Study on the composition and structure characteristics and dry decarbonization separation of coal water slurry gasification fine slag

-

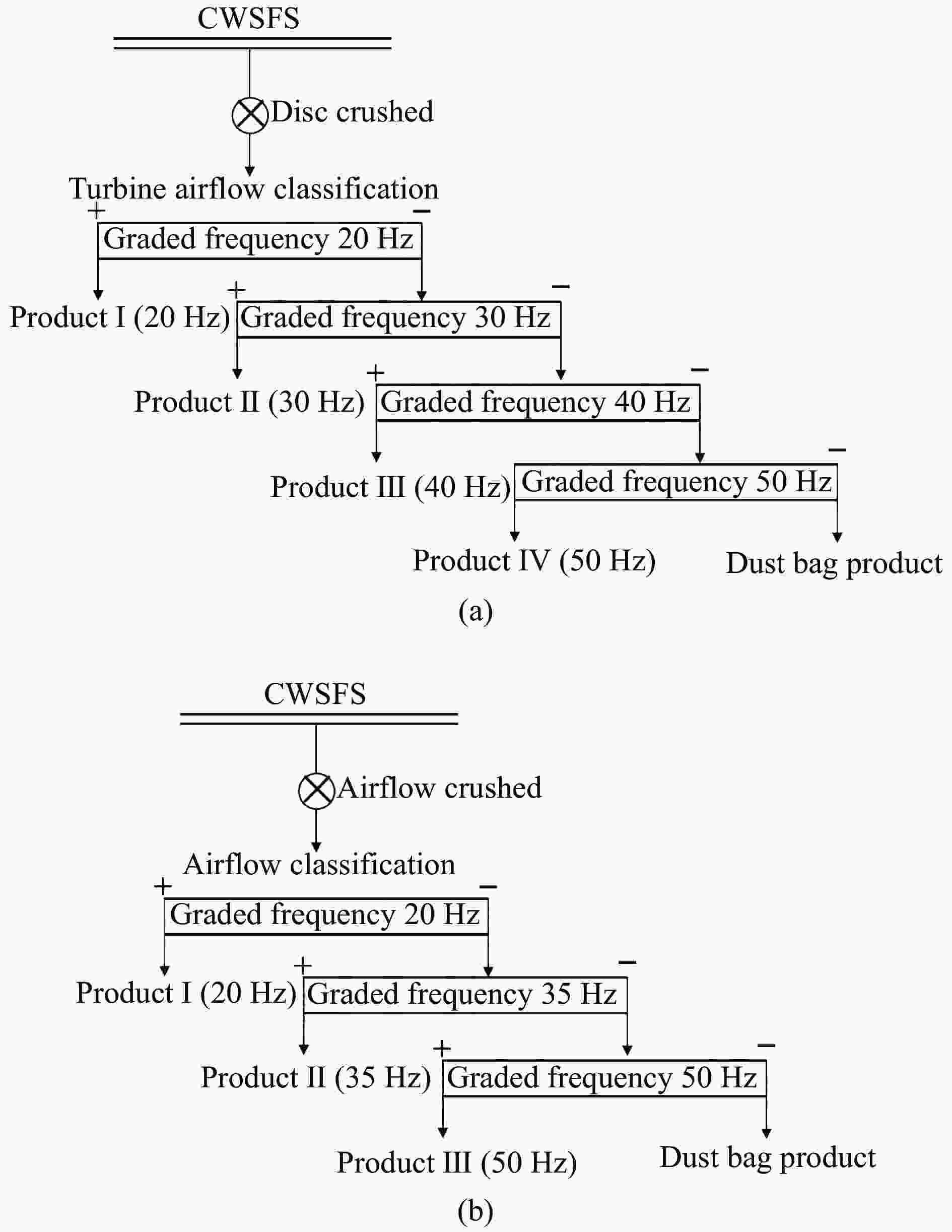

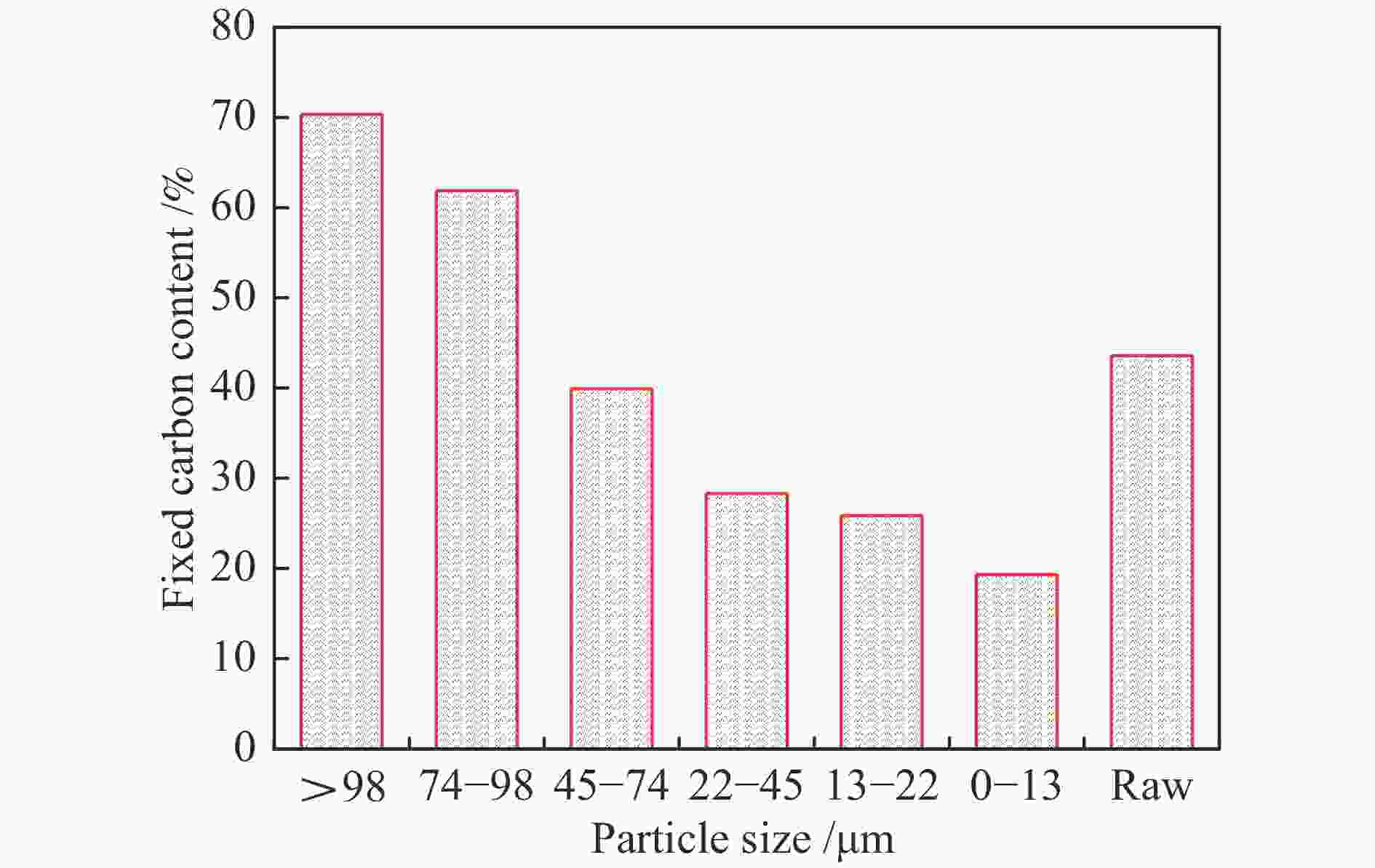

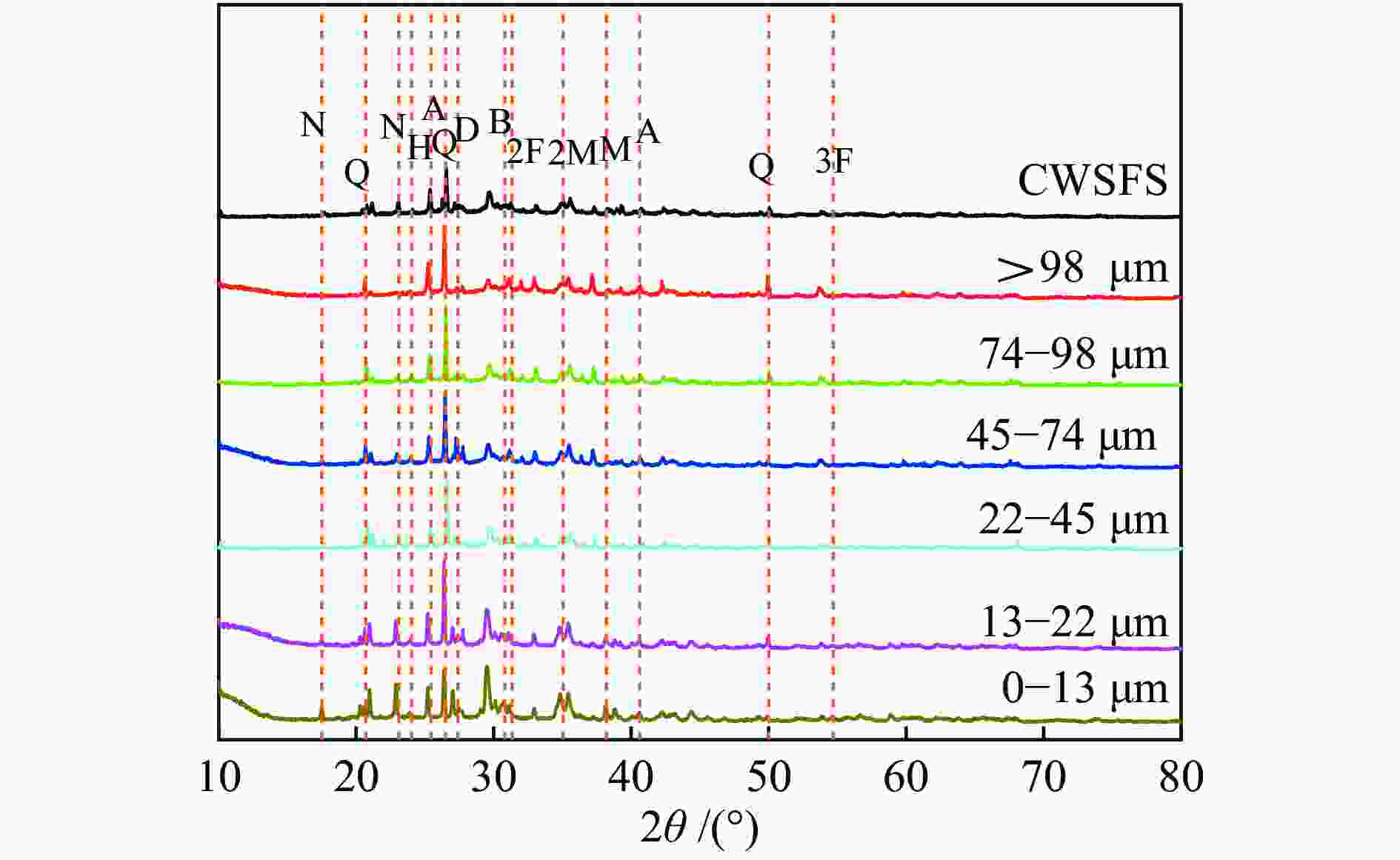

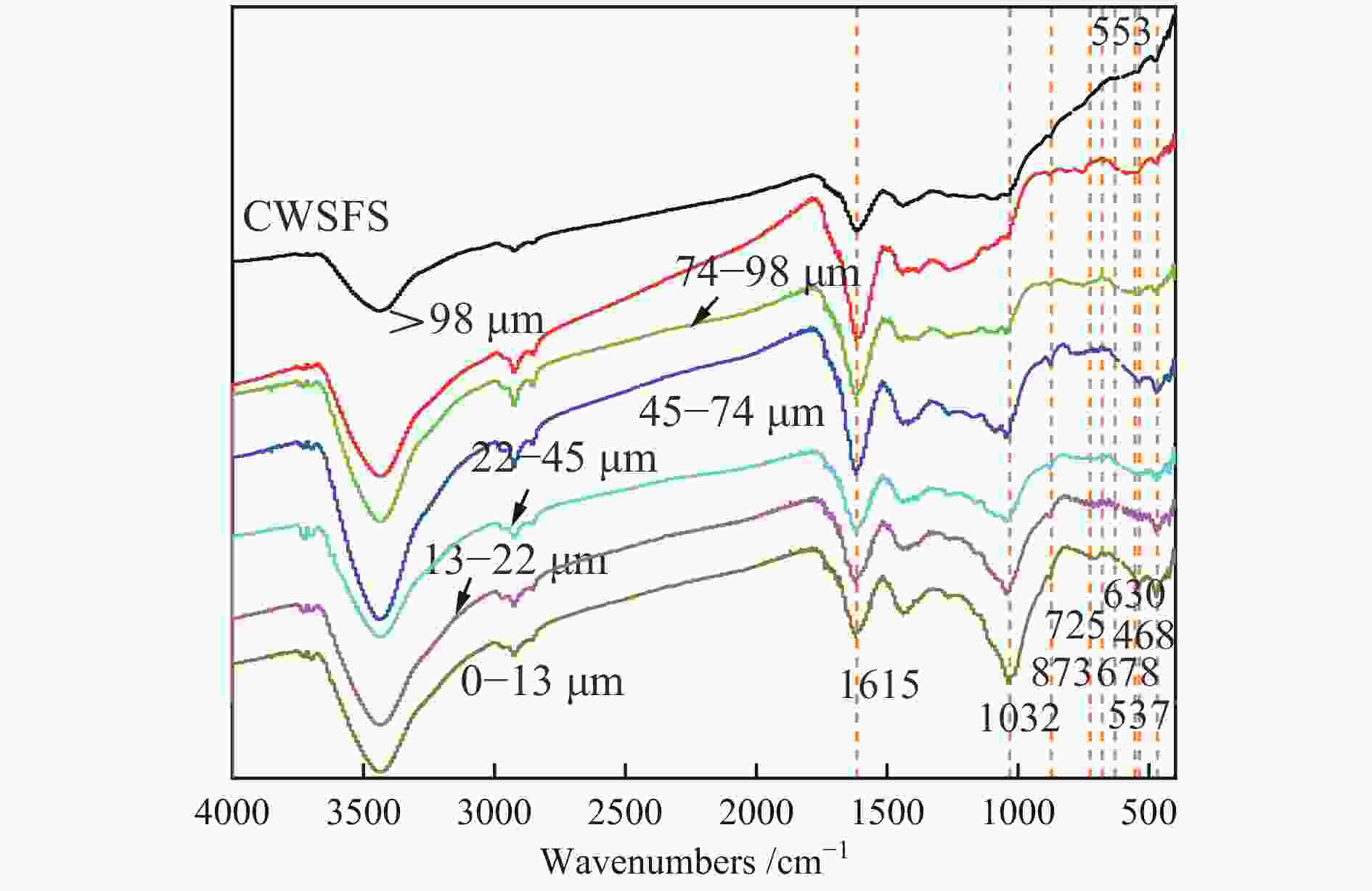

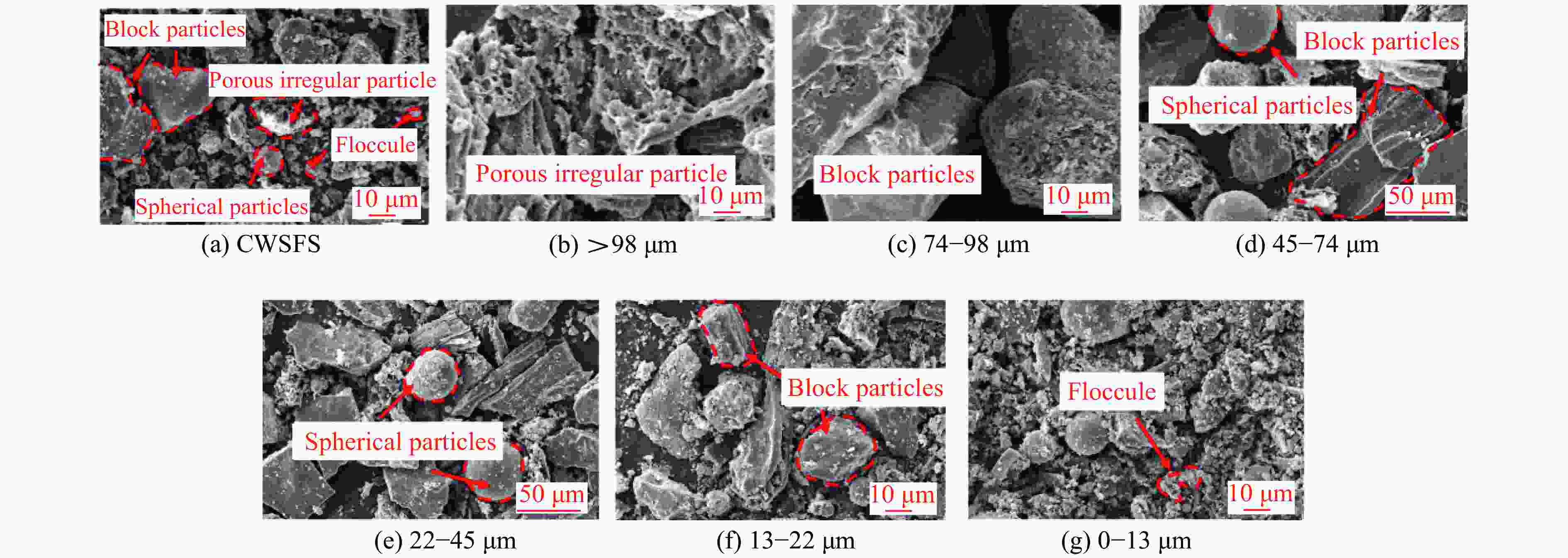

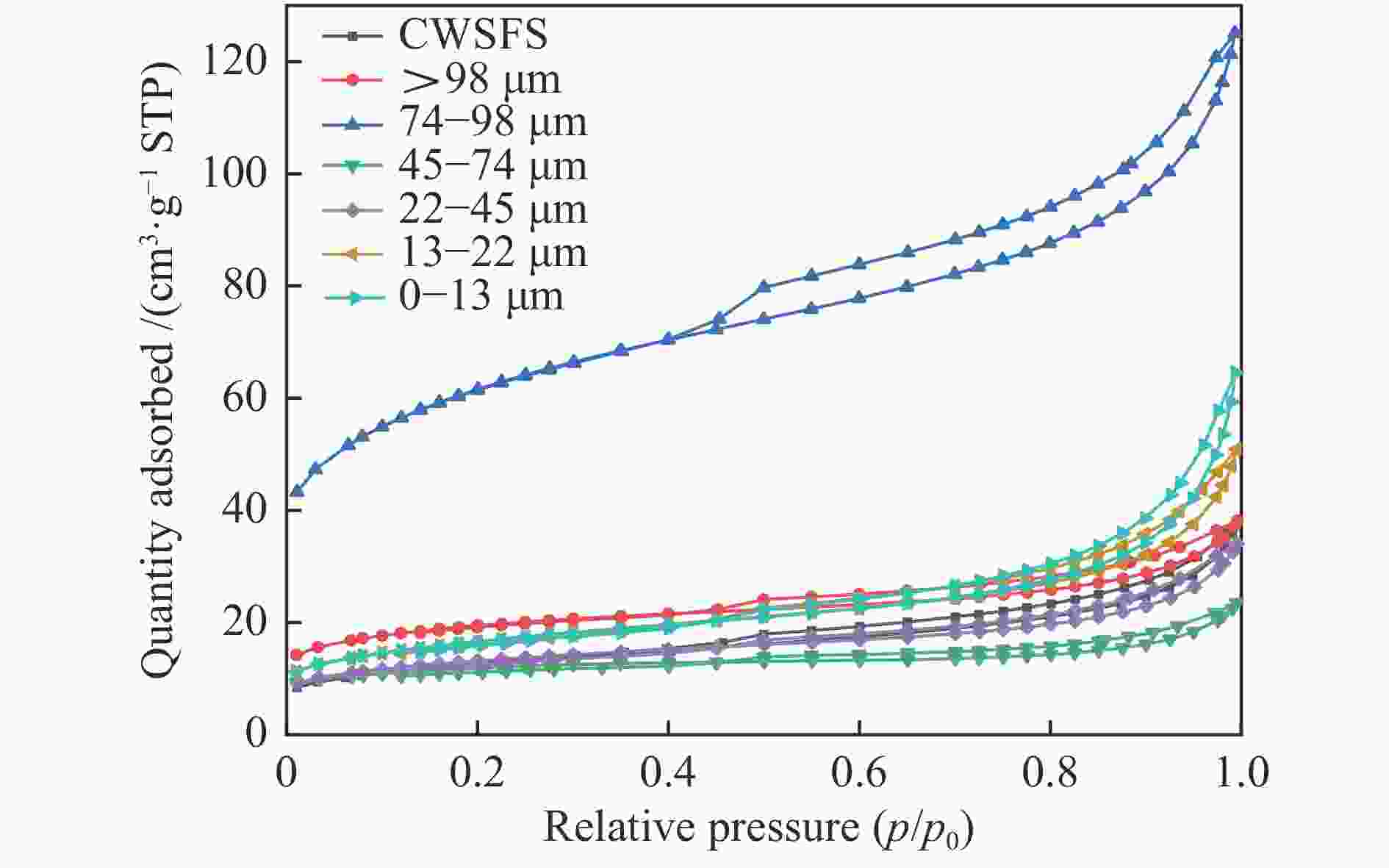

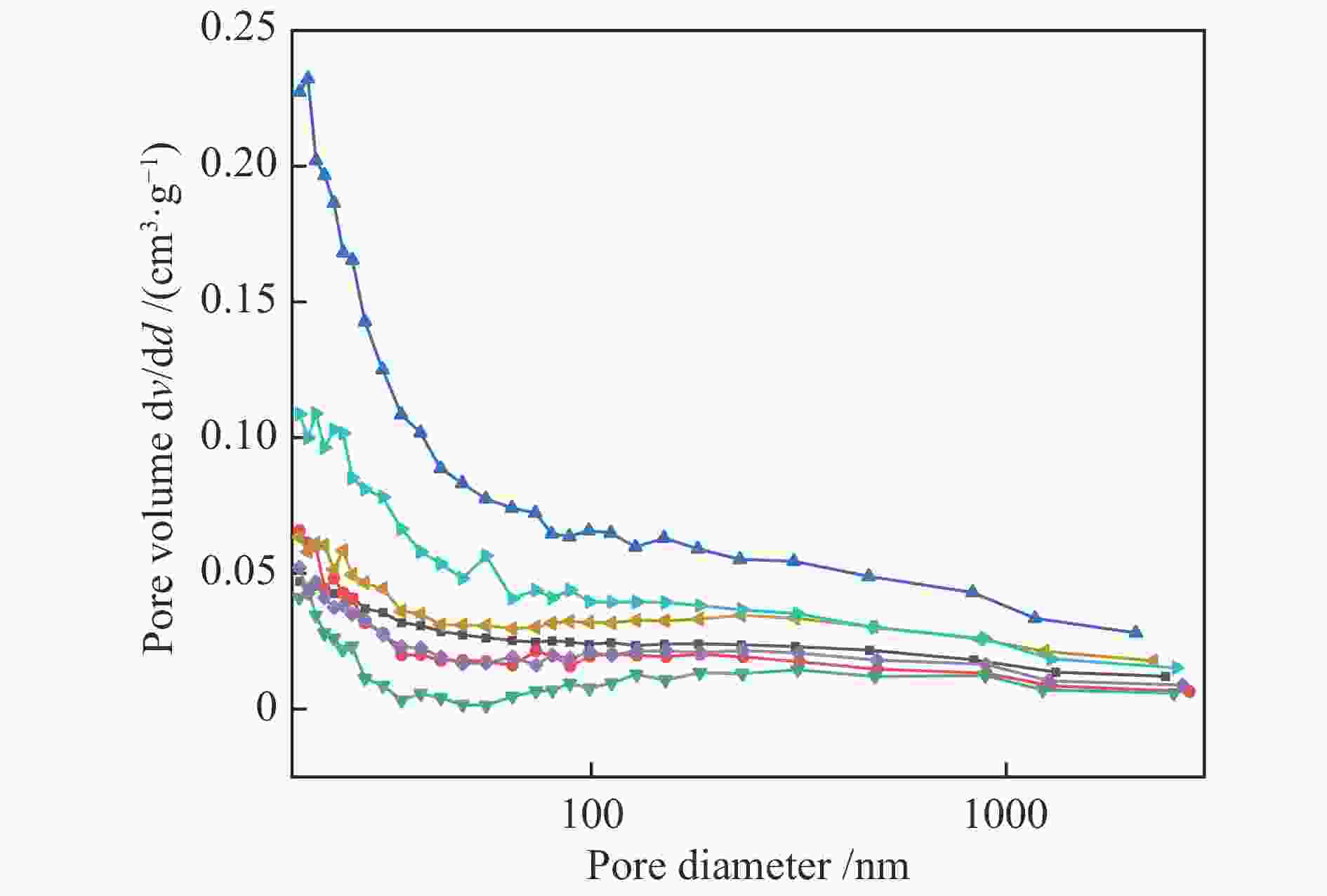

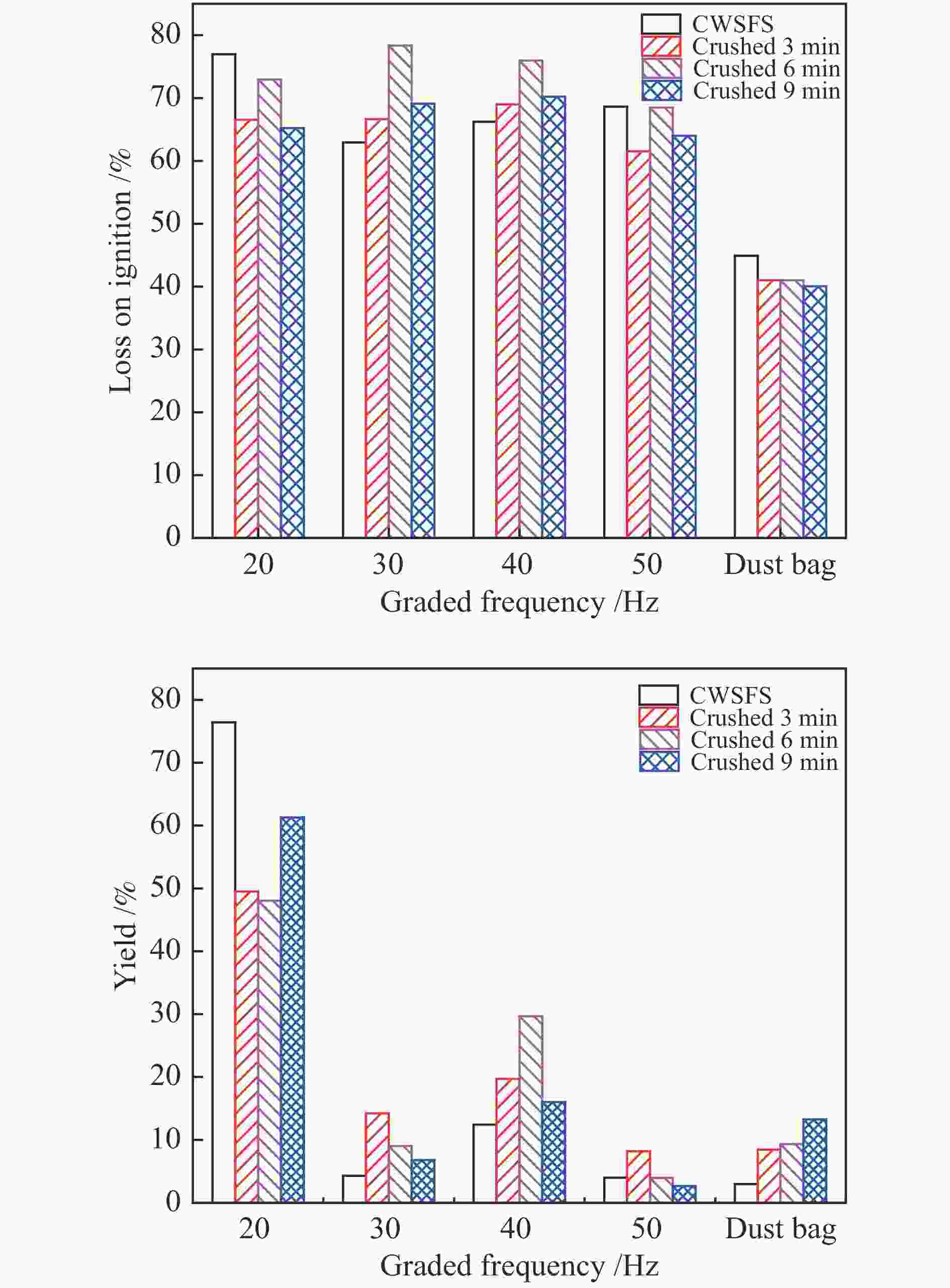

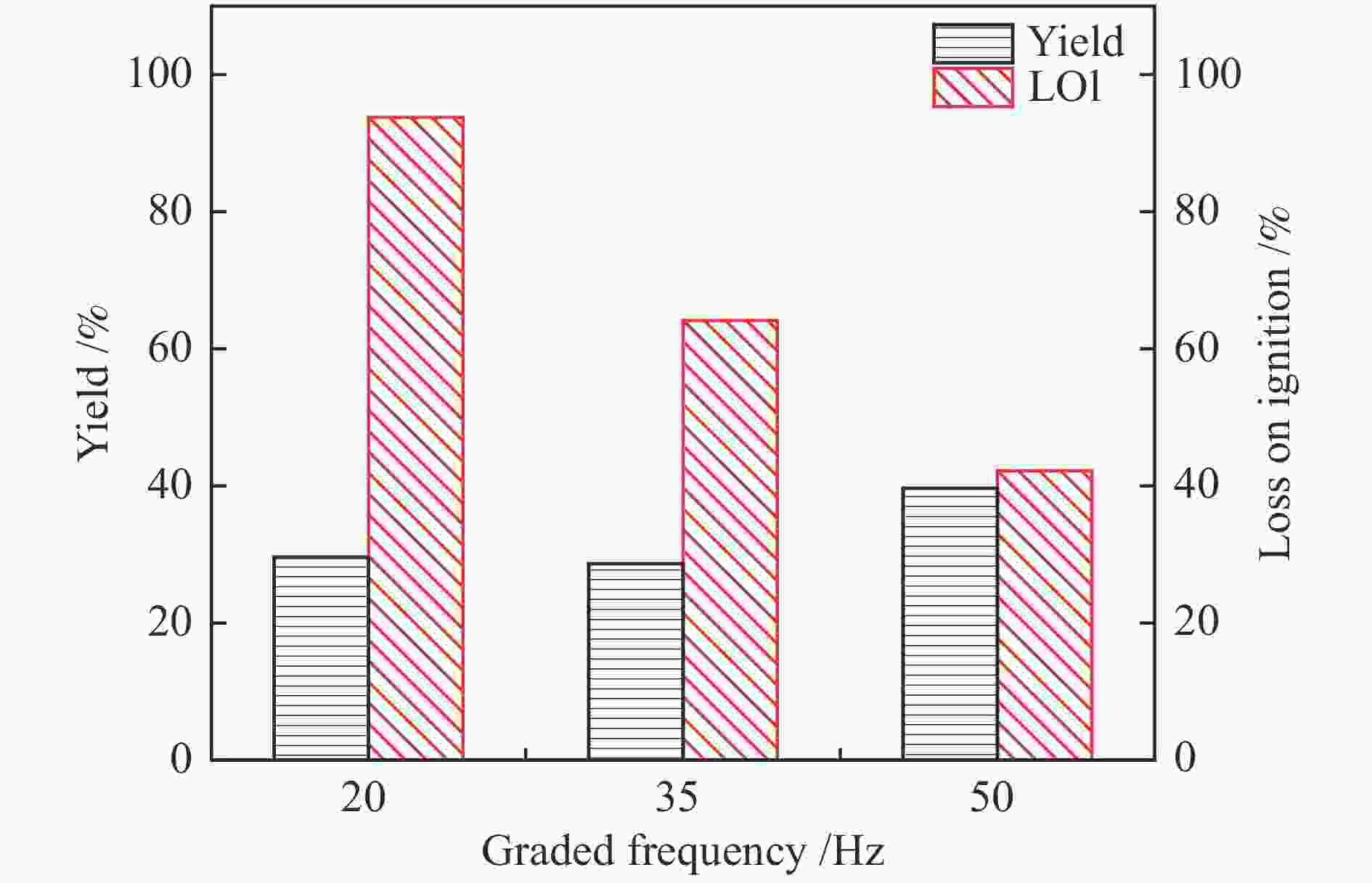

摘要: 本研究以水煤浆气化细渣(CWSFS)为研究对象,将其通过湿法筛分分级,采用工业分析、XRF、XRD、BET、SEM等手段考察粒度组成与结构特征的关系,并提出CWSFS的分类方法,用以指导煤气化灰渣的分质高值化利用;再采用粉碎解离-气流分级联合处理方法开展了水煤浆气化细渣的干法分选研究。结果表明,不同粒级CWSFS,在固定碳含量、灰组成、矿物类型上有明显差异。≥74 μm粒级的CWSFS中,固定碳含量>60%、发热量>20 MJ/kg,比表面积较高,主要为残炭,并含有磁铁矿和板钛矿;13−74 μm粒级的CWSFS中,固定碳含量为20%−60%、发热量为11−19 MJ/kg,比表面积较小,矿物类型主要为辉石、白铁矿和赤铁矿等;0−13 μm粒级的CWSFS中,固定碳含量低于20%、发热量低于10 MJ/kg,主要为富含铝、铁、钙等非晶态玻璃相、石英和少量铁橄榄石、白云母等矿物。根据不同粒级CWSFS的特征,将上述三个组分分别定义为高炭组分、中炭组分和低炭组分。干法分选试验表明,与圆盘粉碎-分级工艺相比,采用气流粉碎-分级工艺可获得产率为29.60%、烧失量高达93.76%的产品,气流粉碎有助于提高残炭的分级分离富集率。Abstract: Efficient separation and high-valued utilization of coal gasification ash or slag limit the clean and green development of coal chemical industry. In this paper, a coal-water slurry gasification fine slag (CWSFS) was studied by wet screening and classification. The relationship between the particle composition with different sizes and the structural characteristics was investigated by means of proximate analysis, XRF, XRD, BET and SEM. A classification method of CWSFS was proposed to guide the high-valued utilization of coal gasification slag. Then, dry separation of a coal-water slurry gasification fine slag was carried out using a combined treatment method of crushing and dissociation and airflow classification. The results show that the CWSFS particles of different sizes have obvious differences in fixed carbon content, ash composition and mineral types. For the CWSFS with the particle size above 74 μm, the fixed carbon content is more than 60%, the calorific value is more than 20 MJ/kg, the specific surface area is relatively high and the main component is the residual carbon that contains magnetite and brookite. For the CWSFS with particle sizes between 13−74 μm, the fixed carbon content is between 20%−60%, the calorific value is between 11−19 MJ/kg, the specific surface area is small and the main mineral types are pyroxene, marcasite and hematite, etc. For the CWSFS with a particle size between 0−13 μm, the fixed carbon content is less than 20% and the calorific value is less than 10 MJ/kg, which mainly includes the amorphous glass phase that was rich in aluminum, iron and calcium, quartz and a small amount of fayalite, muscovite and other minerals. According to the fixed carbon content of CWSFS with different particle sizes, the above three components with varying particle size ranges are defined as high-carbon component, medium-carbon component and low-carbon component, respectively. The dry separation test shows that the air flow crushing and classification process can achieve a higher product yield of 29.60% and a high ignition loss of 93.76%, compared to the traditional disc crushing-classification process. Airflow crushing was proved to be able to effectively increase the dissociation degree of residual carbon and greatly improve the separation and enrichment rate of residual carbon.

-

表 1 水煤浆气化细渣的工业分析和元素分析

Table 1 Proximate and ultimate analyses of coal-water slurry gasification fine slag

Proximate analysis w/% Ultimate analysis wad/% Qgr,d/(MJ·kg−1) Mad Aad Vdaf FCad C H O N St 6.41 29.15 20.86 43.58 54.17 2.31 3.25 1.11 3.60 25.13 表 2 水煤浆气化细渣粒度特性

Table 2 Characteristics of CWSFS in different particle size grades

Particle size/μm Yield/% Ash content/% Fixed carbon content/% Loss on ignition/% Calorific value/(MJ·kg−1) >98 50.83 15.99 70.35 85.52 26.214 74−98 5.66 24.55 61.88 73.21 23.835 45−74 13.89 37.79 39.93 68.95 15.223 22−45 6.41 49.97 28.31 57.57 13.249 13−22 7.86 50.05 25.86 47.3 12.198 0−13 15.35 59.25 19.34 45.7 9.081 Total 100 29.18 43.58 72.59 25.126 表 3 水煤浆气化细渣各粒级氧化物含量

Table 3 Oxide content of size-segmented CWSFS

Particle size/μm Composition w/% SiO2 Al2O3 Fe2O3 CaO K2O TiO2 SO3 ZnO Cr2O3 MnO SrO CuO V2O5 >98 0 38.55 21.16 25.21 1.03 1.68 10.26 0.34 0 0.40 0.67 0.25 0 74−98 23.66 20.43 18.06 24.25 1.15 1.46 9.69 0.27 0 0.37 0.21 0 0 45−74 16.84 18.99 29.61 22.50 1.61 1.55 7.38 0 0 0.52 0.59 0 0.14 22−45 33.88 22.55 15.49 19.02 1.73 1.28 5.38 0 0 0.28 0.14 0 0.10 13−22 40.72 21.71 12.52 15.86 1.78 1.24 4.69 0.78 0.17 0.22 0 0 0 0−13 34.91 24.10 15.72 16.29 2.04 1.69 3.09 0.98 0.41 0.26 0 0 0 CWSFS 21.09 27.96 20.70 19.83 1.85 1.64 5.28 0 0.28 0.37 0.58 0 0 表 4 水煤浆气化细渣EDS分析

Table 4 EDS analysis of CWSFS

Morphology Particle size/μm Element w/% C O Na Al Si S K Ca Ti V Fe Sr Porous irregular particles >98 75.7 15.1 0.18 1.03 3.36 0.9 0.21 1.05 0.13 0 1.81 0.57 74−98 85.3 7.84 0.13 0.75 2.8 0.72 0.17 0.71 0.15 0.04 0.79 0.64 Block particles >98 76.1 12 0.44 1.31 2.94 2.09 0.21 2.22 0.09 0.07 1.61 0.93 74−98 73.5 20.2 0.2 0.82 2.24 0.24 0.12 0.87 0.12 0 1.09 0.63 45−74 73.8 19.4 0.2 0.99 2.44 0.32 0.17 1.06 0.11 0.01 0.89 0.67 22−45 63.7 21.5 0.24 1.42 5.95 1.4 0.35 1.57 0.13 0.03 1.74 2 13−22 54 19.7 0.4 2.7 9.94 1.48 0.6 2.9 0.29 0 4.84 3.16 Spherical particles >98 9.86 41.5 2.86 6.44 11.5 1.02 0.51 6.03 0.4 0 18.2 1.75 74−98 9.66 43 2.8 6.25 11 0.71 0.46 5.59 0.3 0.14 18.2 1.87 45−74 26.7 36.8 2 4.92 8.82 0.94 0.41 4.63 0.25 0 13.2 1.31 22−45 17.6 42.5 2.81 7.13 1.98 0.69 0.44 6.16 0.3 0 19 1.37 13−22 24.7 34.6 2.3 6.6 10.9 0.6 0.4 5.61 0.31 0 12.3 1.68 0−13 20.5 36.8 3.01 6.82 10.4 0.74 0.52 5.98 0.21 0 13.8 1.24 Floccule 0−13 35.9 39.5 2.27 4.7 7.35 0.2 0.57 2.51 0.26 0.05 6.18 0.59 表 5 水煤浆气化细渣各粒径的孔隙特征参数

Table 5 Pore characteristic parameters of size-segmented CWSFS

Particle size/μm Specific surface area/(m2·g−1) Total pore volume/(cm3·g−1) Average aperture/nm >98 67.80 0.041 6.21 74−98 216.93 0.147 5.52 45−74 41.26 0.024 7.42 22−45 46.47 0.044 7.08 13−22 59.01 0.070 7.57 0−13 58.86 0.092 9.80 CWSFS 44.59 0.052 7.12 表 6 水煤浆气化细渣的分类指标及不同类型组分的组成结构特征

Table 6 Classification indexes of CWSFS and composition and structure characteristics of different types of components

Classification index Type Structure and composition characteristics of different types of components fixed carbon content/% calorific value/(MJ·kg−1) particle size range/μm micro morphological characteristics pore structure

characteristics (specific

surface area)/

(m2·g−1)main mineral composition >60 >20 high carbon component >74 porous irregular particle, block particle >67 magnetite, brookite 20−60 11−19 medium carbon component 13−74 block particle, spherical particle 40−60 pyroxene, marcasite, hematite <20 <10 low carbon component <13 floccule <60 quartz, fayalite,

muscovite表 7 不同粉碎方式下球形颗粒的面积统计

Table 7 Statistical results of spherical particle projected area using different crushing methods

CWSFS product Total area of spherical

particles/μm2Ratio of spherical particles to

total sample area/%Disc crushed for 3 min 253.8817 9.4034 Disc crushed for 6 min 189.4517 5.8623 Disc crushed for 9 min 56.4101 1.7996 Airflow crushed

graded frequency 20 Hz58.3324 1.7501 Airflow crushed

graded frequency 35 Hz130.1613 4.3221 Airflow crushed

graded frequency 50 Hz183.0621 5.4915 -

[1] 朱子祺. 煤制油选煤厂煤显微组分迁移规律[J]. 洁净煤技术,2020,26(6):89−95.ZHU Zi-qi. Migration rule of coal macerals in coal-to-oil preparation plant[J]. Clean Coal Technol,2020,26(6):89−95. [2] 任振玚, 井云环, 樊盼盼, 高艳春, 王建成, 董连平, 鲍卫仁, 樊民强, 常丽萍. 气化渣水介重选及其分离炭制备脱硫脱硝活性焦试验研究[J]. 煤炭学报,2021,46(4):1164−1172.REN Zhen-yang, JING Yun-huan, FAN Pan-pan, GAO Yan-chun, WANG Jian-cheng, DONG Lian-ping, BAO Wei-ren, FAN Min-qiang, CHANG Li-ping. Experimental study on the water-medium gravity separation of gasification slag and the preparation of desulfurization and denitrification activated coke using separated carbon[J]. J China Coal Soc,2021,46(4):1164−1172. [3] 张一昕, 郭旸, 王如梦, 贾文科, 郭凡辉, 武建军. 宁东煤气化细渣及其碳灰分离产物物理化学性质研究[J]. 煤炭学报,2021,46(S2):1096−1104.ZHANG Yi-xin, GUO Yang, WANG Ru-meng, JIA Wen-ke, GUO Fan-hui, WU Jian-jun. Study on the physicochemical properties of Ningdong coal gasification fine slag and its carbon-ash separation products[J]. J China Coal Soc,2021,46(S2):1096−1104. [4] 吕飞勇, 初茉, 易浩然, 郝焱, 杨彦博, 石旭, 孙星博. 磁性灰粒在不同粒级气化灰渣中的分布特性[J]. 化工进展,2022,41(5):2372−2378.LV Fei-yong, CHU Mo, YI Hao-ran, HAO Yan, YANG Yan-bo, SHI Xu, SUN Xing-bo. Distribution characteristics of magnetic ash particles in gasification slag of different particle sizes[J]. Chem Ind Eng Prog,2022,41(5):2372−2378. [5] 吴昊东, 邵丰华, 吕鹏, 白永辉, 宋旭东, 王焦飞, 郭庆华, 王学斌, 于广锁. 气流床煤气化细渣结构、性质与其粒度分布关系研究[J]. 燃料化学学报,2022,50(5):513−522.WU Hao-dong, SHAO Feng-hua, LV Peng, BAI Yong-hui, SONG Xu-dong, WANG Jiao-fei, GUO Qing-hua, WANG Xue-bin, YU Guang-suo. Study on the relationship between structure, properties and size distribution of fine slag from entrained flow gasification[J]. J Fuel Chem Technol,2022,50(5):513−522. [6] GUO F, MIAO Z, GUO Z, LI J, ZHANG Y, WU J. Properties of flotation residual carbon from gasification fine slag[J]. Fuel,2020,267:117043. doi: 10.1016/j.fuel.2020.117043 [7] ZHAO X, ZENG C, MAO Y, LI W, PENG Y, WANG T, EITENEER B, ZAMANSKY V, FLETCHER T. The surface characteristics and reactivity of residual carbon in coal gasification slag[J]. Energy Fuels,2010,24(1):91−94. doi: 10.1021/ef9005065 [8] WU S, HUANG S, JI L, WU Y, GAO J. Structure characteristics and gasification activity of residual carbon from entrained-flow coal gasification slag[J]. Fuel,2014,122:67−75. doi: 10.1016/j.fuel.2014.01.011 [9] HUANG S, WU S, PING Y, WU Y, GAO J. Effect of CS2 extraction on the physical properties and gasification activity of liquid-phase carbonization cokes[J]. J Anal Appl Pyrolysis,2012,93:33−40. doi: 10.1016/j.jaap.2011.09.008 [10] 张孝雨, 何国锋, 李磊, 陈浩. 水煤浆性能的影响因素及技术进展[J]. 洁净煤技术,2019,25(6):96−104.ZHANG Xiao-yu, HE Guo-feng, LI Lei, CHEN Hao. Influence factors and technical progress of CWS performance[J]. Clean Coal Technol,2019,25(6):96−104. [11] 蒋煜, 王磊, 涂亚楠. 水煤浆技术研究进展与发展趋势[J]. 煤炭工程,2020,52(5):27−32.JIANG Yu, WANG Lei, TU Ya-nan. Discussion on progress and development trend of coal water slurry technology[J]. Coal Eng,2020,52(5):27−32. [12] 郭庆华, 卫俊涛, 龚岩, 祝慧雯, 于广锁. 多喷嘴对置式气流床气化炉内热态行为的研究进展[J]. 煤炭学报,2020,45(1):403−413.GUO Qing-hua, Wei Jun-tao, Gong Yan, ZHU Hui-wen, YU Guang-suo. Research progress on hot-model behavior of opposed multi-burner entrained-flow gasification[J]. J China Coal Soc,2020,45(1):403−413. [13] HUO W, ZHOU Z, WANG F, WANG Y, YU G. Experimental study of pore diffusion effect on char gasification with CO2 and steam[J]. Fuel,2014,131:59−65. doi: 10.1016/j.fuel.2014.04.058 [14] 何国锋, 柳金秋, 徐彤, 李磊. 水煤浆气化细灰碳灰分布特性及其分离试验研究[J]. 煤炭科学技术,2021,49(4):82−89. doi: 10.13199/j.cnki.cst.2021.04.010HE Guo-feng, LIU Jin-qiu, XU Tong, LI Lei. Distribution characteristics and separation experiment of carbon ash from coal water slurry gasification fine ash[J]. Coal Sci Technol,2021,49(4):82−89. doi: 10.13199/j.cnki.cst.2021.04.010 [15] 王学斌, 于伟, 张韬, 白永辉, 刘莉君, 史兆臣, 殷瑞, 谭厚章. 基于粒度分级的煤气化细渣特性分析及利用研究[J]. 洁净煤技术,2021,27(3):61−69.WANG Xue-bin, YU Wei, ZHANG Tao, BAI Yong-hui, LIU Li-jun, SHI Zhao-chen, YIN Rui, TAN Hou-zhang. Characteristic analysis and utilization of coal gasification fine slag based on particle size classification[J]. Clean Coal Technol,2021,27(3):61−69. [16] 尹艳山, 尹杰, 张巍, 田红, 胡章茂, 冯磊华, 陈冬林. 红外和拉曼光谱的煤灰矿物组成研究[J]. 光谱学与光谱分析,2018,38(3):789−793.YIN Yan-shan, YIN Jie, ZHANG Wei, TIAN Hong, HU Zhang-mao, FENG Lei-hua, CHEN Dong-lin. Characterization of mineral matter in coal ashes with infrared and Raman spectroscopy[J]. Spect Spect Anal,2018,38(3):789−793. [17] 张建法, 梁钦峰, 王剑, 许建良, 刘海峰, 龚欣. Shell粉煤气化炉渣池内熔渣流动特性[J]. 化学工程,2011,39:89−93. doi: 10.3969/j.issn.1005-9954.2011.04.022ZHANG Jian-fa, LIANG Qin-feng, WANG Jian, XU Jian-liang, LIU Hai-feng, GONG Xin. Flow characteristics of slag in Shell gasifier slag bath[J]. Chem Eng,2011,39:89−93. doi: 10.3969/j.issn.1005-9954.2011.04.022 [18] SUN L, GONG Y, GUO Q, YU G. Microscopic characteristics of solid particles in opposed multi-burner gasifier[J]. J Fuel Chem Technol,2014,42(9):1025−1032. doi: 10.1016/S1872-5813(14)60042-6 [19] 吕登攀, 白永辉, 王焦飞, 宋旭东, 苏暐光, 于广锁, 祝贺, 唐广军. 气流床气化细渣中残炭的结构特征及燃烧特性研究[J]. 燃料化学学报,2021,49(2):129−136. doi: 10.1016/S1872-5813(21)60011-7LÜ Deng-pan, BAI Yong-hui, WANG Jiao-fei, SONG Xu-dong, SU Wei-guang, YU Guang-suo, ZHU He, TANG Guang-jun. Structural features and combustion reactivity of residual carbon in fine slag from entrained-flow gasification[J]. J Fuel Chem Technol,2021,49(2):129−136. doi: 10.1016/S1872-5813(21)60011-7 [20] 张杰, 郭庆华, 周志杰, 于广锁. 多喷嘴对置式水煤浆气化炉内颗粒物分布特性的实验研究[J]. 中国电机工程学报,2013,33(20):59−65.ZHANG Jie, GUO Qing-hua, ZHOU Zhi-jie, YU Guang-suo. Experimental study of particle distribution in bench-cale opposed multi-burner gasifiers of coal water slurry[J]. Proc CSEE,2013,33(20):59−65. [21] SING K. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity[J]. Pure Appl Chem,1985,57:603. doi: 10.1351/pac198557040603 [22] 张志清. 气化炉内颗粒物特性及气化灰渣在水煤浆制备中的应用研究[D]. 上海: 华东理工大学, 2019.ZHANG Zhi-qing. Study on characteristics of particulate matter in gasifier and gasification slag blending in the preparation of coal-water slurry[D]. Shanghai: East China University of Science and Technology, 2019. [23] 徐硕, 杨金林, 马少健. 粉煤灰综合利用研究进展[J]. 矿产保护与利用,2021,41(3):104−111.XU Shuo, YANG Jin-lin, MA Shao-jian. Research progress in the comprehensive utilization of fly ash[J]. Conserv Util Min Res,2021,41(3):104−111. [24] 姜龙. 燃煤电厂粉煤灰综合利用现状及发展建议[J]. 洁净煤技术,2020,26(4):31−39.JIANG Long. Comprehensive utilization situation of fly ash in coal-fired power plants and its development suggestions[J]. Clean Coal Technol,2020,26(4):31−39. [25] GU Y, QIAO X. A carbon silica composite prepared from water slurry coal gasification slag[J]. Microporous Mesoporous Mater,2019,276:303−307. doi: 10.1016/j.micromeso.2018.06.025 [26] 赵永彬, 吴海骏, 张学斌, 刘洪刚, 井云环, 袁伟. 煤气化残渣基多孔陶瓷的制备研究[J]. 洁净煤技术,2016,22(5):7−11.ZHAO Yong-bin, WU Hai-jun, ZHANG Xue-bin, LIU Hong-gang, JING Yun-huan, YUAN Wei. Fabrication of porous ceramic from coal gasification residual[J]. Clean Coal Technol,2016,22(5):7−11. [27] 尹洪峰, 汤云, 任耘, 张军战. 气化炉渣合成Ca-α-Sialon-SiC复相陶瓷[J]. 硅酸盐学报,2011,39(2):233−238.YIN Hong-feng, TANG Yun, REN Yun, ZHANG Jun-zhan. Synthesis of Ca-α-Sialon-SiC multiphase ceramics using gasification slag[J]. J Chin Ceram Soc,2011,39(2):233−238. [28] LI Z, ZHANG Y, ZHAO H, CHEN H, HR R. Structure characteristics and composition of hydration products of coal gasification slag mixed cement and lime[J]. Constr Build Mater,2019,213:265−274. doi: 10.1016/j.conbuildmat.2019.03.163 [29] LIU X, JIN Z, JING Y, FAN P, QI Z, BAO W, WANG J, YAN X, LV P, DONG L. Review of the characteristics and graded utilisation of coal gasification slag[J]. Chin J Chem Eng,2021,35:92−106. doi: 10.1016/j.cjche.2021.05.007 [30] 曲江山, 张建波, 孙志刚, 杨晨年, 史达, 李少鹏, 李会泉. 煤气化渣综合利用研究进展[J]. 洁净煤技术,2020,26(1):184−193.QU Jiang-shan, ZHANG Jian-bo, SUN Zhi-gang, YANG Chen-nian, SHI Da, LI Shao-peng, LI Hui-quan. Research progress on comprehensive utilization of coal gasification slag[J]. Clean Coal Technol,2020,26(1):184−193. [31] 张智吉, 魏上津, 郝路路, 张锡泽, 覃思学, 高明, 舒元峰, 许泽胜, 舒新前. 气化灰渣浮选回收炭粉的实验研究[J]. 煤炭加工与综合利用,2021,267(10):62−65.ZHANG Zhi-ji, WEI Shang-ji, HAO Lu-lu, ZHANG Xi-ze, TAN Si-xue, GAO Ming, SHU Yuan-feng, XU Ze-sheng, SHU Xin-qian. Experimental study on decarbonization of gasification slag by flotation[J]. Coal Process Compr Util,2021,267(10):62−65. [32] 于伟, 王学斌, 刘莉君, 白永辉, 史兆臣, 王丽娜, 屈进州. 高含碳煤气化细渣浮选行为研究[J]. 煤炭学报, https://kns.cnki.net/kcms/detail/detail.aspx?doi=10.13225/j.cnki.jccs.FX21.1105YU Wei, WANG Xue-bin, LIU Li-jun, BAI Yong-hui, SHI Zhao-chen, WANG Li-na, QU Jin-zhou. Study on flotation behavior of high carbon coal gasification fine slag[J]. J China Coal Soc, https://kns.cnki.net/kcms/detail/detail.aspx?doi=10.13225/j.cnki.jccs.FX21.1105. [33] 李金凤. 气化滤饼中碳赋存形态及循环掺烧可行性研究[J]. 洁净煤技术,2020,26(6):224−228.LI Jin-feng. Investigation on the occurrence of carbon in gasification filter cake and its feasibility of circulating combustion[J]. Clean Coal Technol,2020,26(6):224−228. [34] 刘华洁, 吴文秀, 田云吉. 涡轮式气流分级机压降分析及流场模拟[J]. 石油机械,2019,47(6):95−100.LIU Hua-jie, WU Wen-xiu, TIAN Yun-ji. Pressure drop analysis and flow field simulation of turbine air classifier[J]. China Pet Machinery,2019,47(6):95−100. [35] 王海旭. 潮湿煤跌落松散与气流分级过程研究[D]. 徐州: 中国矿业大学, 2020.(WANG Hai-xu. Study on falling De-attachment and air flow classification process of wet coal[D]. Xuzhou: China University of Mining and Technology, 2020. [36] 苏偲禹. 气流粉碎对粉体物性的影响及破碎机理研究[D]. 大连: 大连理工大学, 2020.SU Si-yu. Research on the influence of jet crushing on the physical properties of powders and the mechanism of crushing[D]. Dalian: Dalian University of Technology, 2020. -

下载:

下载: