Experimental study on strengthening the electrostatic precipitation removal of PM2.5 and SO3 by desulfurization wastewater evaporation

-

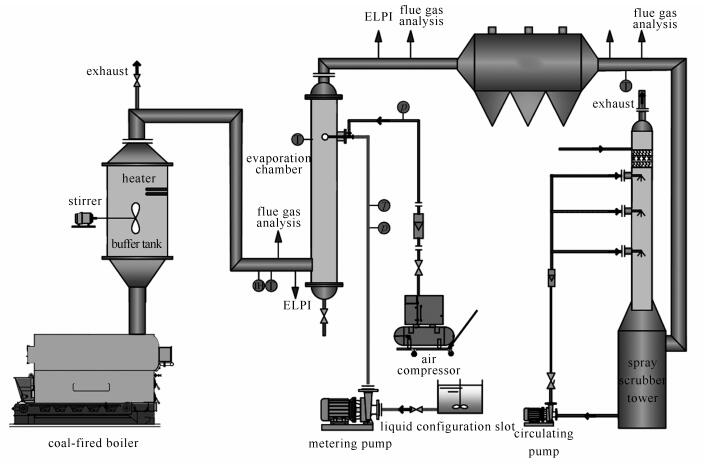

摘要: 搭建燃煤热态实验系统,研究脱硫废水蒸发对电除尘和脱硫系统的影响;考察脱硫废水蒸发前后细颗粒粒径的变化、电除尘出口PM2.5和SO3浓度变化;分析增强电除尘脱除PM2.5和SO3机理。结果表明,脱硫废水蒸发后,蒸发室出口细颗粒粒径峰值由0.1 μm增大到1.1 μm,观察脱硫废水蒸发前后扫描电镜,明显观察到废水蒸发后颗粒团聚长大,颗粒间存在絮状物;采用脱硫废水烟道蒸发后,电除尘细颗粒脱除效率提高5%左右,PM2.5数量浓度脱除效率提高25%左右;SO3脱除效率为60%-80%,烟气中SO3浓度对增强电除尘脱除PM2.5和SO3均有影响;脱硫废水蒸发对脱硫系统的效率和脱硫浆液的pH值没有影响。Abstract: In order to study the influence of desulfurization wastewater evaporation (DWE) on the ESP and the desulfurization performance, an experimental setup with DWE and the coal-fired thermal system was established. The removal of PM2.5 and SO3 from coal combustion with DWE and the evolution of fine particle size and PM2.5 and SO3 concentration at ESP outlet were investigated. Also, the mechanism of PM2.5 and SO3 removal was analyzed. The results show that DWE can increase the average size of particles from 0.1 μm to 1.1 μm. Compared SEM image before DWE with that after DWE, the particles reuniting and floc formation between particles are clearly observed. The ESP efficiency is increased by 5%; the removal efficiency of PM2.5 in number concentration is increased by 25% at the ESP outlet; and the removal efficiency of SO3 by ESP is 60%-80%. The SO3 concentration in flue gas has an effect on PM2.5 and SO3 removal by ESP. However, the DWE has no effect on the desulfurization efficiency and the pH value of the desulfurization slurry.

-

表 1 脱硫废水水质分析

Table 1 Analysis of desulfurization wastewater

表 2 不同液滴粒径烟道蒸发时间

Table 2 Evaporation time for different droplet diameters

-

[1] 杨林军.燃烧源细颗粒物污染控制技术[M].北京:化学工业出版社, 2011.YANG Lin-jun. Pollution Control Technology of Fine Particles from the Combustion Sources[M]. Beijing:Chemical Industry Press, 2011. [2] GB13223-2011, 火电厂大气污染物排放标准[S].GB13223-2011, Emission standard of air pollutants for thermal power plants[S]. [3] 中华人民共和国国家发展和改革委员会. 煤电节能减排升级与改造行动计划(2014-2020)[EB/OL]. http: //www. Sdpc. gov. cn/gzdt/201409/t20140919_626240. ht, 2014-09-12. [4] KIM K, YANG S, EUM H. Analysis of the scale formed in FGD facility[J]. Anal Sci, 2007, 17:i1615-i1617. [5] 李文艳, 王冀星, 车建炜.湿法脱硫烟气湿排问题分析[J].中国电机工程学报, 2007, 27(14):36-40. doi: 10.3321/j.issn:0258-8013.2007.14.007LI Wen-yan, WANG Ji-xing, CHE Jian-wei. Wet flue gas desulfurization wet exhaust problem analysis[J]. Proc CSEE, 2007, 27(14):36-40. doi: 10.3321/j.issn:0258-8013.2007.14.007 [6] MA S C, CHAI J, CHEN G D. Research on desulfurization wastewater evaporation:Present and future perspectives[J]. Renew Sust Energy Rev, 2016, 58:1143-1151. doi: 10.1016/j.rser.2015.12.252 [7] 张志荣. 火电厂湿法烟气脱硫废水喷雾蒸发处理方法关键问题研究[D]. 重庆: 重庆大学, 2011.ZHANG Zhi-rong. Study on key problems of the thermal power plant FGD waste water with evaporation treatment[D]. Chongqing:Chongqing University, 2011. [8] 张子敬, 汪建文, 高艺, 温高, 孙世昌, 朗林茂.燃煤电厂脱硫废水烟气蒸发特性流场模拟[J].煤炭学报, 2015, 40(3):678-683. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201503032.htmZHANG Zi-jing, WANG Jian-wen, GAO Yi, WEN Gao, SUN Shi-chang, LANG Lin-mao. Flow field simulation of smoke and gas evaporation characteristics of desulfurization wastewater in coal-fired power plant[J]. J China Coal Soc, 2015, 40(3):678-683. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201503032.htm [9] 邓佳佳. 燃煤电厂烟气脱硫吸收塔内过程优化及脱硫废水的零排放处理[D]. 重庆: 重庆大学, 2015.DENG Jia-jia. Study on optimization of coal combustion power plant WFGD spray scrubber process and zero discharge of WFGD wastewate[D]. Chongqing:Chongqing University, 2015. [10] 马双忱, 柴峰, 吴文龙, 于伟静, 陈公达.脱硫废水烟道蒸发工艺影响因素实验研究[J].环境科学与技术, 2015, 38(12):297-301. http://www.cnki.com.cn/Article/CJFDTOTAL-FJKS2015S2059.htmMA Shuang-chen, CHAI Feng, WU Wen-long, YU Wei-jin, CHEN Gong-da. Experimental research on influencing factors of flue evaporation treatment for desulfurization wastewater[J]. Environ Sci Technol, 2015, 38(12):297-301. http://www.cnki.com.cn/Article/CJFDTOTAL-FJKS2015S2059.htm [11] Mitsubishi Heavy Industries. Mitsubishi gas-gas heater[Z]. Japan:Mitsubishi Heavy Industries, 1986. [12] HONJO S, SHINODA T, NAKAYAMA Y. MHI Wet-FGD waste water treatment technologies[R]. Japan:Mitsubishi Heavy Industries, 1987. [13] MIERZEJEWSKI M K. The treatment and disposal of wastewater from flue gas desulphurization plant[J]. IWC, 1991, 24(2):125-129. [14] 刘勇, 杨林军, 潘丹萍, 赵汶, 刘瑞, 胡斌.化学团聚降低WFGD系统PM2.5排放的试验研究[J].东南大学学报:自然科学版, 2015, 45(2):320-327. http://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201502022.htmLIU Yong, YANG Lin-jun, PAN Dan-ping, ZHAO Wen, LIU Rui, HU Bin. Experimental study on amount reduce of PM2.5 discharged from WFGD by chemical agglomeration[J]. J Southeast Univ:Nat Sci Ed, 2015, 45(2):320-327. http://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201502022.htm [15] 潘丹萍, 吴昊, 黄荣廷, 张亚平, 杨林军.石灰石-石膏法烟气脱硫过程中SO3酸雾脱除特性[J].东南大学学报:自然科学版, 2016, 46(2):311-316.PAN Dan-ping, WU Hao, HUANG Rong-ting, ZHANG Ya-ping, YANG Lin-jun. Removal properties of sulfuric acid mist during limestone-gypsum flue gas desulfurization process[J]. J Southeast Univ:Nat Sci Ed, 2016, 46(2):311-316. [16] 周力行.多相湍流反应流体力学[M].北京:国防工业出版社, 2002.ZHOU Li-xing. Dynamics of Multiphase Turbulent Reacting Fluid Flows[M]. Beijing:National Defence Industry Press, 2002. [17] KUO K K. Principles of Combustion[M]. New York:John Wiley and Sons, 1986. [18] 岳勇, 陈雷, 姚强, 李水清.燃煤锅炉颗粒物粒径分布和痕量元素富集特性实验研究[J].中国电机工程学报, 2005, 25(18):74-79. doi: 10.3321/j.issn:0258-8013.2005.18.013YUE Yong, CHEN Lei, YAO Qiang, LI Shui-qing. Study on characteristics of particulate matter size distribution and trace elements enrichment in emission from a pulverized coal-fired boiler[J]. Proc CSEE, 2005, 25(18):74-79. doi: 10.3321/j.issn:0258-8013.2005.18.013 [19] 常景彩. 柔性集尘极应用于燃煤脱硫烟气深度净化的试验研究[D]. 济南: 山东大学, 2011.CHANG Jing-cai. Experimental study on flexible collection electrode applied in advanced purification for coal fired flue gas following WFGD[D]. Jinan:Shangdong University, 2011. [20] 齐立强, 阎维平, 原永涛.燃煤锅炉电除尘器飞灰物化性质及逃逸机制[J].中国电机工程学报, 2007, 27(5):45-48. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC200705008.htmQI Li-qiang, YAN Wei-ping, YUAN Yong-tao. Physicochemical characteristics and the mechanism of fly ash escaped from electrostatic precipitator of coal-fired boiler[J]. Proc CSEE, 2007, 27(5):45-48. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC200705008.htm [21] MOSER R E. SO3 impacts on plant O&M:part Ⅰ[J]. Power, 2005, 150(8):10-15. [22] 楼清刚.煤燃烧过程中SO3的生成试验研究[J].能源工程, 2008, 6(1):46-49. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=nygc200806019&dbname=CJFD&dbcode=CJFQLOU Qing-gang. Study on the formation mechanism of SO3 during coal burning[J]. Energy Eng, 2008, 6(1):46-49. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=nygc200806019&dbname=CJFD&dbcode=CJFQ [23] 肖刚, 金保升, 刘继驰, 仲兆平, 肖睿, 黄亚继, 钟文琪, 王小芳, 徐艳.烟气湿法脱硫用石灰石溶解速率定量分析[J].东南大学学报(自然科学版), 2008, 38(6):1029-1033. doi: 10.3969/j.issn.1001-0505.2008.06.018XIAO Gang, JIN Bao-sheng, LIU Ji-chi, ZHONG Zhao-ping, XIAO Rui, HUANG Ya-ji, ZHONG Wen-qi, WANG Xiao-fang, XU Yan. Quantitative analysis of dissolution rate of limestone used in WFGD[J]. J Southeast Univ:Nat Sci Ed, 2008, 38(6):1029-1033. doi: 10.3969/j.issn.1001-0505.2008.06.018 [24] 颜金培, 杨林军, 鲍静静.湿法脱硫烟气中细颗粒物的变化特性[J].东南大学学报(自然科学版), 2011, 41(2):387-392. http://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201102034.htmYAN Jin-pei, YANG Lin-jun, BAO Jing-jing. Impact property on fine particles from coal combustion in wet flue gas desulfurization process[J]. J Southeast Univ:Nat Sci Ed, 2011, 41(2):387-392. http://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201102034.htm -

下载:

下载: