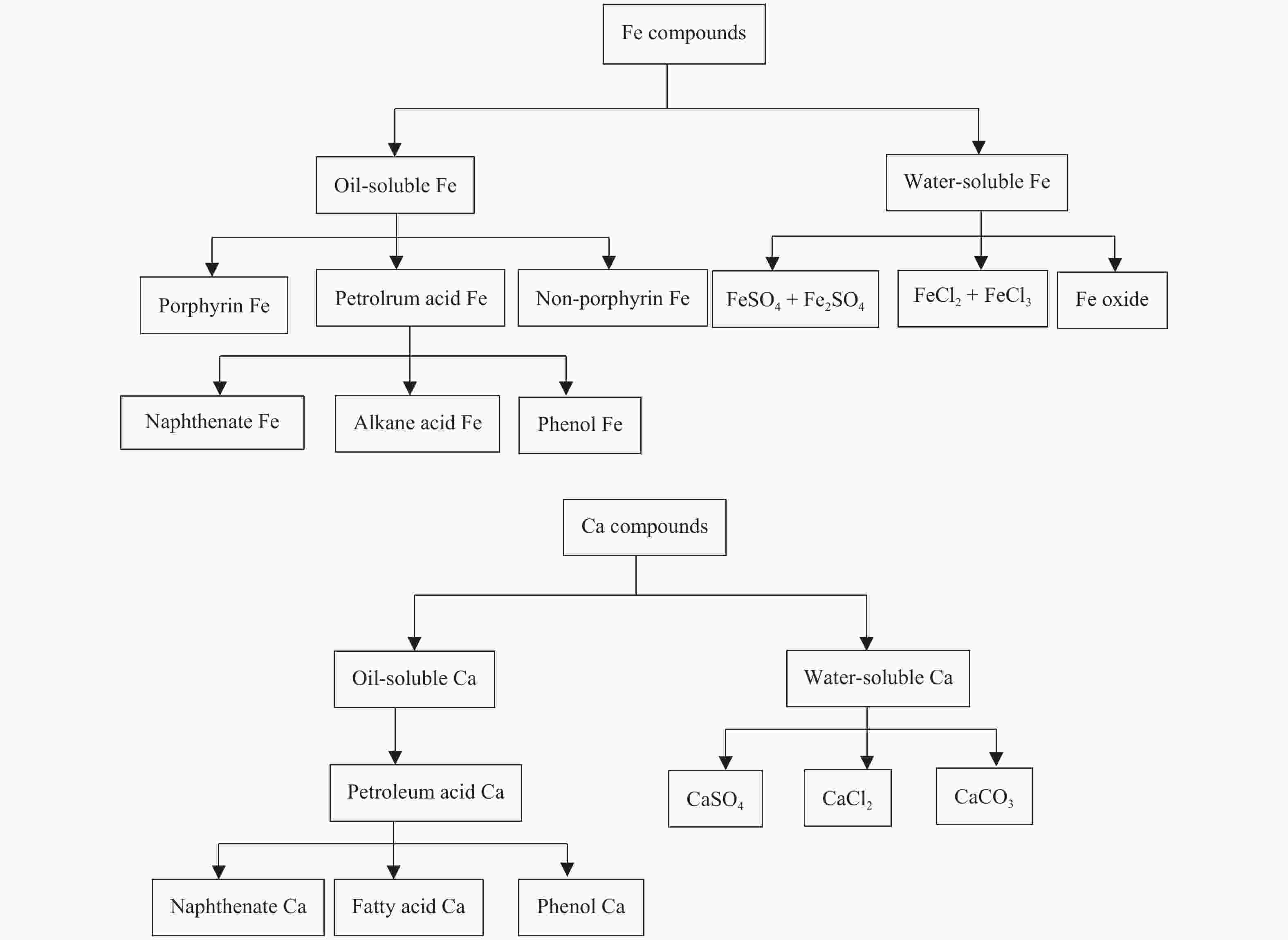

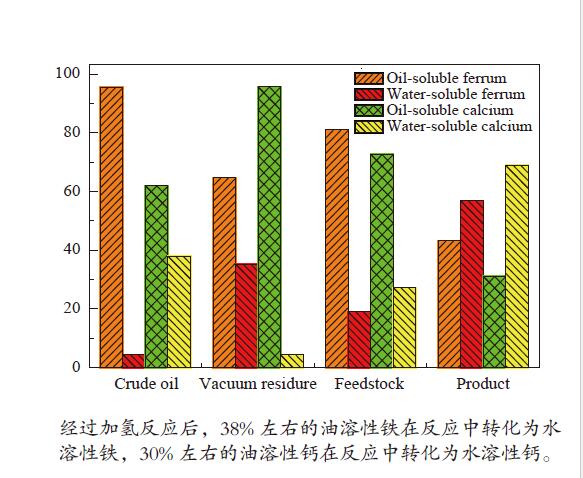

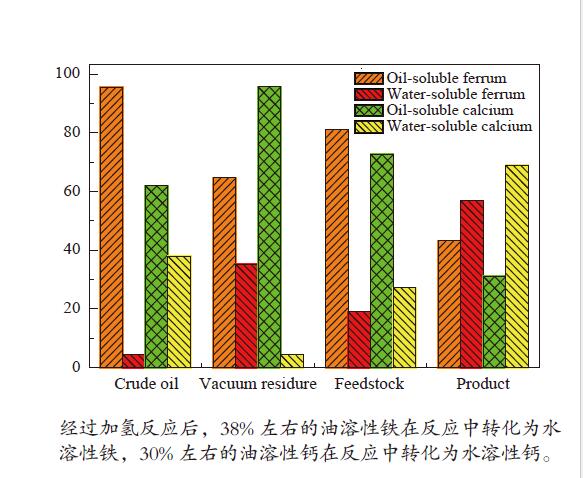

摘要: 以某原油及其对应的减压渣油、加氢原料和加氢产品为研究对象,通过柱色谱分离法和溶剂抽提法,对油样中铁和钙化合物在组分中的含量、分布以及存在形态进行了研究。研究结果表明,柱色谱分离过程中,油样中的含铁或钙的化合物在色谱柱上产生吸附,损失了58%的铁化合物和76%的钙化合物;溶剂抽提法能够有效减少组分中金属元素的损失。原油中97%以上的铁和钙分布在减压渣油馏分中,减压渣油中60%−90%的铁和钙分布在胶质、沥青质组分中。渣油加氢反应过程中,铁、钙化合物主要是从胶质中得到脱除,整体脱除率接近30%,铁化合物更易结合在沥青质中而难以脱除。原油经过常减压蒸馏后,油溶性铁相对分布由95.6%降低为64.7%,水溶性铁相对分布由4.4%升高为35.3%。经过加氢反应后,38%左右的油溶性铁在反应中转化为水溶性铁,30%左右的油溶性钙在反应中转化为水溶性钙。Abstract: The content, distribution and forms of the ferrum or calcium compounds in a crude oil, the corresponding vacuum residue (VR), hydrogenation feedstock and hydrogenation products were studied. The separation method was studied by column chromatography and solvent extraction method. This work indicated that in the process of column chromatographic separation, some ferrum or calcium compounds in the oil samples were irreversibly adsorbed on the chromatographic column, resulting in the loss of 58% of the ferrum compounds and 76% of calcium compounds. The solvent extraction method could effectively reduce the loss of the metal components and was suitable for the study of the content of metal elements. More than 97% of the ferrum or calcium compounds were distributed in the VR fraction. The 60% to 90% of the ferrum or calcium compounds were distributed in the resin and asphaltene components. During the hydrogenation reaction, the ferrum or calcium compounds in vacuum residue were mainly removed from the resin components, and the overall removal ratio was close to 30%. The ferrum compounds prefered to bond in the asphaltene components and were difficult to remove. Through the process of atmospheric distillation and vacuum distillation of the crude oil, the relative distribution of the oil-soluble ferrum compounds decreased from 95.6% to 64.7%, and the relative distribution of the water-soluble ferrum compounds increased from 4.4% to 35.3%. Through the process of the hydrogenation reaction, 38% of the oil-soluble ferrum compounds were converted into the water-soluble ferrum compounds and 30% of the oil-soluble calcium compounds were converted into the water-soluble calcium compounds in the reaction.

-

Key words:

- residue hydrogenation /

- ferrum compounds /

- calcium compounds /

- distribution /

- forms

-

表 1 加氢系列油样A的基础物性参数

Table 1 Basic properties of hydrogenated oil sample A

Analysis item Crude oil Vacuum residue Hydrogenation feedstock Hydrogenation products Density(20 ℃)/(g·cm−3) 0.85 0.96 0.95 0.93 CSP*/(g·g−1) 3.10 4.28 3.36 3.03 Acid value/(mg·g−1) 0.26 0.32 0.42 0.03 Molecular weight/(g·mol−1) $ {\rm{9}}{{.31 \times 1}}{{\rm{0}}^{\rm{2}}}$ $ {\rm{1}}{{.98 \times 1}}{{\rm{0}}^{\rm{3}}}$ $ {\rm{1}}{\rm{.21 \times 1}}{{\rm{0}}^{\rm{3}}} $ $ {\rm{9}}{\rm{.58 \times 1}}{{\rm{0}}^{\rm{2}}}$ Dipole moment/Debye 2.80 4.90 4.00 2.40 C/% 85.5 86.3 86.2 87.0 H/% 13.1 12.5 12.2 12.8 N/% 0.18 0.43 0.37 0.24 S/% 0.77 1.34 1.08 0.61 V/(μg·g−1) 15.6 39.1 33.7 6.60 Ni/(μg·g−1) 6.1 22.1 17.2 4.00 Fe/(μg·g−1) 34.2 112 82.4 72.7 Ca/(μg·g−1) 10.8 61.2 43.1 32.1 *: Drops of diffusion method 表 2 实验试剂一览表

Table 2 List of experiment reagents

Reagent Specification Manufacturer Petroleum ether

(60−90 ℃)analytic

reagentShanghai Woke Biotechnology Co., Ltd Methylbenzene analytic

reagentSinopharm Chemical Reagent Co., Ltd N-eptane analytic

reagentXilong Chemical Co., Ltd Cyclohexane analytic

reagentSinopharm Chemical Reagent Co., Ltd Acetone analytic

reagentTianjin Fuyu Fine Chemicals Co., Ltd Hydrochloric

acidguaranteed reagent Sinopharm Chemical Reagent Co., Ltd 表 3 实验仪器一览表

Table 3 List of experiment equipments

Instrument name Type Manufacturer Automatic rapid

crude oil distillation

apparatusSDM-06A Beijing Opwiye Technology Co., Ltd AAS controAA700 Jena Analytical

Instruments AgSteam pressure penetrator K700 Knauer CHSN

elemental analyzerVARIO EL Ⅲ German Company Elementar Automatic acid

value testerSY-3000A Taizhou Jiangyan Analysis Instrument Factory 表 4 A原油中金属铁和钙随馏程的分布

Table 4 Distribution of the metal ferreum and calcium with distillation range in crude oil A

Sample Fraction content

w/%Fe content/

(μg·g−1)Relative distribution

/%Ca content/

(μg·g−1)Relative distribution

/%Crude oil 100 34.2 100 10.8 100 Gasoline fraction 28.1 0.22 0.18 0.01 0.03 Diesel fraction 20.7 0.53 0.32 0.01 0.02 Vacuum gas oil 27.6 2.60 2.10 0.31 0.79 Vacuum residure 23.6 112 97.4 61.2 99.16 表 5 不同分离方法所得组分中铁和钙的含量

Table 5 Contents of the ferrum and calcium compounds in the components obtained by different separation methods

Separation method Component Component content w/% Ca content/(μg·g−1) Recovery ratio/% Fe content/(μg·g−1) Recovery ratio/% Column chromatography saturated + aromatic 73.7 2.33 2.81 4.75 3.13 resin 24.2 N N 147 31.8 asphaltene 2.1 596 20.4 376 7.05 metal recovery rate/% 23.2 41.9 Solvent

extractionsaturation + aromatic 73.1 11.1 13.3 42.7 27.9 resin 24.7 151 60.9 244 53.8 asphaltene 2.20 856 30.8 781 15.3 metal recovery ratioe/% 105 97.0 N: the value was not detected by the instrument 表 6 金属铁在加氢系列油样A组分中的分布变化

Table 6 Distribution variations of the metallic ferrum compounds in components of hydrogenated oil sample A

Sample Oil (Saturated+ Aromatic) Resin Asphaltene total Fe content/(μg·g−1) Fe content/

(μg·g−1)relative distribution/% Fe content/

(μg·g−1)relative distribution/% Fe content/

(μg·g−1)relative distribution/% Crude oil 34.2 20.1 58.3 372 37.2 669 4.50 Vacuum residue 112 42.7 28.8 244 55.5 781 15.7 Hydrogenation feedstock 82.4 20.4 19.0 271 60.5 812 20.5 Hydrogenation products 72.7 21.9 26.2 239 44.7 992 29.1 表 7 金属钙在加氢系列油样A组分中的分布变化

Table 7 Distribution variations of the metallic calcium compounds in component of hydrogenated oil sample A

Sample Saturated + Aromatic Resin Asphaltene total Ca content/(μg·g−1) Ca content/

(μg·g−1)relative distribution/% Ca content/

(μg·g−1)relative distribution/% Ca content/

(μg·g−1)relative distribution/% Crude oil 10.8 4.17 37.9 170 53.4 424 8.70 Vacuum residue 61.2 11.1 12.7 151 58.1 856 29.2 Hydrogenation feedstock 43.1 13.4 24.2 112 48.6 555 27.2 Hydrogenation products 32.1 15.7 38.0 89.0 33.6 479 28.4 表 8 加氢系列油样A中铁化合物的溶解性能

Table 8 Dissolution performance of the ferrum compounds in hydrogenated oil sample A

Sample Total Fe Oil-soluble Fe Water-soluble Fe Petroleum acid Fe Porphyrin Fe and

non-porphyrin Fecontent/

(μg·g−1)content/

(μg·g−1)relative distribution/% content/

(μg·g−1)relative distribution/% content/

(μg·g−1)relative distribution/% content/

(μg·g−1)relative distribution/% Crude oil 34.2 32.7 95.6 1.50 4.40 19.7 57.5 13.1 38.2 Vacuum residue 112 72.4 64.7 39.6 35.3 44.4 39.6 28.1 25.0 Hydrogenation feedstock 82.4 66.7 81.0 15.7 19.0 25.5 30.9 41.3 50.1 Hydrogenation products 72.7 31.4 43.2 41.3 56.8 6.60 9.10 24.8 34.1 表 9 加氢系列油样A中钙化合物的溶解性能

Table 9 Dissolution performance of the calcium compounds in hydrogenated oil sample A

Sample Total Ca Oil-soluble calcium Water-soluble calcium content/(μg·g−1) content/(μg·g−1) relative distribution/% content/(μg·g−1) relative distribution/% Crude oil 10.8 6.70 62.0 4.10 38.0 Vacuum residue 61.2 58.6 95.7 2.60 4.30 Hydrogenation feedstock 43.1 31.3 72.7 11.8 27.3 Hydrogenation products 32.1 10.0 31.1 22.1 68.9 -

[1] 张甫, 任颖, 杨明, 易金华, 宋怀俊, 任保增. 劣质重油加氢技术的工业应用及发展趋势[J]. 现代化工,2019,39(6):21−26.ZHANG Fu, REN Ying, YANG Ming, YI Jin-hua, SONG Huai-jun, REN Bao-zeng. Industrial application and trend of hydrogenation technology for inferior heavy oil[J]. Mod Chem Ind,2019,39(6):21−26. [2] 王在花, 刘强, 李琰, 赵燕. 国内炼油助剂的研究进展及发展趋势[J]. 炼油与化工,2019,30(1):1−3. doi: 10.3969/j.issn.1671-4962.2019.01.001WANG Zai-hua, LIU Qiang, LI Yan, ZHAO Yan. Research progress and development trend of oil refining additives in China[J]. Refin Chem Ind,2019,30(1):1−3. doi: 10.3969/j.issn.1671-4962.2019.01.001 [3] HERNÁNDEZ-BELTRÁN F, MORENO-MAYORGA J C, QUINTANA-SOLÓRZANO R, SÁNCHEZ-VALENTE J, PEDRAZA-ARCHILA F, PÉREZ-LUNA M. Sulfur reduction in cracked naphtha by a commercial additive: Effect of feed and catalyst properties[J]. Appl Catal B: Environ,2001,34(2):137−148. doi: 10.1016/S0926-3373(01)00213-2 [4] ZHANG S, LIU D, DENG W, QUE G. A review of slurry-phase hydrocracking heavy oil technology[J]. Energy Fuels,2007,21(6):3057−3062. doi: 10.1021/ef700253f [5] LE LANNIC K, GUIBARD I, MERDRIGNAC I. Behavior and role of asphaltenes in a two-stage fixed bed hydrotreating process[J]. Pet Sci Technol,2007,25(1/2):169−186. doi: 10.1080/10916460601054321 [6] 刁玉霞, 袁蕙, 邱丽美, 孙淑玲, 徐广通. 工业装置渣油加氢失活催化剂上的金属赋存状态研究[J]. 石油炼制与化工,2019,50(7):7−12. doi: 10.3969/j.issn.1005-2399.2019.07.003DIAO Yu-xia, YUAN Hui, QIU Li-mei, SUN Shu-ling, XU Guang-tong. Characterization of metal deposition on spent residue hydrotreating catalysts from industrial plant[J]. Pet Process Petrochem,2019,50(7):7−12. doi: 10.3969/j.issn.1005-2399.2019.07.003 [7] 陈士锋, 陈海, 杨朝合. 渣油加氢转化过程结焦催化剂的表征[J]. 石油学报(石油加工),2002,18(3):10−14.CHEN Shi-feng, CHEN Hai, YANG Chao-he. Characterization of coked catalyst for residual hydroconversion process[J]. Acta Pet Sin (Pet Process Sect),2002,18(3):10−14. [8] MILLER J T, FISHER R B, VAN DER EERDEN A M J, KONINGSBERGER, D. C. Structural determination by XAFS spectroscopy of non-porphyrin nickel and vanadium in Maya residuum, hydrocracked residuum, and toluene-insoluble solid[J]. Energy Fuels,1999,13(3):719−727. doi: 10.1021/ef9802328 [9] 刘章勇, 张玉贞. 原油中钙的存在形态及脱除技术研究[J]. 化学世界,2009,50(8):503−506. doi: 10.3969/j.issn.0367-6358.2009.08.016LIU Zhang-yong, ZHANG Yu-zhen. Forms of calcium in crude oil and study on decalcification technologies[J]. Chem World,2009,50(8):503−506. doi: 10.3969/j.issn.0367-6358.2009.08.016 [10] 高鑫, 蔡婷婷, 朱丽君, 周玉路, 项玉芝, 夏道宏. 原油及渣油中Fe含量分布及其存在形态[J]. 石油学报(石油加工),2014,30(2):256−261.GAO Xin, CAI Tingting, ZHU Li-jun, ZHOU Yu-lu, XIANG Yu-zhi, XIA Dao-hong. Content distribution and existing form of Fe in crude and residual oil[J]. Acta Pet Sin (Pet Process Sect),2014,30(2):256−261. [11] 张琼. 委内瑞拉原油中金属元素的赋存状态研究[J]. 科研,2016,(4):212−213.ZHANG Qiong. Occurrence of metallic elements in Venezuelan crude oil[J]. Research,2016,(4):212−213. [12] 侯典国, 汪燮卿. 我国一些原油中钙化合物分布及形态的研究[J]. 石油学报(石油加工),2000,16(1):56−61.HOU Dian-guo, WANG Xie-qing. Study on distribution and composition of calcium in some Chinese crudes[J]. Acta Pet Sin (Pet Process Sect),2000,16(1):56−61. [13] CHIU Y C, HUANG J F. Interfacial tension and formulation principle of ultralow interfacial tension systems formulated with carboxymethyl ethoxylates under extremely high calciumion concentration[J]. J Dispers Sci Technol,1993,14(4):465−479. doi: 10.1080/01932699308943418 [14] 朱玉霞, 汪燮卿. 我国原油中的钙含量及其分布的初步研究[J]. 石油学报(石油加工),1998,14(3):60−64.ZHU Yu-xia, WANG Xie-qing. The study of calcium content and its distribution in domestic crude[J]. Acta Pet Sin (Pet Process Sect),1998,14(3):60−64. [15] TREJO F, ANCHEYTA J. Kinetics of asphaltenes conversion during hydrotreating of Maya crude[J]. Catal Today,2005,109(1/4):99−103. doi: 10.1016/j.cattod.2005.08.005 [16] 边钰清, 赵元生, 张龙力, 赵愉生, 杨朝和. 格尔木渣油加氢反应及生焦行为的研究[J]. 燃料化学学报,2019,47(8):130−138.BIAN Yu-qing, ZHAO Yuan-sheng, ZHANG Long-li, ZHAO Yu-sheng, YANG Chao-he. Study on the hydrogenation reaction and coking behavior in Golmud residue hydrogenation[J]. J Fuel Chem Technol,2019,47(8):130−138. [17] 郑振伟. 超临界萃取法对渣油加氢前后金属含量分析研究[J]. 当代化工,2014,(3):330−333. doi: 10.3969/j.issn.1671-0460.2014.03.005ZHENG Zhen-wei. Study on analysis of metal content in residual oil by SFEF[J]. Contemp Chem Ind,2014,(3):330−333. doi: 10.3969/j.issn.1671-0460.2014.03.005 [18] 邓文安, 马莉莉, 阙国和. 克拉玛依减渣及其临氢热反应产物中钙化合物的分布与存在形态[J]. 石油学报(石油加工),2007,23(3):80−86.DENG Wen-an, MA Li-li, QUE Guo-he. The distribution and configration of calium compounds in the karamary vacuum residue and its thermal reaction products under dispersed catalyst and hydrogen atmosphere[J]. Acta Pet Sin (Pet Process Sect),2007,23(3):80−86. [19] 董凯, 孙淑玲, 邵志才, 胡大为, 戴立顺. 仪长渣油中含钙化合物的分布及加氢脱钙反应的研究[J]. 石油学报(石油加工),2017,33(2):93−98.DONG Kai, SUN Shu-ling, SHAO Zhi-cai, HU Da-wei, DAI Li-shun. Study on calcium compounds distribution in Yichang residue and hydrodecalcium reaction[J]. Acta Pet Sin (Pet Process Sect),2017,33(2):93−98. [20] 张会成, 颜涌捷, 赵荣林, 韩照明. 渣油加氢处理过程中金属分布与脱除规律的研究[J]. 石油炼制与化工,2006,37(11):7−10.ZHANG Hui-cheng, YAN Yong-jie, ZHAO Rong-lin, HAN Zhao-ming. Study on the metals distribution and removal in residue hydrotreating[J]. Pet Process Petrochem,2006,37(11):7−10. [21] LIU G, XU X, GAO J. Study on the deferrization and desalting for crude oils[J]. Energy Fuels,2004,18(4):918−923. doi: 10.1021/ef030127k [22] 李宁, 刘倩倩, 郭伟, 袁帅, 林伟. 催化裂化平衡剂铁含量偏高的原因分析[J]. 石油炼制与化工,2018,49(3):7−12. doi: 10.3969/j.issn.1005-2399.2018.03.003LI Ning, LIU Qian-qian, GUO Wei, YUAN Shuai, LIN Wei. Cause analysis of high iron content on FCC equilibrium catalyst[J]. Pet Process Petrochem,2018,49(3):7−12. doi: 10.3969/j.issn.1005-2399.2018.03.003 [23] 宋丽, 邹滢, 翁惠新, 高玉瑛. 石油中油溶性铁化合物的脱除[J]. 石油炼制与化工,2008,39(9):9−12. doi: 10.3969/j.issn.1005-2399.2008.09.003SONG Li, ZHOU Ying, WENG Hui-xin, GAO Yu-ying. Removal of oil-soluble iron compounds from petroleum[J]. Pet Process Petrochem,2008,39(9):9−12. doi: 10.3969/j.issn.1005-2399.2008.09.003 [24] 邓文安, 王继乾, 刘东, 赵晴晴, 阙国和. 轮古常渣悬浮床加氢裂化反应产物中Ni、V的分布与存在形态[J]. 石油学报(石油加工),2007,23(2):57−61.DENG Wen-an, WANG Ji-qian, LIU Dong, ZHAO Qing-qing, QUE Guo-he. The distribution and configuration of nickel and vanadium compounds in the products of slurry-bed hydrocracking of Lungu atmospheric residue[J]. Acta Pet Sin (Pet Process Sect),2007,23(2):57−61. [25] 刘灿刚, 徐振洪, 朱建华, 樊毅敏. 原油中钙存在状态的研究[J]. 石油化工,2000,29(11):866−868+840. doi: 10.3321/j.issn:1000-8144.2000.11.014LIU Chan-gang, XU Zhen-hong, ZHU Jian-hua, FAN Yi-min. Study on occurrence modes of calcium in crude oil of Dagang oilfield[J]. Petrochem Technol,2000,29(11):866−868+840. doi: 10.3321/j.issn:1000-8144.2000.11.014 -

下载:

下载: