Influence of inherent minerals on CO2 gasification of a lignite with high ash content

-

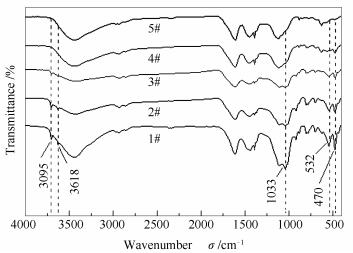

摘要: 利用分选结合逐级酸洗的方法制备出不同灰含量和矿物组成的褐煤煤样,使用沉降管反应器(DTR)和热重分析仪(TGA)研究内在矿物在1 000-1 200℃对褐煤CO2气化的影响。结果表明,内在矿物对褐煤CO2气化具有促进作用,且促进机制具有温度敏感性。低温时(1 000℃),内在矿物可通过增加初生半焦微晶结构的无序度,间接提高气化碳转化率。高温时(1 100-1 200℃),内在矿物通过催化煤焦气化,直接促进气化碳转化率的上升。碱性指数不适用于表征本研究的褐煤内在矿物的催化作用。Ca是内在矿物中影响整体催化能力的主要成分,而且羧酸盐形式的Ca是其中的活性组分。不同的催化机制是导致煤焦中钙的催化活性因其化学形式而异的根本原因。羧酸盐形式的Ca可降低煤焦气化反应的活化能,而CaO则提高反应的表观频率因子。Abstract: Lignite samples with different ash contents and mineral composition were prepared by dry separation and acid washing. A drop tube reactor and thermogravimetric analyzer were used to study effect of inherent minerals on CO2 gasification reaction of lignite at 1 000-1 200 ℃. The results show that the inherent minerals have positive effects on gasification, which are temperature sensitive. At lower gasification temperature (1 000 ℃) the inherent minerals can improve carbon conversion indirectly by obstructing the carbon structure order of nascent char. At higher temperatures (1 100-1 200 ℃)the inherent minerals can improve carbon conversion by catalyzing nascent char gasification directly. The alkaline index is not suitable for characterizing role of the inherent minerals of lignite in this case. Ca leads to the difference in catalytic activity of the inherent minerals where the most active form is carboxylate. Various catalytic mechanisms are the root cause of different catalytic activity of Ca in different chemical forms. Ca in the form of carboxylate can reduce the activation energy of coal/char gasification reaction, while CaO only promotes the apparent frequency factor.

-

Key words:

- lignite /

- inherent minerals /

- CO2 gasification /

- catalytic mechanism /

- chemical form

-

表 1 煤样的工业分析和元素分析

Table 1 Proximate analysis and ultimate analysis of the coals

表 2 灰分的矿物成分

Table 2 Inorganic constituents contents in coal samples in an oxide form

表 3 热解半焦的收率

Table 3 Yield of the char

-

[1] 王辅臣, 于广锁, 龚欣, 刘海峰, 王亦飞, 梁钦峰.大型煤气化技术的研究与发展[J].化工进展, 2009, 28(2):173-180. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ200902002.htmWANG Fu-chen, YU Gang-suo, GONG Xin, LIU Hai-feng, WANG Yi-fei, LIANG Qin-feng. Research and development of large-scale coal gasification technology[J]. Chem Ind Eng Prog, 2009, 28(2):173-180. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ200902002.htm [2] 戴和武, 杜铭华, 谢可玉, 王伟黎.我国低灰分褐煤资源及其优化利用[J].中国煤炭, 2001, 27(2):14-18. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGME200102002.htmDAI He-wu, DU Ming-hua, XIE Ke-yu, WANG Wei-li. Low ash lignite resources in China and its optimization and utilization[J]. China Coal, 2001, 27(2):14-18. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGME200102002.htm [3] CORELLA J, TOLEDO J M, MOLINA G. Steam gasification of coal at low-medium (600-800 degrees C) temperature with simultaneous CO2 capture in fluidized bed at atmospheric pressure:The effect of inorganic species. 1. Literature review and comments[J]. Ind Eng Chem Res, 2006, 45(18):6137-6146. doi: 10.1021/ie0602658 [4] QUYN D M, WU H, HAYASHI J I, LI C Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part Ⅳ. Catalytic effects of NaCl and ion-exchangeable Na in coal on char reactivity[J]. Fuel, 2003, 82(5):587-593. doi: 10.1016/S0016-2361(02)00323-X [5] ZHANG F, XU D P, WANG Y G, WANG Y, GAO Y, POPA T, FAN M H. Catalytic CO2 gasification of a Powder River Basin coal[J]. Fuel Process Technol, 2015, 130:107-116. doi: 10.1016/j.fuproc.2014.09.028 [6] ZHANG F, XU D, WANG Y, ARGYLE M D, FAN M. CO2 gasification of Powder River Basin coal catalyzed by a cost-effective and environmentally friendly iron catalyst[J]. Appl Energy, 2015, 145:295-305. doi: 10.1016/j.apenergy.2015.01.098 [7] LI Y, YANG H P, HU J H, WANG X H, CHEN H P. Effect of catalysts on the reactivity and structure evolution of char in petroleum coke steam gasification[J]. Fuel, 2014, 117:1174-1180. doi: 10.1016/j.fuel.2013.08.066 [8] WANG Y, ZHU S, GAO M, YANG Z, YAN L, BAI Y, LI F. A study of char gasification in H2O and CO2 mixtures:Role of inherent minerals in the coal[J]. Fuel Process Technol, 2016, 141(part 1):9-15. http://www.sciencedirect.com/science/article/pii/S0378382015300308 [9] BENSON S A, HOLM P L. Comparison of inorganic constituents in three low-rank coals[J]. Ind Eng Chen Prod Res Dev, 1985, 24(1):145-149. doi: 10.1021/i300017a027 [10] SKODRAS G, SAKELLAROPOULOS G P. Mineral matter effects in lignite gasification[J]. Fuel Process Technol, 2002, 77:151-158. http://www.sciencedirect.com/science/article/pii/S0378382002000632 [11] 白进, 李文, LI Chun-zhu, 白宗庆, 李保庆.高温下煤中矿物质对气化反应的影响[J].燃料化学学报, 2009, 37(2):134-138. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17416.shtmlBAI Jin, LI Wen, LI Chun-zhu, BAI Zong-qing, LI Bao-qing. Influence of mineral mater on high temeperture of coal char[J]. J Fuel Chem Technol, 2009, 37(2):134-138. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17416.shtml [12] SAKAWA M, SAKURAI Y, HARA Y. Influence of coal characteristics on CO2 gasification[J]. Fuel, 1982, 61(8):717-720. doi: 10.1016/0016-2361(82)90245-9 [13] HATTINGH B B, EVERSON R C, NEOMAGUS H W J P, BUNT J R. Assessing the catalytic effect of coal ash constituents on the CO2 gasification rate of high ash, South African coal[J]. Fuel Process Technol, 2011, 92(10):2048-2054. doi: 10.1016/j.fuproc.2011.06.003 [14] LI X, LI C Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part Ⅷ. Catalysis and changes in char structure during gasification in steam[J]. Fuel, 2006, 85(10/11):1518-1525. http://www.sciencedirect.com/science/article/pii/S0016236106000202 [15] QUYN D M, WU H W, HAYASHI J I, LI C Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part Ⅳ. Catalytic effects of NaCl and ion-exchangeable Na in coal on char reactivity[J]. Fuel, 2003, 82(5):587-593. doi: 10.1016/S0016-2361(02)00323-X [16] AND S M, SRIVASTAVA S K. Minerals transformations in northeastern region coals of india on heat treatment[J]. Energy Fuels, 2006, 20(3):1089-1096. doi: 10.1021/ef050155y [17] BAI J, LI W, LI B. Characterization of low-temperature coal ash behaviors at high temperatures under reducing atmosphere[J]. Fuel, 2008, 87(4/5):583-591. http://www.sciencedirect.com/science/article/pii/S0016236107000919 [18] LIN X, WANG C, IDETA K, MIYAWAKI J, NISHIYAMA Y, WANG Y, YOON S, MOCHIDA I. Insights into the functional group transformation of a Chinese brown coal during slow pyrolysis by combining various experiments[J]. Fuel, 2014, 118:257-264. doi: 10.1016/j.fuel.2013.10.081 [19] 孙加亮, 陈绪军, 王芳, 林雄超, 王永刚.氧气对胜利褐煤水蒸气气化半焦结构及反应性能的影响[J].燃料化学学报, 2015, 43(7):769-778. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18653.shtmlSUN Jia-liang, CHEN Xu-jun, WANG Fang, LIN Xiong-chao, WANG Yong-gang. Effect of oxygen on the structure and reactivity of char during steam gasificaiton of Shengli brown coal[J]. J Fuel Chem Technol, 2015, 43(7):769-778. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18653.shtml [20] TANNER J, KABIR K B, MULLER M, BHATTACHARYA S. Low temperature entrained flow pyrolysis and gasification of a Victorian brown coal[J]. Fuel, 2015, 154(6):107-113. http://www.sciencedirect.com/science/article/pii/S0016236115003658 [21] MIURA K, HASHIMOTO K, SILVESTON P L. Factors affecting the reactivity of coal chars during gasification, and indices representing reactivity[J]. Fuel, 1989, 68(11):1461-1475. doi: 10.1016/0016-2361(89)90046-X [22] LI X J, HAYASHI J I, LI C Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal[J]. Fuel, 2006, 85(12):1700-1707. http://onlinelibrary.wiley.com/resolve/reference/PMED?id=12127369 [23] BENSON S A, HOLM P L. Comparison of inorganic constituents in three low-rank coals[J]. Ind Eng Chen Prod Res Dev, 1985, 24(1):145-149. doi: 10.1021/i300017a027 [24] ZHANG L, KAJITANI S, UMEMOTO S, WANG S, QUYN D, SONG Y, LI T T, ZHANG S, DONG L, LI C Z. Changes in nascent char structure during the gasification of low-rank coals in CO2[J]. Fuel, 2015, 158:711-718. doi: 10.1016/j.fuel.2015.06.014 [25] LI C, YANG S, CHEN X, LIN X, WANG Y. The characteristic of Shengli brown coal fractions from heavy medium separation and its influence on CO2 gasification[J]. Fuel Process Technol, 2017, 155:232-237. doi: 10.1016/j.fuproc.2016.06.041 [26] TAY H L, KAJITANI S, WANG S, LI C Z. A preliminary Raman spectroscopic perspective for the roles of catalysts during char gasification[J]. Fuel, 2014, 121:165-172. doi: 10.1016/j.fuel.2013.12.030 [27] LI C Z. Some recent advances in the understanding of the pyrolysis and gasification behaviour of Victorian brown coal[J]. Fuel, 2007, 86(12):1664-1683. http://www.sciencedirect.com/science/article/pii/S0016236107000361 [28] 唐佳, 王勤辉, 张睿, 施正伦, 岑可法.比表面积和灰分对烟煤半焦气化机理的影响[J].中国电机工程学报, 2015, 35(20):5244-5250. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201520017.htmTANG Jia, WANG Qin-hui, ZHANG Rui, SHI Zheng-lun, CEN Ke-fa. Effect of specific surface area and ash content on the mechanisms of bituminous coal char gasification[J]. Proc CSEE, 2015, 35(20):5244-5250. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201520017.htm [29] OHTSUKA Y, ASAMI K. Highly active catalysts from inexpensive raw materials for coal gasification[J]. Catal Today, 1997, 39(1/2):111-125. http://www.sciencedirect.com/science/article/pii/S092058619700093X [30] 姜明泉. 煤焦碱金属催化水蒸汽气化——产氢行为和催化剂性能的研究[D]. 上海: 华东理工大学, 2013.JIANG Ming-quan. The study on alkali catalyzed gasification of coal char:Behaviour of hydrogen produciton and performance of the catalysts[D]. Shanghai:East China University of Science and Technology, 2013. [31] RADOVIC L R. Catalytic coal gasification:Use of calcium versus potassium[J]. Fuel, 1984, 63(7):1028-1030. doi: 10.1016/0016-2361(84)90329-6 [32] GOMEZ A, MAHINPEY N. A new method to calculate kinetic parameters independent of the kinetic model:Insights on CO2 and steam gasification[J]. Chem Eng Res Des, 2015, 95:346-357. doi: 10.1016/j.cherd.2014.11.012 -

下载:

下载: