-

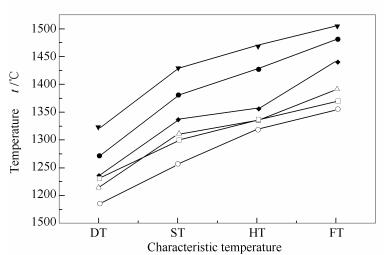

摘要: 利用灰熔融性测定仪、X射线衍射仪、扫描电子显微镜研究了温度、气氛、残炭含量对茌平、宿迁循环流化床气化细粉灰熔融特性的影响。结果表明,弱还原气氛下两种气化细粉灰的熔融温度最低。高温下莫来石的出现导致宿迁气化细粉灰灰熔点明显高于茌平气化细粉灰。两种循环流化床气化细粉灰的熔融特征温度均随着残炭含量的上升而升高,当残炭含量超过3%,温度超过1300 ℃时,两种气化细粉灰均会产生碳硅石。碳硅石的存在是使气化细粉灰熔融性变差的主要原因。Abstract: Effects of temperature, atmosphere and residual carbon on melting behavior and mineral transition mechanism of fine ash from Chiping and Suqian circulating fluidized bed gasifier at high temperature was studied using fusion point analyzer, X-ray diffraction (XRD), and scanning electron microscopy (SEM). The results show that ash fusion temperature of two fine ash is the lowest under reducing atmosphere. The existence of mullite is the major reason for the higher ash fusion temperature of Suqian fine ash than that of Chiping. The ash fusion temperature increases with increasing mass fraction of residual carbon. When temperature is above 1300℃ and the mass fraction of residual carbon is more than 3%, moissanite is formed in slags of both fine ashes. Moissanite is mainly responsible for the worse fusibility of ash with higher content of residual carbon.

-

Key words:

- circulating fluidized bed gasification /

- fine ash /

- ash fusibility /

- residual carbon

-

图 6 添加了不同石墨含量的宿迁气化细粉灰的XRD谱图

Figure 6 XRD patterns of SQ fine ash with different graphite contents under inert atmosphere

1: mullite; 2: anorthite; 3: quartz; 4: moissanite; 5: corundum; 6: iron; 7: oldhamite; 8: fersilicite; 9: iron silicon; 10: halite; 11: cohenite (a): SQ-3%; (b): SQ-5%; (c): SQ-10%; (d): SQ-15%

表 1 茌平、宿迁气化细粉灰的工业分析和元素分析

Table 1 Proximate analysis and ultimate analysis of the fine ash

Sample Proximate analysis wad/% Ultimate analysis wad/% M A V FC C H O N S CP 0.68 33.78 1.98 63.58 65.66 0.78 0.00 0.43 0.94 SQ 0.06 60.66 0.67 38.61 39.08 0.20 0.00 0.26 1.62 表 2 茌平、宿迁气化细粉灰灰成分分析

Table 2 Ash compositions of fine ash from chiping and suqian

Sample Ash compositions w/% SiO2 Al2O3 Fe2O3 CaO MgO SO3 TiO2 P2O5 K2O Na2O CP 51.52 27.29 2.85 6.98 1.15 6.27 0.51 0.46 1.00 1.98 SQ 44.93 33.67 5.71 5.81 0.97 5.02 1.27 0.38 1.27 0.85 -

[1] 屈利娟.流化床煤气化技术的研究进展[J].煤炭转化, 2007, 30(2):81-85. http://www.doc88.com/p-106817534977.htmlQU Li-juan. Research on fluidized bed gasification technology[J]. Coal Convers, 2007, 20(2):81-85. http://www.doc88.com/p-106817534977.html [2] 黄戒介, 房倚天, 王洋.现代煤气化技术的开发与进展[J].燃料化学学报, 2002, 30(5):385-391. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb200205001HUANG Jie-jie, FANG Yi-tian, WANG Yang. Development of modern coal gasification technology[J]. J Fuel Chem Technol, 2002, 30(5):385-391. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb200205001 [3] 谢克昌.煤化工发展与规划[M].北京:化学工业出版社, 2005:11-12.XIE Ke-chang. Focus on Coal Chemical Engineering[M]. Beijing:Chemical Industry Press, 2005:11-12. [4] 陈晓辉, 贾亚龙, 冯杰, 房倚天, 李文英.流化床-气流床耦合反应器中煤气化特性[J].化工学报, 2011, 92(12):3484-3491. doi: 10.3969/j.issn.0438-1157.2011.12.027CHEN Xiao-hui, JIA Ya-long, FENG Jie, FANG Yi-tian, LI Wen-ying. Coal gasification performance in fluidized bed-entrained flow integrated reactor[J]. CIESC Journal, 2011, 62(12):3484-3491. doi: 10.3969/j.issn.0438-1157.2011.12.027 [5] WU J K, FANG Y T, PENG H, WANG Y. A new integrated approach of coal gasification:the concept and preliminary experimental results[J]. Fuel Process. Technol, 2004, 86(3):261-266. doi: 10.1016/j.fuproc.2004.03.005 [6] 周祖旭, 么瑶, 朱建国, 欧阳子区, 贺坤, 吕清刚.煤气化残炭的预热燃烧试验研究[J].锅炉技术, 2015, 46(5):39-43. http://d.old.wanfangdata.com.cn/Periodical/gljs201505009ZHOU Zu-xu, MO Yao, ZHU Jian-guo, OU-Yang Zi-Qu, HE Kun, LV Qing-gang. Experimental research on preheating combustion of coal gasification residual carbon[J]. Boiler Technology, 2015, 46(5):39-43. http://d.old.wanfangdata.com.cn/Periodical/gljs201505009 [7] KELEBOPILE L, SUN R, WANG H, ZHANG X, WU S H. Pore development and combustion behavior of gasified semi-char in a drop tube furnace[J]. Fuel Process Technol, 2013, 111(8):42-54. https://www.sciencedirect.com/science/article/pii/S0378382013000465 [8] KELEBOPILE L, SUN R, LIAO J. Fly ash and coal char reactivity from Thermo-gravimetric (TGA) experiments[J]. Fuel Process Technol, 2011, 92(6):1178-1186. doi: 10.1016/j.fuproc.2011.01.007 [9] 姜永海, 席北斗, 李秀金, 王琪, 张晓萱.垃圾焚烧飞灰熔融固化处理过程特性分析[J].环境科学, 2005, 26(3):176-179. http://www.oalib.com/paper/4735699JIANG Yong-hai, XI Bei-dou, LI You-jin, WANG Qi, ZHANG Xiao-xuan. Characteristics of melting and solidification process of fly ash from refuse incinerator[J]. J Enviror Sci-China, 2005, 26(3):176-179. http://www.oalib.com/paper/4735699 [10] 别如山.垃圾焚烧飞灰旋风炉高温熔融处理技术[J].电站系统工程, 2010, (5):45-49. http://d.wanfangdata.com.cn/Periodical_dzxtgc201004004.aspxBIE Ru-shan. Cyclone furnace technology disposing fly ash from MSW incineration plant[J]. Power System Eng, 2010, (5):45-49. http://d.wanfangdata.com.cn/Periodical_dzxtgc201004004.aspx [11] REN Q Q, BAO S L. Combustion characteristics of ultrafine gasified semi-char in circulating fluidized bed[J]. Can J Chem Eng, 2016, 94(9):1676-1682. doi: 10.1002/cjce.v94.9 [12] ZHANG H, ZHU Z, DONG Q. Structural properties and gasification reactivity of Shenmu fly ash obtained from a 5 t/d circulating fluidized bed gasifier[J]. Procedia Eng, 2015, 102:1104-1111. doi: 10.1016/j.proeng.2015.01.233 [13] 张玉魁, 张海霞, 朱治平.准东煤流化床气化飞灰的理化特性研究[J].燃料化学学报, 2016, 44(3):305-313. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18794.shtmlZHANG Yu-kui, ZHANG Hai-xia, ZHU Zhi-ping. Research on physical and chemical properties of fly ash from fluidized bed gasification of Zhundong coal[J]. J Fuel Chem Technol, 2016, 44(3):305-313. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18794.shtml [14] 杨鑫, 黄戒介, 房倚天, 王洋.无烟煤流化床气化飞灰的结渣特性[J].燃料化学学报, 2013, 41(1):1-8. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18092.shtmlYANG Xin, HUANG Jie-jie, FANG Yi-tian, WANG Yang. Slagging characteristics of fly ash from anthracite gasification in fluidized bed[J]. J Fuel Chem Technol, 2013, 41(1):1-8. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18092.shtml [15] OBOIRIEN B O, ENGELBRECHT A D, NORTH B C. Mineral-char interaction during gasification of high-ash coals in fluidized-bed gasification[J]. Energy & Fuels, 2011, 25(11):5189-5199. doi: 10.1021/ef201056j [16] CHEN D X, TANG L H, ZHOU Y M. Effect of char on the melting characteristics of coal ash[J]. J Fuel Chem Technol, 2007, 35(2):136-140. doi: 10.1016/S1872-5813(07)60014-0 [17] 李风海, 黄戒介, 房倚天, 王洋.霍林河褐煤灰熔融特性的影响因素[J].煤炭转化, 2010, 33(4):9-13. http://d.old.wanfangdata.com.cn/Periodical/mtzh201004003LI Feng-hai, HUANG Jie-jie, FANG Yi-tian, WANG Yang. Effect of the melting characteristics of Huolinhe lignite ash[J]. Coal Convers, 2010, 33(4):9-13. http://d.old.wanfangdata.com.cn/Periodical/mtzh201004003 [18] KONG L X, BAI J, LI W. The internal and external factor on coal ash slag viscosity at high temperatures, Part 2:Effect of residual carbon on slag viscosity[J]. Fuel, 2015, 158:976-982. doi: 10.1016/j.fuel.2015.06.055 [19] 董一真. 煤灰中成分结渣特性研究[D]. 杭州: 浙江大学, 2006. http://cdmd.cnki.com.cn/Article/CDMD-10335-2006175829.htmDONG Yi-zhen. Study on the slagging characteristics of main components in coal ash[D]. Hangzhou: Zhejiang university, 2006. http://cdmd.cnki.com.cn/Article/CDMD-10335-2006175829.htm [20] VASSILEV S V, KITANO K, VASSILEVA C G. Some relationships between coal rank and chemical and mineral composition[J]. Fuel, 1996, 75(13):1537-1542. doi: 10.1016/0016-2361(96)00116-0 [21] 黄继武, 李周.多晶材料X射线衍射-实验原理方法与应用[M].北京:冶金工业出版社, 2013.HUANG Ji-wu, LI Zhou. X-ray Diffraction of Polycrystalline Materials[M]. Beijing:Metallurgical Industry Press, 2013. [22] VAN D J C, MELZER S, SOBIECKI A. Mineral matter transformation during Sasol-Lurgi fixed bed dry bottom gasification-utilization of HT-XRD and FactSage modelling[J]. Miner Eng, 2006, 19(10):1126-1135. doi: 10.1016/j.mineng.2006.03.008 [23] 贾明生, 张乾熙.影响煤灰熔融性温度的控制因素[J].煤化工, 2007, 35(3):1-5. http://d.wanfangdata.com.cn/Periodical_kjcb201310104.aspxJIA Ming-sheng, ZHANG Gan-qian. Key factors affecting fusion temperature of coal ash[J]. Coal Chemical Industry, 2007, 35(3):1-5. http://d.wanfangdata.com.cn/Periodical_kjcb201310104.aspx [24] 宋文佳. 高温煤气化炉中煤灰熔融、流动和流变行为特性研究[D]. 上海: 华东理工大学, 2011. http://cdmd.cnki.com.cn/Article/CDMD-10251-1011175352.htmSONG Wen-jia. Fusibility, flow characteristics and rheological properties of coal ash in the ultra-high temperature gasifier[D]. Shanghai: East China University of Science and Technology, 2011. http://cdmd.cnki.com.cn/Article/CDMD-10251-1011175352.htm [25] VORRES K S. Metling behavior of coal ash materials from coal ash composition[J]. J Eng Power Trans ASME, 1977, 101:118-123. http://www.researchgate.net/publication/242054932_Melting_behavior_of_coal_ash_materials_from_coal_ash_composition [26] VASSILEV S V, KITANO K, TAKEDA S, TSURUE T. Influence of mineral and chemical composition of coal ashes on their fusibility[J]. Fuel Process Technol, 1995, 45(1):27-51. doi: 10.1016/0378-3820(95)00032-3 [27] BAI J, LI W, LI B. Characterization of low-temperature coal ash behaviors at high temperatures under reducing atmosphere[J]. Fuel, 2008, 87(4):583-591. https://www.sciencedirect.com/science/article/pii/S0016236107000919 [28] VAN D J. Understanding the influence of acidic components (Si, Al, and Ti) on ash flow temperature of South African coal sources[J]. Miner Eng, 2006, 19(3):280-286. doi: 10.1016/j.mineng.2005.06.018 [29] 曹敏, 谷小虎, 樊崇, 张爱民.义马煤灰高温下矿物质变化[J].煤炭转化, 2010, 33(1):12-15+21. http://d.old.wanfangdata.com.cn/Periodical/mtzh201001004CAO Min, GU Xiao-hu, FAN Chong, ZHANG Ai-min. Mineral behavior in coal ash at high temperature[J]. Coal Convers, 2010, 33(1):12-15+21. http://d.old.wanfangdata.com.cn/Periodical/mtzh201001004 [30] 乌晓江, 张忠孝, 周托.气化条件下灰的熔融行为及矿物质演变规律[J].工程热物理学报, 2010, 31(9):1590-1594. http://jetp.iet.cn/CN/abstract/abstract7966.shtmlWU Xiao-jiang, ZHANG Zhong-xiao, ZHOU Tuo. Ash melting behavior and mineral transition mechanism under gasification condition[J]. J Eng Thermophys, 2010, 31(9):1590-1594. http://jetp.iet.cn/CN/abstract/abstract7966.shtml [31] NISHI T, HARAGUCHI H, OKUHARA T. Deterioration of coke by ash-carbon reaction in coke during high-temperature treatment[J]. J Fuel Soc Jpn, 1990, 69(2):126-133. doi: 10.3775/jie.69.126 [32] WANG J, ISHIDA R, TAKARADA T. Carbothermal reactions of quartz and kaolinite with coal char[J]. Energy fuels, 2000, 14(5):1108-1114. doi: 10.1021/ef000084x [33] WANG J, MORISHITA K, TAKARADA T. High-temperature interactions between coal char and mixtures of calcium oxide, quartz, and kaolinite[J]. Energy fuels, 2001, 15(5):1145-1152. doi: 10.1021/ef0100092 [34] MA Z B, BAI J, WEN X, LI X, SHI Y, BAI Z, KONG L X, GUO Z, YAN J, LI W. Mineral transformation in char and its effect on coal char gasification reactivity at high temperatures Part 3:Carbon thermal reaction[J]. Energy Fuels, 2014, 28(5):3066-3073. doi: 10.1021/ef5004792 -

下载:

下载: