-

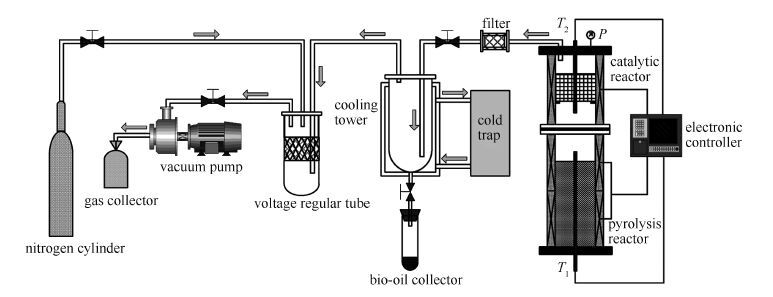

摘要: 以油菜秸秆为原料,采用两种方案分层布置催化剂(HZSM-5/MCM-41和MCM-41/HZSM-5),并与MCM-41和HZSM-5单独催化进行对比,从生物油品质和催化剂耐久性两个角度探究协同催化作用机理;对精制生物油有机相进行理化特性分析,采用FT-IR和GC-MS进行成分分析,对催化剂进行耐久性分析。结果表明,与单独催化相比,协同催化所得精制生物油液相产率略有降低,气相产率升高,精制生物油有机相理化特性进一步提高,其中,MCM-41/HZSM-5协同催化所得精制生物油有机相热值较高,为34.31 MJ/kg;精制生物油有机相中含有多种芳香族类物质和少量的羰基类物质,协同催化较单独催化能产生较多的烃类物质及较少的含氧芳香族类物质,其中,MCM-41/HZSM-5协同催化所得精制生物油有机相中烃类物质含量较高,且以单环芳香烃为主;HZSM-5分子筛在300-800℃有两个失重峰,MCM-41分子筛在300-800℃仅有一个失重峰,表明MCM-41催化剂上沉积的焦炭成分单一,较易去除,且协同催化后分子筛表面沉积的焦炭总含量较少。Abstract: The rape straw was taken as raw materials, and the HZSM-5 and MCM-41 catalysts were used and loaded into bed in two layers with different ways (HZSM-5/MCM-41 and MCM-41/HZSM-5) to explore the synergistic catalytic mechanism on the basis of bio-oil quality and catalyst durability. The physical and chemical characteristics of organic phase in purified bio-oil were analyzed, the compositions were analyzed by FT-IR and GC-MS, and the durability of catalysts was analyzed by TG. The results show that compared with the singular catalytic reaction, the liquid yield from synergistic catalytic reaction lowers somewhat and the gas yield increases. The physciochemical properties of organic phase in purified bio-oil increase and the organic phase obtained from MCM-41/HZSM-5 synergistic catalytic reaction has a relatively higher calorific value, 34.31 MJ/kg. The organic phase in refined bio-oil contains a variety of aromatic substances and a small amount of carbonyl substances, the synergistic catalytic reaction can produce more hydrocarbons and less oxygen-contained aromatic substances. The MCM-41/HZSM-5 synergistic catalytic reaction can produce higher levels of hydrocarbons in organic phase of refined bio-oil, which are mainly in single ring aromatics. There are two weight loss peaks for deactivated HZSM-5 molecular sieve and only one weight loss peak for deactivated MCM-41 molecular sieve in the range of 300-800℃, which show that the coke deposited on the MCM-41 catalyst has a single composition and is easy to remove and the synergistic catalytic reaction forms less coke.

-

Key words:

- rape straw /

- component analysis /

- durability /

- synergistic catalysis

-

表 1 油菜秸秆的元素分析和工业分析

Table 1 Ultimate and proximate analyses of rape straw

Sample Ultimate analysis w/% Proximate analysis wad/% QHHV/(MJ·kg-1) C H Oa N S M V A FC Rape straw 42.22 5.53 51.77 0.41 0.07 6.12 72.84 3.69 17.35 15.92 a: by difference 表 2 MCM-41和HZSM-5孔结构特征参数

Table 2 Pore structure characteristic parameters of MCM-41 and HZSM-5

Catalyst Specific surface area A/(m2·g-1) Pore volume v/(cm3·g-1) MCM-41 791 0.65 HZSM-5 342 0.20 表 3 不同布置方案精制生物油有机相的理化特性

Table 3 Physical properties of refined bio-oil with different layout schemes

Physical property Y0d, b[14] Y1 Y2 Y3 Y4 Diesel fuel Density ρ/(g·cm-3) 1.18 0.98 0.96 0.95 0.97 0.84 pH value 2.10 5.12 5.95 5.84 6.01 ndb Kinematic viscosity v/(mm2·s-1) 8.85 5.87 6.01 5.86 5.14 3-8(20 ℃) QHHV /(MJ·kg-1) 28.44 33.08 33.02 33.56 34.31 45.50 C w /% 59.95 74.67 75.41 76.70 78.80 86.58 H w /% 9.14 8.01 7.71 7.93 8.10 13.29 Oa w /% 30.91 17.32 16.88 15.37 13.10 0.01 a: by difference; b: not determined; d, b: dry base 表 4 不同布置方案精制生物油有机相主要产物

Table 4 Main components of refined bio-oil with different loading ways

Compound Content w/% MCM-41 HZSM-5 HZSM-5/MCM-41 MCM-41/HZSM-5 Toluene 1.67 3.75 Ethylbenzene 6.64 18.63 Benzene, 1-ethyl-2-methyl- 0.47 1.26 6.36 8.44 Indene 1.72 0.58 Benzene, 1, 2, 4, 5-tetramethyl- 4.63 1.23 1H-indene, 2, 3-dihydro-4-methyl- 1.04 1.05 1.34 1H-indene, 1-methyl- 1.7 1.06 Naphthalene 0.89 1.22 0.87 Naphthalene, 2-methyl- 1.16 0.73 1.56 2.35 Naphthalene, 1, 4-dimethyl- 1.16 0.92 1.75 Phenol 4.1 1.79 3.07 3.1 Phenol, 2-methyl- 7.28 1.15 5.46 5.71 Phenol, 2-methoxy- 4.27 6.58 4.91 5 Phenol, 2, 4-dimethyl- 5.65 4.48 3.28 1.79 Phenol, 2-methoxy-4-methyl- 2.42 4.05 2.14 2.56 1, 2-benzenediol, 3-methoxy- 0.93 3.15 1.05 Phenol, 4-ethyl-2-methoxy- 1.87 3.64 1.86 1.84 表 5 不同失活催化剂的积炭含量

Table 5 Coke contents of the deactivated catalysts

Sample M1 H2 H3 M3 M4 H4 Weight loss w/% 20.57 22.85 16.04 11.62 13.43 5.54 -

[1] 徐莹, 王铁军, 马隆龙, 张琦, 陈冠益.真空热解松木粉制备生物油[J].农业工程学报, 2013, 29(1):196-201. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201301028.htmXU Ying, WANG Tie-jun, MA Long-long, ZHANG Qi, CHEN Guan-yi.Technology of bio-oil preparation by vacuum pyrolysis of pine straw[J].Trans Chin Soc Agric Eng, 2013, 29(1):196-201. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201301028.htm [2] 吴创之, 周肇秋, 阴秀丽, 易维明.我国生物质能源发展现状与思考[J].农业机械学报, 2009, 40(1):91-99. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200901021.htmWU Chuang-zhi, ZHOU Zhao-qiu, YIN Xiu-li, YI Wei-ming.Current status of biomass energy development in China[J].Trans Chin Soc Agric Mach, 2009, 40(1):91-99. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200901021.htm [3] BRIDGWATER A V.Review of fast pyrolysis of biomass and product upgrading[J].Biomass Bioenergy, 2012, 38:68-94. doi: 10.1016/j.biombioe.2011.01.048 [4] 谭顺, 张志军, 孙剑平, 王清文.HZSM-5生物质催化裂解的近期研究进展[J].催化学报, 2013, 34(4):641-650. doi: 10.1016/S1872-2067(12)60531-2TAN Shun, ZHANG Zhi-jun, SUN Jian-ping, WANG Qing-wen.Recent progress of catalytic pyrolysis of biomass by HZSM-5[J].Chin J Catal, 2013, 34(4):641-650. doi: 10.1016/S1872-2067(12)60531-2 [5] COURTNEY A F, TONYA M, YAYING J, MARK C, CZARENA C, SAM A.Bio-oil upgrading over platinum catalysts using in situ generated hydrogen[J].Appl Catal A:Gen, 2009, 358(2):150-156. doi: 10.1016/j.apcata.2009.02.006 [6] 张琦, 常杰, 王铁军, 徐莹.生物质裂解油的性质及精制研究进展[J].石油化工, 2006, 35(5):493-498. http://www.cnki.com.cn/Article/CJFDTOTAL-SYHG200605020.htmZHANG Qi, CHANG Jie, WANG Tie-jun, XU Ying.Progress on research of properties and upgrading of bio-oil[J].Petrochem Technol, 2006, 35(5):493-498. http://www.cnki.com.cn/Article/CJFDTOTAL-SYHG200605020.htm [7] 刘荣厚, 黄彩霞, 蔡均猛, 邓春健.生物质热裂解生物油精制的研究进展[J].农业工程学报, 2008, 24(3):308-308. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU200803067.htmLIU Rong-hou, HUANG Cai-xia, CAI Jun-meng, DENG Chun-jian.Research progress in the upgrading of bio-oil from biomass pyrolysis[J].Trans Chin Soc Agric Eng, 2008, 24(3):308-308. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU200803067.htm [8] 骆仲泱, 张晓东, 周劲松, 倪明江, 岑可法.生物质热解焦油的热裂解与催化裂解[J].高校化学工程学报, 2004, 18(2):162-167. http://www.cnki.com.cn/Article/CJFDTOTAL-GXHX200402005.htmLUO Zhong-yang, ZHANG Xiao-dong, ZHOU Jin-song, NI Ming-jiang, CEN Ke-fa.Experimental study on catalytic and thermal cracking of tar from biomass pyrolysis[J].J Chem Eng Chin Univ, 2004, 18(2):162-167. http://www.cnki.com.cn/Article/CJFDTOTAL-GXHX200402005.htm [9] LI G J, ZHAO R Y, BAI L P.Effects of catalysts on pyrolysis of chlorella[J].Microporous Mesoporous Mater, 2012, 433-440:161-165. [10] ADAM J, ANTONAKOU E, LAPPAS A, STOCKER M, MERETE H N, BOUZGA A.In suit catalytic upgrading of biomass derived fast pyrolysis vapours in a fixed bed reactor using mesoporous materials[J].Microporpus Mesoporous Mater, 2006, 96(1/3):93-101. [11] LI H Y, YAN Y J, REN Z W.Online upgrading of organic vapors from the fast pyrolysis of biomass[J].J Fuel Chem Technol, 2008, 36(6):666-671. doi: 10.1016/S1872-5813(09)60002-5 [12] WILLIAMS P T, NITTAYA N.Comparison of products from the pyrolysis and catalytic pyrolysis of rice husks[J].Energy, 2000, 25(6):493-513. doi: 10.1016/S0360-5442(00)00009-8 [13] DIAO Z H, LI W, ZHANG X W, LIU G Z.Catalytic cracking of supercritical n-dodecane over meso-HZSM-5@Al-MCM-41 zeolites[J].Chem Eng Sci, 2015, 135:452-460. doi: 10.1016/j.ces.2014.12.048 [14] KÖLDSTRÖM M, KUMAR N, HEIKKILA T, TⅡTTA M, SALMI T, YU D.Transformation of levoglucosan over H-MCM-22 zeolite and H-MCM-41 mesoporous molecular sieve catalysts[J].Biomass Bioenergy, 2011, 35(5):1967-1976. doi: 10.1016/j.biombioe.2011.01.046 [15] 樊永胜, 蔡忆昔, 李小华, 赵卫东, 俞宁.真空热解工艺参数对生物油产率的影响研究[J].林产化学与工业, 2014, 34(1):79-85. http://www.cnki.com.cn/Article/CJFDTOTAL-LCHX201401017.htmFAN Yong-sheng, CAI Yi-xi, LI Xiao-hua, ZHAO Wei-dong, YU Ning.Influence of process parameters on bio-oil yield by vacuum pyrolysis[J].Chem Ind Forest Prod, 2014, 34(1):79-85. http://www.cnki.com.cn/Article/CJFDTOTAL-LCHX201401017.htm [16] 樊永胜, 蔡忆昔, 李小华, 俞宁, 尹海云.油菜秸秆真空热解蒸气在线催化提质研究[J].农业机械学报, 2014, 45(12):234-240. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201412035.htmFAN Yong-sheng, CAI Yi-xi, LI Xiao-hua, YU Ning, YIN Hai-yun.Catalytic upgrading of pyrolytic vapors from rape straw vacuum pyrolysis[J].Trans Chin Soc Agric Mach, 2014, 45(12):234-240. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201412035.htm [17] FAN Y S, CAI Y X, LI X H, YIN H Y, YU N, ZHANG R X, ZHAO W D.Rape straw as a source of bio-oil via vacuum pyrolysis:Optimization of bio-oil yield using orthogonal design method and characterization of bio-oil[J].J Anal Appl Pyrolysis, 2014, 106:63-70. doi: 10.1016/j.jaap.2013.12.011 [18] CORMA A, GRANDE M S, GONZALEZ V A, ORCHILLES A V.Cracking activity and hydrothermal stability of MCM-41 and its comparison with amorphous silica-alumina and a USY zeolite[J].J Catal, 1996, 159(2):375-382. doi: 10.1006/jcat.1996.0100 [19] AHO A, KUMAR N, LASHKUL A V, ERANEN K, ZIOLEK M, DECYK M.Catalytic upgrading of woody biomass derived pyrolysis vapours over iron modified zeolites in a dual-fluidized bed reactor[J].Fuel, 2010, 89(8):1992-2000. doi: 10.1016/j.fuel.2010.02.009 [20] 李婷婷, 张晖, 吴彩娥, 范龚建.油茶籽糖蛋白提取工艺优化及抗氧化性[J].农业机械学报, 2012, 43(4):148-155. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201204029.htmLI Ting-ting, ZHANG Hui, WU Cai-e, FAN Gong-jian.Extraction optimization and antioxidant activity of glycoprotein from camellia oleifera seed[J].Trans Chin Soc Agric Mach, 2012, 43(4):148-155. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201204029.htm [21] POUYA S R, HODA S, WAN M A W D.Production of green aromatics and olefins by catalytic cracking of oxygenate compounds derived from biomass pyrolysis:A review[J].Appl Catal A:Gen, 2014, 469:490-511. doi: 10.1016/j.apcata.2013.09.036 [22] ILIOPOULOU E F, ANTONAKOU E V, KARAKOULIA S A, VASALOS I A, LAPPAS A A, TRIANTAFYLLIDIS K S.Catalytic conversion of biomass pyrolysis products by mesoporous materials:Effects of steam stability and acidity of Al-MCM-41 catalysts[J].Chem Eng J, 2007, 134(1/3):51-57. [23] 尹海云, 李小华, 张蓉仙, 樊永胜, 俞宁, 蔡忆昔.HSZM-5在线提质生物油及催化剂失活机理分析[J].燃料化学学报, 2014, 42(9):1077-1086. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18487.shtmlYIN Hai-yun, LI Xiao-hua, ZHANG Rong-xian, FAN Yong-sheng, YU Ning, CAI Yi-xi.Online catalytic cracking of bio-oil over HZSM-5 zeolite and analysis of catalyst deactivation[J].J Fuel Chem Technol, 2014, 42(9):1077-1086. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18487.shtml [24] 郭春垒, 方向晨, 贾立明, 刘全杰.分子筛重整催化剂Pt/HZSM-5积碳失活研究[J].石油炼制与化工, 2012, 43(4):25-29.GUO Chun-lei, FANG Xiang-chen, JIA Li-ming, LIU Quan-jie.Study on the deactivation of Pt/HZSM-5 zeolitic reforming catalyst by coke deposition[J].Petrol Proc Petrochem, 2012, 43(4):25-29. [25] 李望良, 柳云骐, 刘春英, 刘晨光.MCM-41负载Mo-Ni-P催化剂的加氢性能[J].石油学报, 2004, 20(2):69-74. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJG200402011.htmLI Wang-liang, LIU Yun-qi, LIU Chun-ying, LIU Chen-guang.Hydrogenation properties of Mo-Ni-P catalyst on MCM-41 supported[J].Acta Pet Sin (Pet Process Sect), 2004, 20(2):69-74. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJG200402011.htm -

下载:

下载: