Low-temperature combustion synthesis of the Mn-CeOx catalyst and its performance in the selective catalytic reduction of NOx by NH3

-

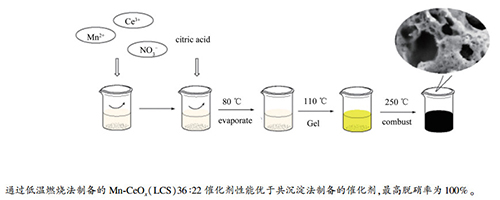

摘要: 通过低温燃烧法(LCS)制备了不同金属硝酸盐与柠檬酸物质的量比的系列Mn-CeOx(LCS)锰铈催化剂,将其与共沉淀法(CP)制备的Mn-CeOx(CP)锰铈催化剂相对比,结合XRD、XPS、FESEM和H2-TPR等技术表征,对其NH3-SCR脱硝催化性能进行了研究。结果表明,金属硝酸盐与柠檬酸的物质的量比是影响Mn-CeOx(LCS)催化剂脱硝性能的重要因素。虽然两种催化剂中的锰氧化物组分均为无定型,但相较于Mn-CeOx(CP),Mn-CeOx(LCS)表面具有较高的锰含量与Oα/(Oα+Oβ)比,其脱硝催化性能也较高;同时,Mn-CeOx(LCS)锰铈催化剂上有更多的多级孔,有利于气体在催化剂上的吸附和反应。硝酸盐与柠檬酸物质的量比为36:22的Mn-CeOx(LCS)锰铈催化剂在80-180℃下脱硝率可达75%-100%;即使通入SO2,180℃下的脱硝率仍可稳定于74%。Abstract: A series of Mn-CeOx(LCS) catalysts with different molar ratios of metal nitrates to citric acid were prepared by low-temperature combustion synthesis (LCS) method. Through a comparison with the Mn-CeOx(CP) catalysts prepared by coprecipitation method (CP) as well as various characterization techniques such as XRD, XPS, FESEM, H2-TPR and nitrogen physisorption, the catalytic performance of Mn-CeOx(LCS) in the selective catalytic reduction (SCR) of NOx by NH3 was then investigated. The results show that the molar ratio of metal nitrate to citric acid is an important factor affecting the denitrification performance of the Mn-CeOx(LCS) catalysts. In comparison with the Mn-CeOx(CP) catalysts, the Mn-CeOx(LCS) catalysts are provided with a higher manganese content and high Oα/(Oα+Oβ) ratio on the surface as well as more hierarchical pores favorable for adsorption and reaction of reactants, which affords the Mn-CeOx(LCS) catalysts much better denitrification performance. Over the Mn-CeOx(LCS) catalyst with a molar ratio of metal nitrate to citric acid of 36:22, the denitrification rate at 80-180℃ reaches 75%-100%; even in the presence of SO2, the denitrification rate over the Mn-CeOx(LCS) catalyst at 180℃ keeps at the level of 74%.

-

Key words:

- low-temperature combustion synthesis /

- Mn-CeOx /

- NH3-SCR /

- nitrogen oxides

-

表 1 金属硝酸盐与柠檬酸物质的量比对燃烧产物纯度的影响

Table 1 Influence of the molar ratio of metal nitrate to citric acid on the purity of combustion products

Sample (Mn2++Ce3+):C3H8O7 Combustion state Product 1 36:28 burning intensely coarse powder 2 36:25 burning intensely coarse powder 3 36:22 burning intensely and completely fluffy fine powder 4 36:19 mild burning slightly coarse powder 5 36:16 mild burning coarse powder 表 2 催化剂Mn-CeOx的BET比表面积、孔体积和平均孔径

Table 2 BET specific surface area, pore volume and average pore diameter of the Mn-CeOxcatalysts

Sample Surface area A/(m2·g-1) Pore volume v/(cm3·g-1) Average pore diameter d/nm Mn-CeOx(LCS)36:22 24.5 0.0795 11.8 Mn-CeOx(LCS)36:19 30.1 0.0980 11.5 Mn-CeOx(LCS)36:16 31.6 0.1037 11.6 Mn-CeOx(CP) 107.7 0.1532 6.6 表 3 锰铈催化剂Mn-CeOx(LCS)36:22和Mn-CeOx(CP)表面元素的相对含量

Table 3 Relative contents of surface elements for the Mn-CeOx(LCS)36:22 and Mn-CeOx(CP) catalysts

Sample Mn /% Ce /% O /% Mn4+ Mn3+ Mn2+ Ce3+ Ce4+ Oα Oβ Mn-CeOx(LCS)-36:22 13.8 80.7 5.5 17.5 82.5 50.9 49.1 Mn-CeOx(CP) 16.0 84.0 - 17.1 82.9 44.6 55.4 -

[1] CHEN L, SI Z C, WU X D, WENG D, RAN R, YU J. Rare earth containing catalysts for selective catalytic reduction of NOx with ammonia:A review[J]. J Rare Earth, 2014, 32(10):907-917. doi: 10.1016/S1002-0721(14)60162-9 [2] LIU C, SHI J W, GAO C, NIU C M. Manganese oxide-based catalysts for low-temperature selective catalytic reduction of NOx with NH3:A review[J]. Appl Catal A:Gen, 2016, 522:54-69. doi: 10.1016/j.apcata.2016.04.023 [3] MENG L K, WANG J, SUN Z H, ZHU J X, LI H, WANG J Q, SHEN M Q. Active manganese oxide on MnOx-CeO2 catalysts for low-temperature NO oxidation:Characterization and kinetics study[J]. J Rare Earth, 2018, 36:142-147. doi: 10.1016/j.jre.2017.05.017 [4] XIA F T, SONG Z X, LIU X, LIU X, YANG Y H, ZHANG Q L, PENG J H. Improved catalytic activity and N2 selectivity of Fe-Mn-Ox catalyst for selective catalytic reduction of NO by NH3 at low temperature[J]. Res Chem Interm, 2018, 44:2703-2717. doi: 10.1007/s11164-018-3255-x [5] ZHANG Z J, WANG W Z, SHANG M, YIN W Z. Low-temperature combustion synthesis of Bi2WO6 nanoparticles as a visible-light-driven photocatalyst[J]. J Hazard Mater, 2010, 177:1013-1018. doi: 10.1016/j.jhazmat.2010.01.020 [6] 卢利平, 张希艳, 柏朝晖, 米晓云.低温燃烧合成法研究进展[J].长春理工大学学报(自然科学版), 2008, 31(3):82-84. doi: 10.3969/j.issn.1672-9870.2008.03.023LU Li-ping, ZHANG Xi-yan, BAI Zhao-hui, MI Xiao-yun. Research progress of low-temperature combustion synthesis method[J]. J Changchun Univ Sci Technol(Nat Sci Ed), 2008, 31(3):82-84. doi: 10.3969/j.issn.1672-9870.2008.03.023 [7] JAYANTHI M, LAVANYA T, SARADHA N A, SATHEESH K, CHENTHAMARAI S, JAYAVEL R. Superior photocatalytic performance of CeO2 nanoparticles and reduced graphene oxide nanocomposite prepared by low cost co-precipitation method[J]. J Nanosci Nanotechnol, 2018, 18(5):3257-3265. doi: 10.1166/jnn.2018.14701 [8] POURKHALIL M, MOGHADDAM A Z, RASHIDI A, TOWFIGHI J, JOZANI K J, BOZORGZADEH H. Synthesis of MnOx/oxidized-MWNTs for abatement of nitrogen oxides[J]. Catal Lett, 2013, 143(2):184-192. doi: 10.1007/s10562-012-0938-6 [9] LIOTTA L, DI CARLO G, PANTALEO G, VENEZIA A, DEGANELLO G. Co3O4/CeO2 composite oxides for methane emissions abatement:Relationship between Co3O4-CeO2 interaction and catalytic activity[J]. Appl Catal B:Environ, 2006, 66(3/4):217-227. https://www.sciencedirect.com/science/article/pii/S0926337306001068 [10] 陈雪红, 郑玉婴, 付彬彬, 郑伟杰.原位聚合MnO2/PoPD@PPS复合滤料及其NH3-SCR脱硝性能研究[J].燃料化学学报, 2017, 45(12):1514-1521. doi: 10.3969/j.issn.0253-2409.2017.12.014CHEN Xue-hong, ZHENG Yu-ying, FU Bin-bin, ZHENG Wei-jie. Preparation of MnO2/PoPD@PPS functional composites for low-temperature NO reduction with NH3[J]. J Fuel Chem Technol, 2017, 45(12):1514-1521. doi: 10.3969/j.issn.0253-2409.2017.12.014 [11] QIAO J S, WANG N, WANG Z H, SUN W, SUN K N. Porous bimetallic Mn2Co1Ox catalysts prepared by a one-step combustion method for the low temperature selective catalytic reduction of NOx with NH3[J]. Catal Commun, 2015, 72:111-115. https://www.sciencedirect.com/science/article/pii/S1566736715300844 [12] MENG D M, ZHAN W C, GUO Y, GUO Y L, WANG L, LU G Z. A highly effective catalyst of Sm-MnOx for the NH3-SCR of NOx at low temperature:Promotional role of Sm and its catalytic performance[J]. Acs Catal, 2015, 5:5973-5983. doi: 10.1021/acscatal.5b00747 -

下载:

下载: