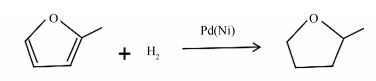

Catalytic performance of Ni/Al2O3 catalyst for hydrogenation of 2-methylfuran to 2-methyltetrahydrofuran

-

摘要: 采用浸渍法制备了不同NiO含量的Ni/Al2O3催化剂,并进行了2-甲基呋喃加氢制2-甲基四氢呋喃性能的考察。结果表明,在制备的NiO负载量为10%、20%、25%、30%和40%的Ni/Al2O3催化剂中,随着NiO负载量增加,加氢反应的选择性与2-甲基呋喃的转化率均呈现出先增加后减小的趋势。其原因是由于适当增加NiO负载量有利于催化剂表面活性中心的形成,有利于加氢反应的进行;但是过度负载的NiO容易堵塞Al2O3载体中的介孔通道,降低反应的转化率与选择性。在釜式反应器中进行反应,对加氢反应条件进行了优化,发现在反应压力为3 MPa、反应温度150℃、机械搅拌速率为1000 r/min时,Ni/Al2O3催化2-甲基呋喃加氢制2-甲基四氢呋喃具有较高的选择性。当NiO负载量为25%时,2-甲基四氢呋喃的选择性最高为97.1%,2-甲基呋喃的转化率达到99.4%。

-

关键词:

- 浸渍法 /

- 2-甲基呋喃 /

- 2-甲基四氢呋喃 /

- 加氢 /

- Ni/Al2O3催化剂

Abstract: Ni/Al2O3 catalyst with various NiO loading was prepared with impregnation method. The catalytic performance for hydrogenation of 2-methylfuran to 2-methyltetrahydrofuran was investigated in this work. The results indicated that with an increase of NiO contents (10%, 20%, 25%, 30% and 40%), 2-methylfuran conversion rate first increased and then droped to a low level. The selectivity of this hydrogenation reaction showed the same trend. It was mainly because that NiO can produce more active center on catalyst surface, which was good for hydrogenation reaction. However, overloading of NiO blocked the mesopores of supportive Al2O3, and thus reduce the reaction selectivity and conversion rate. In batch reactor, after optimization the hydrogenation selectivity rate can be improved under hydrogen partial pressure of 3 MPa, reaction temperature of 150℃ and stirring speed of 1000 r/min. As a result, 2-methyltetrahydrofuran selectivity of 97.1% and 2-methylfuran conversion rate of 99.4% can be achieved with 25% NiO loading.-

Key words:

- impregnation method /

- 2-methylfuran /

- 2-methyltetrahydrofuran /

- hydrogenation /

- Ni/Al2O3 catalyst

1) 本文的英文电子版由Elsevier出版社在ScienceDirect上出版(http://www.sciencedirect.com/science/journal/18725813) -

表 1 载体的BET数据

Table 1 BET analysis supports

Sample A BET

/(m2·g-1)Pore volume

v/(cm3·g-1)Average pore

diameter d/nmActivated

alumina313 0.4488 5.73 γ-Al2O3 243 0.4048 6.64 activated alumina is used as carrier; γ-Al2O3 was prepared by calcination of activated alumina at 600 ℃ 表 2 xNi/Al2O3催化剂的BET数据

Table 2 BET analysis of calcined xNi/Al2O3 catalysts

NiO w/% ABET

/(m2·g-1)Pore volume

v/(cm3·g-1)Average pore

diameter d/nm10 140 0.3242 8.64 25 149 0.3225 8.67 30 152 0.3486 9.17 40 108 0.2448 9.04 activated alumina is used as carrier 表 3 不同NiO负载量对催化剂催化性能影响

Table 3 Effects of different NiO loadings on catalytic performance of catalysts

NiO w/% 2-MF

conversion x/%Product selectivity s/% 2-MTHF others 10 80.2 92.3 7.7 20 98.9 94.3 5.7 25 99.6 96.4 3.6 30 99.3 93.6 6.3 35 98.4 95.0 5.0 40 88.9 95.4 4.6 2-MF: 15 mL; catalyst: 0.5 g; reaction pressure: 4 MPa; reaction temperature: 150 ℃ 表 4 反应压力对Ni/Al2O3催化剂催化性能影响

Table 4 Effect of reaction pressure on catalytic performance of Ni/Al2O3 catalyst

Pressure

p/MPa2-MF

conversion x/%Product selectivity s/% 2-MTHF others 2 99.6 93.4 6.6 3 99.4 97.1 2.9 4 99.6 96.4 3.6 5 99.7 96.1 3.9 6 99.7 96.2 3.8 2-MF: 15 mL; catalyst: 0.5 g; reaction temperature: 150 ℃ 表 5 反应温度对Ni/Al2O3催化剂催化性能影响

Table 5 Effect of reaction temperature on catalytic performance of Ni/Al2O3 catalyst

Reaction

temperature t/℃2-MF

conversion x/%Product selectivity s/% 2-MTHF others 90 53.0 39.2 60.8 120 96.8 95.2 4.8 140 98.2 95.4 4.6 150 99.4 97.1 2.9 180 98.2 58.4 41.6 2-MF: 15 mL; catalyst: 0.5 g; reaction pressure: 3 MPa -

[1] XIU S, SHAHBAZI A. Bio-oil production and upgrading research:A review[J]. Renewable Sustainable Energy Rev, 2012, 16(7):4406-4414. doi: 10.1016/j.rser.2012.04.028 [2] ZHENG H, ZHU Y, TENG B, BA Z, ZHANG C, XIANG H, LI Y. Towards understanding the reaction pathway in vapour phase hydrogenation of furfural to 2-methylfuran[J]. J Mol Catal A:Chem, 2006, 246(1):18-23. https://www.sciencedirect.com/science/article/pii/S1381116905007065 [3] RAGAN J A, ENDE D J, BRENEK S J, EISENBEIS S A, SINGER R A, TICKNER D L, TEIXEIRA J J, VANDERPLAS B C, WESTONET N. Safe execution of a large-scale ozonolysis:Preparation of the bisulfite adduct of 2-hydroxyindan-2-carboxaldehyde and its utility in a reductive amination[J]. Org Process Res Dev, 2003, 7(2):155-160. doi: 10.1021/op0202235 [4] YANG J, ZHENG H, ZHU Y, ZHAO G, ZHANG C, TENG B, XIANG H, LI Y. Effects of calcination temperature on performance of Cu-Zn-Al catalyst for synthesizing c-butyrolactone and 2-methylfuran through the coupling of dehydrogenation and hydrogenation[J]. Catal Commun, 2004, 5(9):505-510. doi: 10.1016/j.catcom.2004.06.005 [5] YAN K, WU G, LAFLEUR T, JARVIS C. Production, properties and catalytic hydrogenation of furfural to fuel additives and value-added chemicals[J]. Renewable Sustainable Energy Rev, 2014, 38(5):663-676. https://www.sciencedirect.com/science/article/pii/S1364032114004559 [6] NAKAGAWA Y, TAMURA M, TOMISHIGE K. Catalytic reduction of biomass-derived furanic compounds with hydrogen[J]. Acs Catal, 2013, 3(12):2655-2668. doi: 10.1021/cs400616p [7] 郭清泉, 陈焕钦.乙酰丙酸及其衍生物的研究进展[J].精细石油化工, 2003, 20(3):45-48. doi: 10.3969/j.issn.1003-9384.2003.03.016GUO Qing-quan, CHEN Huan-qin. Development on prepartion of levulinic acid and its derivatives[J]. Spec Petrochem, 2003, 20(3):45-48. doi: 10.3969/j.issn.1003-9384.2003.03.016 [8] DENNEY D B, DENNEY D Z, GIGANTINO J J. Cyclodehydration of 1, 4-butanediols by pentaethoxyphosphorane[J]. J Org Chem, 1984, 49(15):2831-2832. doi: 10.1021/jo00189a044 [9] BISWAS P, LIN J H, KANG J, GULIANTS V V. Vapor phase hydrogenation of 2-methylfuran over noble and base metal catalysts[J]. Appl Catal A:Gen, 2014, 475(5):379-385. https://www.researchgate.net/publication/260340394_Vapor_phase_hydrogenation_of_2-methylfuran_over_noble_and_base_metal_catalysts [10] SITTHISA S, SOOKNOI T, MA Y, BALBUENA P B, RESASCO D E. Kinetics and mechanism of hydrogenation of furfural on Cu/SiO2 catalysts[J]. J Catal, 2011, 277(1):1-13. doi: 10.1016/j.jcat.2010.10.005 [11] DONG F, ZHU Y, DING G, CUI J, LI X, LI Y. One-step conversion of furfural into 2-methyltetrahydrofuran under mild conditions[J]. ChemSusChem, 2015, 8(9):1534-1537. doi: 10.1002/cssc.201500178 [12] 王保伟, 尚玉光, 丁国忠, 王海洋, 王二东, 李振花, 马新宾, 秦绍东, 孙琦.铈铝复合载体对钼基催化剂耐硫甲烷化催化性能的研究[J].燃料化学学报, 2012, 40(11):1390-1396. doi: 10.3969/j.issn.0253-2409.2012.11.018WANG Bao-wei, SHANG Yu-guang, DING Guo-zhong, WANG Hai-yang, WANG Er-dong, LI Zhen-hua, MA Xin-bin, QIN Shao-dong, SUN Qi. Ceria-alumina composite support on the sulfur-resistant methanation activity of Mo-based catalyst[J]. J Fuel Chem Technol, 2012, 40(11):1390-1396. doi: 10.3969/j.issn.0253-2409.2012.11.018 [13] 孙蛟, 任国卿, 黄玉辉, 陈晓蓉, 梅华.焙烧温度对CuMgAl催化剂催化糠醛气相加氢制糠醇性能的影响[J].燃料化学学报, 2017, 45(1):43-47. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18960.shtmlSUN Jiao, REN Guo-qing, HUANG Yu-hui, CHEN Xiao-rong, MEI Hua. Effect of calcination temperature on the catalytic performance of CuMgAl catalysts for furfural gas phese selective hydrogenation to furfuryl alcohol[J]. J Fuel Chem Technol, 2017, 45(1):43-47. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18960.shtml [14] SEPEHRI S, REZAEI M. Preparation of highly active nickel catalysts supported on mesoporous nanocrystallineγ-Al2O3 for methane autothermal reforming[J]. Chem Eng Technol, 2015, 38(9):1637-1645. doi: 10.1002/ceat.201400566 [15] BSHISH A, YAAKOB Z, EBSHISH A, ALHASAN F H. Hydrogen production via ethanol steam reforming over Ni/Al2O3 catalysts:Effect of Ni loading[J]. J Energy Resour Technol, 2014, 136(1):1-13. https://ukm.pure.elsevier.com/en/publications/hydrogen-production-via-ethanol-steam-reforming-over-nial-sub2sub [16] ZHAO A, YING W, ZHANG H, MA H, FANG D. Ni-Al2O3 catalysts prepared by solution combustion method for syngas methanation[J]. Catal Commun, 2012, 17(5):34-38. http://www.academia.edu/18629893/Fundamentals_properties_and_applications_of_solid_catalysts_prepared_by_solution_combustion_synthesis_SCS_ [17] BASF European Company. One step preparation of 2-mthyltetrahydrofuran from furfural in structured-bed with two catalysts:CN, 101558052A[P]. 2009-11-25. [18] 莫勇, 王贵武, 陈茜文.超细Cu/Ni催化糠醛加氢合成2-甲基四氢呋喃[J].精细化工, 2013, 30(7):821-824. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jxhg201307024&dbname=CJFD&dbcode=CJFQMO Yong, WANG Gui-wu, CHEN Xi-wen. Liquid phase furfural hydrogenation to synthesize 2-methyltetrahydrofuran over Cu/Ni ultrafne mixed catalyst[J]. Fine Chem, 2013, 30(7):821-824. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jxhg201307024&dbname=CJFD&dbcode=CJFQ -

下载:

下载: