Structural characteristics and thermal conversion performance of ash and slag from circulating fluidized bed gasifier

-

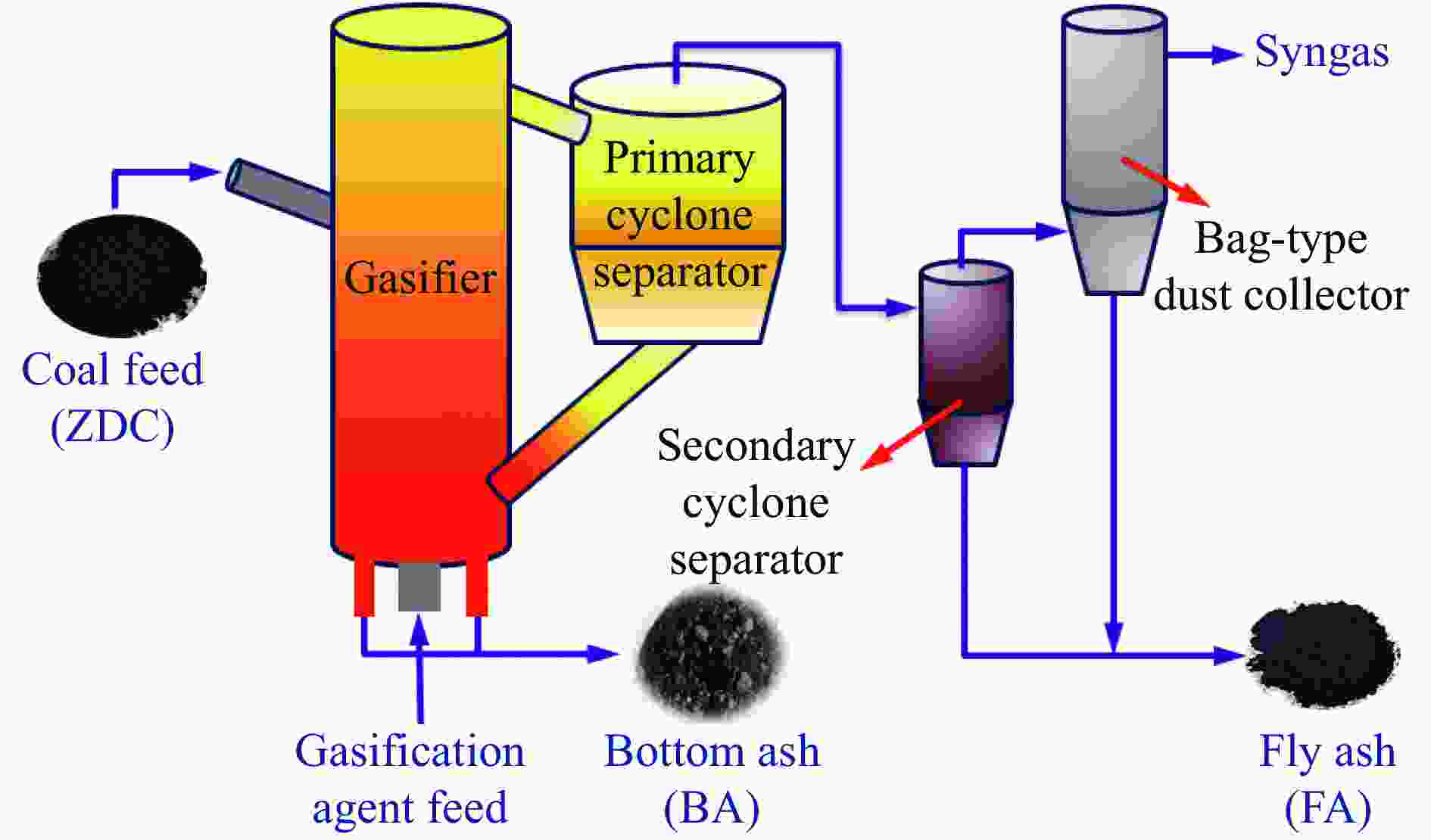

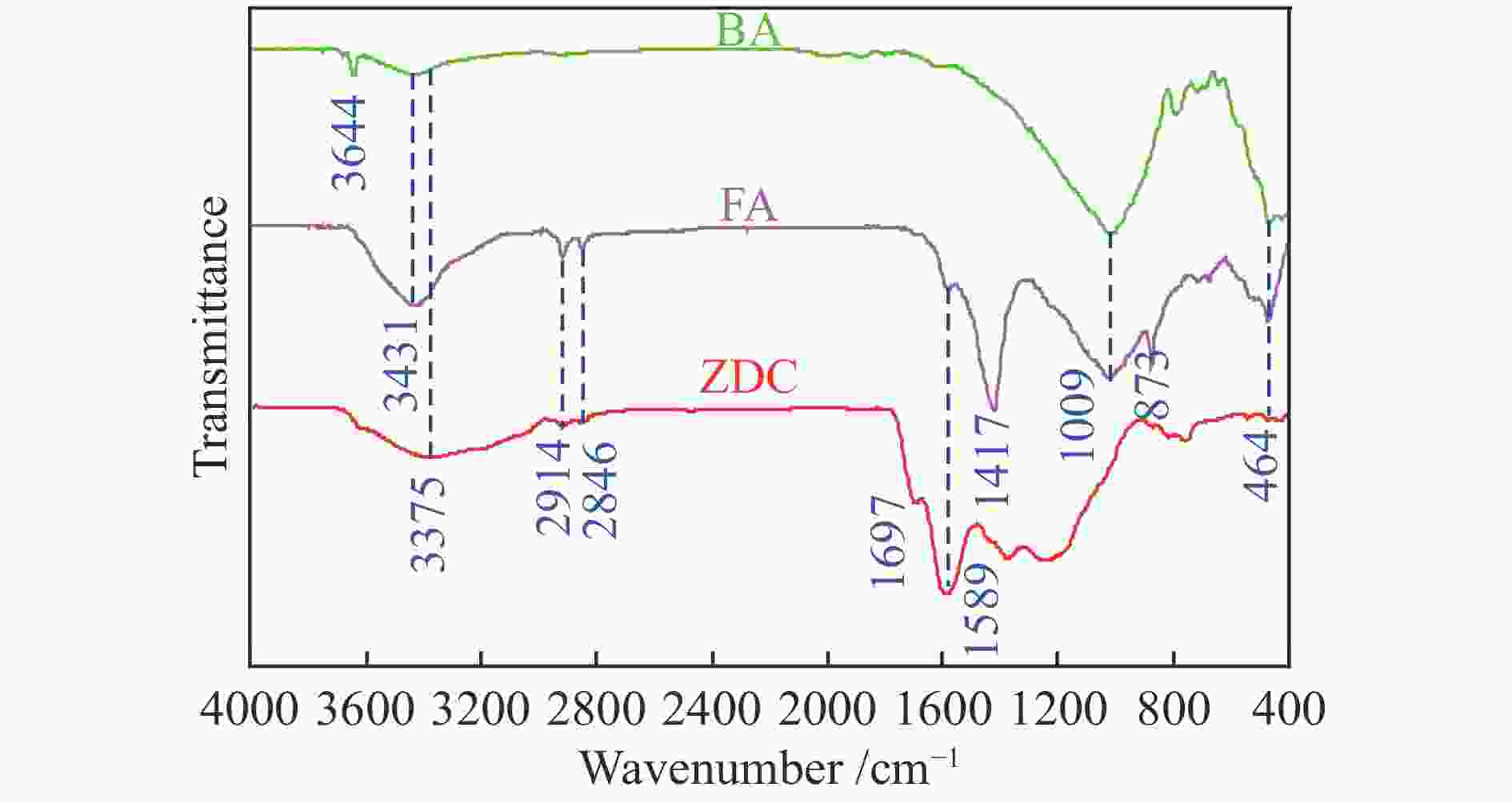

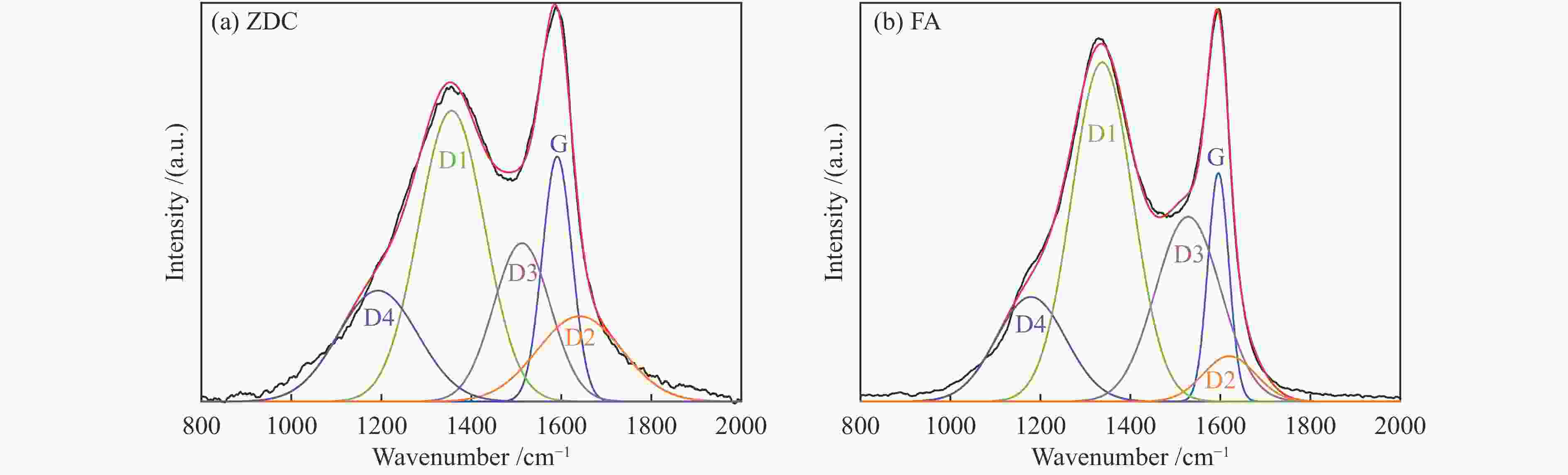

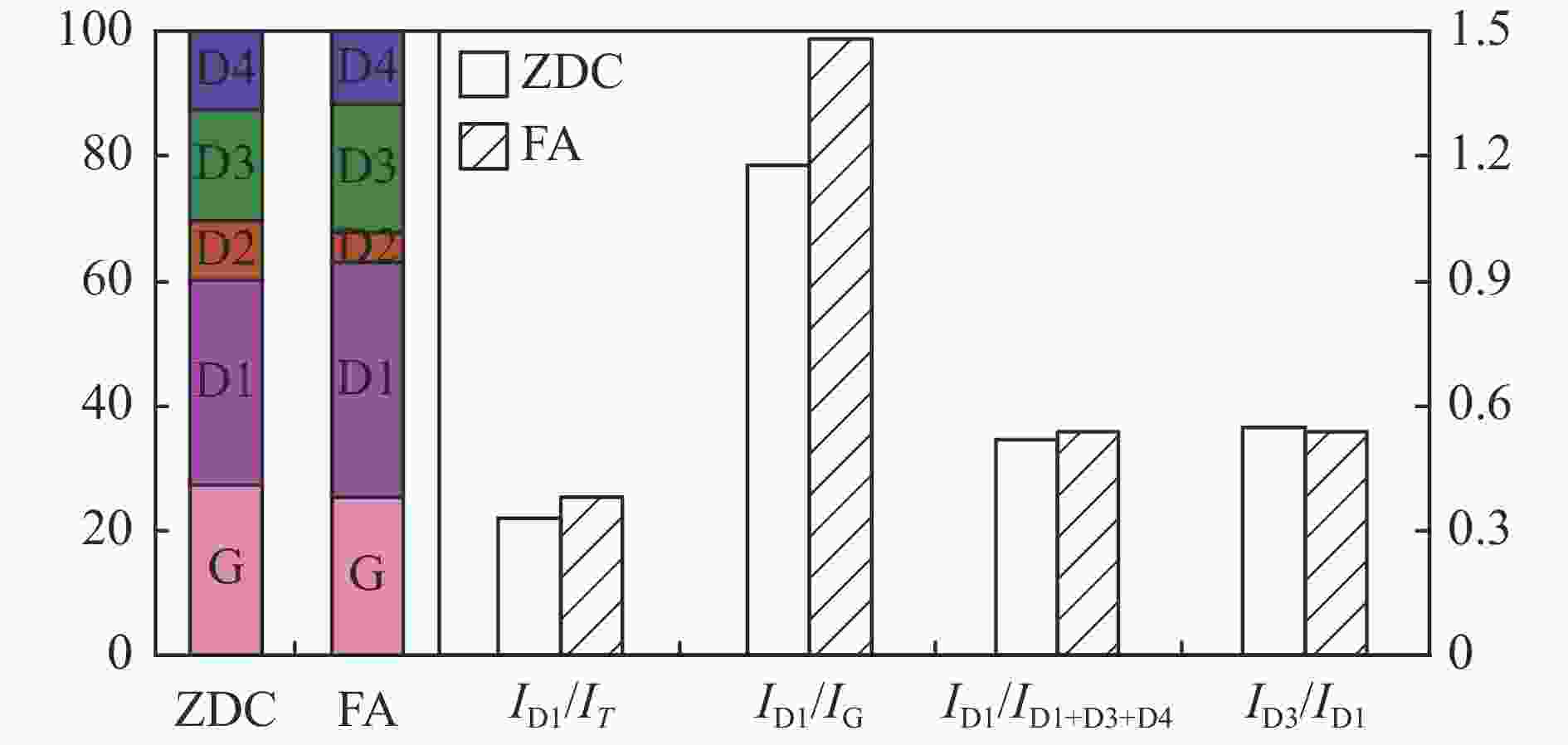

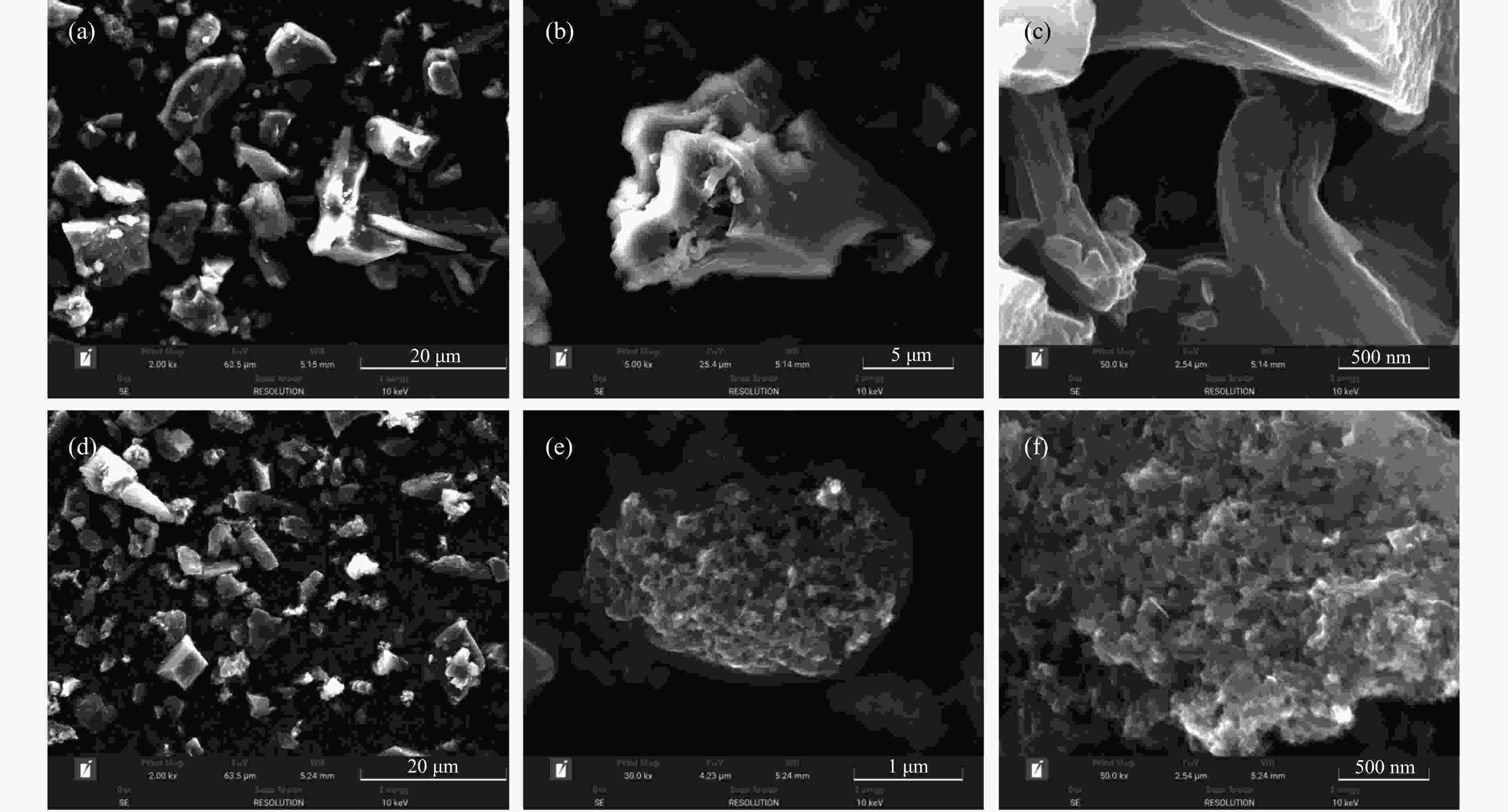

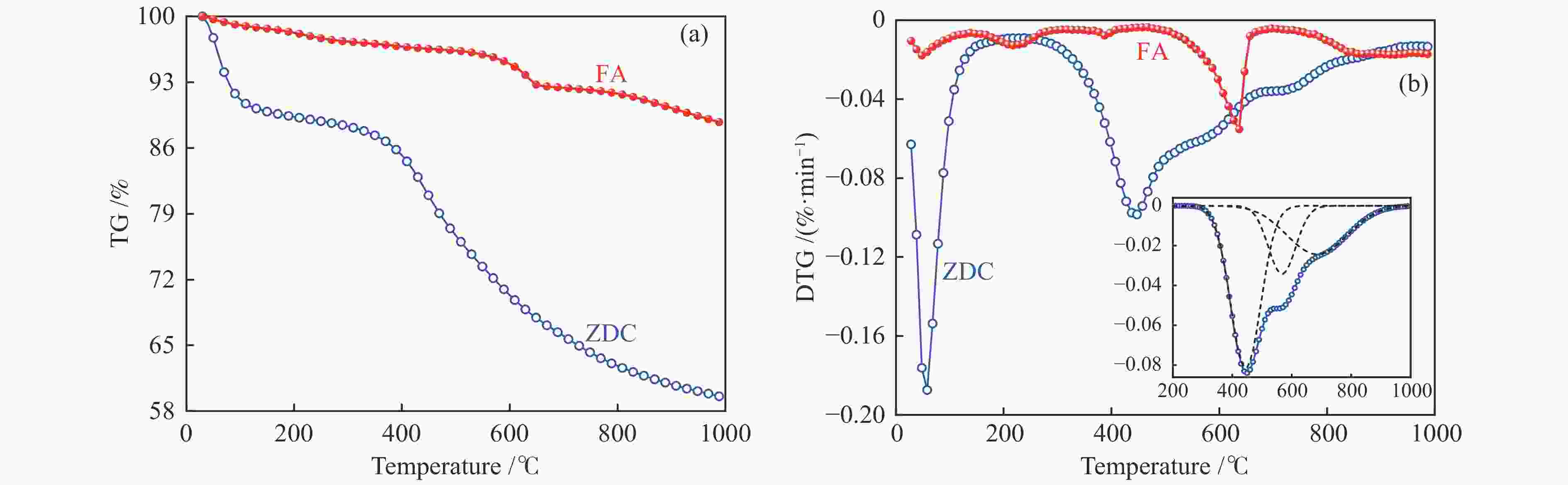

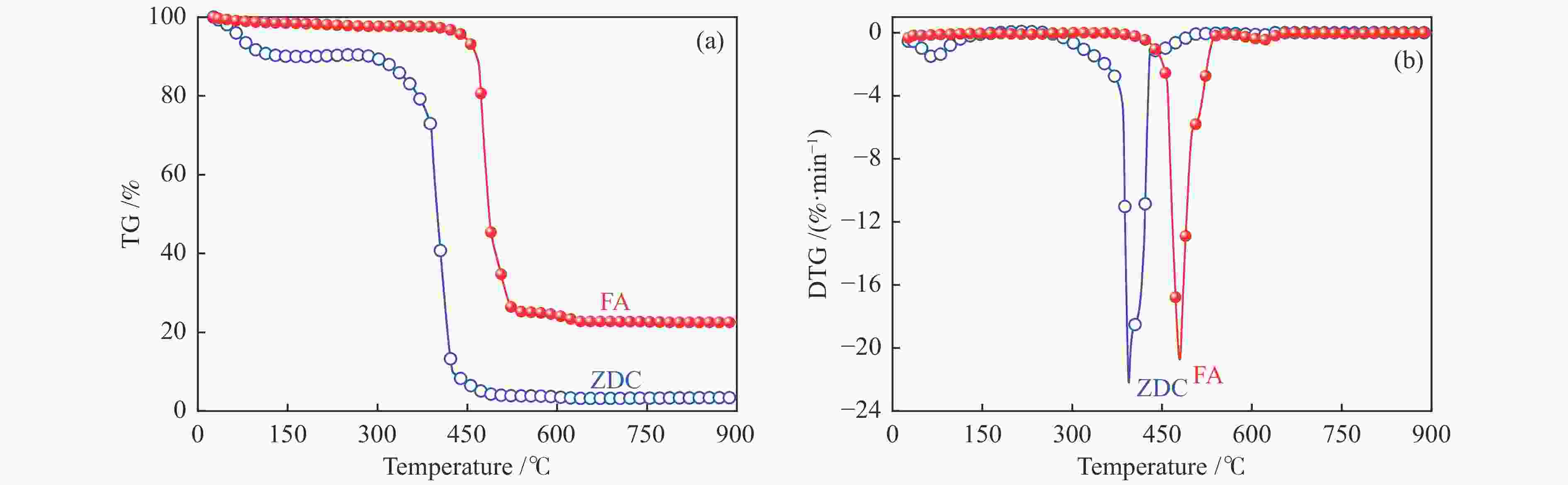

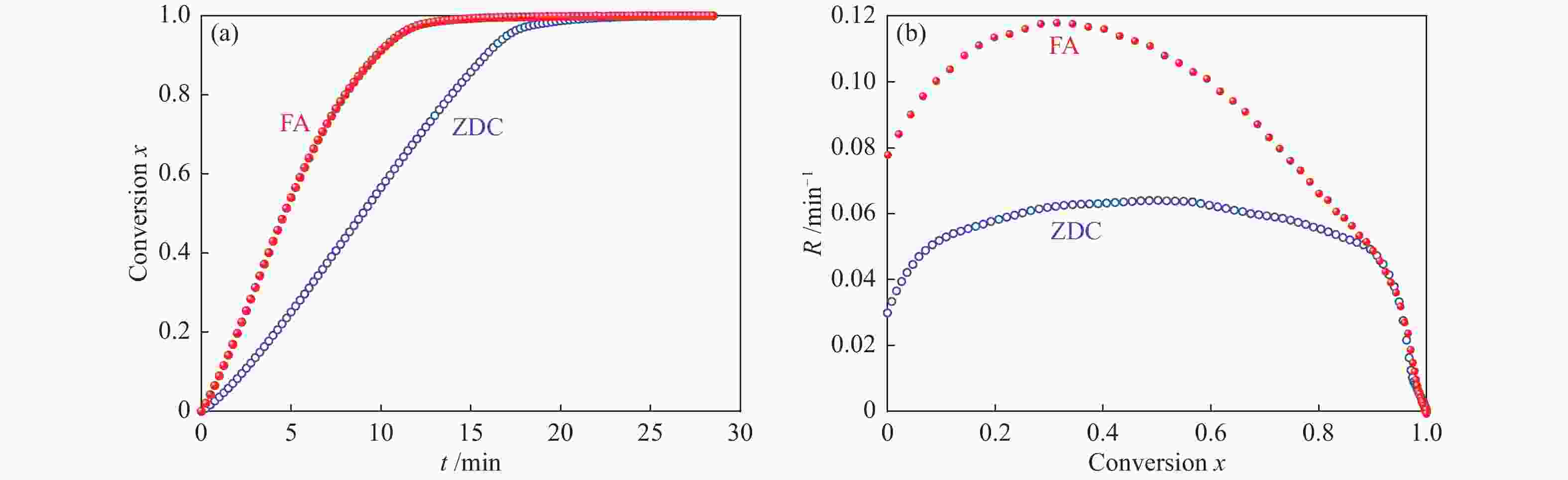

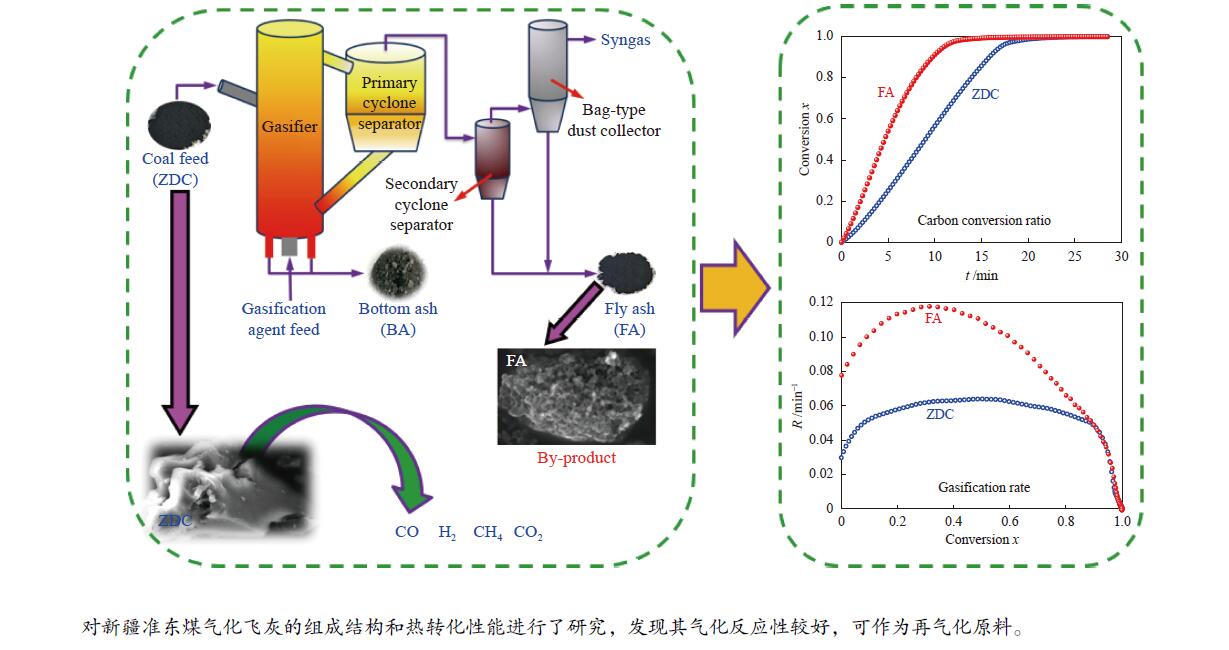

摘要: 通过工业分析、元素分析和傅里叶红外光谱测试基于循环流化床的新疆准东煤(ZDC)气化灰渣(FA:飞灰;BA:底渣),获得灰渣的基本性质和官能团种类。结果显示,BA的灰分含量高达99.30%,而FA的固定碳和碳元素含量较高,分别为69.30%和73.78%。进一步采用Raman、XRPES和SEM表征ZDC和FA的碳质形式和表面形貌,利用TG-DTG技术考察ZDC和FA的热解、燃烧和气化反应特性。XRPES结果显示,FA表面C元素含量为89.42%,主要以>C−C<和>C−H的形式存在,而O元素主要以>C=O的形式存在。碱土金属Ca与上述涉碳官能团结合,导致FA无序程度较高。SEM观察到熔融矿物质球形颗粒附着和镶嵌在FA表面和孔道中,导致表面粗糙多孔。热转化特性显示,FA的热解和燃烧最大失重速率峰温度均较ZDC明显升高,表明FA的热解和燃烧性能降低。然而,FA的100%碳转化率所用气化时间仅为ZDC的一半,气化性能显著提高,原因在于FA具有发达的孔道结构、较多的无定形碳及丰富的活性位点,强化了气化剂CO2的扩散过程。因此,FA可直接回收用作循环流化床的气化原料。Abstract: Based on the circulating fluidized bed (CFB), Xinjiang Zhundong coal (ZDC) gasification ash (FA: fly ash; BA: bottom slag) was analyzed by industrial analysis, ultimate analysis and Fourier infrared spectroscopy to determine the basic properties and functional group species. The results show that BA contains up to 99.30% in ash, while FA shows high fixed carbon and C content of 69.30% and 73.78% respectively. Furthermore, the carbonaceous forms and surface morphology of ZDC and FA were characterized by Raman, XRPES and SEM, and the pyrolysis, combustion and gasification characteristics of ZDC and FA were studied with TG-DTG methods. XRPES show that C content of the FA surface is 89.42%, and exists primarily as >C–C< and >C–H, while O was in the form of >C=O. Alkaline earth metals Ca bound to the above-mentioned carbon-involved functional groups cause high disorder in FA. SEM observed that the rough and porous FA surface occurs due to spherical particles of molten mineral attached and embedded surface and pore channels. The thermal conversion characteristics show that the maximum weight loss rate peak temperature of pyrolysis and combustion of FA is significantly higher than that of ZDC, indicating that the pyrolysis and combustion performance of FA is reduced. However, 100% carbon conversion of FA uses about half the time compared with ZDC and the gasification performance has improved significantly since it has well-developed pore structures, more amorphous carbon and abundant active sites, enhancing diffusion of CO2 from gasifiers. Briefly, FA has the potential and ability to be recycled for direct utilization in CFB as gasification feed.

-

Key words:

- coal gasification /

- zhundong coal /

- ash and slag /

- composition structure /

- thermal conversion

-

表 1 样品的工业分析和元素分析

Table 1 Proximate and ultimate analyses

Sample Proximate analysis wad/% LOI /% Ultimate analysis wdaf/% H/C QHHV/

(MJ·kg−1)M A V FC C H N O* S ZDC 10.96 2.73 27.79 58.52 − 68.42 4.27 2.63 24.20 0.48 0.75 28.00 FA 1.27 23.68 5.75 69.30 − 73.78 0.57 2.50 22.11 1.04 0.09 25.53 BA 0.30 99.30 0.30 0.10 0.84 0.55 0.04 2.25 − 0.35 − − ad: air-dry basis; daf: dry and ash-free basis; M: moisture; A: ash; V: volatile matter; FC: fixed carbon; LOI: A weight loss percentage on ignition (900 ℃, 30 min); *: by difference 表 2 ZDC、FA和BA的灰成分分析

Table 2 Ash compositions of ZDC, FA and BA

Sample Content w/% CaO Fe2O3 SO3 MgO Na2O Al2O3 SiO2 SrO Cl K2O TiO2 ZDC 47.97 20.45 11.37 5.32 4.39 2.65 2.56 1.89 1.80 0.10 0.35 FA 37.53 9.16 11.65 12.95 3.19 7.58 11.35 1.30 2.43 1.03 0.76 BA 36.77 9.77 0.80 12.80 2.13 8.47 25.46 1.03 0.14 0.53 0.93 表 3 ZDC和FA的Raman光谱拟合峰归属和面积比例

Table 3 Assignment and area of Raman spectrum fitting peaks of ZDC and FA

Band Center /cm−1 Assignment Area /% ZDC FA G 1580 stretching vibration mode of carbon atom in the graphite crystalline 27.52 25.32 D1 1350 the vibration of disordered graphitic lattices within plan imperfections,

such as defects and heteroatoms32.65 37.59 D2 1620 vibration mode involving graphene layers 9.58 5.03 D3 1530 amorphous sp2-band forms, including organic molecules, fragments, or

functional groups, and in poorly organized carbonaceous materials17.79 20.47 D4 1200 mixed sp2-sp3 mixed bond in poorly organized structures,

such as the periphery of crystallites12.45 11.59 表 4 ZDC和FA中C和O的分布形式

Table 4 Distribution of C and O forms in ZDC and FA from analysis with XRPES

Elemental peak Functionality Binding energy /eV Molar content /% ZDC FA C 1s >C−C< 284.4 52.92 45.42 >C−H 285.2 30.06 30.52 >C−O− 286.3 9.36 3.21 >C=O 287.3 5.64 2.91 −COO− 288.6 2.01 11.10 π−π* 291.5 − 6.84 O 1s >C=O 531.6 19.30 57.65 >C−OH 532.4 33.77 19.65 >C−O− 533.1 26.72 14.02 −COOH 534.1 20.20 8.68 表 5 ZDC和FA燃烧曲线的特征参数

Table 5 Combustion characteristic parameters of ZDC and FA

Sample ts /℃ tmax /℃ tf /℃ (dw/dt)max /(%·min−1) (dw/dt)mean /(%·min−1) S/(%2·min−2·℃−3) D/(%·min−1·℃−2) ZDC 368.2 411.0 630.1 22.36 6.50 21.5×10−7 1.48×10−4 FA 456.8 479.2 634.3 20.35 4.20 6.54×10−7 7.71×10−4 -

[1] LI J W, CHEN Z C, LI L K, QIAN Y Y, YUAN Z H, ZENG L Y, LI Z Q. Study on pore and chemical structure characteristics of atmospheric circulating fluidized bed coal gasification fly ash[J]. J Cleaner Prod,2021,308(7):127395. [2] ZHANG W W, HUANG S, WU S Y, WU Y Q, GAO J S. Study on the structure characteristics and gasification activity of residual carbon in biomass ashes obtained from different gasification technologies[J]. Fuel,2019,254:115699. [3] JIANG D H, SONG W J, WANG X F, ZHU Z P. Physicochemical properties of bottom ash obtained from an industrial CFB gasifier[J]. J Energy Inst,2021,95:1−7. doi: 10.1016/j.joei.2020.12.004 [4] LIU X D, JIN Z W, JING Y H, FAN P P, QI Z L, BAO W R, WANG J C, YAN X H, LV P, DONG L P. Review of the characteristics and graded utilisation of coal gasification slag[J]. Chin J Chem Eng,2021,35(7):92−106. [5] DAI G F, ZHENG S J, WANG X B, BAI Y H, DONG Y S, DU J, SUN X W, TAN H Z. Combustibility analysis of high-carbon fine slags from an entrained flow gasifier[J]. J Environ Manage,2020,271:111009. doi: 10.1016/j.jenvman.2020.111009 [6] GUO F H, MIAO Z K, GUO Z K, LI J, ZHANG Y X, WU J J. Properties of flotation residual carbon from gasification fine slag[J]. Fuel,2020,267:117043. doi: 10.1016/j.fuel.2020.117043 [7] DU M J, HUANG J J, LIU Z Y, ZHOU X, GUO S, WANG Z Q, FANG Y T. Reaction characteristics and evolution of constituents and structure of a gasification slag during acid treatment[J]. Fuel,2018,224:178−185. doi: 10.1016/j.fuel.2018.03.073 [8] ZHANG Y C, LI H X, WU C L. Study on distribution, chemical states and binding energy shifts of elements on the surface of gasification fine ash[J]. Res Chem Intermed,2019,45(7):3855−3864. doi: 10.1007/s11164-019-03824-1 [9] MIAO Z K, CHEN L Q, CHEN K N, ZHANG X X, ZHANG Y X, WU J J. Physical properties and microstructures of residual carbon and slag particles present in fine slag from entrained-flow coal gasification[J]. Adv Powder Technol,2020,31(9):3781−3789. doi: 10.1016/j.apt.2020.07.019 [10] WEI R D, REN L W, GENG F J. Gasification reactivity and characteristics of coal chars and petcokes[J]. J Energy Inst,2021,96:25−30. doi: 10.1016/j.joei.2020.07.012 [11] 吕登攀, 白永辉, 王焦飞, 宋旭东, 苏暐光, 于广锁, 祝贺, 唐广军. 气流床气化细渣中残炭的结构特征及燃烧特性研究[J]. 燃料化学学报,2021,49(2):129−136. doi: 10.1016/S1872-5813(21)60011-7LÜ Deng-pan, BAI Yong-hui, WANG Jiao-fei, SONG Xu-dong, SU Wei-guang, YU Guang-suo, ZHU he, TANG Guang-jun. Structural features and combustion reactivity of residual carbon in fine slag from entrained-flow gasification[J]. J Fuel Chem Technol,2021,49(2):129−136. doi: 10.1016/S1872-5813(21)60011-7 [12] WU S H, HUANG S, JI L Y, WU Y Q, GAO J S. Structure characteristics and gasification activity of residual carbon from entrained-flow coal gasification slag[J]. Fuel,2014,122:67−75. doi: 10.1016/j.fuel.2014.01.011 [13] ZHANG H X, ZHU Z P, DONG Q, YU K S, LU Q G. Structural properties and gasification reactivity of Shenmu fly ash obtained from a 5t/d circulating fluidized bed gasifier[J]. Procedia Eng,2015,102:1104−1111. doi: 10.1016/j.proeng.2015.01.233 [14] JING X L, WANG Z Q, YU Z L, ZHANG Q, LI C Y, FANG Y T. Experimental and kinetic investigations of CO2 gasification of fine chars separated from a pilot-scale fluidized-bed gasifier[J]. Energy Fuels,2013,27:2422−2430. doi: 10.1021/ef4002296 [15] KELEOPILE L, SUN R, LIAO J. Fly ash and coal char reactivity from thermo-gravimetric (TGA) experiments[J]. Fuel Process Technol,2011,92(6):1178−1186. doi: 10.1016/j.fuproc.2011.01.007 [16] LI X, LI J, WU G G, BAI Z Q, L W. Clean and efficient utilization of sodium-rich Zhundong coals in China: Behaviors of sodium species during thermal conversion processes[J]. Fuel,2018,218:162−173. doi: 10.1016/j.fuel.2018.01.027 [17] PARIKH J, GHOSALG C S. A correlation for calculating HHV from proximate analysis of solid fuels[J]. Fuel,2004,84(5):487−494. [18] DIAO R, ZHU X F, WANG C, ZHU X F. Synergistic effect of physicochemical properties and reaction temperature on gasification reactivity of walnut shell chars[J]. Energy Convers Manage,2018,204:112313. [19] GUO Y, GUO F H, ZHOU L, GUO Z K, MIAO Z K, LIU H, ZHANG X X, WU J J, ZHANG Y X. Investigation on co-combustion of coal gasification fine slag residual carbon and sawdust char blends: Physiochemical properties, combustion characteristic and kinetic behavior[J]. Fuel,2021,292(2):120387. [20] PAINTER P C, COLEMAN M M, JENKINS R G, WHANG P W, WALKER J. Fourier Transform Infrared study of mineral matter in coal. A novel method for quantitative mineralogical analysis[J]. Fuel,1978,57(6):337−344. doi: 10.1016/0016-2361(78)90170-9 [21] YU P, KIRKPARTRICK R J, POE B, MCMILLAN P F, CONG X D. Structure of calcium silicate hydrate (C-S-H): Near-, Mid-, and Far-Infrared spectroscopy[J]. J Am Ceram Soc,1999,82(3):742−748. [22] YU S H, ZHANG C, ZHANG X P, LI X, WEI B, TAN P, FANG Q Y, CHEN G, XIA J. Release and transformation characteristics of Na/Ca/S compounds of Zhundong coal during combustion/CO2 gasification[J]. J Energy Inst,2020,93(2):752−765. doi: 10.1016/j.joei.2019.05.007 [23] YASERI S, VERKI V M, MAHDIKHANI M. Utilization of high volume cement kiln dust and rice husk ash in the production of sustainable geopolymer[J]. J Cleaner Prod,2019,230:592−602. doi: 10.1016/j.jclepro.2019.05.056 [24] GUO Y, MA C F, ZHANG Y X, ZHOU L, HUO Z K, MIAO Z K, ZHAO X, WU J J, GUO F H. Comparative study on the structure characteristics, combustion reactivity, and potential environmental impacts of coal gasification fine slag with different particle size fractions[J]. Fuel,2022,311:122493. doi: 10.1016/j.fuel.2021.122493 [25] LI F H, LIU Q R, LI M, FANG Y T. Understanding fly-ash formation during fluidized-bed gasification of high-silicon-aluminum coal based on its characteristics[J]. Energy,2018,150:142−152. doi: 10.1016/j.energy.2018.02.137 [26] JOHNSON C A, PATRICK J W, THOMAS K M. Mark Thomas. Characterization of coal chars by Raman spectroscopy, X-ray diffraction and reflectance measurements[J]. Fuel,1986,65(9):1284−1290. doi: 10.1016/0016-2361(86)90243-7 [27] HUANG S, WU S Y, WU Y Q, GAO J S. Structure characteristics and gasification activity of residual carbon from updraft fixed-bed biomass gasification ash[J]. Energy Convers Manage,2017,136:108−118. doi: 10.1016/j.enconman.2016.12.091 [28] QIU P H, DU C S, LIU L. Structural characteristics of char derived from acid-washed coal pyrolysis and its corrections with char reactivity[J]. J China Coal Soc,2017,42:233−239. [29] FUCHS W, SANDHOFF A G. Theory of coal pyrolysis[J]. Ind Eng Chem,1942,34(5):567−571. doi: 10.1021/ie50389a010 [30] WANG N, MAO M, MAO G Y, YIN J B, HE R X, ZHOU H C, LI N, LIU Q S, ZHI K D. Investigation on carbide slag catalytic effect of Mongolian bituminous coal steam gasification process[J]. Chemosphere,2021,264:128500. doi: 10.1016/j.chemosphere.2020.128500 [31] WANG H, LIU S L, LI X T, YANG D W, WANG X Y, SONG C. Morphological and structural evolution of bituminous coal slime particles during the process of combustion[J]. Fuel,2018,218:49−58. doi: 10.1016/j.fuel.2018.01.022 [32] WANGER N J, MATJIE R H, SLAGHUIS J H, HEERDEN V. Characterization of unburned carbon present in coarse gasification ash[J]. Fuel,2008,87(6):683−691. doi: 10.1016/j.fuel.2007.05.022 [33] PAN C C, LIANG Q F, GUO X L, DAI Z H, LIU H F, GONG X. Characteristics of different sized slag particles from entrained-flow coal gasification[J]. Energy Fuels,2016,30(2):1487−1495. doi: 10.1021/acs.energyfuels.5b01326 [34] MO W L, WU Z F, HE X Q, QIANG W J, WEI B, WEI X Y, WU Y L, FAN X, MA F Y. Functional group characteristics and pyrolysis/combustion performance of fly ashes from Karamay oily sludge based on FT-IR and TG-DTG analyses[J]. Fuel,2021,296(5):120669. [35] 景旭亮, 王志青, 张乾, 房倚天. 流化床气化炉半焦细粉的燃烧特性及其动力学研究[J]. 燃料化学学报,2014,42(1):13−21.JING Xu-liang, WANG Zhi-qing, ZHANG Qian, FANG Yi-tian. Combustion property and kinetics of fine chars derived from fluidized bed gasifier[J]. J Fuel Chem Technol,2014,42(1):13−21. [36] 张新沙, 宋旭东, 苏暐光, 卫俊涛, 白永辉, 于广锁. 宁东煤煤焦-CO2气化反应特性的原位研究[J]. 燃料化学学报,2019,47(4):385−392. doi: 10.1016/S1872-5813(19)30018-0ZHANG Xin-sha, SONG Xu-dong, SU Wei-guang, WEI Jun-tao, BAI Yong-hui, YU Guang-suo. In-situ study on gasification reaction characteristics of Ningdong coal chars with CO2[J]. J Fuel Chem Technol,2019,47(4):385−392. doi: 10.1016/S1872-5813(19)30018-0 [37] MIAO Z K, GUO F H, ZHAO X, GUO Z K, GUO Y, ZHANG Y X, WU J J. Effects of acid treatment on physicochemical properties and gasification reactivity of fine slag from Texaco gasifier[J]. Chem Eng Res Des,2021,169:1−8. doi: 10.1016/j.cherd.2021.01.020 -

下载:

下载: