Effect of Ce modified Co/SEP catalyst on hydrogen production via ethanol steam reforming

-

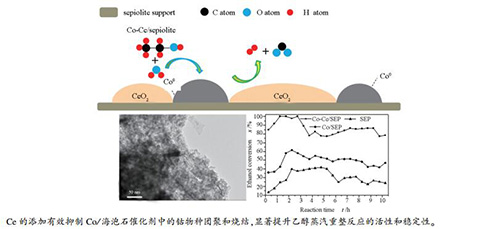

摘要: 采用海泡石(SEP)为载体,通过化学沉淀法制备了Co/SEP和Co-Ce/SEP催化剂,对催化剂进行X射线衍射(XRD)、H2-程序升温还原(H2-TPR)和透射电镜(TEM)等表征。结果表明,Ce的加入显著改善催化剂的分散度和还原性;两种催化剂应用于乙醇重整制氢实验,考察Ce的加入、反应时间、反应温度和水碳比(S/C比)对制氢的影响。结果表明,在WHSV为20.5h-1,水碳比(S/C)为3,反应温度600℃时,Co-Ce/SEP乙醇转化率和氢气产率达到最高,分别为85%和65%。同时Ce的添加能使Co-Ce/SEP拥有更优的活性和稳定性。Abstract: Co/SEP and Co-Ce/SEP catalysts were prepared by chemical precipitation method with sepiolite (SEP) as support. X-ray diffraction (XRD), H2-programmed reduction (H2-TPR) and transmission electron microscopy (TEM) were used to characterize the catalysts. It is proved that the addition of Ce significantly improved the dispersion and reducibility of the catalyst. The effects of Ce addition, reaction time, reaction temperature and steam/carbon (S/C) ratio on hydrogen production were investigated. The results show that the ethanol conversion and hydrogen production of Co-Ce/SEP are the highest values, 85% and 65%, respectively, when the WHSV is 20.5 h-1, the S/C ratio is 3 and the reaction temperature is 600℃. Meanwhile, the addition of Ce can make Co-Ce/SEP possess superior activity and stability.

-

表 1 反应前催化剂的物化性质

Table 1 Physico-chemical properties of the catalysts before reaction

Catalyst Low temperature zone H2 consumption

/(mmol·g-1)High temperature zone H2 consumption

/(mmol·g-1)Total H2 consumption

/(mmol·g-1)Reduction degree/%a dCo3O4

/nmbdCo

/nmcCo/SEP 0.2765 0.5836 0.8601 41.1 13 19.2 Co-Ce/SEP 0.6152 0.5101 1.1253 53.5 10.7 14.1 a: ${\rm{reduction}}\;{\rm{degree}} = \frac{{{\rm{mole}}\;\left( {{\rm{total}}\;{{\rm{H}}_2}\;{\rm{consumption}}} \right)/{{\rm{g}}_{{\rm{catalyst}}}}}}{{4/3 \times {\rm{mole}}\;({\rm{mean}}\;{\rm{Co}}\;{\rm{meatal}}\;{\rm{loading}})/{{\rm{g}}_{{\rm{catalyst}}}}}} \times 100\% $;

b/c: derived from diffraction peak in XRD corresponding to the Co3O4 (440) plane at 65.2° or Co0 (111) plane at 44.2° by the Scherrer formula -

[1] SOHN H, OZKAN U S. Cobalt-based catalysts for ethanol steam reforming:An overview[J]. Energy Fuels, 2016, 30(7):5309-5322. doi: 10.1021/acs.energyfuels.6b00577 [2] LI D, LI Y, GONG J. Catalytic reforming of oxygenates:State of the art and future prospects[J]. Chem Rev, 2016, 116(19):11529-11653. doi: 10.1021/acs.chemrev.6b00099 [3] 胡恩源, 闫常峰, 蔡炽柳, 胡蓉蓉.生物油水溶性组分的水蒸气催化重整制氢实验研究[J].燃料化学学报, 2009, 37(2):177-182. doi: 10.3969/j.issn.0253-2409.2009.02.010HU En-yuan, YAN Chang-feng, CAI Chi-liu, HU Rong-rong. Experimental research on hydrogen production by catalytic steam reforming of bio-oil aqueous fraction[J]. J Fuel Chem Technol, 2009, 37(2):177-182. doi: 10.3969/j.issn.0253-2409.2009.02.010 [4] DAN M, MIHET M, TASNADI-ASZTALOS Z, IMRE-LUCACI A, KATONA G, LAZAR M D. Hydrogen production by ethaol steam reforming on nickel catalysts:Effect of support modification by CeO2 and La2O3[J]. Fuel, 2015, 147:260-268. doi: 10.1016/j.fuel.2015.01.050 [5] ARSLAN A, DOǦU T. Effect of calcination/reduction temperature of Ni impregnated CeO2-ZrO2 catalysts on hydrogen yield and coke minimization in low temperature reforming of ethanol[J]. Int J Hydrogen Energy, 2016, 41(38):16752-16761. doi: 10.1016/j.ijhydene.2016.07.082 [6] CASANOVAS A, ROIG M, LEITENBURG C D, TROVARELLI A, LLORCA J. Ethanol steam reforming and water gas shift over Co/ZnO catalytic honeycombs doped with Fe, Ni, Cu, Cr and Na[J]. Int J Hydrogen Energy, 2010, 35(15):7690-7698. doi: 10.1016/j.ijhydene.2010.05.099 [7] DA SILVA A L M, DEN BREEJEN J P D, MATTOS L V, BITTER J H, DE JONG K P, NORONHA B F. Cobalt particle size effects on catalytic performance, for ethanol steam reforming-Smaller is better[J]. J Catal, 2014, 318:67-74. doi: 10.1016/j.jcat.2014.07.020 [8] SUN J, WANG Y, LI J, XIAO G, ZHANG L, LI H, CHENG Y, SUN C, CHENG Z, DONG Z, CHEN L. H2 production from stable ethanol steam reforming over catalyst of NiO based on flowerlike CeO2 microspheres[J]. Int J Hydrogen Energy, 2010, 35(7):3087-3091. doi: 10.1016/j.ijhydene.2009.07.020 [9] LONERGAN W W, VLACHOS D G, CHEN J. Correlating extent of Pt-Ni bond formation with low-temperature hydrogenation of benzene and 1, 3-butadiene over supported Pt/Ni bimetallic catalysts[J]. J Catal, 2010, 271(2):239-250. http://www.sciencedirect.com/science/article/pii/S0021951710000278 [10] VAGIA E C, LEMONIDOU A A. Investigations on the properties of ceria-zirconia-supported Ni and Rh catalysts and their performance in acetic acid steam reforming[J]. J Catal, 2010, 269(2):388-396. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=190a9e9dfa4f7153aa9be6554659961e [11] DEMSASH H D, KONDAMUDI K V K, UPADHYAYULA R, MOHAN R. Ruthenium doped nickel-alumina-ceria catalyst in glycerol steam reforming[J]. Fuel Process Technol, 2018, 169:150-156. doi: 10.1016/j.fuproc.2017.09.017 [12] HE L, HU S, JIAN G, LIAO G, CHEN X, HAN H, XIAO, L, REN Q, WANG Y, SU S, XIANG J. Carbon nanotubes formation and its influence on steam reforming of toluene over Ni/Al2O3 catalysts:Roles of catalyst supports[J]. Fuel Process Technol, 2018, 176:7-14. doi: 10.1016/j.fuproc.2018.03.007 [13] OCHOA A, ARREGI A, AMUTIO M, GAYUBO A G, OLAZAR M, BILBAO J, CASTAÑO P. Coking and sintering progress of a Ni supported catalyst in the steam reforming of biomass pyrolysis volatiles[J]. Appl Catal B:Environ, 2018, 233:289-300. doi: 10.1016/j.apcatb.2018.04.002 [14] HE L, HU S, JIANG L, SYED-HASSAN S S A, WANG Y, XU K, SU S, XIANG J, XIAO L, CHI H, CHEN X. Opposite effects of self-growth amorphous carbon and carbon nanotubes on the reforming of toluene with Ni/α-Al2O3 for hydrogen production[J]. Int J Hydrogen Energy, 2017, 42:14439-144438. doi: 10.1016/j.ijhydene.2017.04.230 [15] BARROSO M N, GOMEZ M F, ARRÚA L A, ABELLO M C. Co catalysts modified by rare earths(La, Ce or Pr) for hydrogen production[J]. Int J Hydrogen Energy, 2014, 39(16):8712-8719. doi: 10.1016/j.ijhydene.2013.12.043 [16] TURCZYNIAK S, TESCHNER D, MACHOCKI A, ZAFEIRATOS S. Effect of the surface state on the catalytic performance of a Co/CeO2 ethanol steam-reforming catalyst[J]. J Catal, 2016, 340:321-330. doi: 10.1016/j.jcat.2016.05.017 [17] LIN S S-Y, KIM D H, ENGELHARD M H, HA S Y. Water-induced formation of cobalt oxides over supported cobalt/ceria-zirconia catalysts under ethanol-steam conditions[J]. J Catal, 2010, 273(2):229-235. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f47fa7ae4223effdf7ffb67c713a549b [18] LIU S, CHEN M, CHU L YANG Z, ZHU C, WANG J, CHENG M. Catalytic steam reforming of bio-oil aqueous fraction for hydrogen production over Ni-Mo supported on modified sepiolite catalysts[J]. Int J Hydrogen Energy, 2013, 38(10):3948-3955. doi: 10.1016/j.ijhydene.2013.01.117 [19] LIANG T, WANG Y, CHEN M, YANG Z, LIU S, ZHOU Z, LI X, CHENG M. Steam reforming of phenol-ethanol to produce hydrogen over bimetallic Ni-Cu catalysts supported on sepiolite[J]. Int J Hydrogen Energy, 2017, 42:28233-28246. doi: 10.1016/j.ijhydene.2017.09.134 [20] 陈明强, 梁添, 王一双, 杨忠连, 刘少敏, 周中山, 李晓静. Ni-Cu/海泡石水蒸汽催化重整苯酚-乙醇制氢[J].安徽理工大学学报(自然科学版), 2017, (6): 46-51, 75. http://www.cnki.com.cn/Article/CJFDTotal-HLGB201706008.htmCHEN Ming-qiang, LIANG Tian, WANG Yi-shuang, YANG Zhong-lian, LI Xiao-jing, ZHOU Zhong-shan. Hydrogen Production via Catalytic Steam Reforming of the Mixture of Phenol and Ethanol over Ni-Cu/Sepolite Catalyst[J]. J Anhui Univ Sci Technol (Nat Sci), 2017, (6): 46-51, 75. http://www.cnki.com.cn/Article/CJFDTotal-HLGB201706008.htm [21] 王一双, 陈明强, 刘少敏, 杨忠连, 沈朝萍, 刘珂.负载NiO-Fe2O3的凹凸棒石对生物油模型物催化重整制氢性能的影响[J].燃料化学学报, 2015, 43(12):1470-1475. doi: 10.3969/j.issn.0253-2409.2015.12.010WANG Yi-shuang, CHEN Ming-qiang, LIU Shao-min, YANG Zhong-lian, SHEN Chao-ping, LIU Ke. Hydrogen production via catalytic steam reforming of bio-oil model compounds over NiO-Fe2O3-loaded palygouskite[J]. J Fuel Chem Technol, 2015, 43(12):1470-1475. doi: 10.3969/j.issn.0253-2409.2015.12.010 [22] DOBOSZ J, CICHY M, ZAWADZKI M, BOROWIECKI T. Glycerol steam reforming over calcium hydroxyapatite supported cobalt and cobalt-cerium catalysts[J]. J Energy Chem, 2018, 27(2):404-412. doi: 10.1016/j.jechem.2017.12.004 [23] SONG H, OZKAN US. The role of impregnation medium on the activity of ceria-supported cobalt catalysts for ethanol steam reforming[J]. J Mol Catal A:Chem, 2010, 318(1):21-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f9b80ff70cafb093212a26bd954ee884 [24] LIN S S-Y, DAIMON H, HA S Y. Co/CeO2-ZrO2 catalysts prepared by impregnation and coprecipitation for ethanol steam reforming[J]. Appl Catal A:Gen, 2009, 366(2):252-261. doi: 10.1016/j.apcata.2009.07.010 [25] CARVALHO F L S, ASENCIOS Y J O, BELLIDO J D A, ASSAF E M. Bio-ethanol steam reforming for hydrogen production over Co3O4/CeO2 catalysts synthesized by one-step polymerization method[J]. Fuel Process Technol, 2016, 142:182-191. doi: 10.1016/j.fuproc.2015.10.010 [26] MARCOS F C F, LUCREDIO A F, ASSAF E M. Effects of adding basic oxides of La and/or Ce to SiO2-supported Co catalysts for ethanol steam reforming[J]. RSC Adv, 2014, 4:43839-43849. doi: 10.1039/C4RA04157G [27] HU X, LU G. Acetic acid steam reforming to hydrogen over Co-Ce/Al2O3and Co-La/Al2O3 catalysts-The promotion effect of Ce and La addition[J]. Catal Commun, 2011, 12(1):50-53. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3e1c9bd5489a990e2295589e6c5be6d9 [28] LI L, TANG D, SONG Y, JIANG B, ZHANG Q. Hydrogen production from ethanol steam reforming on Ni-Ce/MMT catalysts[J]. Energy, 2018, 149:937-943. doi: 10.1016/j.energy.2018.02.116 [29] ARAIZA D G, GÓMEZ-CORTÉS A, DÍAZ G. Effect of ceria morphology on the carbon deposition during steam reforming of ethanol over Ni/CeO2catalysts[J]. Catal Today(2018), https://doi.org/10.1016/j.cattod.2018.03.016. doi: 10.1016/j.cattod.2018.03.016 [30] ZOU X, CHEN T, ZHANG P, CHEN D, HE J, DANG Y, MA Z, CHEN Y, TOLOUEINIA P, ZHU, C, XIE J, LIU H, SUIB S L. High catalytic performance of Fe-Ni/Palygorskite in the steam reforming of toluene for hydrogen production.[J]. Appl Energy, 2018, (226):827-837. http://www.sciencedirect.com/science/article/pii/S0306261918308729 [31] 杨宇, 马建新.镍负载量对乙醇水蒸气重整制氢催化性能和催化剂的影响[J].燃料化学学报, 2006, 34(3):337-342. doi: 10.3969/j.issn.0253-2409.2006.03.016YANG Yu, MA Jian-xin. Effect of nickel loading on the production of hydrogen via ethanol steam reforming[J]. J Fuel Chem Technol, 2006, 34(3):337-342. doi: 10.3969/j.issn.0253-2409.2006.03.016 [32] BEPARI S, BASU S, PRADHAN N C, DALAI A Y. Steam reforming of ethanol over cerium-promoted Ni-Mg-Al hydrotalcite catalysts[J]. Catal Today, 2017, 291:47-57. doi: 10.1016/j.cattod.2017.01.027 [33] WANG S, ZHANG F, CAI Q, LI X, ZHU L, WANG Q, LUO Z. Catalytic steam reforming of bio-oil model compounds for hydrogen production over coal ash supported Ni catalyst[J]. Int J Hydrogen Energy, 2014, 39(5):2018-2025. doi: 10.1016/j.ijhydene.2013.11.129 -

下载:

下载: