Preparation of coal derived nitrogen-doped mesoporous carbon for the catalytic oxidation of H2S at room temperature

-

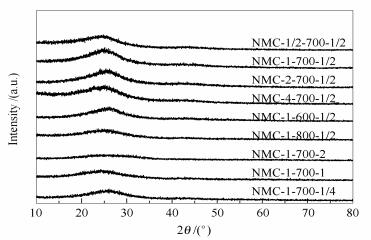

摘要: 采用纳米二氧化硅模板辅助的共炭化方法,以煤转化副产物煤焦油的蒽油馏分为碳源、三聚氰胺为氮源,制备出高氮元素掺杂、发达介孔结构的氮掺杂介孔炭(NMCs)。结合元素分析、扫描/透射电镜观察、低温氮气吸附-脱附及X射线光电子能谱测试分析,对比考察了不同合成条件对所得样品的组成、结构及其室温催化脱硫性能的影响。结果表明,控制合适的模板剂用量、碳/氮源比例和炭化温度(700℃),所制备的样品具有适宜的氮元素掺杂量及丰富的吡啶/吡咯氮构型、较大比表面积、介孔孔径和孔容,在室温下对H2S的氧化脱除显示出高效催化性能。Abstract: Nitrogen-doped mesoporous carbon (NMCs) with high N doping level and developed mesoporous structure were prepared by a nanoscale-size SiO2 template-assisted blend carbonization process, using anthracene oil (AO), one of distillates of coal tar, as carbon source and melamine (M) as nitrogen source. With the assistance of elemental analysis, FESEM/TEM, N2 adsorption-desorption and XPS characterizations, the effects of various synthesis parameters on the chemical composition, pore structure and the catalytic performance of NMCs in H2S oxidation at room temperature were investigated. The results show that NMC sample with suitable nitrogen doping level, abundant pyridinic/pyrrolic configurations, uniform large mesopore size, as well as high pore volume and specific surface area can be prepared by using appropriate amount of template agent, carbon/nitrogen source ratio and carbonization temperature (700℃), which exhibits high efficiency in the removal of H2S through catalytic oxidation at room temperature.

-

Key words:

- mesoporous carbon /

- coal tar /

- nitrogen-doping /

- hydrogen sulfide /

- catalytic oxidation

-

图 5 NMCs催化剂上H2S催化氧化脱硫穿透曲线

Figure 5 Breakthrough curves for the removal of H2S through catalytic oxidation over NMC-x-t-y

(a): NMC-x-700-1/2; —■—: NMC-0.5-700-1/2; —●—: NMC-1-700-1/2; —▲—: NMC-2-700-1/2; —▼—: NMC-4-700-1/2; (b): NMC-1-t-1/2; —■—: NMC-1-600-1/2; —●—: NMC-1-700-1/2; —▲—: NMC-1-800-1/2; (c): NMC-1-700-y; —■—: NMC-1-700-2; —●—: NMC-1-700-1; —▲—: NMC-1-700-1/2; —▼—: NMC-1-700-1/4

表 1 不同条件下合成NMCs样品的氮含量、比表面积、孔结构参数及其硫容

Table 1 Doped-nitrogen content, surface area, pore parameters and sulfur capacity of various NMCs samples

Series Sample Element N/% content C/N ABET /(m2·g-1) vtotal /(cm3·g-1) Sulfur capacity /(gH2S·gcat-1) Ⅰ NMC-0.5-700-1/2 13.2 0.18 473 1.23 4.25 NMC-1-700-1/2 19.1 0.29 468 1.34 4.74 NMC-2-700-1/2 12.0 0.21 572 0.85 0.60 NMC-4-700-1/2 6.5 0.09 796 0.88 0.76 Ⅱ NMC-1-600-1/2 28.0 0.49 275 0.79 2.88 NMC-1-800-1/2 16.4 0.24 579 1.37 3.72 Ⅲ NMC-1-700-2 4.6 0.06 663 1.66 4.40 NMC-1-700-1 12.6 0.18 570 1.49 4.55 NMC-1-700-1/4 24.1 0.40 343 0.85 2.51 a: mass ratio of C/N -

[1] 谢巍, 常丽萍, 余江龙, 谢克昌.煤气净化中H2S干法脱除的研究进展[J].化工学报, 2006, 57(9):2012-2019. http://www.cqvip.com/QK/97122A/199903/671878984199903001.htmlXIE Wei, CHANG Li-ping, YU Jiang-long, XIE Ke-chang. Research progress of removal of H2S from coal gas by dry method[J]. CIESE, 2006, 57(9):2012-2019. http://www.cqvip.com/QK/97122A/199903/671878984199903001.html [2] 李芬, 张杰, 姜安玺, 邵纯红, 闫波.低温脱硫剂的研究进展[J].化工进展, 2007, 26(4):519-525. http://www.hgjz.com.cn/CN/abstract/abstract10281.shtmlLI Fen, ZHANG Jie, JIANG An-xi, SHAO Chun-hong, YAN Bo. Research progress of desulfurizer at a low temperature[J]. Prog Chem, 2007, 26(4):519-525. http://www.hgjz.com.cn/CN/abstract/abstract10281.shtml [3] KLEIN J, HENNING L D. Catalytic oxidation of hydrogen sulfide on activated carbons[J]. Fuel, 1984, 8:1064-1067. doi: 10.1021/ef800711c [4] LEE J, KIM J, HYEON T. Recent progress in the synthesis of porous carbon materials[J]. Adv Mater, 2006, 18(16):2073-2094. doi: 10.1002/(ISSN)1521-4095 [5] WEI J, ZHOU D D, SUN Z K, DENG YH, XIA Y Y, ZHAO D Y. A controllable synthesis of rich nitrogen-doped ordered mesoporous carbon for CO2 capture and supercapacitors[J]. Adv Funct Mater, 2013, 23(18):2322-2328. doi: 10.1002/adfm.201202764 [6] LONG D H, ZHANG R, QIAO W M, ZHANG L, LIANG X Y, LING L C. Biomolecular adsorption behavior on spherical carbon aerogels with various mesopore sizes[J]. J Colloid Interf Sci, 2009, 331(1):40-46. doi: 10.1016/j.jcis.2008.11.026 [7] 侯良培, 赵荣祥, 李秀萍.一步法制备含W介孔炭材料及其氧化脱硫性能研究[J].燃料化学学报, 2017, 45(3):345-353. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18999.shtmlHOU Liang-pei, ZHAO Rong-xiang, LI Xiu-ping. One-step preparation of mesoporous carbon containing tungsten and its desulfurization performance[J]. J Fuel Chem Technol, 2017, 45(3):345-353. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18999.shtml [8] CHEN B, SHANG S, ZHANG Y, GAO S. Mesoporous carbon derived from vitamin B12:A high-performance bifunctional catalyst for imine formation[J]. Chem Commun, 2016, 52(3):481-484. doi: 10.1039/C5CC06179B [9] TAN Y M, XU C F, CHEN G X, FANG X L, ZHENG N F, XIE Q J. Facile synthesis of manganese-oxide-containing msoporous nitrogen-doped carbon for efficient oxygen reduction[J]. Adv Funct Mater, 2012, 22(21):4584-4591. doi: 10.1002/adfm.v22.21 [10] 刘美君, 付冬梅, 王春雷.活化方式对有序介孔孔结构及电化学性能的影响[J].新型碳材料, 2017, 32(2):123-129.LIU Mei-jun, FU Dong-mei, WANG Chun-lei. The effects of activation method on the pore structure and electrochemical properties of ordered mesoporous carbons used as the electrode materials of supercapacitors[J]. New Carbon Mater, 2017, 32(2):123-129. [11] MAO Y, DUAN H, XU B, ZHANG L, HU Y S, ZHAO C C, WANG Z X, CHEN L Q, YANG Y S. Lithium storage in nitrogen-rich mesoporous carbon materials[J]. Energy Environ Sci, 2012, 5(7):7950-7955. doi: 10.1039/c2ee21817h [12] SHEN W, FAN W. Nitrogen-containing porous carbons:Synthesis and application[J]. J Mater Chem, 2013, 1(4):999-1013. doi: 10.1039/C2TA00028H [13] XIA Y, MOKAYA R. Synthesis of ordered mesoporous carbon and nitrogen-doped carbon materials with graphitic pore walls via a simple chemical vapor deposition method[J]. Adv Mater, 2004, 16(17):1553-1558. doi: 10.1002/(ISSN)1521-4095 [14] ZHAO Y F, ZHAO L, YAO K X, YANG Y, ZHANG Q, HAN Y. Novel porous carbon materials with ultrahigh nitrogen contents for selective CO2 capture[J]. J Mater Chem, 2012, 22(37):19726-19731. doi: 10.1039/c2jm33091a [15] HAO G P, LI W C, LU A H. Novel porous solids for carbon dioxide capture[J]. J Mater Chem, 2011, 21(18):6447-6451. doi: 10.1039/c0jm03564e [16] ZHANG Z, JIANG W, LONG D, WANG J, QIAO W, LING L. A general slica-templating synthesis of akaline mesoporous carbon catalysts for highly efficient H2S oxidation at room temperature[J]. ACS Appl Mater Inter, 2017, 9:2477-2484. doi: 10.1021/acsami.6b13597 [17] 许亮, 杨梅, 葛书生, 陆云.氧化钴/氮掺杂介孔炭球的制备及其电化学性能的研究[J].功能材料, 2016, 47(7):7168-7172. http://www.cnki.com.cn/Article/CJFDTotal-GNCL201607032.htmXU Liang, YANG Mei, GE Shu-yun, LU Yun. Synthesis and electrochemical performance of cobalt oxide/nitrogen-doped mesoporous composite carbon sphere[J]. J Funct Mater, 2016, 47(7):7168-7172. http://www.cnki.com.cn/Article/CJFDTotal-GNCL201607032.htm [18] MACHNIKOWSKI J, GRZYB B, MACHNIKOWSKA H, WEBER J V. Surface chemistry of porous carbons from N-polymers and their blends with pitch[J]. Microporous Mesoporous Mater, 2005, 82(1):113-120. http://www.sciencedirect.com/science/article/pii/S1387181105001058 [19] KOWALEWSKI. T, TSAREVSKY N V, MATYJASZEWSKI K. Nanostructured carbon arrays from block copolymers of polyacrylonitrile[J]. J Am Chem Soc, 2002, 124(36):10632-10633. doi: 10.1021/ja0178970 [20] HONG B, ZHAO L, LI J, YANG Y M, ZHANG Y. Nanostructured polypyrrole/carbon composite as Pt catalyst support for fuel cell applications[J]. J Power Sources, 2008, 184(2):375-380. doi: 10.1016/j.jpowsour.2008.03.024 [21] LONG D H, ZHANG J, YANG J H, HU Z J, LI T Q, CHENG G, ZHANG R, LING L C. Preparation and microstructure control of carbon aerogels produced using m-cresol mediated sol-gel polymerization of phenol and furfural[J]. New Carbon Mater, 2008, 23(2):165-170. doi: 10.1016/S1872-5805(08)60020-7 [22] LIU N N, YIN L W, WANG C X, ZHANG L Y, LUN N, XIANG D, QI Y X, GAO R. Adjusting the texture and nitrogen content of ordered mesoporous nitrogen-doped carbon materials prepared using SBA-15 silica as a template[J]. Carbon, 2010, 48(12):3579-3591. doi: 10.1016/j.carbon.2010.06.001 [23] LONG D H, CHEN Q J, QIAO W M, ZHAN L, LIANG X Y, LING L C. Three-dimensional mesoporous carbon aerogels:Ideal catalyst supports for enhanced H2S oxidation[J]. Chem Commun, 2009, 26:3898-3900. [24] 徐春霞.煤焦油的性质与加工利用[J].洁净煤技术, 2013, 5:63-67. https://www.wenkuxiazai.com/doc/75f3c9484431b90d6d85c746.htmlXU Chun-xia. Properties, processing and utilization of coal tar[J]. Purified Coal Technol, 2013, 5:63-67. https://www.wenkuxiazai.com/doc/75f3c9484431b90d6d85c746.html [25] CHEN Q J, WANG J T, LIU X J, ZHAO X, QIAO W M, LONG D H, LING L C. Alkaline carbon nanotubes as effective catalysts for H2S oxidation[J]. Carbon, 2011, 49(12):3773-3780. doi: 10.1016/j.carbon.2011.05.011 [26] 詹冬武. 氮掺杂碳纳米笼及其复合物的构筑与催化氧化H2S性能研究[D]. 大连: 大连理工大学, 2015ZHAN Dong-wu. Fabrication of nitrogen-doped carbon nanocages and their composites for catalytic oxidation of H2S[D]. Dalian: Dalian University of Technology, 2015 [27] CHEN Q J, WANG J T, LIU X J, ZE S I, LI Z S, QIAO W M, LONG D H, LING L C. Structure-dependent catalytic oxidation of H2S over Na2CO3impregnated carbon aerogels[J]. Microporous Mesoporous Mater, 2011, 142(2):641-648. [28] WANG H, MAIYALAGAN T, WANG X. Review on recent progress in nitrogen-doped graphene:Synthesis, characterization, and Its potential applications[J]. ACS Catal, 2012, 2:781-794. doi: 10.1021/cs200652y [29] LEI Z B, BAI D, ZHAO X S. Improving the electrocapacitive properties of mesoporous CMK-5 carbon with carbon nanotubes and nitrogen doping[J]. Microporous Mesoporous Mater, 2012, 147:86-93. doi: 10.1016/j.micromeso.2011.06.002 [30] GONG K P, DU F, XIA Z H, DURSTOCK M, DAI L M. Nitrogen-doped carbon nanotube arrays with high electrocatalytic activity for oxygen reduction[J]. Science, 2009, 323(5915):760-764. doi: 10.1126/science.1168049 [31] CHEN Q J, WANG Z, LONG D H, LIU X J, ZHAN L, LIANG X Y, QIAO W M, LING L C. Role of pore structure of activated carbon fibers in the catalytic oxidation of H2S[J]. Ind Eng Chem Res, 2010, 49(7):3152-3159. doi: 10.1021/ie901223j [32] BAGREEV A, BANDOSZ T. J. A role of sodium hydroxide in the process of hydrogen sulfide adsorption/oxidation on caustic-impregnated activated carbons[J]. Ind Eng Chem Res, 2002, 41:672-679. doi: 10.1021/ie010599r [33] SUN FG, LIU J, CHEN H C, ZHANG Z X, QIAO W M, LONG D H, LING L C. Nitrogen-rich mesoporous carbons:Highly efficient, regenerable metal-free catalysts for low-temperature oxidation of H2S[J]. ACS Catal, 2013, 3(5):862-870. doi: 10.1021/cs300791j [34] YU Z F, WANG X Z, SONG X D, YANG LIU Y, QIU J S. Molten salt synthesis of nitrogen-doped porous carbons for hydrogen sulfide adsorptive removal[J]. Carbon, 2015, 95:852-860. doi: 10.1016/j.carbon.2015.08.105 [35] BAGREEV A, ANGEL M J, DUKHNO I, TARASENKO Y, BANDOSZ T J. Bituminous coal-based activated carbons modified with nitrogen as adsorbents of hydrogen sulfide[J]. Carbon, 2004, 42(3):469-476. doi: 10.1016/j.carbon.2003.10.042 [36] 肖永厚, 王树东, 袁权.浸渍活性炭脱除硫化氢研究进展[J].化工进展, 2006, 25(9):1025-1030. http://www.hgjz.com.cn/CN/abstract/abstract10515.shtmlXIAO Yong-hou, WANG Shu-dong, YUAN Quan. Research progress of removal of H2S on impregnated activated carbon[J]. Prog Chem Eng, 2006, 25(9):1025-1030. http://www.hgjz.com.cn/CN/abstract/abstract10515.shtml -

下载:

下载: