Promoting effect of oxidation reaction on steam gasification reaction in Shengli lignite gasification processⅡ.Mechanism study

-

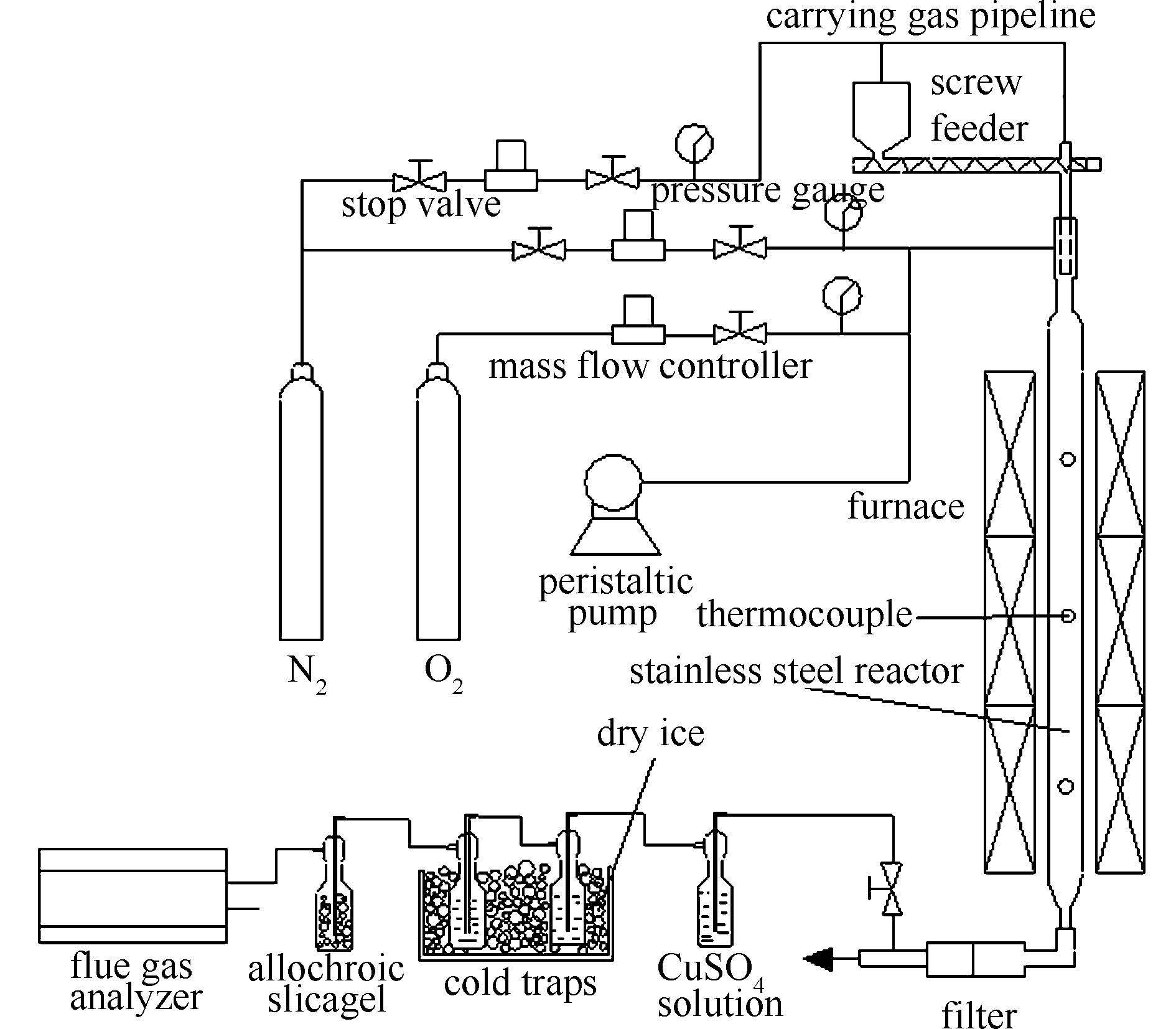

摘要: 在φ80×3 000 mm耐高温不锈钢管反应器中,进行了N2/N2+O2/N2+H2O/N2+O2+H2O气氛下800和900℃的胜利褐煤气化实验,采用红外光谱、X射线光电子能谱、拉曼光谱和烟气在线分析等研究了添加氧气前后半焦的物理结构、官能团及煤气组成的变化,旨在探讨氧化反应促进水蒸气气化反应的作用机理。结果表明,氧化反应对水蒸气气化反应的促进作用可用半焦的微观结构变化和水蒸气气化解离吸附机理解释。氧化反应的开孔和扩孔作用使碳颗粒微孔数量、比表面积、孔容、吸附量明显增加,更多的碳表面活性位暴露出来,也促进了半焦中甲基、亚甲基、C=O键、C-O键的断裂和高活性的羧基COO-和大量氢自由基的生成,这些都有利于水蒸气气化反应的进行,尤其在高温和水蒸气含量较高时。同时,氧气的加入改变了反应气氛中CO2、CO、H2相对含量和水蒸气分子/活性炭原子内能,也有利于水蒸气气化反应的进行,这与水蒸气气化解离吸附机理相吻合。Abstract: Shengli brown coal was gasified at 800-900℃ in a simulated entrained-flow reactor, φ 80×3 000 mm.The physical structure and functional groups of char were tested by infrared spectroscopy, X-ray photoelectron spectroscopy and Raman spectroscopy while coal gas was tested by gas on-line analysis instrument in order to explore the mechanism of promoting effect of oxidation reaction on steam gasification reaction.The results show that the synergy effects can be explained by dissociated adsorption reaction mechanisms of steam gasification reaction and semi-coke pore structure features under different atmospheres.The oxidation reaction can make microspores number, specific surface area, pore volume and adsorption capacity of the char particles greatly increase and more carbon active sites expose by producing microspores, developing mesopores;it also prompts small groups as-CH3, -CH2-, > C=O & > C-O-fractured and generation of hydrogen free-radical and carboxyl.All these promote steam gasification reaction rate, especially at a higher water vapor content or temperature.Meanwhile, the oxidation reaction can change the relative content of CO2, CO, H2 and internal energy of steam molecules and activated carbon atoms, in favor of steam gasification reaction.

-

Key words:

- mild gasification /

- synergistic effect /

- steam gasification /

- pore structure /

- dissociated adsorption

-

表 1 胜利褐煤的工业分析和元素分析

Table 1 Proximate and ultimate analysis of material

Material Proximate analysis w/% Elemental analysis wdaf/% Mad A V FC C H S O N Shengli lignite 5.89 9.87 36.23 53.90 62.26 6.12 0.66 29.85 1.11 表 2 氧交换机理和水蒸气解离吸附机理

Table 2 Oxygen-exchange & dissociative adsorption mechanisms for steam gasification reaction

Oxygen-exchange mechanisms Dissociative adsorption mechanisms H2O+Cf C(H)+C(OH) Adsorption of water molecules H2O+Cf H2+C(O) C(OH)+Cf→C(H)+C(O) and the formation of H2 C(H) 1/2H2+Cf Formation of CO C(O)→CO C(O)→CO Formation of CO2 CO+C(O) CO2+Cf CO+C(O) CO2+Cf -

[1] LEE J G, KIM J H, LEE H G. Characteristics of entrained flow coal gasification in a drop tube reactor[J]. Fuel, 1996, 75(9):1035-1042. doi: 10.1016/0016-2361(96)00084-1 [2] ZENG X, WANG Y, YU J, WU S S, ZHONG M, XU S P, XU G W. Coal pyrolysis in a fluidized bed for adapting to a two-stage gasification process[J]. Energy Fuels, 2011, 25(3):1092-1098. doi: 10.1021/ef101441j [3] CMOMARKOVIC N, REPIC B, MLADENOVIC R, NESKOVICO, VELJKOVIC M. Experimental investigation of role of steam in entrained flow coal gasification[J]. Fuel, 2007, 86(1):194-202. [4] LI T T, ZHANG L, DONG L, LI C Z. Effects of gasification atmosphere and temperature on char structural evolution during the gasification of Collie sub-bituminous coal[J]. Fuel, 2014, 117(part B):1190-1195. [5] TAY H L, KAJITAANI S, ZHANG S, LI C Z. Effects of gasifying agent on the evolution of char structure during the gasification of Victorian brown coal[J]. Fuel, 2013, 103:22-28. doi: 10.1016/j.fuel.2011.02.044 [6] TAY H L, LI C Z. Changes in char reactivity and structure during the gasification of a Victorian brown coal:Comparison between gasification in O2 and CO2 [J]. Fuel Process Technol, 2010, 91(8):800-804. doi: 10.1016/j.fuproc.2009.10.016 [7] ZHANG S, HAYASHI J I, LI C Z. Volatilization and catalytic effects of alkali and alkaline earth metallic species during the paralysis and gasification of Victorian brown coal. Part IX. Effects of volatile-charinteractions on char-H2O and char-O2 reactivates[J]. Fuel, 2011, 90(4):1655-1661. doi: 10.1016/j.fuel.2010.11.008 [8] ZHANG S, MIN Z H, TAY HL, ASADULLAH M, LI C Z. Effects of volatile-char interactions on the evolution of char structure during the gasification of Victorian brown coal in steam[J]. Fuel, 2011, 90(4):1529-1535. doi: 10.1016/j.fuel.2010.11.010 [9] WU H W, LI X J, HAYASHI J I, CHIBA T, LI C Z. Effects of volatile-char interactions on the reactivity of chars from NaCl-loaded Loy Yang brown coal[J]. Fuel, 2005, 84(10):1221-1228. doi: 10.1016/j.fuel.2004.06.037 [10] WANG F J, ZHANG S, CHEN Z D, LIU C, WANG Y G. Tar reforming using char as catalyst during pyrolysis and gasification of Shengli brown coal[J]. J Anal Appl Pyrolysis, 2014, 105:269-275. doi: 10.1016/j.jaap.2013.11.013 [11] 王永刚, 孙加亮, 张书. 反应气氛对褐煤气化反应性及半焦结构的影响[J]. 煤炭学报, 2014, 39(8):1765-1771. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201408051.htmWANG Yong-gang, SUN Jia-liang, ZHANG Shu. Impacts of the gas atmosphere on the gasification reactivity and char structure of the brown coal[J]. J China Coal Soc, 2014, 39(8):1765-1771. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201408051.htm [12] 孙加亮, 陈绪军, 王芳, 林雄超, 王永刚. 氧气对胜利褐煤水蒸气气化半焦结构及反应性的影响[J]. 燃料化学学报, 2015, 43(7):769-778. doi: 10.1016/S1872-5813(15)30023-2SUN Jia-liang, CHEN Xu-jun, WANG Fang, LIN Xiong-chao, WANG Yong-gang. Effects of oxygen on the structure and reactivity of char during steam gasification of Shengli brown coal[J]. J Fuel Chem Technol, 2015, 43(7):769-778. doi: 10.1016/S1872-5813(15)30023-2 [13] 程相龙, 王永刚, 孙加亮, 申恬, 张海永, 许德平. 氧化反应对胜利褐煤水蒸气气化反应的促进作用Ⅰ:宏观反应特性研究[J]. 燃料化学学报, 2017, 45(1):15-20. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18956.shtmlCHENG Xiang-long, WANG Yong-gang, SUN Jia-liang, SHEN Tian, ZHANG Hai-yong, XU De-ping. Promoting effect of oxidation reaction on steam gasification reaction in Shengli lignite gasification process I:Macroscopic reaction characteristic[J]. J Fuel Chem Technol, 2017, 45(1):15-20. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18956.shtml [14] SHU X Q, XU X C. Study on morphology of chars from coal pyrolysis[J]. Energy Fuels, 2001, 15(6):1347-1353. doi: 10.1021/ef000202g [15] 吴仕生, 曾玺, 任明威, 汪印, 徐绍平, 许光文. 含氧/蒸气气氛中煤高温分解产物分布及反应性[J]. 燃料化学学报, 2012, 40(6):660-665. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17960.shtmlWU Shi-sheng, ZENG Xi, REN Ming-wei, WANG Yin, XU Shao-ping, XU Guang-wen.Product distribution andreactivity of coal pyrolysis at high temperature and in atmospheres containing O2/H2O[J]. J Fuel Chem Technol, 2012, 40(6):660-665. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17960.shtml [16] JOCHEN S, TORE M. Reduction of a detailed reaction mechanism for hydrogen combustion under gas turbine conditions[J]. Combust Flame, 2006, 144(3):545-557. doi: 10.1016/j.combustflame.2005.08.011 [17] ALESSANDRA B, PIO F, ELISEO R. Production of olefins via oxidative dehydrogenation of propane in autothermalconditions[J]. J Catal, 1999, 184(2):469-478. doi: 10.1006/jcat.1999.2447 [18] 许修强, 王永刚, 陈宗定, 白磊, 张锟俊, 杨萨莎, 张书. 胜利褐煤半焦冷却处理对其微观结构及反应性能的影响[J]. 燃料化学学报, 2015, 43(1):1-8. doi: 10.1016/S1872-5813(15)60005-6XU Xiu-qiang, WANG Yong-gang, CHEN Zong-ding, BAI Lei, ZHANG Kun-jun, YANG Sa-sha, ZHANG Shu. Influence of cooling treatments on char microstructure and reactivity of Shengli brown coal[J]. J Fuel Chem Technol, 2015, 43(1):1-8. doi: 10.1016/S1872-5813(15)60005-6 [19] 许修强, 王永刚, 张书, 陈宗定, 陈绪军, 贺欣. 褐煤原位气化半焦的反应性及微观结构的演化行为[J]. 燃料化学学报, 2015, 43(3):273-280. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18585.shtmlXU Xiu-qiang, WANG Yong-gang, ZHANG Shu, CHEN Zong-ding, CHEN Xu-jun, HE Xin. Evolution behavior of reactivity and microstructure of lignite char during in-situ gasification with steam[J]. J Fuel Chem Technol, 2015, 43(3):273-280. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18585.shtml [20] 孙加亮, 王永刚, 王芳, 张锟俊, 王会, 张书. H2O/O2气氛下胜利褐煤气化半焦的孔隙特性[J]. 化工进展, 2015, 34(3):695-700.SUN Jia-liang, WANG Yong-gang, WANG Fang, ZHANG Kun-jun, WANG Hui, ZHANG Shu. Porosity characteristics of chars from Shengli brown coal gasification under H2O/O2 atmospheres[J]. Chem Ind Eng Prog(China), 2015, 34(3):695-700. [21] PERRY D L, GRINT A. Application of XPS to coal characterization[J]. Fuel, 1983, 62(9):1024-1033. doi: 10.1016/0016-2361(83)90135-7 [22] KELEMEN S R, AFEWORKI A M, GORBATY M L, COHEN A D. Characterization of organically bound oxygen forms in lignites, peats, and pyrolyzed peats by X-ray photoelectron spectroscopy (XPS) and solid-state 13C NMR methods[J]. Energy Fuels, 2002, 16(6):1450-1462. doi: 10.1021/ef020050k [23] GRZYBEK T, KREINER K. Surface changes in coals after oxidation. 1. X-ray photoelectron spectroscopy studies[J]. Langmuir, 1997, 13(5):909-912. doi: 10.1021/la9510893 [24] FAURE P, VILMIN F, MICHELS R, JARDE E. Application of thermodesorption and pyrolysis-GC-AED to the analysis of river sediments and sewage sludges for environmental purpose[J]. J Anal Appl Pyrolysis, 2002, 62(2):297-318. doi: 10.1016/S0165-2370(01)00127-9 [25] 常海洲, 王传格, 曾凡桂, 李军, 李文英, 谢克昌. 不同还原程度煤显微组分组表面结构XPS对比分析[J]. 燃料化学学报, 2006, 34(4):389-394. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17034.shtmlCHANG Hai-zhou, WANG Chuan-ge, ZENG Fan-gui, LI Jun, LI Wen-ying, XIE Ke-chang. XPS comparative analysis of coal macerals with different reducibility[J]. J Fuel Chem Technol, 2006, 34(4):389-394. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17034.shtml [26] 向军, 胡松, 孙路石, 徐明厚, 李培生, 苏胜, 孙学信. 煤燃烧过程中碳、氧官能团演化行为[J]. 化工学报, 2006, 57(9):2180-2184. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ200609031.htmXIANG Jun, HU Song, SUN Lu-shi, XU Ming-hou, LI Pei-sheng, SU Sheng, SUN Xue-xin. Evolution of carbon and oxygen functional groups during coal combustion[J]. CIESC J(China), 2006, 57(9):2180-2184. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ200609031.htm [27] TAY H L, KAJITANI S, ZHANG S, LI C Z. Inhibiting and other effects of hydrogen during gasification:Further insights from FT-Raman spectroscopy[J]. Fuel, 2014, 116:1-6. doi: 10.1016/j.fuel.2013.07.066 [28] ERGUN S. Kinetics of the reactions of carbon dioxide and steam with coke(No. Bulletin 598)[R]. Washington:United States Government Printing Office, 1962. [29] JOHNSON J L. Kinetics of coal Gasification[M]. New York:John Willy and Sons, 1979. [30] 贺永德. 现代煤化工技术手册[M]. 2版. 北京:化学工业出版社, 2011.HE Yong-de. Modern Coal Chemical Industry Technical Manuals[M]. 2nd ed. Beijing:Chemical Industry Press, 2001. [31] WALKER P L, RUSINKO F, AUSTIN L G. Gas reactions of carbon[J]. Adv Catal, 1959, 11:133-221. [32] PILCHER J M, WALKER P L, WRIGHT C C. Kinetic study of the steam-carbon reaction-influence of temperature, partial pressure of water vapor, and nature of carbon on gasification rates[J]. Ind Eng Chem, 1955, 47(9):1742-1749. doi: 10.1021/ie50549a021 [33] LONG FJ, SYKES KW. The mechanism of the steam-carbon reaction[J]. Proc Roy Soc, 1948, A193:377-99. [34] BAYARSAIKHAN B, SONOYAMA N, HOSOKAI S, SHIMADA T. Inhibition of steam gasification of char by volatiles in a fluidized bed under continuous feeding of a brown coal[J]. Fuel, 2006, 85(3):340-349. doi: 10.1016/j.fuel.2005.06.001 -

下载:

下载: