Improvement in removal of fine particles and SO3 acid mist from desulfurized flue gas with heterogeneous condensation

-

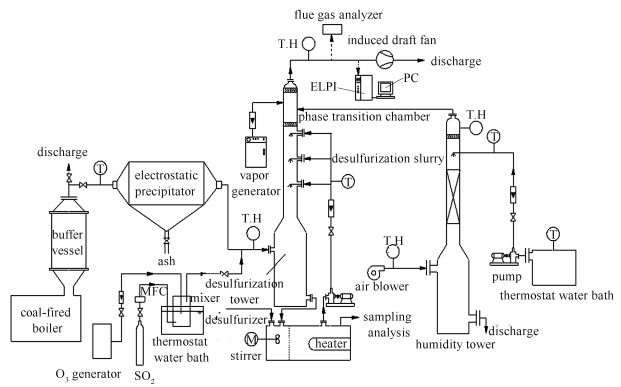

摘要: 在石灰石-石膏法脱硫净烟气中分别采用添加适量蒸汽和湿空气方式建立PM2.5和SO3酸雾凝结长大所需的过饱和水汽环境, 在测试分析湿法脱硫净烟气中PM2.5及SO3酸雾物性的基础上, 考察了蒸汽及湿空气添加量、脱硫净烟气温度等的影响。结果表明, 湿法脱硫净烟气中PM2.5除含有燃煤飞灰外, 含CaSO4、CaSO3及未反应的CaCO3等组分; 由于SO3酸雾基本处于亚微米级粒径范围, 湿法烟气脱硫(WFGD) 系统对SO3酸雾的脱除率仅为35%-55%;添加适量蒸汽及湿空气方式均可促进湿法脱硫净烟气中PM2.5和SO3酸雾脱除, 最终排放浓度随蒸汽或湿空气添加量的增加而降低, 其中, 添加蒸汽方式适合于脱硫净烟气温度较低(≤50-55 ℃) 的场合, 在脱硫净烟气温度较高(≥55-60 ℃) 时, 利用添加湿空气方式替代添加蒸汽更具技术经济优势。Abstract: The supersaturated water vapor environment for condensational growth of fine particles (PM2.5) and SO3 acid mist was achieved by adding water vapor or humid air into the limestone-gypsum desulfurized flue gas. The influences of the addition amount of water vapor and humid air as well as the desulfurized flue gas temperature were analyzed based on the property analysis of PM2.5 and SO3 acid mist. The results show that except for coal-fired ash, the desulfurized flue gas also includes CaSO4, CaSO3 and unreacted CaCO3 in PM2.5. The removal efficiency of SO3 acid mist is 35%-55% merely by wet flue gas desulfurization (WFGD) system because SO3 acid mist is mostly submicron particles. PM2.5 and SO3 acid mist can be removed effectively by adding either water vapor or humid air, and the emission concentration decreases with increasing the amount of water vapor or humid air. Moreover, it is found that it is better to add water vapor to establish the supersaturated water vapor environment for lower temperature desulfurized flue gas (≤50-55 ℃), while it is more appropriate to add humid air for higher temperature desulfurized flue gas (≥55-60℃).

-

Key words:

- PM2.5 /

- WFGD /

- SO3 acid mist /

- heterogeneous condensation /

- removal

-

图 6 脱硫净烟气温度对过饱和水汽环境形成的影响

Figure 6 Effect of desulfurized flue gas temperature on supersaturation and condensable water vapor

(a): adding vapor; (b): adding moist air supersaturation: a: adding amount of vapor 0.05 kg/m3; b: adding amount of vapor 0.08 kg/m3; mass of condensable water vapor: c: adding amount of vapor 0.05 kg/m3; d: adding amount of vapor 0.08 kg/m3

-

[1] 王珲, 宋蔷, 姚强, 陈昌和.电厂湿法脱硫系统对烟气中细颗粒物脱除作用的实验研究[J].中国电机工程学报, 2008, 28(5): 1-7. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC200805001.htmWANG Hui, SONG Qiang, YAO Qiang, CHEN Chang-he. Experimental study on removal effect of wet flue gas desulfurization system on fine particles from a coal-fired power plant[J]. Proc CSEE, 2008, 28(5): 1-7. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC200805001.htm [2] MEIJ R, WINKEL H. The emissions and environmental impact of PM10 and trace elements from a modern coal-fired power plant equipped with ESP and wet FGD[J]. Fuel Process Technol, 2004, 85(6/7): 641-656. https://www.researchgate.net/publication/222317389_The_emissions_and_environmental_impact_of_PM10_and_trace_elements_from_a_modern_coal-fired_power_plant_equipped_with_ESP_and_wet_FGD [3] NIELSEN M T, LIVBJERG H, FOGH C L, JENSEN J N, SIMONSEN P, LUND C, POULSEN K, SANDER B. Formation and emission of fine particles from two coal-fired power plants[J]. Combust Sci Technol, 2002, 174(2): 79-113. doi: 10.1080/714922606 [4] 鲍静静, 杨林军, 颜金培, 刘锦辉, 宋世娟.烟气湿法脱硫系统对细颗粒脱除性能的实验研究[J].化工学报, 2009, 60(5): 1260-1267. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ200905037.htmBAO Jing-jing, YANG Lin-jun, YAN Jin-pei, LIU Jin-hui, SONG Shi-juan. Performance of removal of fine particles by WFGD system[J]. CIESC J, 2009, 60(5): 1260-1267. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ200905037.htm [5] GOOCH J P, DISMUKES E B. Formation of sulfate aerosol in a SO2 scrubbing system. Presented at the Formation, Distribution, Impact, and Fate of Sulfur Trioxide in Utility Flue Gas Streams Conference, 1998. [6] SRIVASTAVA R K, MILLER C A. Emissions of sulfur trioxide from coal-fired power plants, Technical publication, Presented at POWER-GEN International 2002, December 10-12, 2002. Orlando, Florida. [7] 杨林军.燃烧源细颗粒物污染控制技术[M].北京:化学工业出版社, 2011.YANG Lin-jun. Control technology of fine particles from combustion[M]. Beijing: Chemical Industry Press, 2011. [8] JOANNON M, COZZOLINO G, CAVALIERE A, RAGUCCIA R. Heterogeneous nucleation activation in a condensational scrubber for particulate abatement[J]. Fuel Process Technol, 2013, 107: 113-118. doi: 10.1016/j.fuproc.2012.10.004 [9] CALVERT S, JHAVERI N C. Flux force/condensation scrubbing[J]. J Air Pollut Control Assoc, 1974, 24(10): 946-951. doi: 10.1080/00022470.1974.10469994 [10] HEIDENREICH S, VOGT U, BVTTNER H, EBERT F.A novel process to separate submicron particles from gases-a cascade of packed columns[J].Chem Eng Sci, 2000, 55(15): 2895-2905. doi: 10.1016/S0009-2509(99)00554-0 [11] YANG L J, BAO J J, YAN J P, LIU J H, SONG S J, FAN F X.Removal of fine particles in wet flue gas desulfurization system by heterogeneous condensation[J]. Chem Eng J, 2010, 156(1): 25-32. doi: 10.1016/j.cej.2009.09.026 [12] 鲍静静.应用蒸汽相变促进WFGD系统脱除细颗粒物的研究[D].南京:东南大学, 2012.BAO Jing-jing. Study on improving the removal of fine particles by heterogeneous condensation in WFGD system[D].Nanjing: Southeast University, 2012. [13] BRACHERT L, MERTENS J, KHAKHARIA P, SCHABER K. The challenge of measuring sulfuric acid aerosols: Number concentration and size evaluation using a condensation particle counter (CPC) and an electrical low pressure impactor (ELPI+)[J]. J Aerosol Sci, 2014, 67: 21-27. doi: 10.1016/j.jaerosci.2013.09.006 [14] GB/T 21508-2008, 燃煤烟气脱硫设备性能测试方法[S].GB/T 21508-2008, Performance test method for coal-fired flue gas desulphurization equipment[S]. [15] 王宝华, 张泽廷, 李群生.新型高效丝网除雾器的研究与应用[J].现代化工, 2004, 24(5): 50-53. http://www.cnki.com.cn/Article/CJFDTOTAL-XDHG200405015.htmWANG Bao-hua, ZHANG Ze-ting, LI Qun-sheng. Research and application of a new type of high efficient mesh mist eliminator[J]. Mod Chem Ind, 2004, 24(5): 50-53. http://www.cnki.com.cn/Article/CJFDTOTAL-XDHG200405015.htm [16] FLETCHER N H. The pysics of rainclouds[M]. London: Cambridge University Press, 1962, 386. [17] GORBUNOV B, HAMILTON R, CLEGG N, TOUMI R. Water nucleation on aerosol particles containing both organic and soluble inorganic substances[J]. Atmos Res, 1998, 47-48(1): 271-283. https://www.researchgate.net/publication/223328970_Water_nucleation_on_aerosol_particles_containing_both_organic_and_soluble_inorganic_substances [18] 熊桂龙, 辛成运, 杨林军, 陆斌.蒸汽相变协同湿法烟气脱硫系统烟气温湿度变化特性[J].中国电机工程学报, 2011, 31(8): 18-24. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201108003.htmXIONG Gui-long, XIN Cheng-yun, YANG Lin-jun, LU Bin. Temperature and humidity characteristics of flue gas from combined wet flue gas desulfurization system and heterogenous condensation[J]. Proc CSEE, 2011, 31(8): 18-24. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201108003.htm [19] HEIDENREICH S, EBERT F. Condensational droplet growth as a preconditioning technique for the separation of submicron particles from gases[J]. Chem Eng Process, 1995, 34(3): 235-244. doi: 10.1016/0255-2701(94)04009-5 -

下载:

下载: