Effect of NaOH post-treatment on the catalytic performance of hierarchical Hβ zeolites in the pyrolysis of lignin

-

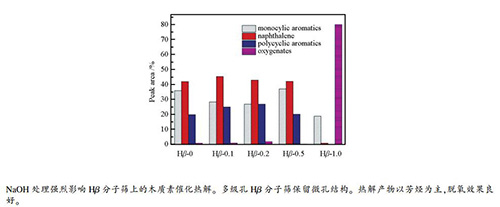

摘要: 采用碱性条件下"后处理"脱硅的方法,制备了一系列多级孔Hβ分子筛,考察了NaOH浓度对Hβ分子筛上木质素催化热解性能的影响。结果表明,当NaOH浓度小于0.2 mol/L时,碱处理后的多级孔Hβ分子筛的介孔数量增加,木质素热解液体产物的收率随着NaOH浓度提高而显著增加。当NaOH浓度小于0.5 mol/L时,碱处理可以保持多级孔Hβ分子筛的微孔结构基本不被破坏,木质素催化热解具有较好的脱氧效果;产物以芳烃为主,含氧化合物的收率始终小于3%。当NaOH的浓度增加到1 mol/L时,会造成Hβ分子筛过度脱硅,骨架坍塌;由于Hβ分子筛的多级孔结构被破坏,此时不仅木质素热解液体产物的收率降低,而且脱氧效果变差。Abstract: A series of hierarchical Hβ zeolites were prepared by using NaOH post-treatment methods, viz., desilication under alkaline conditions; the effect of NaOH concentration on the catalytic performance of hierarchical Hβ zeolites in the pyrolysis of lignin was investigated. The results illustrated that with the increase of NaOH concentration up to 0.2 mol/L, the amount of mesopores in the hierarchical Hβ zeolites is increased, accompanying with a significant increase in the yield of liquid products for the lignin pyrolysis over Hβ zeolites. By the alkaline treatment with a NaOH concentration lower than 0.5 mol/L, the microporous structure of hierarchical Hβ zeolites remains basically intact and over them a good deoxidation effect is observed for the lignin pyrolysis; the product is mainly composed of aromatic hydrocarbons and the yield of oxygenates is always less than 3%. However, if the NaOH concentration for post-treatment is further increased to 1 mol/L, the microporous structure of Hβ zeolites is substantially destroyed, leading to a decrease in the yield of liquid products for lignin pyrolysis as well as a poor deoxidization effect.

-

Key words:

- lignin /

- catalytic pyrolysis /

- hierarchical Hβ zeolites /

- NaOH post-processing /

- desilication

-

表 1 不同浓度NaOH处理的Hβ分子筛的孔结构

Table 1 Textural properties of Hβ zeolites treated with NaOH of different concentrations

Sample NaOH concentration/(mol·L-1) Smicro/(m2·g-1) Smeso/(m2·g-1) vmicro/(cm3·g-1) vmeso/(cm3·g-1) Hβ-0 0.0 545 86 0.21 0.22 Hβ-0.1 0.1 519 129 0.30 0.32 Hβ-0.2 0.2 451 171 0.18 0.37 Hβ-0.5 0.5 517 154 0.20 0.45 Hβ-1.0 1.0 5 27 0.01 0.13 -

[1] LIU C J, WANG H M, KARIM A M, SUN J M, WANG Y. Catalytic fast pyrolysis of lignocellulosic biomass[J]. Chem Soc Rev, 2014, 43:7594-7623 doi: 10.1039/C3CS60414D [2] PATWARDHAN P, BROWN R, SHANKS B. Understanding the fast pyrolysis of lignin[J]. ChemSusChem, 2011, 4:1629-1636. doi: 10.1002/cssc.v4.11 [3] REZAEI P, SHAFAGHAT H, DAUD W. Aromatic hydrocarbon production by catalytic pyrolysis of palm kernel shell waste using a bifunctional Fe/HBeta catalyst:Effect of lignin-derived phenolics on zeolite deactivation[J]. Green Chem, 2016, 18:1684-1693. doi: 10.1039/C5GC01935D [4] WANG K, KIM K, BROWN R. Catalytic pyrolysis of individual components of lignocellulosic biomass[J]. Green Chem, 2014, 16:727-735. doi: 10.1039/C3GC41288A [5] ZHOU J, LIU Z C, LI L Y, WANG Y D, GAO H X, YANG W M, XIE Z K, TANG Y. Hierarchical mesoporous ZSM5 zeolite with increased external surface acid sites and high catalytic performance in o-xylene isomerization[J]. Chin J Catal, 2013, 34:1429-1433. doi: 10.1016/S1872-2067(12)60602-0 [6] JIA L Y, RAAD M, HAMIEH S, TOUFAILY J, HAMIEH T, BETTAHAR M M, MAUVIEL G, TARRIGHI M, PINARD L, DUFOUR A. Catalytic fast pyrolysis of biomass:Superior selectivity of hierarchical zeolites to aromatics[J]. Green Chem., 2017, 19:5442-5459. doi: 10.1039/C7GC02309J [7] PENG P, ZHANG Z Q, WANG Y H, FAZLE S, YAN Z F. Hierarchical molecular sieves:Synthesis and catalytic applications[J]. Prog Chem, 2013, 25(12):2028-2036. http://d.old.wanfangdata.com.cn/Periodical/xdhg201802036 [8] KOU L, WANG Y, PENG P, YAN Z F. Synthesis of mesoporous zeolite[J]. Prog Chem, 2014, 26(4):522-528. http://d.old.wanfangdata.com.cn/Periodical/hxxb201223006 [9] PUERTOLAS B, VESES A, CALLEN M S, MITCHELL S, GARCIA T, PEREZ-RAMIREZ J. Porosity-acidity interplay in hierarchical ZSM-5 zeolites for pyrolysis oil valorization to aromatics[J]. ChemSusChem, 2015, 8:3283-3293. doi: 10.1002/cssc.201500685 [10] HOFF T C, GARDNER D W, THILAKARATNE R, PROANO-AVILES J, BROWN R C, TESSONNIER J P. Elucidating the effect of desilication on aluminum-rich ZSM-5 zeolite and its consequences on biomass catalytic fast pyrolysis[J]. Appl Catal A:Gen, 2017, 529:68-78. doi: 10.1016/j.apcata.2016.10.009 [11] WANG K G, ZHANG J, SHANKS B H, BROWN R C. Catalytic conversion of carbohydrate-derived oxygenates over HZSM-5 in a tandem micro-reactor system[J]. Green Chem, 2015, 17:557-564. doi: 10.1039/C4GC01784F [12] KARAGOZ S, KAWAKAMI T, KAKO A, ⅡGUNI Y, OHTANI H. Single shot pyrolysis and on-line conversion of lignocellulosic biomass with HZSM-5 catalyst using tandem microreactor GC-MS[J]. RSC Adv, 2016, 6:46108-46115. doi: 10.1039/C6RA04225B [13] FREEMAN R R, WATANABE A, WATANABE C, TERAMAE N, WANG K. Material characterization using a tandem micro reactor GC-MS[J]. J Anal Appl Pyrolysis, 2015, 111:41-46. doi: 10.1016/j.jaap.2014.12.014 -

下载:

下载: