Catalytic decomposition of N2O over Y-Co3O4 composite oxides prepared by one-step hydrothermal method

-

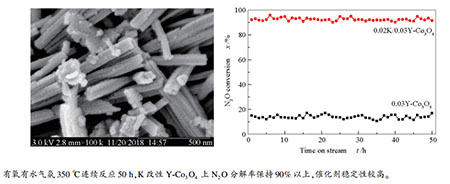

摘要: 用一步水热、分步水热、浸渍等方法分别制备Y-Co3O4复合氧化物,用于催化分解N2O的反应,其中,一步水热法制备的催化剂活性较高。再用一步水热法制备了不同Y/Co物质的量比的Y-Co3O4复合氧化物,在优化出的催化剂(0.03Y-Co3O4)表面浸渍K2CO3溶液,制备K改性催化剂(0.02K/0.03Y-Co3O4)。用X射线衍射(XRD)、N2物理吸附、H2程序升温还原(H2-TPR)、O2程序升温脱附(O2-TPD)、扫描电镜(SEM)、X射线光电子谱(XPS)等技术表征催化剂结构。研究发现,Co3O4和Y-Co3O4同为尖晶石结构,但Y-Co3O4的催化活性显著高于Co3O4。K改性增加了催化剂表面的活性位(Co2+),还有利于吸附氧的脱除,从而提高了催化剂活性。在无氧无水、有氧无水、有氧有水气氛中,K改性催化剂上的N2O全分解温度分别为325、350、375 ℃,催化剂活性较高。有氧有水气氛350 ℃连续反应50 h,K改性催化剂上N2O分解率保持90%以上,稳定性较高。研究发现,Y-Co3O4及K改性催化剂上N2O分解反应的Ea和lnA之间存在动力学补偿效应。

-

关键词:

- N2O催化分解 /

- Y-Co3O4复合氧化物催化剂 /

- K改性催化剂 /

- 一步水热合成 /

- 催化活性

Abstract: Y-Co3O4 catalysts with Y/Co molar ratio of 0.03 were prepared by several methods, such as one-step hydrothermal, two-step hydrothermal, and impregnation methods, to catalyze the decomposition of N2O. Among these catalysts, the one prepared by one-step hydrothermal method exhibited the highest activity, and then the Y-Co3O4 catalysts with various molar ratios of Y/Co were synthesized by one-step hydrothermal method. Subsequently, the optimized 0.03Y-Co3O4 was impregnated by K2CO3 solution to prepare K-modified catalyst and named as 0.02K/0.03Y-Co3O4. These catalysts were characterized by X-ray diffraction (XRD), nitrogen physisorption, hydrogen temperature-programmed reduction (H2-TPR), oxygen temperature-programmed desorption (O2-TPD), scanning electron microscopy (SEM), and X-ray photoelectron spectroscopy (XPS) techniques. The results show that both Co3O4 and Y-Co3O4 exhibit spinel structure, however Y-doped Co3O4 catalysts are more active than bare Co3O4. After further modified by potassium, the 0.02K/0.03Y-Co3O4 reveals higher activity due to the more active sites (Co2+) and easier desorption of surface oxygen species than un-modified 0.03Y-Co3O4. In detail, the temperatures of N2O full conversion over 0.02K/0.03Y-Co3O4 catalyst are 325, 350, 375℃, under the reaction atmospheres of 1%N2O+Ar, 1%N2O+2%O2+Ar, 1%N2O+2%O2+8.2%H2O+Ar, respectively. In addition, over 90% conversion of N2O can be maintained at 350℃ after continuous reaction for 50 h in the co-presence of oxygen and steam on K-modified Y-Co3O4 catalyst. There is a dynamic compensation effect between apparent activation energy (Ea) and pre-exponential factor (A) in N2O decomposition over Y-Co3O4 and K-modified catalysts.-

Key words:

- catalytic decomposition of N2O /

- Y-Co3O4 composite oxides /

- K-modified catalyst /

- one-step hydrothermal method /

- catalytic activity

-

Table 1 Specific surface area of Y-Co3O4 catalysts with various Y/Co molar ratios

Y-Co3O4 catalyst Specific surface area A/(m2·g-1) Co3O4 28.5 Y/Co=0.01 47.7 Y/Co=0.02 61.2 Y/Co=0.03 72.7 Y/Co=0.04 70.8 Y/Co=0.05 80.3 Table 2 Kinetic data of N2O decomposition on Y-Co3O4 catalysts with various Y/Co molar ratios

Catalyst k/s-1 Ea/(kJ·mol-1) lnA 275 ℃ 300 ℃ 325 ℃ 350 ℃ 375 ℃ Co3O4 0.26 0.67 1.37 3.02 4.73 86.7 17.7 Y/Co=0.01 0.41 1.18 2.49 4.58 7.29 79.9 16.9 Y/Co=0.02 0.51 1.17 2.50 4.47 7.15 78.5 16.6 Y/Co=0.03 0.50 1.25 2.58 4.57 6.77 77.6 16.4 Y/Co=0.04 0.29 0.90 2.02 3.80 6.28 90.2 18.7 Y/Co=0.05 0.26 0.87 1.82 3.49 5.81 90.7 18.7 Table 3 Kinetic data of N2O decomposition over 0.03Y-Co3O4 and K-modified catalysts under various reaction atmospheres

Reaction atmospheres 0.03Y-Co3O4 catalyst 0.02K/0.03Y-Co3O4 catalyst Ea /(kJ·mol-1) lnA Ea /(kJ·mol-1) lnA 1%N2O+Ar 77.6 16.4 63.9 15.5 1%N2O+2%O2+Ar 91.6 18.7 76.6 18.0 1%N2O+2%O2+8.2%H2O+Ar 110.0 20.6 86.8 19.2 -

[1] REILLY J, PRINN R, HARNISCH J, FITZMAURICE J, JACOBY H, KICKLIGHTER D, MELILLO J, STONE P, SOKOLOV A, WANG C. Multi-gas assessment of the Kyoto Protocol[J]. Nature, 1999, 401:549-555. doi: 10.1038/44069 [2] ZHENG L, LI H J, XU X F. Catalytic decomposition of N2O over Mg-Co composite oxides hydrothermally prepared by using carbon sphere as template[J]. J Fuel Chem Technol, 2018, 46(5):569-577 doi: 10.1016/S1872-5813(18)30024-0 [3] YAN L, REN T, WANG X L, JI D, SUO J S. Catalytic decomposition of N2O over MxCo1-xCo2O4(M=Ni, Mg) spinel oxides[J]. Appl Catal B:Environ, 2003, 45(2):85-90. doi: 10.1016/S0926-3373(03)00174-7 [4] IVANOVA Y A, SUTORMINA E F, ISUPOVA L A, ROGOV V A. Effect of the composition of NixCo3-xO4(x =0-0.9) oxides on their catalytic activity in the low-temperature reaction of N2O decomposition[J]. Kinet Catal, 2018, 59(3):365-370. [5] DOU Z, ZHANG H J, PAN Y F, XU X F. Catalytic decomposition of N2O over potassium-modified Cu-Co spinel oxides[J]. J Fuel Chem Technol, 2014, 42(2):238-245. doi: 10.1016/S1872-5813(14)60016-5 [6] FRANKEN T, PALKOVITS R. Investigation of potassium doped mixed spinels CuxCo3-xO4 as catalysts for an efficient N2O decomposition in real reaction conditions[J]. Appl Catal B:Environ, 2015, 176/177:298-305. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=32c40fec229970f8343d2616d47ad12c [7] WANG Y Z, HUO X B, ZHANG K, WEI X H, ZHAO Y X. Effect of SnO2 on the structure and catalytic performance of Co3O4 for N2O decomposition[J]. Catal Commun, 2018, 111:70-74. doi: 10.1016/j.catcom.2018.04.004 [8] TURSUN M, WANG X P, ZHANG F, YU H B. Bi-Co3O4 catalyzing N2O decomposition with strong resistance to CO2[J]. Catal Commun, 2015, 65:1-5. doi: 10.1016/j.catcom.2015.02.013 [9] YU H B, TURSUN M, WANG X P, WU X X. Pb0.04Co catalyst for N2O decomposition in presence of impurity gases[J]. Appl Catal B:Environ, 2016, 185:110-118. doi: 10.1016/j.apcatb.2015.12.011 [10] YU H B, WANG X P, WU X X, CHEN Y. Promotion of Ag for Co3O4 catalyzing N2O decomposition under simulated real reaction conditions[J]. Chem Eng J, 2018, 334:800-806. doi: 10.1016/j.cej.2017.10.079 [11] KIM M J, LEE S J, RYU I S, JEON M W, MOON S H, ROH H S, JEON S G. Catalytic decomposition of N2O over cobalt based spinel oxides:The role of additives[J]. Mol Catal, 2017, 422:202-207. [12] XUE L, HE H, LIU C, ZHANG C B, ZHANG B. Promotion effects and mechanism of alkali metals and alkaline earth metals on cobalt-cerium composite oxide catalysts for N2O decomposition[J]. Environ Sci Technol, 2009, 43(3):890-895. doi: 10.1021/es801867y [13] DZIEMBAJR, ZAITZ MM, RUTKOWSKAM, MOLENDAM, CHMIELARZL.Nanostructured Co-Ce-O systems for catalytic decomposition of N2O[J]. Catal Today, 2012, 191(1):121-124. doi: 10.1016/j.cattod.2012.02.045 [14] YOU Y, CHANG H, MA L, GUO L, QIN X, LI J Y, LI J H. Enhancement of N2O decomposition performance by N2O pretreatment over Ce-Co-O catalyst[J]. Chem Eng J, 2018, 347:184-192. doi: 10.1016/j.cej.2018.04.081 [15] ABUZIED B M, BAWAKED S M, KOSA S A, SCHWIEGER W. Effect of Pr, Sm, and Tb doping on the morphology, crystallite size, and N2O decomposition activity of Co3O4 nanorods[J]. J Nanomater, 2015, 56(12):1417-1423. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Doaj000004122728 [16] GRANGER P, ESTEVES P, KIEGER S, NAVASCUES L, LECLERCQ G. Effect of yttrium on the performances of zirconia based catalysts for the decomposition of N2O at high temperature[J]. Appl Catal B:Environ, 2006, 62:236-243. doi: 10.1016/j.apcatb.2005.07.015 [17] ABU-ZIED B M, BAWAKED S M, KOSA S A, ALI T T, SCHWIEGER W, AQLAN F M. Effects of Nd-, Pr-, Tb-and Y-doping on the structural, textural, electrical and N2O decomposition activity of mesoporous NiO nanoparticles[J]. Appl Surf Sci, 2017, 419:399-408. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ec49120e4200154b11a1ad6fe130f0f7 [18] ABU-ZIED B M, BAWAKED S M, KOSA S A, SCHWIEGER W. Impact of Gd-, La-, Nd-and Y-doping on the textural, electrical conductivity and N2O decomposition activity of CuO catalyst[J]. Int J Electrochem Sci, 2016, 11:2230-2246. [19] QIU Y J, HUANG S Q, PANG Z T, SONG Y J, WANG X C, LI C Q, WANG H. Catalytic decomposition of N2O over CuYO/γ-Al2O3 catalysts[J]. Environ Chem, 2018, 37(7):1591-1598. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjhx201807016 [20] LIU Z M, HE C X, CHEN B H, LIU H Y. CuO-CeO2 mixed oxide catalyst for the catalytic decomposition of N2O in the presence of oxygen[J]. Catal Today, 2017, 297:78-83. doi: 10.1016/j.cattod.2017.05.074 [21] PAN Y F, FENG M, CUI X, XU X F. Catalytic activity of alkali metal doped Cu-Al mixed oxides for N2O decomposition in the presence of oxygen[J]. J Fuel Chem Technol, 2012, 40(5):601-607. doi: 10.1016/S1872-5813(12)60024-3 [22] STELMACHOWSKI P, MANIAK G, KOTARBA A, SOJKA Z. Strong electronic promotion of Co3O4 towards N2O decomposition by surface alkali dopants[J]. Catal Commun, 2009, 10(7):1062-1065. doi: 10.1016/j.catcom.2008.12.057 [23] LI H J, ZHENG L, ZHAO T Q, XU X F. Effect of preparation parameters on the catalytic performance of hydrothermally synthesized Co3O4 in the decomposition of N2O[J]. J Fuel Chem Technol, 2018, 46(6):717-724. doi: 10.1016/S1872-5813(18)30031-8 -

下载:

下载: