Preparation of layered K-Fe-Zn-Ti catalyst and its performance in the hydrogenation of carbon dioxide to light olefins

-

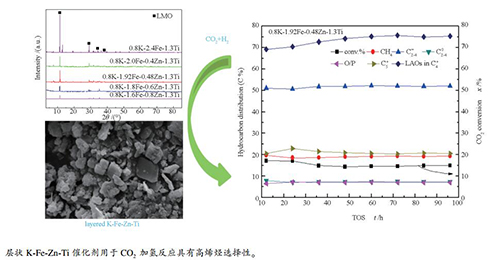

摘要: 采用高温固相法制备了系列Zn改性的层状K-Fe-Zn-Ti催化剂,用于CO2加氢经费托合成直接制烯烃反应。采用SEM、TEM、XRD、H2-TPR、CO2-TPD、XPS、N2吸附-脱附和TG等手段对反应前后的催化剂进行了表征,对K-Fe-Zn-Ti催化剂的组成-结构-性能关系进行了关联研究。结果表明,所制备的催化剂均出现K2.3Fe2.3Ti5.7O16物相,为典型的层状金属氧化物(Layered Metal Oxides,LMO)结构;Zn改性后生成了ZnFe2O4物相,降低了催化剂样品结晶度,增强了表面碱性,促进了CO2表面吸附。在CO2加氢反应中,K-Fe-Zn-Ti系列催化剂均具有较高的烯烃选择性(O/P>6.5),Zn改性促进了C5+的生成,显著提高了C4+线性α-烯烃(linear α-olefins,LAOs)的选择性,C4+烃中LAOs含量由Zn改性前的54.6%提高至75.2%。在所考察的范围内,随Zn/Fe比的增加,烯/烷比(C2-4=/C2-40,O/P)先增加后降低,但对重烃含量以及LAOs选择性影响不明显。K-Fe-Zn-Ti催化剂具有较好的稳定性,经100 h在线反应后,仍保持LMO结构。

-

关键词:

- 层状K-Fe-Zn-Ti催化剂 /

- CO2加氢 /

- 低碳烯烃 /

- 线性α-烯烃

Abstract: A series of layered K-Fe-Zn-Ti catalysts with different Zn/Fe molar ratios were prepared by high-temperature solid state reaction and characterized by SEM, TEM, XRD, H2-TPR, CO2-TPD, XPS, N2 sorption and TG measurements; the performance of K-Fe-Zn-Ti catalysts in the hydrogenation of CO2 to light olefins was investigated. The results indicate that the K-Fe-Zn-Ti catalysts have the typical layered structure with K2.3Fe2.3Ti5.7O16 as the main phase. ZnFe2O4 appears on the Zn promoted K-Fe-Zn-Ti catalysts, which may reduce the crystallinity, enhance the surface basicity, and promote the adsorption of CO2. The K-Fe-Zn-Ti catalysts exhibit high selectivity to olefins in CO2 hydrogenation; the ratio of olefins to paraffins in the products (O/P) is higher than 6.5. The addition of Zn can enhance the formation of C5+ hydrocarbons and especially C4+ linear alpha-olefins (LAOs); the content of LAOs in C4+ hydrocarbons over Zn promoted K-Fe-Zn-Ti reaches 75.2%, in comparison with the value of 54.6% over the Zn-free K-Fe-Ti catalyst. In particular, the 0.8K-1.8Fe-0.6Zn-1.3Ti catalyst displays the highest O/P value (7.8), although the effect of Zn content in the Zn-promoted K-Fe-Zn-Ti catalysts on the yield of heavy hydrocarbons and selectivity to alpha-olefins is less significant. Moreover, the K-Fe-Zn-Ti catalysts display high stability in CO2 hydrogenation and the LMO structure remains almost intact after a long term reaction test of 100 h.-

Key words:

- layered K-Fe-Zn-Ti catalyst /

- CO2 hydrogenation /

- light olefins /

- linear α-olefins

-

表 1 催化剂的织构性质

Table 1 Textural properties of the K-Fe-Zn-Ti catalysts

Catalyst Surface area A/(m2·g-1) Pore volume v/(cm3·g-1) Average pore size d/nm 0.8K-2.4Fe-1.3Ti 4.11 0.020 1.51 0.8K-2.0Fe-0.4Zn-1.3Ti 2.91 0.010 2.59 0.8K-1.92Fe-0.48Zn-1.3Ti 3.38 0.004 1.96 0.8K-1.8Fe-0.6Zn-1.3Ti 5.91 0.013 1.96 0.8K-1.6Fe-0.8Zn-1.3Ti 1.66 0.008 3.86 表 2 反应前后催化剂样品的表面组成

Table 2 Surface composition of the K-Fe-Zn-Ti catalysts determined by XPS

Catalyst Surface element content wmola/% Fe/Ti Fe/K Fe/Zn K Fe Ti Zn O C 0.8K-2.4Fe-1.3Ti 14.99 7.61 7.67 0 50.72 18.19 0.99 0.51 0 0.8K-2.0Fe-0.4Zn-1.3Ti 15.53 7.28 5.55 1.55 47.48 22.31 1.31 0.47 4.70 0.8K-1.8Fe-0.6Zn-1.3Ti 12.98 3.07 4.42 1.12 37.14 37.39 0.69 0.24 2.74 0.8K-1.6Fe-0.8Zn-1.3Ti 11.25 2.50 3.51 1.08 34.83 46.83 0.71 0.22 2.32 AR-0.8K-2.4Fe-1.3Ti 16.34 1.69 2.78 0 32.19 46.09 0.61 0.10 0 AR-0.8K-2.0Fe-0.4Zn-1.3Ti 12.02 1.39 3.32 0.91 28.51 53.97 0.42 0.12 1.53 AR-0.8K-1.8Fe-0.6Zn-1.3Ti 18.57 1.06 2.11 0.59 33.10 44.55 0.66 0.54 1.31 AR-0.8K-1.6Fe-0.8Zn-1.3Ti 14.28 0.42 0.98 0.26 22.52 61.52 0.43 0.03 1.62 a: calculated from peak area of XPS spectra 表 3 催化剂的活性评价

Table 3 Performances of the K-Fe-Zn-Ti catalysts in CO2 hydrogenation

Catalyst CO2

conv. x/%Selectivity s/% Hydrocarbon distribution C/% O/P CO HC oxy CH4 C2-4= C2-40 C5+ α-olefins(C4+) 0.8K-2.4Fe-1.3Ti 35.2 70.1 22.4 7.5 23.3 59.3 8.1 9.3 54.6 7.3 0.8K-2.0Fe-0.4Zn-1.3Ti 13.2 56.4 38.8 4.8 21.0 51.1 7.8 20.1 72.6 6.6 0.8K-1.92Fe-0.48Zn-1.3Ti 14.6 53.6 41.6 4.9 19.2 52.2 7.3 21.3 75.2 7.1 0.8K-1.8Fe-0.6Zn-1.3Ti 16.1 75.4 21.8 2.8 20.4 51.6 6.6 21.4 73.2 7.8 0.8K-1.6Fe-0.8Zn-1.3Ti 13.0 49.1 46.0 4.8 19.9 51.2 7.9 21.1 70.9 6.5 reaction condition: 320 ℃, 2 MPa, H2/CO2 = 3.0, GHSV = 1000 h-1, TOS = 72 h -

[1] WANG W, WANG S P, MA X B, GONG J L. Recent advances in catalytic hydrogenation of carbon dioxide[J]. Chem Soc Rev, 2011, 40(7):3703-3727. doi: 10.1039/c1cs15008a [2] WANG J J, YOU Z Y, ZHANG Q H, DENG W P, WANG Y. Synthesis of lower olefins by hydrogenation of carbon dioxide over supported iron catalysts[J]. Catal Today, 2013, 215(41):186-193. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3d6ffc760d22c2f19df1f6a1915f2c20 [3] WEI J, GE Q J, YAO R W, WEN Z Y, FANG C Y, GUO L S, XU H Y, SUN J. Directly converting CO2 into a gasoline fuel[J]. Nat Commun, 2017, 8:15174. doi: 10.1038/ncomms15174 [4] ROHDE M P, UNRUH D, SCHAUB G. Membrane application in Fischer-Tropsch synthesis to enhance CO2 Hydrogenation[J]. Ind Eng Chem Res, 2005, 44(25):9653-9658. doi: 10.1021/ie050289z [5] SONG C. Global challenges and strategies for control, conversion and utilization of CO2 for sustainable development involving energy, catalysis, adsorption and chemical processing[J]. Catal Today, 2006, 115(1):2-32. doi: 10.1016-j.cattod.2006.02.029/ [6] PRASAD P S S, BAE J W, JUN K W, LEE K W. Fischer-Tropsch synthesis by carbon dioxide hydrogenation on Fe-based catalysts[J]. Catal Surv Asia, 2008, 12(3):170-183. http://cn.bing.com/academic/profile?id=fd84d6633630497eeb14af15f1fb2a63&encoded=0&v=paper_preview&mkt=zh-cn [7] 张娟, 陈建刚, 陈从标, 王占修, 王俊刚, 孙予罕. Co基催化剂上费托合成中烯烃二次反应行为的研究[J].石油化工, 2010, 39(8):855-860. http://d.old.wanfangdata.com.cn/Periodical/syhg201008005ZHANG Juan, CHEN Jian-gang, CHEN Cong-biao, WANG Zhan-xiu, WANG Jun-gang, SUN Yu-han. Secondary reaction of olefin over Co-based catalyst for Fischer-Tropsch synthesis[J]. Petrochem Technol, 2010, 39(8):855-860. http://d.old.wanfangdata.com.cn/Periodical/syhg201008005 [8] GUO L S, SUN J, JI X W, WEI J, WEN Z Y, YAO R W, XU H Y, QE Q J. Directly converting carbon dioxide to linearα-olefins on bio-promoted catalysts[J]. Commun Chem, 2018, 1:11. doi: 10.1038/s42004-018-0012-4 [9] 涂军令, 徐勇军, 定明月, 王铁军, 王隆龙, 王敏龙. Fe3O4纳米催化剂的制备及其F-T合成性能研究[J].燃料化学学报, 2015, 43(7):839-845. doi: 10.3969/j.issn.0253-2409.2015.07.008TU Jun-ling, XU Yong-jun, DING Ming-yue, WANG Tie-jun, WANG Long-long, WANG Min-long. Preparation of nano-structured Fe3O4 catalysts and their performance in Fischer-Tropsch synthesis[J]. J Fuel Chem Technol, 2015, 43(7):839-845. doi: 10.3969/j.issn.0253-2409.2015.07.008 [10] WANG X, WU D K, ZHANG J L, GAO X H, MA Q X, FAN S B, ZAHO T S. Highly selective conversion of CO2 to light olefins via Fischer-Tropsch synthesis over stable layered K-Fe-Ti catalysts[J]. Appl Catal A:Gen, 2019, 573:32-40. doi: 10.1016/j.apcata.2019.01.005 [11] CHOI Y H, JANG Y J, PARK H, KIM W Y, LEE Y H, CHOI S H, LEE J S. Carbon dioxide Fischer-Tropsch synthesis:A new path to carbon-neutral fuels[J]. Appl Catal B:Environ, 2017, 202:605-610. doi: 10.1016/j.apcatb.2016.09.072 [12] LI S Z, LI A W, KRISHNAMOORTHY S, IGLESIA E. Effects of Zn, Cu, and K promoters on the structure and on the reduction, carburization, and catalytic behavior of iron-based Fischer-Tropsch synthesis catalysts[J]. Catal Lett, 2001, 77(4):197-205. http://cn.bing.com/academic/profile?id=b4e0fe30fef7f9fe6b91ca3ffbf17914&encoded=0&v=paper_preview&mkt=zh-cn [13] WANG H L, YANG Y, XU J, WANG H, DING M Y, LI Y W. Study of bimetallic interactions and promoter effects of FeZn, FeMn and FeCr Fischer-Tropsch synthesis catalysts[J]. J Mol Catal A:Chem, 2010, 326(1):29-40. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=09c846d79fb509d9f76832d57cc74ad6 [14] LIU X M, LU M, YAN Z F, BELTRAMINI J. Recent advances in catalysts for methanol synthesis via hydrogenation of CO and CO2[J]. Ind Eng Chem Res, 2003, 42(25):6518-6530. doi: 10.1021/ie020979s [15] SHIDO T, IWASSAWA Y. Reactant-promoted reaction mechanism for water-gas shift reaction on ZnO, as the genesis of surface catalysis[J]. J Catal, 1991, 129(2):343-355. http://cn.bing.com/academic/profile?id=b3750d0c7ad951c00ebccf58540b26b9&encoded=0&v=paper_preview&mkt=zh-cn [16] MASAHIRO S, WU J G, KAZUMI T, ISAO T, KAZUHISA M. Effects of ZnO contained in supported Cu-based catalysts on their activities for several reactions[J].Catal Lett, 2002, 83(1/2):1-4. doi: 10.1023/A:1020693226903 [17] KOOHSARYAN E, ANBIA M. Nanosized and hierarchical zeolites:A short review[J]. Chin J Catal, 2016, 37(4):447-467. http://d.old.wanfangdata.com.cn/Periodical/cuihuaxb201604001 [18] 张莉莉, 杨娟, 张维光, 陆路德, 杨绪杰, 汪信.软化学法低温合成超细K2La2Ti3O10及其剥离性质[J].应用化学, 2005, 22(1):64-66. http://d.old.wanfangdata.com.cn/Periodical/yyhx200501014ZHANG Li-li, YANG Juan, ZHANG Wei-guang, LU Lu-de, YANG Xu-jie, WANG Xin. Preparation of ultrafine K2La2Ti3O10 by soft chemistry method at low temperature and its exfoliation behavior[J]. Chin J Appl Chem, 2005, 22(1):64-66. http://d.old.wanfangdata.com.cn/Periodical/yyhx200501014 [19] 吴大雄, 朱海涛, 孙凯.层状K-Fe-Ti氧化物的剥离及光催化性能[J].化工新型材料, 2009, 37(9):56-57. doi: 10.3969/j.issn.1006-3536.2009.09.018WU Da-xiong, ZHU Hai-tao, SUN Kai. Exfoliation and photocatalytic activity of layered K-Fe-Ti oxide[J]. New Chem Mater, 2009, 37(9):56-57. doi: 10.3969/j.issn.1006-3536.2009.09.018 [20] WANG S R, ZHANG J X, YANG J D, GAO X L. Spinel ZnFe2O4 nanoparticle-decorated rod-like ZnO nanohetero structures for enhanced gas sensing performances[J]. Rsc Adv, 2015, 5(13):10048-10057. doi: 10.1039/C4RA14033H [21] LU Y E, YAN Q G, HAN J, CAO B B, STREET J, YU F. Fischer-Tropsch synthesis of olefin-rich liquid hydrocarbons from biomass-derived syngas over carbon-encapsulated iron carbide/iron nanoparticles catalyst[J]. Fuel, 2017, 193:369-384. doi: 10.1016/j.fuel.2016.12.061 [22] 张建利, 王旭, 马丽萍, 于旭飞, 马清祥, 范素兵, 赵天生.层状K/Mg-Fe-Al催化剂的制备及其CO加氢性能研究[J].燃料化学学报, 2017, 45(12):1489-1498. doi: 10.3969/j.issn.0253-2409.2017.12.011ZHANG Jian-li, WANG Xu, Ma Li-ping, YU Xu-fei, MA Qing-xiang, FAN Su-bing, ZHAO Tian-sheng. Preparation of layered K/Mg-Fe-Al catalysts and its catalytic performances in CO hydrogenation[J]. J Fuel Chem Technol, 2017, 45(12):1489-1498. doi: 10.3969/j.issn.0253-2409.2017.12.011 [23] LI Z L, WANG J J, QU Y Z, LIU H L. Highly selective conversion of carbon dioxide to lower olefins[J]. ACS Catal, 2017, 7:8544-8548. doi: 10.1021/acscatal.7b03251 [24] ZHANG C H, YANG Y, TENG B T, LI T, ZHENG H, XIANG H, LI Y. Study of an iron-manganese Fischer-Tropsch synthesis catalyst promoted with copper[J]. J Catal, 2006, 237(2):405-415. http://cn.bing.com/academic/profile?id=c65080a18786083e192f4d736240d190&encoded=0&v=paper_preview&mkt=zh-cn [25] LIANG M S, KANG W K, XIE K C. Comparison of reduction behavior of Fe2O3, ZnO and ZnFe2O4 by TPR technique[J]. J Nat Gas Chem, 2009, 18(1):110-113. doi: 10.1016/S1003-9953(08)60073-0 [26] 郭伟, 高文桂, 王华, 田俊杰, 韩冲, 覃志强. Fe添加对Cu/Zn/ZrO2催化剂CO2加氢合成低碳醇性能的影响[J].材料导报, 2013, 27(20):44-47. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cldb201320013GUO Wei, GAO Wen-gui, WANG Hua, TIAN-Jun-jie, HAN-Chong, QIN Zhi-qiang. Effect of Fe addition on Cu/Zn/ZrO2 catalyst for hydrogenation of carbon dioxide to higher alcohol[J]. Mater Rev, 2013, 27(20):44-47. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cldb201320013 [27] MAZAN M O, MARRERO-JEREZ J, SOLDATI A, NÚÑEZ P, LARRONDO S A. Fe-doped ceria nanopowders synthesized by freeze-drying precursor method for electrocatalytic applications[J]. Int J Hydrogen Energy, 2015, 40(10):3981-3989. doi: 10.1016/j.ijhydene.2015.01.006 [28] 马丽萍, 张建利, 马清祥, 范素兵, 赵天生. K/MgFeZn-HTLcs催化CO加氢制低碳烯烃性能研究[J].燃料化学学报, 2016, 44(4):449-456. doi: 10.3969/j.issn.0253-2409.2016.04.009MA Li-ping, ZHANG Jian-li, MA Qing-xiang, FAN Su-bing, ZHAO Tian-sheng. Direct synthesis of light olefins from CO hydrogenation over K/MgFeZn-HTLcs catalysts[J]. J Fuel Chem Technol, 2016, 44(4):449-456. doi: 10.3969/j.issn.0253-2409.2016.04.009 [29] DING M Y, YANG Y, LI Y W, WANG T J, MA L L, WU C Z. Impact of H2/CO ratios on phase and performance of Mn-modified Fe-based Fischer-Tropsch synthesis catalyst[J]. Appl Energy, 2013, 112(4):1241-1246. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=4a922087a8b3945a0552c939498e3b25 [30] SUO H Y, WANG S G, ZHANG C H, XU J, WU B, YANG Y, XIANG H W, LI Y W. Chemical and structural effects of silica in iron-based Fischer-Tropsch synthesis catalysts[J]. J Catal, 2012, 286(2):111-123. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b4aea61b0d5e5304a3dc21ee95051543 -

下载:

下载: