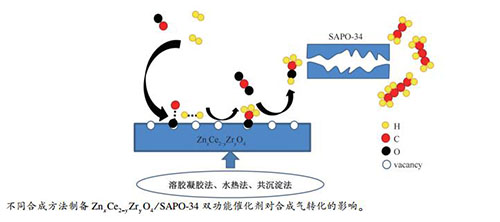

Study on different synthesis methods of ZnxCe2-yZryO4/SAPO-34 catalyst and its catalytic performance in syngas to low-carbon olefins

-

摘要: 通过溶胶凝胶法、水热法、共沉淀法合成了不同的ZnxCe2-yZryO4金属氧化物,并对其结构性质进行了XRD、BET、HRTEM、CO-TPD、Raman以及XPS等多种技术表征。考察不同合成方法(溶胶-凝胶法、共沉淀法和水热法)所制备的ZnxCe2-yZryO4金属氧化物形貌、晶粒粒径和氧空穴浓度变化情况,及其对合成气制低碳烯烃性能的影响。结果表明,ZnxCe2-yZryO4固溶体的形貌、暴露晶面、晶粒粒径和表面氧空穴浓度强烈依赖于合成方法。在300 ℃、1.0 MPa条件下,采用溶胶-凝胶法制备的ZnxCe2-yZryO4与SAPO-34组成的双功能催化剂具有最高的低碳烯烃(C2-4=)选择性(79.5%),同时甲烷和CO2的选择性分别仅为5.5%和10.7%。实现了低温低压条件直接转化合成气制低碳烯烃,同时大幅降低了甲烷和CO2的释放。Abstract: A series of ZnxCe2-yZryO4 metal oxides were synthesized by sol gel method, hydrothermal method and co-precipitation method respectively and characterized by XRD, BET, HRTEM, CO-TPD, Raman and XPS. The effects of the synthesis method on the morphology, grain size and oxygen vacancy concentration and the catalytic performance in syngas to low-carbon olefin reaction of the ZnxCe2-yZryO4 catalysts were investigated. The results show that the shape, exposed crystal surface, grain size and surface oxygen vacancy concentration of ZnxCe2-yZryO4 solid solution are strongly dependent on the synthesis method. Under the reaction conditions of 300 ℃ and 1.0 MPa, the dual-functional catalysts of ZnxCe2-yZryO4/SAPO-34 prepared by sol-gel method have the highest low-carbon olefin (C2-4=) selectivity (79.5%), while the selectivities of methane and CO2 are only 5.5% and 10.7%, respectively. Here the direct conversion of syngas to low-carbon olefins are realized at low temperature and pressure and the formation of methane and CO2 is greatly reduced.

-

表 1 不同合成方法制备的ZnxCe2-yZryO4/SAPO-34合成气制烯烃反应产物分布和CO转化率

Table 1 CO conversion and product distribution of the ZnxCe2-yZryO4/SAPO-34 dual functional catalysts

Sample Selectivitys/% CO conversion x/% CO2 selectivity s/% C2-4= C2-40 CH4 others ZnCeZr(s)a /SAPO-34 79.5 4.1 5.5 10.9 6.4 10.7 ZnCeZr(h)b /SAPO-34 77.0 3.0 6.4 13.5 5.4 4.5 ZnCeZr(c)c/SAPO-34 73.1 9.4 6.7 10.8 6.6 12.6 a: sol-gel method; b: hydrothermal method; c: co-precipitation method 表 2 不同合成方法制备的ZnxCe2-yZryO4表面氧空穴浓度

Table 2 Concentration of surface oxygen vacancies of the ZnxCe2-yZryO4 catalyst prepared with different methods

Sample Ov/Ototal (%)a Odefect(%)b Ce3+/(Ce4++Ce3+) (%)c ZnCeZr(sol-gel) 23.8% 29.7% 30.0% ZnCeZr(hydrothermal) 15.9% 25.5% 24.5% ZnCeZr(co-precipitation) 15.7% 27.7% 25.3% a: the Ov/Ototal ratio was obtained from the Raman spectra by the equation: Ov/Ototal=I630/(I475+I630), whereI630 andI475 correspond to the intensity of peaks at 600 and 475cm-1, respectively;

b: the Odefect(Ovacancy) concentration was calculated from the O 1s XPS spectra by the equation: concentration of Odefect=IOdefect/(IOdefect+IOlattice), whereIOdefect andIOlattice correspond to the intensity of peaks at 530.5 and 529.5eV, which are assigned to Ovacancy(Odefect) and lattice oxygen species (Olattice) respectively;

c: the proportion of Ce3+ (P(Ce3+)) on the surface was calculated from the Ce 3d XPS spectra by the equation:$p\left( {{\rm{C}}{{\rm{e}}^{3 + }}} \right) = \frac{{I\left( {{{\rm{u}}_1}} \right) + I\left( {{{\rm{v}}_1}} \right)}}{{\sum\limits_i {\left( {I\left( {{{\rm{u}}_i}} \right) + I\left( {{{\rm{v}}_i}} \right)} \right)} }} $whereI(x) represents the intensity ofu0 (900.9eV) andv0 (882.5eV), u1(903.2eV) andv1 (884.7eV), u2 (907.3eV) andv2 (888.8eV), andu3 (916.6eV) andv3 (898.4eV) signals, respectively, in Ce 3d XPS spectra -

[1] TORRES GALVIS H M, DE JONG K P. Catalysts for production of lower olefins from synthesis gas:A review[J]. ACS Catal, 2013, 3(9):2130-2149. doi: 10.1021/cs4003436 [2] WANG W, WANG S P, MA X B, GONG J L. Recent advances in catalytic hydrogenation of carbon dioxide[J]. Chem Soc Rev, 2011, 40(7):3703-3727. doi: 10.1039/c1cs15008a [3] ARESTA M, DIBENEDETTO A, ANGELINI A. Catalysis for the valorization of exhaust carbon:from CO2 to chemicals, materials, and fuels. technological use of CO2[J]. Chem Rev, 2014, 114(3):1709-1742. doi: 10.1021/cr4002758 [4] GALVIS H M T, BITTER J H, DAVIDIAN T, MATTHIJS R, DUGULAN A L, JONG K P D. Iron particle size effects for direct production of lower olefins from synthesis gas[J]. JACS, 2012, 134(39):16207-16215. doi: 10.1021/ja304958u [5] CHENG K, KANG J C, KING D L, SUBRAMANIAN V Y, ZHOU C, ZHANG Q H, WANG Y. Advances in catalysis for syngas conversion to hydrocarbons[J]. Adv Catal, 2017, 60:125-208. https://www.sciencedirect.com/science/article/abs/pii/S0360056417300032 [6] JIAO F, LI J, PAN X L, XIAO J, LI H, MA H, WEI M, PAN Y, ZHOU Z, LI M. Selective conversion of synthesis gas into lower olefins[J]. Science, 2016, 351(6277):1065-1068. doi: 10.1126/science.aaf1835 [7] CHENG K, GU B, LIU X, KANG J C, ZHANG Q H, WANG Y. Direct and highly selective conversion of synthesis gas to lower olefins:Design of a bifunctional catalyst combining methanol synthesis and carbon-carbon coupling[J]. Angew Chem Int Ed, 2016, 55(15):4725-4728. doi: 10.1002/anie.201601208 [8] ZHU Y F, PAN X L, JIAO F, LI J, YANG J H, DING M Z, HAN Y, LIU Z, BAO X H. Role of manganese oxide in syngas conversion to light olefins[J]. ACS Catal, 2017, 7:2800-2804. doi: 10.1021/acscatal.7b00221 [9] LIU X L, ZHOU W, YANG Y, CHENG K, KANG J C, ZHANG L, ZHANG G Q, MIN X J, ZHANG Q H, WANG Y. Design of efficient bifunctional catalysts for direct conversion of syngas into lower olefins via methanol/dimethyl ether intermediates[J]. Chem Sci, 2018, 9(20):4708-4718. doi: 10.1039/C8SC01597J [10] SU J J, WANG D, Wang Y D, ZHOU H B, LIU C, LIU S, WANG C M, YANG W M, XIE Z K, HE M Y. Direct conversion of syngas to light olefins over Zr-In2O3 and SAPO-34 bifunctional catalysts:Design of oxide component and construction of reaction network[J]. ChemCatChem, 2018, 10:1536-1541. doi: 10.1002/cctc.201702054 [11] REDDY B M, KHAN A, LAKSHMANAN P, AOUINE M, LORIDANT S, VOLTA J C. Structural characterization of nanosized CeO2-SiO2, CeO2-TiO2, and CeO2-ZrO2 catalysts by XRD, Raman, and HREM techniques[J]. J Phys Chem B, 2005, 109(8):3355-3363. doi: 10.1021/jp045193h [12] CHEN A L, ZHOU Y, TA N, LI Y, SHEN W J. Redox properties and catalytic performance of ceria-zirconia nanorods[J]. Catal Sci Technol, 2015, 5(8):4184-4192. doi: 10.1039/C5CY00564G [13] ZHANG P P, TAN L, YANG G H, TSUBAKI N. One-pass selective conversion of syngas to paraxylene[J]. Chem Sci, 2017, 8(12):7941-7946. doi: 10.1039/C7SC03427J [14] ZHOU C, SHI J Q, ZHOU W, CHENG K, ZHANG Q H, KANG J C, WANG Y. Highly active ZnO-ZrO2 aerogels integrated with H-ZSM-5 for aromatics synthesis from carbon dioxide[J]. ACS Catal, 2020, 10(1):302-310. doi: 10.1021/acscatal.9b04309 [15] ZHANG Z X, WANG Y H, LU J M, ZHANG C F, WANG M, LI M R, LIU X B, WANG F. Conversion of isobutene and formaldehyde to diol using praseodymium-doped CeO2 catalyst[J]. ACS Catal, 2016, 8:2635-2644. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7215bbd058fcd6c7e9a0a51dfd4e9ec5 [16] LIANG F L, YU Y, ZHOU W, XU X Y, ZHU Z H. Highly defective CeO2 as a promoter for efficient and stable water oxidation[J]. J Mater Chem A, 2015, 3(2):634-640. doi: 10.1039/C4TA05770H [17] PIUMETTI M, BENSAID S, RUSSO N, FINO D. Nanostructured ceria-based catalysts for soot combustion:Investigations on the surface sensitivity[J]. Appl Catal B:Environ, 2015, 165:742-751. doi: 10.1016/j.apcatb.2014.10.062 -

下载:

下载: