Preparation of Ru/Co-Al-O supported catalysts and its hydrodeoxygenation properties

-

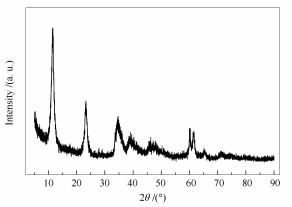

摘要: 先采用共沉淀法制备出Co-Al类水滑石, 其经煅烧后形成的复合氧化物用作载体制备出一系列Ru/Co-Al-O负载型催化剂, 并采用XRD、BET、FT-IR等方法对其结构性能进行表征分析, 最后以木质素生物质油的典型含氧化合物对甲基苯酚为模型, 测试所制催化剂的加氢脱氧性能。主要研究了载体中Co/Al物质的量比、催化剂还原温度等因素对催化剂加氢脱氧活性的影响, 并优化了HDO反应温度。结果表明, 当Co/Al物质的量比为3:1, 催化剂还原温度为350 ℃, 反应温度为275 ℃时, 催化剂的加氢脱氧活性最高, 催化对甲基苯酚加氢脱氧反应的转化率和脱氧率都达到了100%。Abstract: Co-Al layered double hydroxides were prepared by co-precipitation method and converted into composite oxides via calcination.The composite oxide were then used to prepare a series of Ru/Co-Al-O supported catalysts.The structures and properties of the catalysts were characterized by XRD, BET and FT-IR.The hydrodeoxygenation (HDO) properties of these catalysts were tested by using 4-methylphenol as a typical oxygen-containing model compound of lignin biomass oil.This study concentrated on the effects of Co/Al molar ratio and the reduction temperature of the catalyst on the hydrodeoxygenation activity of Ru/Co-Al-O and the optimization of HDO temperature.The results showed that when the molar ratio of Co/Al was 3:1, the catalyst reduction temperature was 350℃ and the reaction temperature was 275℃, the HDO activity was the highest:both the conversion and deoxygenation degree in the HDO of p-methyl phenol reached up to 100%.

-

Key words:

- hydrodeoxygenation /

- Co-Al layered double hydroxides /

- Ru /

- 4-methylphenol /

- composite oxides

-

图 4 275 ℃下Ru/Co-Al-O催化对甲基苯酚HDO反应2 h后的转化率、产物分布及脱氧率

:conversion; :methylcyclohexane;

:3-methylcyclohexene; :toluene;

:4-methylcyclohexanol;

:4-methylcyclohexanone; :deoxidation rateFigure 4 Catalytic reaction results over different Ru/Co-Al-O catalysts reaction conditions:reaction time:2 h, 275 ℃, 4 MPa

表 1 Ru/Co-Al-O负载型催化剂对应的制备条件及BET分析

Table 1 Ru/Co-Al-O supported catalyst corresponding to the preparation conditions and BET analysis results

Catalyst Co/Al(molar ratio) Reduction temperature t/℃ Specific surface area A/(m2·g-1) Pore volume v/(mL·g-1) Pore diameter d/nm Ru/Co4Al-350 4 350 65 0.22 12.3 Ru/Co3Al-350 3 350 79 0.29 13.4 Ru/Co3Al-500 3 500 48 0.21 16.2 Ru/Co2Al-350 2 350 67 0.31 10.9 Ru/Co1Al-350 1 350 40 0.10 9.4 Ru/Al-350 0 350 194 0.32 5.1 表 2 275 ℃反应2 h时不同还原温度的催化剂催化对甲基苯酚HDO产物分布

Table 2 HDO product distribution of the catalysts reduced at different temperatures

Catalyst Ru/Co3Al-350 Ru/Co3Al-500 Conversion rate x/% 100 99.2 Product distribution w/% Methylcyclohexane 92.1 83.8 4-methylcyclohexanol 0 8.5 4-methylcyclohexanone 0 0.3 3-methylcyclohexene 0 0.9 Toluene 7.9 6.5 Deoxidation rate η/% 100 89.6 表 3 不同温度下Ru/Co3Al-350催化对甲基苯酚HDO反应的转化率、产物分布及脱氧率

Table 3 Effect of reaction temperature on HDO

225 ℃ 250 ℃ 275 ℃ Conversion x/% 56.0 94.6 100 Product distribution w/% Methylcyclohexane 23.7 80.4 92.1 4-methylcyclohexanol 65.3 10.5 0 4-methylcyclohexanone 6.0 1.1 0 3-methylcyclohexene 1.7 1.6 0 Toluene 3.3 6.4 7.9 Deoxidation rate η/% 16.5 82.3 100 -

[1] LIU Z, GUAN D, WEI W, DAVIS S J, CIAIS P, BAI J, PENG S, ZHANG Q, HUBACEK K, MARLAND G, ANDRES R J, CRAWFORD-BROWN D, LIN J, ZHAO H, HONG C, BODEN T A, FENG K, PETERS G P, XI F, LIU J, LI Y, ZHAO Y, ZENG N, HE K.Reduced carbon emission estimates from fossil fuel combustion and cement production in China[J].Nature, 2015, 524(7565):335-338. doi: 10.1038/nature14677 [2] LI C, ZHAO X, WANG A, HUBER G W, ZHANG T.Catalytic transformation of lignin for the production of chemicals and fuels[J].Chem Rev, 2015, 115(21):11559-11624. doi: 10.1021/acs.chemrev.5b00155 [3] SAIDI M, SAMIMI F, KARIMIPOURFARD D, NIMMANWUDIPONG T, GATES B C, RAHIMPOUR, M R.Upgrading of lignin-derived bio-oils by catalytic hydrodeoxygenation[J].Energy Environ Sci, 2014, 7(1):103-129. doi: 10.1039/C3EE43081B [4] ZHAO C, LERCHER J A.Upgrading pyrolysis oil over Ni/HZSM-5 by cascade reactions[J].Angew Chem Int Ed, 2012, 51(24):5935-5940. doi: 10.1002/anie.201108306 [5] HONG Y, ZHANG H, SUN J, AYMAN K M, HENSLEY A J R, Gu M, ENGELHARD M H, MCEWEN J-S, Wang Y.Synergistic catalysis between Pd and Fe in gas phase hydrodeoxygenation of m-cresol[J].ACS Catal, 2014, 4(10):3335-3345. doi: 10.1021/cs500578g [6] WANG G H, CAO Z, GU D, PFÄNDER N, SWERTZ A C, SPLIETHOFF, BONGARD H J, WEIDENTHALER C, SCHMIDT W, RINALDI R, SCHUTH F.Nitrogen-doped ordered mesoporous carbon supported bimetallic PtCo nanoparticles for upgrading of biophenolics[J].Angew Chem Int Ed, 2016, 55(31):8850-8855. doi: 10.1002/anie.201511558 [7] GRILC M, VERYASOV G, LIKOZAR B, JESIH A, LEVEC J.Hydrodeoxygenation of solvolysed lignocellulosic biomass by unsupported MoS2, MoO2, Mo2C and WS2 catalysts[J].Appl Catal B:Environ, 2015, 1633(0):467-477. https://www.researchgate.net/profile/Adolf_Jesih [8] CECILIA J A, INFANTES-MOLINA A, SANMARTIN-DONOSO J, RODRIGUEZ-AGUADO E, BALLESTEROS-PLATA D, RODRIGUEZ-CASTELLON, E.Enhanced HDO activity of Ni2P promoted with noble metals[J].Catal Sci Technol, 2016, 6(19):7323-7333. doi: 10.1039/C6CY00639F [9] DING R, WU Y, CHEN Y, CHEN H, WANG J, SHI, Y, YANG M.Catalytic hydrodeoxygenation of palmitic acid over a bifunctional Co-doped MoO2/CNTs catalyst:an insight into the promoting effect of cobalt[J].Catal Sci Technol, 2016, 6(7):2065-2076. doi: 10.1039/C5CY01575H [10] PATEL M, KUMAR A.Production of renewable diesel through the hydroprocessing of lignocellulosic biomass-derived bio-oil:A review[J].Renewable Sustainable Energy Rev, 2016, 58(4):1293-1307. https://www.sciencedirect.com/science/article/pii/S1364032115015294 [11] WANG W, LIU P, WU K, TAN S, LI W, YANG Y.Preparation of hydrophobic reduced graphene oxide supported Ni-B-P-O and Co-B-P-O catalyst and their high hydrodeoxygenation activities[J].Green Chem, 2016, 18(4):984-988. doi: 10.1039/C5GC02073E [12] KUSUMOTO S, NOZAKI K, Direct and selective hydrogenolysis of arenols and aryl methyl ethers[J].Nature Communications, 2015, 6(3):6296. https://www.researchgate.net/publication/272750703_Direct_and_selective_hydrogenolysis_of_arenols_and_aryl_methyl_ethers [13] DE SOUZA P M, RABELO-NETO R C, BORGES L E P, JACOBS G, DAVIS B H, GRAHAM U M, REASASCO D E, NORONHA F B.Effect of zirconia morphology on hydrodeoxygenation of phenol over Pd/ZrO2[J].ACS Catal, 2015, 5(12):7385-7398. doi: 10.1021/acscatal.5b01501 [14] WANG L, ZHANG J, YI X, ZHENG A, DENG F, CHEN C, JI Y, LIU F, MENG X, XIAO F S.Mesoporous ZSM-5 zeolite-supported Ru nanoparticles as highly efficient catalysts for upgrading phenolic biomolecules[J].ACS Catal, 2015, 5(5):2727-2734. doi: 10.1021/acscatal.5b00083 [15] LUSKA K L, MIGOWSKI P, EL SAYED S, LEITNER W.Synergistic interaction within bifunctional ruthenium nanoparticle/SILP catalysts for the selective hydrodeoxygenation of phenols[J].Angew Chem Int Ed, 2015, 54(52):15750-15755. doi: 10.1002/anie.201508513 [16] DE SOUZA P M, RABELONETO R C, P, BORGES L E, JACOBS G, DAVIS B H, RESASCO D E, NORONHA F B.Hydrodeoxygenation of phenol over Pd catalysts.Effect of support on reaction mechanism and catalyst deactivation[J].ACS Catal, 2017, 4(5):986-990. doi: 10.1021/acscatal.6b02022 [17] SUN Q, CHEN G, WANG H, LIU X, HAN J, GE Q, ZHU, X.Insights into the major reaction pathways of vapor-phase hydrodeoxygenation of m-cresol on a Pt/HBeta catalyst[J].ChemCatChem, 2016, 8(3):551-561. doi: 10.1002/cctc.201501232 [18] FAN G, LI F, EVANS D G, DUAN X.Catalytic applications of layered double hydroxides:Recent advances and perspectives[J].Chem Soc Rev, 2014, 43(20):7040-7066. doi: 10.1039/C4CS00160E [19] TIAN Z, LI Q, HOU J, PEI L, LI Y, AI S.Platinum nanocrystals supported on CoAl mixed metal oxide nanosheets derived from layered double hydroxides as catalysts for selective hydrogenation of cinnamaldehyde[J].J Catal, 2015, 331(3):193-202. https://www.sciencedirect.com/science/article/pii/S0021951715002833 [20] MANFRO R L, PIRES T P M D, RIBEIRO N F P, SOUZA M M V M.Aqueous-phase reforming of glycerol using Ni-Cu catalysts prepared from hydrotalcite-like precursors[J].Catal Sci Technol, 2013, 3(5):1278-1287. doi: 10.1039/c3cy20770f [21] WANG W, ZHANG K, YANG Y, LIU H, QIAO Z, LUO H.Synthesis of mesoporous Al2O3 with large surface area and large pore diameter by improved precipitation method[J].Microporous Mesoporous Mater, 2014, 193(0):47-53. https://www.scientific.net/AMR.554-556.498 [22] WANG Z, JIANG Z, SHANGGUAN W, Simultaneous catalytic removal of NOx and soot particulate over Co-Al mixed oxide catalysts derived from hydrotalcites[J].Catal Commun, 2007, 8(11):1659-1664. doi: 10.1016/j.catcom.2007.01.025 [23] LIU X, FAN B, GAO S, LI R.Transesterification of tributyrin with methanol over MgAl mixed oxides derived from MgAl hydrotalcites synthesized in the presence of glucose[J].Fuel Process Technol, 2013, 106(6):761-768. https://www.sciencedirect.com/science/article/pii/S0378382012004031 [24] POPOV A, KONDRATIEVA E, MARIEY L, GOUPIL J M, EL FALLAH J, GILSON, J-P, TRAVERT A, MAUGE F.Bio-oil hydrodeoxygenation:Adsorption of phenolic compounds on sulfided (Co)Mo catalysts[J].J Catal, 2013, 297(0):176-186. https://www.sciencedirect.com/science/article/pii/S0021951712003181#! [25] YANG Y, LUO H A, TONG G, SMITH K J, TYE C T.Hydrodeoxygenation of phenolic model compounds over MoS2 catalysts with different structures[J].Chin J Chem Eng, 2008, 16(5):733-739. doi: 10.1016/S1004-9541(08)60148-2 -

下载:

下载: