Study on the regulation mechanism of torrefaction pretreatment on fuel quality and pyrolysis characteristics of rice husk

-

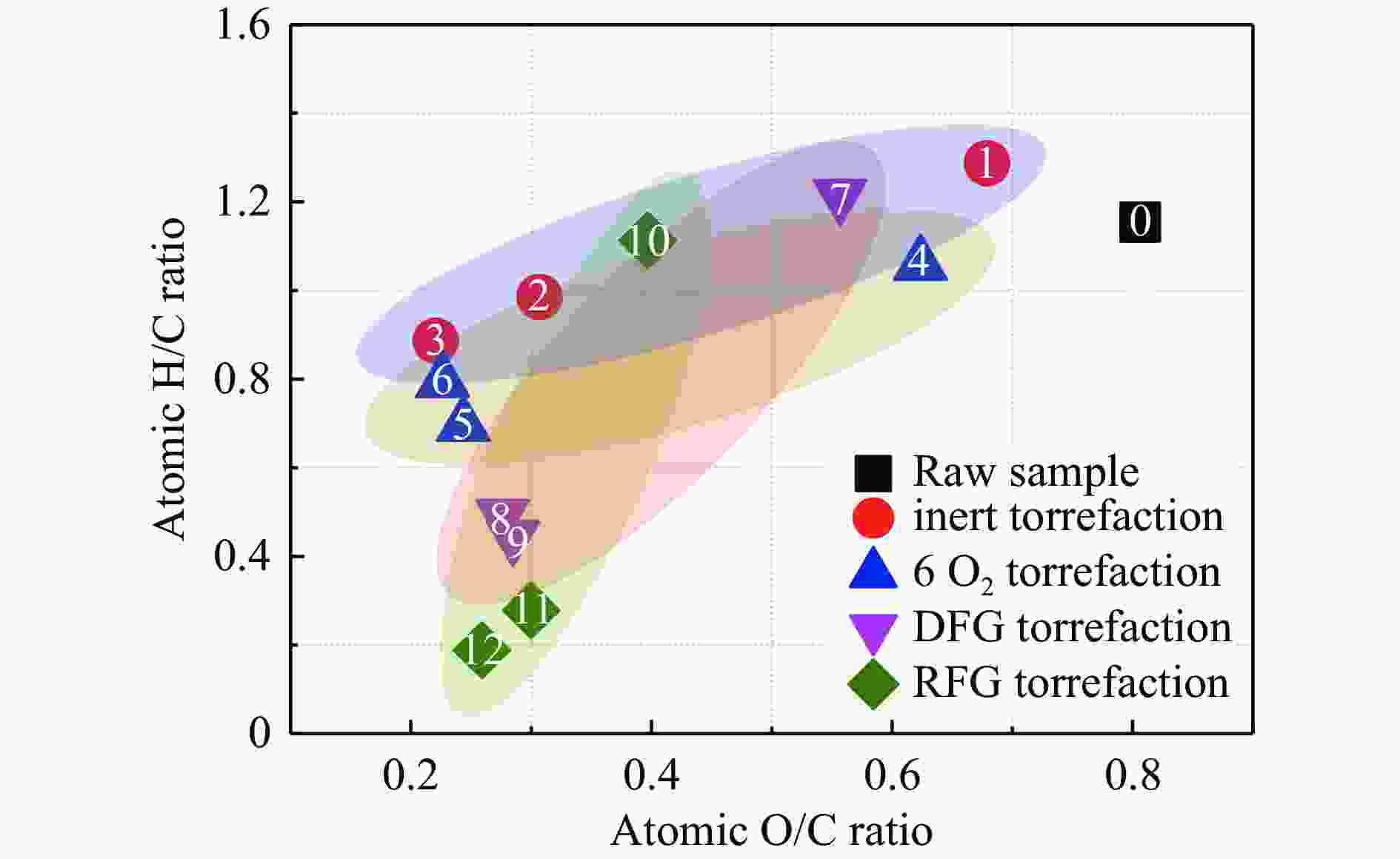

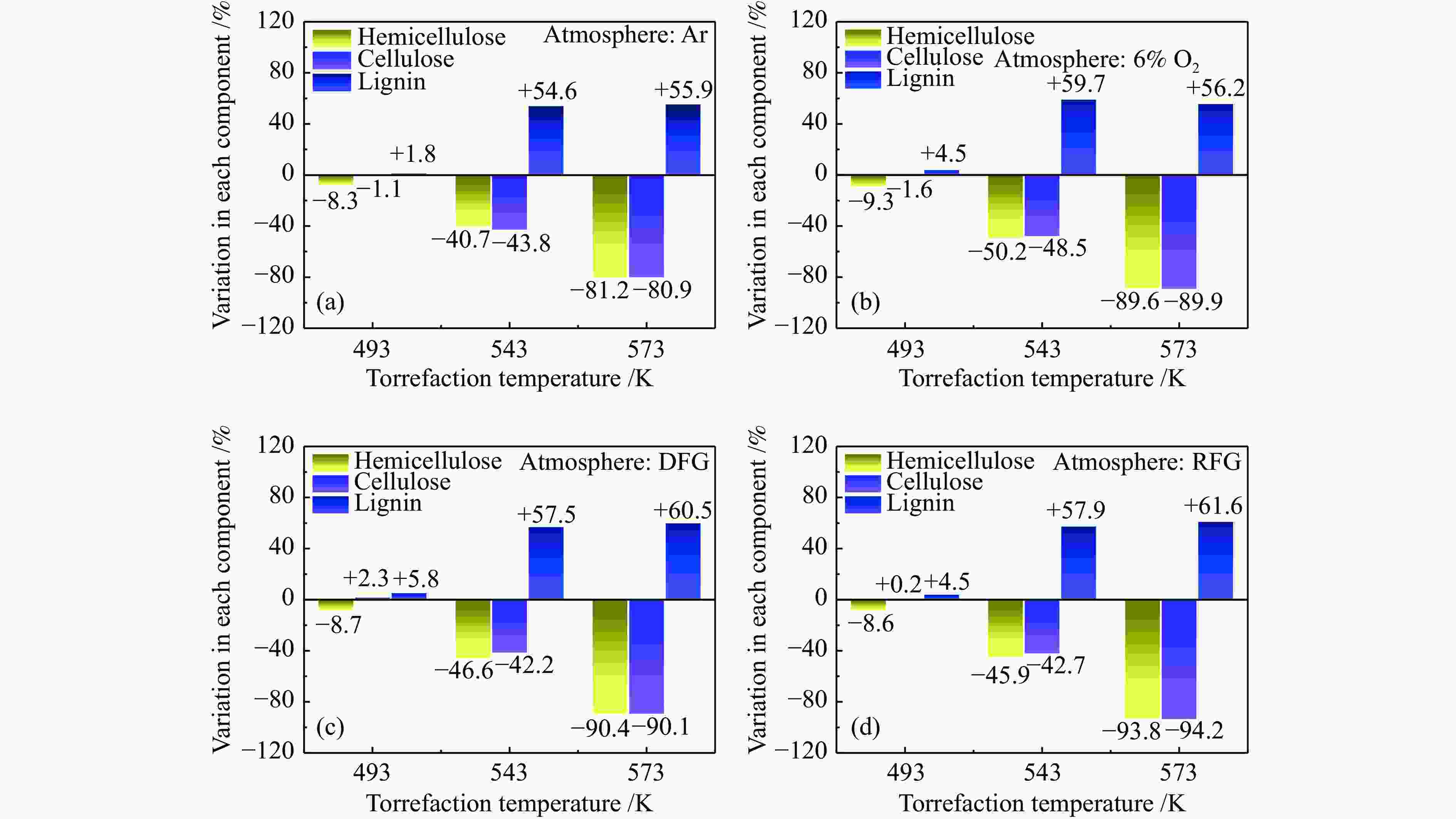

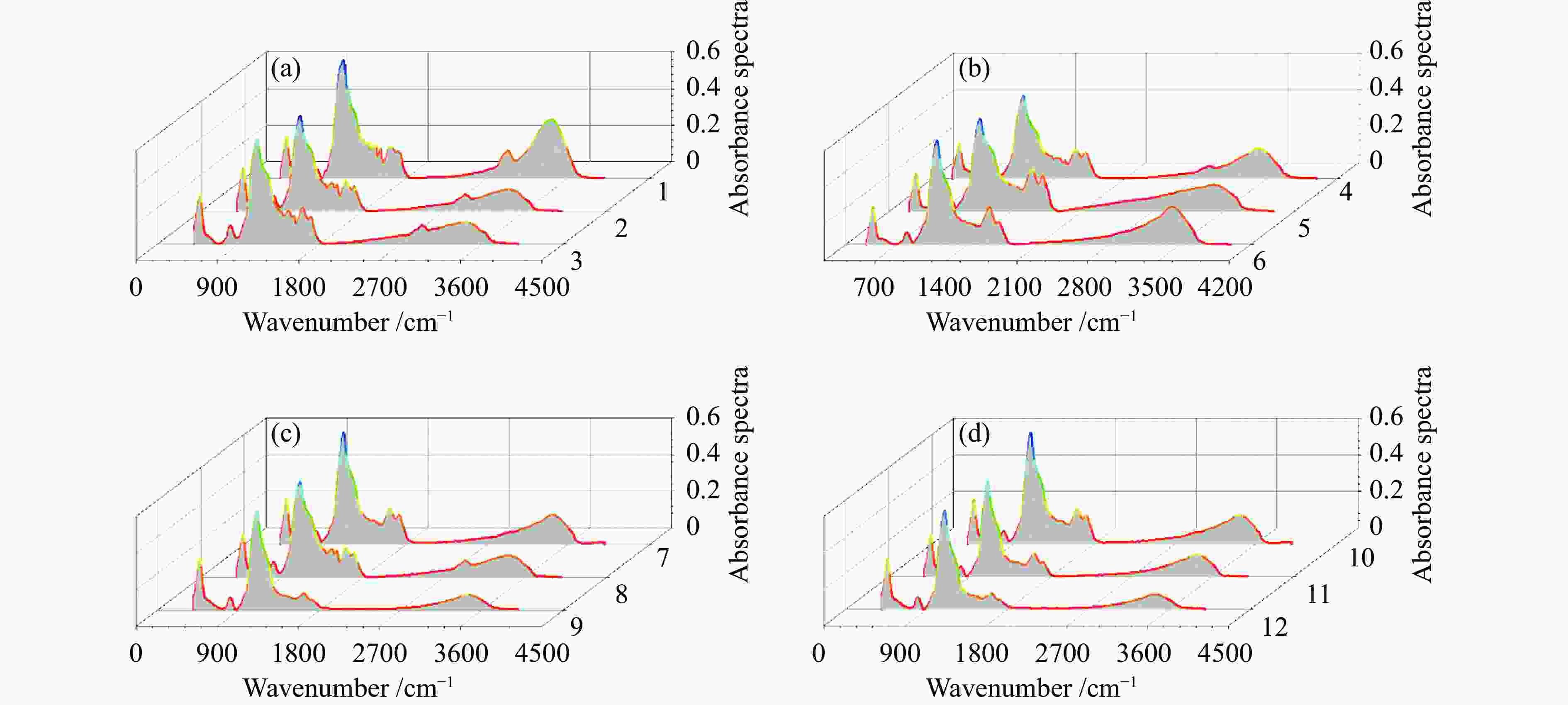

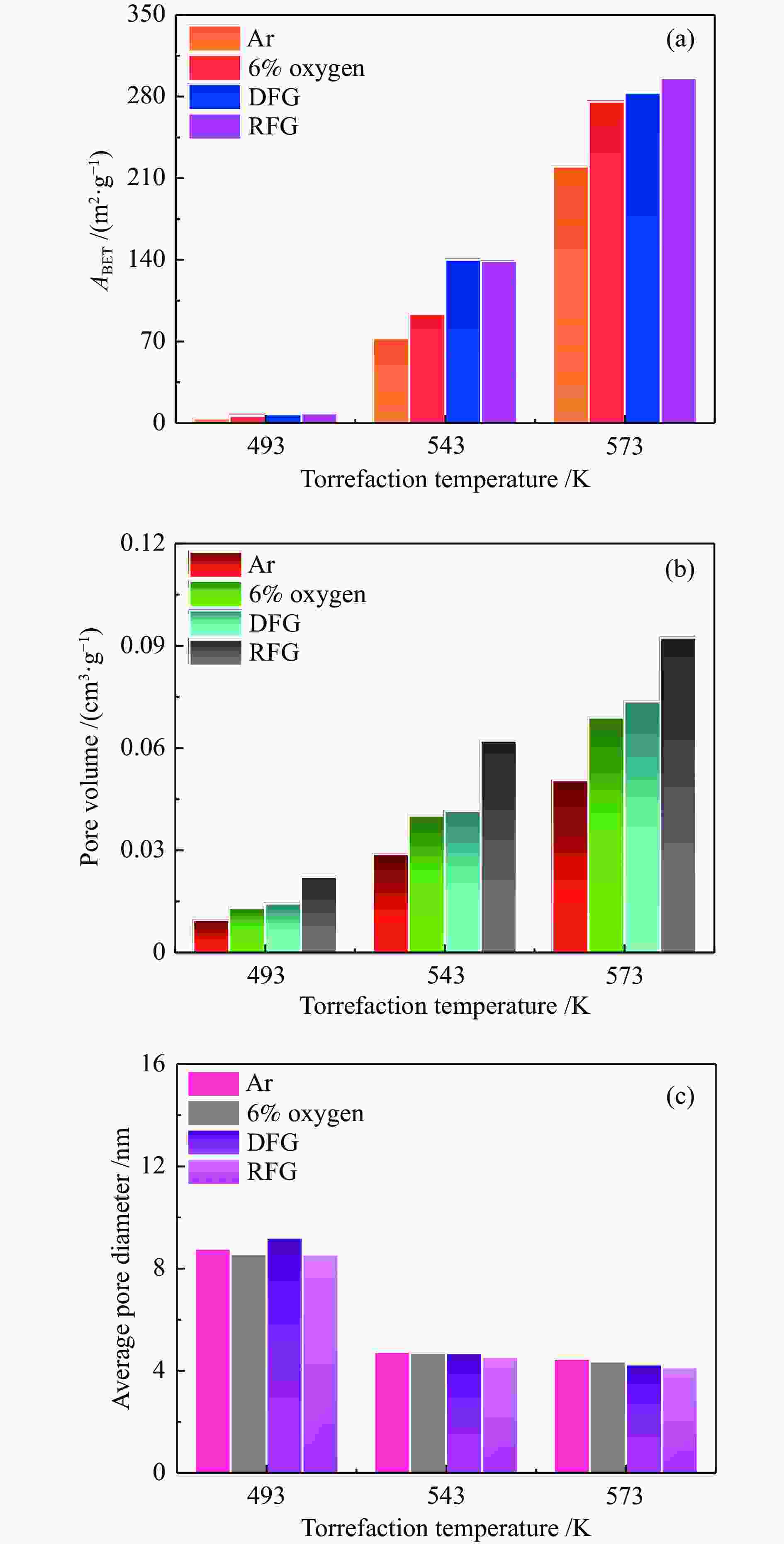

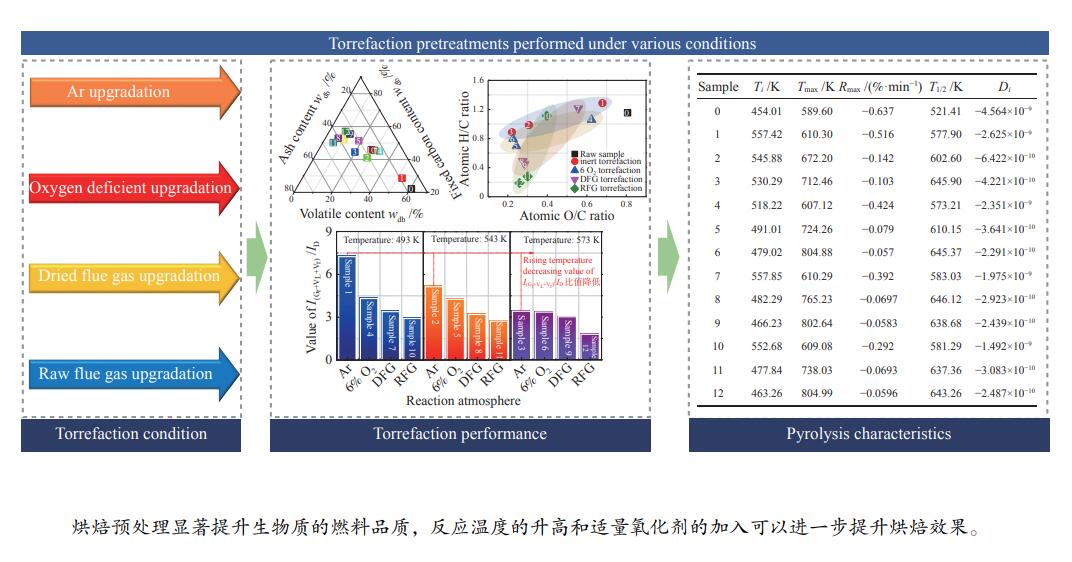

摘要: 研究493–573 K惰性烘焙和有氧烘焙对稻壳元素构成、组分分布、芳香结构、孔隙结构、热解特性和反应动力学的影响规律。结果表明,烘焙温度对生物质燃料品质影响最为明显,氧化剂的加入可以增加生物质燃料品质对温度变化的敏感性。烘焙温度的升高促使生物质中含氧结构逐渐解离,当烘焙条件为573 K的烟气气氛时,样品的H/C和O/C比明显降低(0.188和0.259)。多种氧化剂能够协同调控生物质的官能团结构、活性芳香结构和孔隙结构,温度的升高促使稻壳中羟基减少、活性芳香结构占比逐渐降低和轻质挥发分的解离,在573 K烟气烘焙后活性结构占比达到最小值1.79、比表面积达到最大值295.78 m2/g。稻壳的热解动力学参数可以通过Coats-Redfern近似函数求解,烘焙可以有效提高生物质发生热解的温度和活化能(14.84 → 28.82 kJ/mol)。相较于惰性气氛和贫氧气氛,烟气气氛能够更加节能、高效地提高生物质的燃料品质和存储稳定性。Abstract: Elemental distribution, compositional variation, microstructural feature, surface pore structure, pyrolysis characteristic and reactivity of samples derived from inert/oxidative torrefaction performed in 493–573 K were investigated. The results illustrated that reaction temperature was the dominant factor affecting fuel quality of torrefied sample, and the addition of oxidizing agents would strengthen the variations in fuel properties after undergoing torrefaction. Increasing reaction temperature would promote the decomposition of oxygen containing functional groups from the particles, when torrefaction performed in raw flue gas atmosphere at 573 K, the H/C and O/C reached the minimum values (0.188 and 0.259). Additional oxidizing agents would synergistically modify the surface functionality distribution, microstructure and surface physical structure of rice husk particles, and the increase of temperature was beneficial to this phenomenon. The critical values were obtained from the sample torrefied in raw flue gas atmosphere at 573 K, the minimum I(Gr + VL + Vr)/ID value was 1.79 and the maximum specific surface area was 295.78 m2/g. By means of the utilization of Coats-Redfern approximation function, the pyrolysis kinetics (14.84 → 28.82 kJ/mol) and characteristic parameters would be determined via the TGA data for each sample. Flue gas seemed to be more energy-saving and efficient for improving fuel quality and storage stability of biomass.

-

Key words:

- biomass /

- torrefaction /

- fuel quality /

- pyrolysis /

- reactivity

-

表 1 原料和烘焙样品的基本分析

Table 1 Basic analysis data for raw and torrefied sample

Sample Ultimate analysis war/% Proximate analysis war/% QHHV/(MJ·kg−1) C H N S Oa Mar V FC A 0. raw sample 38.18 3.67 0.69 0.43 41.05 7.44 56.13 20.45 15.98 12.88 1. Ar 493 40.35 4.33 0.58 0.19 36.53 4.87 49.89 27.22 18.02 13.21 2. Ar 543 46.38 3.81 0.59 0.11 18.98 3.09 27.01 39.77 30.13 13.67 3. Ar 573 47.12 3.48 0.90 0.07 13.86 3.34 19.08 43.01 34.57 13.95 4. O2 493 40.55 3.58 0.62 0.15 33.72 5.21 30.79 42.62 21.38 14.19 5. O2 543 50.75 2.94 0.58 0.06 16.50 3.81 17.58 49.44 29.17 16.08 6. O2 573 45.75 3.03 0.85 0.04 13.82 3.35 9.77 50.37 36.51 16.04 7. DFG 493 40.71 4.12 0.87 0.09 30.23 3.99 28.32 43.71 23.98 14.37 8. DFG 543 42.65 1.58 0.65 0.03 16.20 3.63 6.54 50.94 38.89 15.89 9. DFG 573 47.78 1.96 0.96 0.05 17.61 3.77 11.22 53.37 31.64 16.56 10. RFG 493 45.47 4.22 0.68 0.09 24.06 3.73 26.58 44.21 25.48 14.52 11. RFG 543 39.98 0.93 0.19 0.12 15.99 3.37 5.27 48.57 42.79 15.81 12. RFG 573 48.54 0.76 0.64 0.07 16.77 3.59 9.21 53.98 33.22 16.88 a: calculated by difference;ar: as received basis 表 2 原始稻壳样品的灰成分分析

Table 2 Ash chemical composition of the rice husk

Sample Content w/% Total Others SiO2 Al2O3 Fe2O3 CaO Na2O K2O MgO Raw sample 39.3 7.4 4.8 11.3 5.8 7.2 7.1 82.9 17.1 表 3 原始及烘焙样品热解特性参数

Table 3 Pyrolysis characteristic parameters for raw and torrefied sample

Sample Ti/K Tmax/K Rmax/

(%·min−1)T1/2/K Di 0 454.01 589.60 −0.637 521.41 −4.564×10−9 1 557.42 610.30 −0.516 577.90 −2.625×10−9 2 545.88 672.20 −0.142 602.60 −6.422×10−10 3 530.29 712.46 −0.103 645.90 −4.221×10−10 4 518.22 607.12 −0.424 573.21 −2.351×10−9 5 491.01 724.26 −0.079 610.15 −3.641×10−10 6 479.02 804.88 −0.057 645.37 −2.291×10−10 7 557.85 610.29 −0.392 583.03 −1.975×10−9 8 482.29 765.23 −0.0697 646.12 −2.923×10−10 9 466.23 802.64 −0.0583 638.68 −2.439×10−10 10 552.68 609.08 −0.292 581.29 −1.492×10−9 11 477.84 738.03 −0.0693 637.36 −3.083×10−10 12 463.26 804.99 −0.0596 643.26 −2.487×10−10 表 4 原始及烘焙稻壳的热解动力学参数

Table 4 Pyrolysis kinetic parameters for raw and torrefied rice husk samples

Sample Temperature range/K E/(kJ·mol−1) A/min−1 R2 0 493–573 14.84 0.317×10−4 0.955 1 493–573 15.93 0.336×10−5 0.948 2 493–573 16.59 0.641×10−5 0.997 3 493–573 17.95 0.539×10−6 0.944 4 493–573 16.25 0.384×10−5 0.951 5 493–573 16.61 0.413×10−5 0.948 6 493–573 17.99 0.801×10−6 0.959 7 493–573 16.42 0.404×10−5 0.954 8 493–573 17.38 0.512×10−5 0.949 9 493–573 26.44 4.907×10−7 0.943 10 493–573 16.63 0.397×10−5 0.957 11 493–573 17.82 0.603×10−6 0.981 12 493–573 28.82 4.332×10−7 0.989 -

[1] 开兴平, 余祎腾, 杨天华, 朱景博. 有氧烘焙提质改性对稻秆理化特性的影响研究[J]. 燃料化学学报,2021,49(12):1812−1820.WANG Xing-ping, YU Yi-teng, YANG Tian-hua, ZHU Jing-bo. Effect of oxidative torrefaction upgrade on physicochemical properties of rice straw[J]. J Fuel Chem Technol,2021,49(12):1812−1820. [2] SIMONIC M, GORICANEC D, URBANCL D. Impact of torrefaction on biomass properties depending on temperature and operation time[J]. Sci Total Environ,2020,740:140086. doi: 10.1016/j.scitotenv.2020.140086 [3] KWON G, BHATNAGAR A, WANG H, KWON E E, SONG H. A review of recent advancements in utilization of biomass and industrial wastes into engineered biochar[J]. J Hazard Mater,2020,400:123242. doi: 10.1016/j.jhazmat.2020.123242 [4] 谢腾, 丛宏斌, 赵立欣, 丘凌, 姚宗路, 张天乐, 霍丽丽. 烘焙对生物质理化特性影响综述与秸秆烘焙研究前景分析[J]. 应用化工,2020,49(11):2841−2846.XIE Teng, CONG Hong-bin, ZHAO Li-xin, QIU Ling, YAO Zong-lu, ZHANG Tian-le, CUI Li-li. A review of the effects of torrefaction on biomass physicochemical properties and analysis of research prospects for straw torrefaction[J]. Appl Chem Ind,2020,49(11):2841−2846. [5] 黄劢, 刘建国, 韩向新, 姜秀民. 棉秆经微波预处理改性后的热解特性研究[J]. 太阳能学报,2022,43(2):27−32.HUANG Mai, LIU Jian-guo, HAN Xiang-xin, JIANG Xiu-min. Pyrolysis characteristics of cotton stalk modified by microwave pretreatment[J]. Acta Energ Sol Sin,2022,43(2):27−32. [6] KONGTO P, PALAMANIT A, CHAIPRAPAT S. TIPPAYAWONG N. Enhancing the fuel properties of rubberwood biomass by moving bed torrefaction process for further applications[J]. Renewable Energy,2021,170:703−713. doi: 10.1016/j.renene.2021.02.012 [7] CHEN W H, LIN B J, LIN Y Y, CHU Y S, UBANDO A Y, SHOW P L, ONG H C, CHANG J S, HO S H, CULABA A B, PÉTRISSANS A, PÉTRISSANS M. Progress in biomass torrefaction: Principles, applications and challenges[J]. Prog Energy Combust Sci,2021,82:100887. doi: 10.1016/j.pecs.2020.100887 [8] CAHYANTI M N, DODDAPANENI T R K C, KIKAS T. Biomass torrefaction: An overview on process parameters, economic and environmental aspects and recent advancements[J]. Bioresour Technol,2020,301:122737. doi: 10.1016/j.biortech.2020.122737 [9] 邓剑, 罗永浩, 王贵军, 张睿智, 匡江红, 张云亮. 稻秆的烘焙预处理及其固体产物的气化反应性能[J]. 燃料化学学报,2011,39(1):26−32.DENG Jian, LUO Yong-hao, WANG Gui-jun, ZHAGN Rui-zhi, KUANG Jiang-hong, ZHAGN Yun-liang. Torrefaction pretreatment of straw and gasification reactivity of the solid product[J]. J Fuel Chem Technol,2011,39(1):26−32. [10] CEN K, ZHUANG X, GAN Z, MA Z, LI M, CHEN D. Effect of the combined pretreatment of leaching and torrefaction on the production of bio-aromatics from rice straw via the shape selective catalytic fast pyrolysis[J]. Energy Rep,2021,7:732−739. doi: 10.1016/j.egyr.2021.01.031 [11] CHEN W H, PENG J, T. BI X. A state-of-the-art review of biomass torrefaction, densification and applications[J]. Renewable Sustainable Energy Rev,2015,44:847−866. doi: 10.1016/j.rser.2014.12.039 [12] CHEN D, GAO A, CEN K, ZHANG J, CAO X, MA Z. Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin[J]. Energy Convers Manag,2018,169:228−237. doi: 10.1016/j.enconman.2018.05.063 [13] ZHANG C, WANG C, CAO G, CHEN W H, HO S H. Comparison and characterization of property variation of microalgal biomass with non-oxidative and oxidative torrefaction[J]. Fuel,2019,246:375−385. doi: 10.1016/j.fuel.2019.02.139 [14] CHEN W H, LU K M, LIU S H, TSAI C M, LEE W J, LIN T C. Biomass torrefaction characteristics in inert and oxidative atmospheres at various superficial velocities[J]. Bioresour Technol,2013,146:152−160. doi: 10.1016/j.biortech.2013.07.064 [15] LI X, LU Z, CHEN J, CHEN X, JIANG Y, JIAN J, YAO S. Effect of oxidative torrefaction on high temperature combustion process of wood sphere[J]. Fuel,2021,286:119379. doi: 10.1016/j.fuel.2020.119379 [16] ONSREE T, TIPPAYAWONG N. Analysis of reaction kinetics for torrefaction of pelletized agricultural biomass with dry flue gas[J]. Energy Rep,2020,6:61−65. doi: 10.1016/j.egyr.2020.10.038 [17] ONG H C, YU K L, CHEN W H, PILLEJERA M K, BI X, TRAN K Q, PÉTRISSANS A, PÉTRISSANS M. Variation of lignocellulosic biomass structure from torrefaction: A critical review[J]. Renewable Sustainable Energy Rev,2021,152:111698. doi: 10.1016/j.rser.2021.111698 [18] ZHAO Z, FENG S, ZHAO Y, WANG Z, MA Z, XU L, YANG J, SHEN B. Investigation on the fuel quality and hydrophobicity of upgraded rice husk derived from various inert and oxidative torrefaction conditions[J]. Renewable Energy,2022,189:1234−1248. doi: 10.1016/j.renene.2022.03.087 [19] TAY H L, KAJITANI S, WANG S, LI C Z. A preliminary Raman spectroscopic perspective for the roles of catalysts during char gasification[J]. Fuel,2014,121:165−172. doi: 10.1016/j.fuel.2013.12.030 [20] 张岚清, 沈德魁. 含氧气氛下的稻杆低温烘焙研究[J]. 北京化工大学学报(自然科学报),2017,44(5):27−32.ZHANG Lan-qing, SHEN De-kui. Oxidative torrefaction of rice straw under different oxygen concentrations[J]. J Beijing Univ Chem Technol (Nat Sci),2017,44(5):27−32. [21] ZHANG C, HO S H, CHEN W S, XIE Y, LIU Z, CHANG J S. Torrefaction performance and energy usage of biomass wastes and their correlations with torrefaction severity index[J]. Appl Energy,2018,220:598−604. doi: 10.1016/j.apenergy.2018.03.129 [22] HINTERSTOISSER B, SALMÉN L. Application of dynamic 2D FTIR to cellulose[J]. Vib Spectrosc,2000,22:111−118. doi: 10.1016/S0924-2031(99)00063-6 [23] SILVA C M S D, VITAL B R, CARNEIRO A D C O, COSTA E V S, MAGALHÃES M A D, TRUGILHO P F. Structural and compositional changes in eucalyptus wood chips subjected to dry torrefaction[J]. Ind Crops Prod,2017,109:598−602. doi: 10.1016/j.indcrop.2017.09.010 [24] ÁLVAREZ A, MIGOYA S, MENÉNDEZ R, GUTIÉRREZ G, PIZARRO C, BUENO J L. Torrefaction of short rotation coppice willow. characterization, hydrophobicity assessment and kinetics of the process[J]. Fuel,2021,295:120601. doi: 10.1016/j.fuel.2021.120601 [25] ZHANG L, WANG Z, MA J, KONG W, YUAN P, SUN R, SHEN B. Analysis of functionality distribution and microstructural characteristics of upgraded rice husk after undergoing non-oxidative and oxidative torrefaction[J]. Fuel,2022,310:122477. doi: 10.1016/j.fuel.2021.122477 [26] YAN W, PEREZ S, SHENG K. Upgrading fuel quality of moso bamboo via low temperature thermochemical treatments: Dry torrefaction and hydrothermal carbonization[J]. Fuel,2017,196:473−480. doi: 10.1016/j.fuel.2017.02.015 [27] UEMURA Y, SAADON S, OSMAN N, MANSOR N, TANOUE K. Torrefaction of oil palm kernel shell in the presence of oxygen and carbon dioxide[J]. Fuel,2015,144:171−179. doi: 10.1016/j.fuel.2014.12.050 [28] CHENG X, HUANG Z, WANG Z, MA C, CHEN S. A novel on-site wheat straw pretreatment method: Enclosed torrefaction[J]. Bioresour Technol,2019,281:48−55. doi: 10.1016/j.biortech.2019.02.075 [29] TAY H L, KAJITANI S, ZHANG S, LI C Z. Inhibiting and other effects of hydrogen during gasification: Further insights from FT-Raman spectroscopy[J]. Fuel,2014,116:1−6. doi: 10.1016/j.fuel.2013.07.066 [30] WANG Z, SUN R, ZHAO Y, LI Y, REN X. Effect of steam concentration on demineralized coal char surface behaviors and structural characteristics during the oxy-steam combustion process[J]. Energy,2019,174:339−349. doi: 10.1016/j.energy.2019.02.187 [31] WANG Z, LI Y, ZHU W, SUN R, ZHAO Y, REN X. Effects of reaction condition on the emission characteristics of fuel-N during the O2/H2O combustion process of demineralized coal[J]. Energy Fuels,2019,33:6187−6196. doi: 10.1021/acs.energyfuels.9b01031 [32] CHEN H, CHEN X, QIN Y, WEI J, LIU H. Effect of torrefaction on the properties of rice straw high temperature pyrolysis char: Pore structure, aromaticity and gasification activity[J]. Bioresour Technol,2017,228:241−249. doi: 10.1016/j.biortech.2016.12.074 [33] 刘文质, 梅艳阳, 杨晴, 杨海萍, 陈汉平. 生物质低温脱氧中产物特性变化及其反应动力学研究[J]. 太阳能学报,2019,40(2):312−318.LIU Wen-zhi, MEI Yan-yang, YANG Qing, YANG Hai-ping, CHEN Han-ping. Study on changes in product characteristics and reaction kinetics of deoxygenation for biomass at low temperatures[J]. Acta Energ Sol Sin,2019,40(2):312−318. [34] 高攀, 赵泽衡, 刘禹彤, 郭得忠, 杨少霞. 气体加压烘焙对玉米秸秆提质及热解特性的影响[J]. 燃料化学学报,2022,50(6):735−746. doi: 10.1016/S1872-5813(21)60136-6GAO Pan, ZHAO Ze-heng, LIU Yu-tong, GUO De-zhong, YANG Shao-xia. Effect of gas-pressurized torrefaction on corn stalk upgrading and pyrolysis characteristics[J]. J Fuel Chem Technol,2022,50(6):735−746. doi: 10.1016/S1872-5813(21)60136-6 [35] DAI L, WANG Y, LIU Y, RUAN R, HE C, YU Z, JIANG L, ZENG Z, TIAN X. Integrated process of lignocellulosic biomass torrefaction and pyrolysis for upgrading bio-oil production: A state-of-the-art review[J]. Renewable Sustainable Energy Rev,2019,107:20−36. doi: 10.1016/j.rser.2019.02.015 [36] 陈登宇, 朱锡锋. 生物质热解反应机理与活化能确定方法II. 热解段研究[J]. 燃料化学学报,2011,39(9):670−674.CHEN Deng-yu, ZHU Xi-feng. Thermal reaction mechanism of biomass and determination of activation energy II. Pyrolysis section[J]. J Fuel Chem Technol,2011,39(9):670−674. [37] CIOLKOSZ D, WALLACE R. A review of torrefaction for bioenergy feedstock production[J]. Biofuel Bioprod Biorefin,2011,5(3):317−329. doi: 10.1002/bbb.275 -

下载:

下载: