Decarbonylation and hydrogenation reaction of furfural on Pd/Cu (111) surface

-

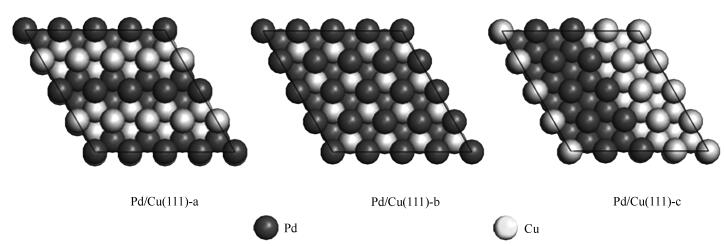

摘要: 采用密度泛函理论(DFT)研究糠醛在最稳定Pd/Cu(111)双金属表面上的吸附构型和糠醛脱碳及加氢的反应机理。结果表明,当糠醛初始吸附于O3-Pd-top、O7-Cu-hcp位时,吸附构型最稳定,其吸附能为73.4 kJ/mol。糠醛在Pd/Cu(111)双金属表面上更易发生脱碳反应。对于糠醛脱碳反应,所需活化能较低,各个基元反应均为放热反应,糠醛更易先失去支链上的H形成(C4H3O)CO,然后中间体脱碳加氢得到呋喃,其中,C4H3O加氢生成呋喃所需活化能(72.6 kJ/mol)最高,是反应的控速步骤。对于加氢反应,糠醛与首个氢原子的反应需要最大的活化能(290.4 kJ/mol),是反应的限速步骤。Abstract: The adsorption behavior, decarbonylation and hydrogenation reaction mechanisms of furfural on best Pd/Cu (111) bimetallic model were investigated by density functional theory method. The results show that the initial adsorption at O3-Pd-top and O7-Cu-hcp site is most stable, with the adsorption energy of 73.4 kJ/mol. On the Pd/Cu (111) bimetallic surface, decarbonylation reaction of furfural is more likely to occur. The decarbonylation reaction of furfural has low activation energy. Each steps of decarbonylation mechanism is exothermic reaction. Furfural tends to form (C4H3O) CO by losing the H atom from the branch chain, and furan is then formed by decarbonylation and hydrogenation of the intermediate. Throughout the process, the hydrogenation of C4H3O is the rate-determining step with the highest activation energy barrier of 72.6 kJ/mol. For the hydrogenation of furfural, reacting with the first hydrogen is the rate-determining step, and it has the highest reaction energy barrier of 290.4 kJ/mol.

-

Key words:

- furfural /

- density functional theory /

- Pd/Cu (111) bimetallic surface /

- adsorption /

- decarbonylation /

- hydrogenation

-

表 1 糠醛分子吸附在Pd/Cu (111)表面的吸附能量

Table 1 Adsorption energy of furfural molecule on Pd/Cu (111) surface

Adsorption site Eads/(kJ·mol-1) Adsorption site Eads/(kJ·mol-1) O3-top-O7-top O3-bridge-O7-hcp Cu-Cu 70.6 Cu-Cu 64.4 Pd-Pd 66.7 Pd-Pd 61.0 Cu-Pd 72.8 Cu-Pd 66.5 Pd-Cu 68.1 Pd-Cu 71.5 O3-top-O7-hcp O3-bridge-O7-fcc Cu-Cu 64.2 Cu-Cu 62.4 Pd-Pd 61.8 Pd-Pd 62.5 Cu-Pd 63.7 Cu-Pd 70.4 Pd-Cu 73.4 Pd-Cu 71.2 O3-top-O7-fcc O3-hcp-O7-hcp Cu-Cu 69.7 Cu-Cu 64.1 Pd-Pd 60.8 Pd-Pd 68.2 Cu-Pd 63.8 Cu-Pd 62.0 Pd-Cu 60.9 Pd-Cu 65.7 O3-top-O7-bridge O3-hcp-O7-fcc Cu-Cu 64.9 Cu-Cu 69.7 Pd-Pd 62.3 Pd-Pd 60.8 Cu-Pd 63.0 Cu-Pd 63.8 Pd-Cu 61.9 Pd-Cu 60.9 O3-bridge-O7-bridge O3-fcc-O7-fcc Cu-Cu 64.0 Cu-Cu 65.1 Pd-Pd 62.8 Pd-Pd 63.3 Cu-Pd 71.4 Cu-Pd 67.0 Pd-Cu 71.6 Pd-Cu 63.2 表 2 脱碳反应中各反应在Pd/Cu (111)面的活化能和反应能量变化

Table 2 Activation barriers and reaction energies of elementary reactions for decarbonylation reaction on Pd/Cu (111) surface

Reaction Ea/(kJ·mol-1) ΔE/(kJ·mol-1) Path A (1) (C4H3O) CHO*+*→C4H3O*+CHO* 66.5 -26.7 Path B (2) (C4H3O) CHO*+*→(C4H3O) CO*+H* 19.9 -13.5 (3) (C4H3O) CO*+*→C4H3O*+CO* 6.6 -18.8 (4) C4H3O*+H*→C4H4O 72.6 -41.1 表 3 加氢反应中各反应在Pd/Cu (111)面的活化能和反应能量

Table 3 Activation barriers and reaction energies of elementary reactions for hydrogenation reaction on Pd/Cu (111) surface

Step Reaction Ea/(kJ·mol-1) ΔE/(kJ·mol-1) A1 (C4H3O) CHO*+H*→(C4H3O) CHOH* 37.7 115.6 (C4H3O) CHOH*+H*→(C4H3O) CH2OH* 367.5 -98.1 A2 (C4H3O) CHO*+H*→(C4H3O) CH2O* 290.4 111.8 (C4H3O) CH2O*+H*→(C4H3O) CH2OH* 15.7 -103.7 A′ (C4H3O) CH2O*→(C4H3O) CHOH* 140.1 3.8 B1 (C4H3O) CH2OH*+H*→α-(C4H4O) CH2OH* 89.4 82.6 B2 (C4H3O) CH2OH*+H*→β-(C4H4O) CH2OH* 252.9 105.9 B3 (C4H3O) CH2OH*+H*→γ-(C4H4O) CH2OH* 92.2 25.5 B4 (C4H3O) CH2OH*+H*→θ-(C4H4O) CH2OH* 193.4 19.1 C1 α-(C4H4O) CH2OH*+H*→α, α-(C4H5O) CH2OH* 328.5 111.1 C2 α-(C4H4O) CH2OH*+H*→α, β-(C4H5O) CH2OH* 89.8 -37.5 D1 α, β-(C4H5O) CH2OH*+H*→α, β, α-(C4H6O) CH2OH* 279.7 139.6 D2 α, β-(C4H5O) CH2OH*+H*→α, β, β-(C4H6O) CH2OH* 95.3 85.3 E α, β, β-(C4H6O) CH2OH*+H*→(C4H7O) CH2OH 41.2 -59.2 -

[1] YAN K, CHEN A C. Efficient hydrogenation of biomass-derived furfural and levulinic acid on the facilely synthesized noble-metal-free Cu-Cr catalyst[J]. Energy, 2013, 58:357-363. doi: 10.1016/j.energy.2013.05.035 [2] 张俊姣, 廖航涛, 陆强, 张阳, 董长青.果糖低温快速热解制备糠醛的机理研究[J].燃料化学学报, 2013, 41(11):1303-1309. doi: 10.1016/S1872-5813(14)60001-3ZHANG Jun-jiao, LIAO Hang-tao, LU Qiang, ZHANG Yang, DONG Chang-qing. Mechanistic study on low-temperature fast pyrolysis of fructose to produce furfural[J]. J Fuel Chem Technol, 2013, 41(11):1303-1309. doi: 10.1016/S1872-5813(14)60001-3 [3] YU W T, XIONG K, JI N, MARC D P, CHEN J G.Theoretical and experimental studies of the adsorption geometry and reaction pathways of furfural over FeNi bimetallic model surfaces and supported catalysts[J]. J Catal, 2014, 317:253-262. doi: 10.1016/j.jcat.2014.06.025 [4] CHEN X C, SUN W, XIAO N, YAN Y J, LIU S W. Experimental study for liquid phase selective hydrogenation of furfuryl alcohol to tetrahydrofurfuryl alcohol on supported Ni catalysts[J]. Chem Eng J, 2007, 126(1):5-11. doi: 10.1016/j.cej.2006.08.019 [5] YANG Y L, DU Z T, HUANG Y Z, LU F, WANG F, GAO J, XU J. Conversion of furfural into cyclopentanone over Ni-Cu bimetallic catalysts[J].Green Chem, 2013, 15(7):1932-1940. doi: 10.1039/c3gc37133f [6] SURAPA S, WEI A, DANIEL E R. Selective conversion of furfural to methylfuran over silica-supported Ni-Fe bimetallic catalysts[J]. J Catal, 2011, 284(1):90-101. doi: 10.1016/j.jcat.2011.09.005 [7] YOSHINAO N, HIROYA N, HIDEO W, KEIICHI T. Total hydrogenation of furfural over a silica-supported nickel catalyst prepared by the reduction of a nickel nitrate precursor[J]. ChemCatChem, 2012, 4(11):1791-1797. doi: 10.1002/cctc.v4.11 [8] KAIPROMMARAT S, KONGPARAKUL S, REUBROYCHAROEN P, GUAN G Q, SAMART C. Highly efficient sulfonic MCM-41 catalyst for furfural production:Furan-based biofuel agent[J]. Fuel, 2016, 174:189-196. doi: 10.1016/j.fuel.2016.02.011 [9] LUO J, MONAI M, YUN H, ARROYO-RAMIRE L, WANG C, MURRAY C B, FORNASIERO P, GORTE R J. The H-2 pressure dependence of hydrodeoxygenation selectivities for furfural over Pt/C catalysts[J]. Catal Lett, 2016, 146(4):711-717. doi: 10.1007/s10562-016-1705-x [10] SIMON H P, NICOLE E L, MEDLIN J W. Synergistic effects of alloying and thiolate modification in furfural hydrogenation over Cu-based catalysts[J]. J Phys Chem Lett, 2014, 5(23):4110-4114. doi: 10.1021/jz502153q [11] LIU S B, YASUSHI A, MASAZUMI T, YOSHINAO N, KEIICHI T. One-pot selective conversion of furfural into 1, 5-pentanediol over a Pd-added Ir-ReOx/SiO2 bifunctional catalyst[J]. Green Chem, 2012, 16(2):617-626. [12] FAROOQ-AHMAD K, ARMELLE V, GEOR S F. Highly selective low-temperature hydrogenation of furfuryl alcohol to tetrahydrofurfuryl alcohol catalysed by hectorite-supported ruthenium nanoparticles[J]. Catal Commun, 2011, 12(15):1428-1431. doi: 10.1016/j.catcom.2011.05.024 [13] ZHANG W, ZHU Y L, NIU S S, LI Y W. A study of furfural decarbonylation on K-doped Pd/Al2O3 catalysts[J]. J Mol Catal A:Chem, 2011, 335(1/2):71-81. [14] CAMEN P J G, JUAN A C, DESIRÉE D M, RAMÓN M T, JOSÉ S G, JOSEFA M R, RAFAEL M, PEDRO M T. Gas-phase hydrogenation of furfural to furfuryl alcohol over Cu/ZnO catalysts[J]. J Catal, 2016, 336:107-115. doi: 10.1016/j.jcat.2016.01.012 [15] YOSHINAO N, KANA T, MASAZUMI T, KEIICHI T. Total hydrogenation of furfural and 5hydroxymethylfurfural over supported Pd-Ir alloy catalyst[J]. ACS Catal, 2014, 4(8):2718-2726. doi: 10.1021/cs500620b [16] SURSURAPAS S, TAWAN S, YU G M, PERLA B B, DANIEL E R. Kinetics and mechanism of hydrogenation of furfural on Cu/SiO2 catalysts[J]. J Catal, 2011, 277(1):1-13. doi: 10.1016/j.jcat.2010.10.005 [17] VASSILI V, GIANNIS M, DIONISIOS G V. DFT study of furfural conversion to furan, furfuryl alcohol, and 2-methylfuran on Pd (111)[J]. ACS Catal, 2012, 2(12):2496-2504. doi: 10.1021/cs300395a [18] 夏明玉, 曹晓霞, 倪哲明, 施炜, 付晓微. Cu (111)面上糠醇加氢生成2-甲基呋喃的反应机理[J].催化学报, 2012, 33(6):1000-1006. http://www.cnki.com.cn/Article/CJFDTOTAL-CHUA201206015.htmXIA Ming-yu, CAO Xiao-xia, NI Zhe-ming, SHI Wei, FU Xiao-wei. Reaction mechanism for 2-methylfuran formation during hydrogenation of furfuryl alcohol catalyzed by Cu (111) plane[J]. Chin J Catal, 2012, 33(6):1000-1006. http://www.cnki.com.cn/Article/CJFDTOTAL-CHUA201206015.htm [19] 倪哲明, 夏明玉, 施炜, 钱萍萍.糠醛在Pt (111)表面的吸附和脱碳反应[J].物理化学学报, 2013, 29(9):1916-1922. http://www.cnki.com.cn/Article/CJFDTOTAL-WLHX201309010.htmNI Zhe-ming, XIA Ming-yu, SHI Wei, QIAN Ping-ping. Adsorption and decarbonylation reaction of furfural on Pt (111) surface[J]. Acta Phys-Chim Sin, 2013, 29(9):1916-1922. http://www.cnki.com.cn/Article/CJFDTOTAL-WLHX201309010.htm [20] ZHAO Y Y. Facile synthesis of Pd nanoparticles on SiO2 for hydrogenation of biomass-derived furfural[J]. Environ Chem Lett, 2014, 12(1):185-190. doi: 10.1007/s10311-013-0424-4 [21] VILLAVERDE M M, BERTERO N M, GARETTO T F, MARCHI A J. Selective liquid-phase hydrogenation of furfural to furfuryl alcohol over Cu-based catalysts[J]. Catal Today, 2013, 213:87-92. doi: 10.1016/j.cattod.2013.02.031 [22] SURAPAS S D E R. Hydrodeoxygenation of furfural over supported metal catalysts:A comparative study of Cu, Pd and Ni[J]. Catal Lett, 2011, 141(6):784-791. doi: 10.1007/s10562-011-0581-7 [23] LIU D X, DMITRY Z, WU T P, RODRIGO J L L, JAMES A D, JEFFREY T M, CHRISTOPHER L M. Deactivation mechanistic studies of copper chromite catalyst for selective hydrogenation of 2-furfuraldehyde[J]. J Catal, 2013, 299:336-345. doi: 10.1016/j.jcat.2012.10.026 [24] DELLEY B. From molecules to solids with the DMol (3) approach[J]. J Chem Phys, 2000, 113(18):7756-7764. doi: 10.1063/1.1316015 [25] PERDEW J P, CHEWARY J A, VOSKO S H, JACKSON K A, PEDERSONE M R, SINGH D J, FIOLHAIS C. Atoms, molecules, solids, and surfaces-applications of the generalized gradient approximation for exchange and correlation[J]. Phys Rev B, 1992, 46(7):6671-6687. [26] GE Q, JENKINS S J, KING D A. Localisation of adsorbate-induced demagnetisation:CO chemisorbed on Ni (110)[J]. Chem Phys Lett, 2000, 327(3/4):125-130. [27] WANG S G, VASSILI V, DIONISIOS G V. Coverage-induced conformational effects on activity and selectivity:Hydrogenation and decarbonylation of furfural on Pd (111)[J]. ACS Catal, 2015, 5(1):104-112. doi: 10.1021/cs5015145 [28] SURAPAS S, TRUNG P, TEERAWITE P, TAWAN S, RICHARD G M, DANIEL E R. Conversion of furfural and 2-methylpentanal on Pd/SiO2 and Pd-Cu/SiO2 catalysts[J]. J Catal, 2011, 280(1):17-27. doi: 10.1016/j.jcat.2011.02.006 -

下载:

下载: