Effects of N-tert-butyl-α-phenylnitrone on the product distribution of cellulose liquefaction in supercritical ethanol

-

摘要: 以N-叔丁基-α-苯基硝酮(PBN)为自由基结合剂,采用间歇式高温高压反应釜对玉米秸秆纤维素进行超临界乙醇液化,考察PBN用量(浓度)和反应温度(活性)对纤维素液化产物及生物油中主要化合物分布的影响。结果表明,在320℃,仅有超临界乙醇作用,生物油收率为37.17%,挥发分收率高达50.08%;随着PBN用量增加到0.4 g,生物油收率最高提升至48.35%,挥发分最低下降到35.65%。在超临界乙醇和PBN作用下,随着反应温度从250℃升高至340℃,纤维素转化率从23.10%急剧增加至88.92%,生物油收率从19.18%上升到最高48.35%(320℃)后略有下降,挥发分也从6.03%急剧上升至50.28%。GC-MS结果显示,酯类、酮类、烃类、醇类、酸类及苯类化合物是生物油的主要成分,各组分的最高相对含量分别为27.91%、15.77%、13.44%、12.42%、16.07%、19.81%。实验结果证实了PBN对纤维素超临界乙醇液化产物及生物油组分分布产生了较明显的影响,尤其能通过与含苯基、乙基等活性碎片结合促进挥发分与生物油之间的转化,且PBN用量及液化温度的改变可以促使生物油中主要化合物发生不同程度的相互转化。

-

关键词:

- 纤维素 /

- 液化 /

- 超临界乙醇 /

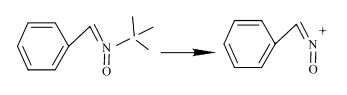

- N-叔丁基-α-苯基硝酮

Abstract: With N-tert-butyl-α-phenylnitrone (PBN) as free radicals trapper, the effects of PBN dosage and reaction temperature on the product distribution and bio-oil component distribution of cellulose liquefaction in supercritical ethanol were investigated using an autoclave. The results showed that the yields of bio-oil and volatile compounds were 37.17% and 50.08% without PBN, respectively; meanwhile the highest yield of bio-oil increased to 48.35%, whereas the volatile compound yield decreased to 35.65% with the PBN dosage increased from 0 to 0.4 g. With the increase of reaction temperature from 250℃ to 340℃, the cellulose conversion rate increased sharply from 23.10% to 88.92% while the bio-oil yield increased from 19.18% to 48.35% (320℃) and the volatile compound yield increased from 6.03% to 50.28% quickly. The GC-MS results showed that the dominant compounds in bio-oil were esters, ketones, alkanes, alcohols, acids and benzenes with the highest relative contents of 27.91%, 15.77%, 13.44%, 12.42%, 16.07% and 19.81%, respectively. The present results proved that PBN has obvious effects on the product distribution and bio-oil component distribution of cellulose liquefaction in supercritical ethanol, especially PBN can enhance the transformation between bio-oil and volatile compounds via reacting with benzyl radicals, methyl radicals, ethyl radicals, etc. The transformation among dominant compounds in bio-oil can be regulated by varying PBN dosage and reaction temperature.-

Key words:

- cellulose /

- liquefaction /

- supercritical ethanol /

- N-tert-butyl-α-phenylnitrone

-

图 4 不同PBN用量下纤维素液化残渣的FT-IR谱图

Figure 4 FT-IR analysis for RE obtained from cellulose liquefaction with various dosage of PBN in 100 mL ethanol under 8.6-9.6 MPa and 320 ℃ for 60 min

a: 0 g; b: 0.1 g; c: 0.2 g; d: 0.3 g; e: 0.4 g absorption peak[25-27]: 1 060-1 160 cm-1 C-O-C; 1 680-1 715 cm-1 -C=O; 1 710-1 770 cm-1 -COOH; 2 900-3 100 cm-1 -C-H; 3 300-3 600 cm-1 -O-H

图 6 不同反应温度下纤维素液化残渣的FT-IR谱图

Figure 6 FT-IR analysis for RE obtained from cellulose liquefaction with various reaction temperatures in 100 mL ethanol and 0.2 g PBN under 6.4-10.2 MPa for 60 min

a: 250 ℃; b: 280 ℃; c: 300 ℃; d: 320 ℃; e: 340 ℃ absorption peak: 1 060-1 160 cm-1 C-O-C; 1 680-1 715 cm-1 -C=O; 1 710-1 770 cm-1 -COOH; 2 900-3 100 cm-1 -C-H; 3 300-3 600 cm-1 -O-H

表 1 不同PBN用量下纤维素超临界乙醇液化生物油产物GC-MS分析

Table 1 GC-MS analysis for BO with various dosage of PBN for cellulose liquefaction in 100 mL ethanol under 8.6-9.6 MPa and 320 ℃ for 60 min

RT

t/minName of compounds Formula Area/% 0.1 g 0.2 g 0.3 g 0.4 g Esters 5.335 propanoic acid, 2-hydroxy-2-methyl-, ethyl ester C6H12O3 0.27 - 0.21 0.17 5.867 2-butenoic acid, ethyl ester, (E)- C6H10O2 2.09 1.99 2.19 2.76 6.054 pentanoic acid, propyl ester C8H16O2 0.29 0.27 - - 6.065 butanoic acid, 2-methyl-, ethyl ester C7H14O2 - - 0.15 0.32 7.552 tetrahydrofurfuryl acrylate C8H12O3 0.48 0.50 - - 7.737 2-propenoic acid, butyl ester C7H12O2 0.70 0.66 0.74 0.58 7.845 ethyl 2-methyl cyclopropanecarboxylate C7H12O2 0.19 0.18 0.21 - 7.904 octanoic acid, ethyl ester C10H20O2 0.89 0.80 - - 7.911 pentanoic acid, ethyl ester C7H14O2 - - 0.83 1.07 8.045 butanoic acid, 2-hydroxy-, ethyl ester C6H12O3 4.06 4.05 - - 8.405 acetic acid, ethoxy-, ethyl ester C6H12O3 0.83 0.66 0.44 0.87 8.653 4-pentenoic acid, ethyl ester C7H12O2 0.58 0.62 0.62 0.61 8.717 propanoic acid, 2-(1-ethoxyethoxy)-, ethyl ester C9H18O4 - 2.42 - - 9.252 ethyl tiglate C7H12O2 0.19 0.21 0.18 0.12 9.567 ethyl trans-2-pentenoate C7H12O2 0.39 0.37 0.35 0.38 10.096 butanoic acid, 2-hydroxy-3-methyl-, ethyl ester C7H14O3 0.41 0.39 0.50 0.32 13.196 pentanoic acid, 4-oxo-, ethyl ester C7H12O3 0.60 0.71 0.41 0.29 13.292 ethyl 2, 4-dioxovalerate C7H10O4 0.52 0.50 - - 14.009 pentanoic acid, 2-methyl-4-oxo-, ethyl ester C8H14O3 0.23 0.18 - - 14.136 ethyl dl-2-hydroxycaproate C8H16O3 0.43 0.39 0.32 0.35 14.281 isophytol, acetate C22H42O2 - 0.64 0.41 - 15.408 2-(2-methylpropenyl) cyclopropanecarboxylic C18H30O2 1.18 1.21 1.06 0.84 acid, 2-isopropyl-5-methyl-cyclohexyl ester 16.120 benzoic acid, ethyl ester C9H10O2 0.29 0.34 0.50 0.46 16.454 butanedioic acid, diethyl ester C8H14O4 0.77 0.69 0.50 - 16.541 5-keto-2, 2-dimethylheptanoic acid, ethyl (ester) C11H20O3 0.33 - 0.53 0.35 17.119 diethyl methyl succinate C9H16O4 1.06 1.01 0.83 0.73 17.650 2-propenoic acid, 6-methylheptyl ester C11H20O2 0.23 0.32 0.35 0.41 17.905 diethyl malonic acid, 4-methoxyphenyl pentyl ester C19H28O5 - - 0.18 0.38 18.057 benzeneacetic acid, ethyl ester C10H12O2 - 0.37 0.35 - 18.670 hexanoic acid, 3-oxo-, ethyl ester C8H14O3 0.54 0.48 0.27 - 19.022 pentanedioic acid, diethyl ester C9H16O4 0.91 0.96 0.41 0.52 19.168 hexanedioic acid, monoethyl ester C8H14O4 1.14 1.12 0.32 0.67 19.842 pentanoic acid, 3, 4, 4-trimethyl-, ethyl ester C10H20O2 0.58 0.62 - - 20.630 benzenepropanoic acid, ethyl ester C11H14O2 - 0.16 0.18 0.15 20.967 diethyl pimelate C11H20O4 0.54 0.62 0.30 - 21.854 oxalic acid, bis (6-ethyloct-3-yl) ester C22H42O4 0.14 0.69 - 0.17 22.010 2, 4-pentadienoic acid, 3, 4-dimethyl-, isopropyl ester C10H16O2 - - 0.18 0.23 22.178 4-(4-methoxycarbonylbutyl)-4-butanolide C10H16O4 - - 0.27 0.38 22.527 cyclopropanecarboxylic acid, 2, 2-dimethyl- C11H18O2 0.23 - 0.18 - 3-(2-propenyl)-, ethyl ester, trans- 26.994 benzenepropanoic acid, 3, 5-bis (1, 1-dimethylethyl)- C18H28O3 0.21 - - 0.17 4-hydroxy-, methyl ester 27.061 l-(+)-ascorbic acid 2, 6-dihexadecanoate C38H68O8 0.58 0.62 0.32 0.52 27.289 hexadecanoic acid, ethyl ester C18H36O2 1.08 1.21 1.54 1.19 28.024 9-octadecenoic acid (Z)-, octadecyl ester C36H70O2 - - 0.41 - 29.031 octacosyl acetate C30H60O2 1.14 0.18 0.30 - 34.003 bis (2-ethylhexyl) phthalate C24H38O4 0.56 0.53 0.80 0.81 Ketones 5.571 2-cyclopenten-1-one C5H6O 0.50 0.55 0.32 0.44 5.640 cyclopentanone, 2-methyl- C6H10O 0.72 0.73 0.80 0.93 5.761 2-pentanone, 4-hydroxy-4-methyl- C6H12O2 3.81 3.82 5.41 6.76 7.560 cyclohexanone C8H14O - - 0.47 0.52 8.335 ethanone, 1-(2-furanyl)- C6H6O2 0.23 0.25 0.24 - 9.106 cyclopentanone, 2-ethyl- C7H12O 0.19 0.21 0.21 0.55 9.170 2-cyclopenten-1-one, 2, 3-dimethyl- C7H10O 0.60 1.35 0.95 0.75 11.083 cyclohexanone, 3-ethyl- C8H14O 0.17 - 0.24 0.15 12.155 2-cyclopenten-1-one, 2-hydroxy-3-methyl- C6H8O2 - 0.66 0.27 - 12.935 2-cyclopenten-1-one, 3-ethyl-2-hydroxy- C7H10O2 1.24 1.92 1.51 0.93 13.125 2-cyclopenten-1-one, 3, 4, 4-trimethyl- C8H12O 0.35 - - 0.26 13.496 2-acetylcyclopentanone C7H10O2 0.23 - 0.21 - 15.506 1, 3-cyclopentanedione, 2-ethyl-2-methyl- C8H12O2 1.72 1.83 1.80 - 17.770 2-cyclohexen-1-one, 2-hydroxy-3- C10H16O2 1.72 1.92 1.71 1.13 methyl-6-(1-methylethyl)- 18.590 1(2H)-naphthalenone, 2-(1, 1-dimethylethyl)- C14H18O 0.83 - - - 3, 4-dihydro- 24.455 benzophenone C13H10O - 0.32 - - 26.864 7, 9-di-tert-butyl-1-oxaspiro (4, 5) deca-6 C17H24O3 0.29 0.23 0.18 0.29 9-diene-2, 8-dione Alkanes 7.450 4-octene, (E)- C8H16 0.23 0.18 0.24 0.17 8.714 ethane, 1, 1-diethoxy- C6H14O2 3.00 - 2.10 2.26 9.701 2-methyl-2-octene C9H18 0.25 - - 0.15 10.887 cyclohexene, 4, 4-dimethyl- C8H14 - 0.27 0.15 - 12.872 dodecane, 4, 6-dimethyl- C14H30 0.60 0.62 1.00 1.07 15.123 cyclohexane, (1-methylethylidene)- C9H16 - 0.27 0.27 - 16.620 1-dodecene C12H24 0.37 - - 0.32 18.475 nonadecane, 9-methyl- C20H42 0.14 - 0.42 0.26 18.907 heptadecane, 8-methyl- C18H38 0.81 0.75 0.15 0.20 19.295 nonane, 3-methyl-5-propyl- C13H28 0.14 - 0.27 - 21.495 tetradecane C14H30 0.25 0.32 0.24 0.20 21.852 eicosane C20H42 3.31 2.97 1.60 2.15 22.280 heptadecane C18H38 0.39 0.41 0.32 - 22.409 heneicosane C21H44 0.89 1.23 1.21 1.39 23.629 2-methylhexacosane C27H56 0.49 0.18 - 0.35 24.017 hexadecane C16H34 0.33 0.18 0.18 - 24.235 tetradecane, 4-methyl- C15H32 - 0.23 0.30 0.15 24.503 pentadecane, 2, 6, 10, 14-tetramethyl- C19H40 - 0.39 0.30 0.81 24.599 decane, 1, 1′-oxybis- C20H42O - 0.30 0.27 0.35 24.755 undecane, 5-ethyl-5-propyl- C16H34 - 0.30 - 0.32 24.861 tetracontane C44H90 0.21 - 0.38 - 24.863 hexadecane, 2, 6, 10, 14-tetramethyl- C20H42 0.17 - - 0.81 25.300 5, 5-diethylpentadecane C19H40 - 0.25 0.21 - 25.515 heptadecane, 2-methyl- C18H38 0.14 0.30 - 0.35 26.808 5, 5-diethylheptadecane C21H44 0.46 0.59 0.50 0.35 Alcohols 7.675 3-hexanol, 2-methyl- C7H16O 0.14 4.30 4.19 3.89 8.055 o-menthan-8-ol C10H20O - - 3.63 3.68 8.170 ethanol, 2-butoxy- C6H14O2 0.72 0.85 1.03 0.96 11.181 1, 2-pentanediol C5H12O2 4.41 - - - 12.345 benzyl alcohol C7H8O 0.21 1.03 0.89 1.10 12.397 4-nonanol C9H20O 0.27 - 0.50 0.73 13.297 4-methyl-1, 6-heptadien-4-ol C8H14O - - 0.47 0.32 14.283 cyclohexanol, 2-(1-methylethyl)- C9H18O 0.62 - - - 16.364 2H-pyran-2-methanol, tetrahydro- C6H12O2 - 1.07 - 0.81 19.849 4-heptanol, 2, 6-dimethyl-4-(1-methylethyl)- C12H26O - - 0.44 - 21.858 1-dodecanol, 2-octyl- C20H42O 0.17 0.21 0.53 0.29 Acids 8.365 butanoic acid, 4-hydroxy- C4H8O3 0.21 0.27 - - 9.702 2-propenoic acid, 2-methyl-, 2-methylpropyl ester C8H14O2 - 0.16 0.27 - 12.043 2-hexenoic acid, 3, 4, 4-trimethyl-5-oxo-, (Z)- C9H14O3 0.21 - 0.21 - 13.569 butanoic acid, anhydride C8H14O3 15.28 15.45 16.07 15.64 13.732 2-oxopentanedioic acid C5H6O5 1.93 - 0.62 0.61 28.612 octadecanoic acid C18H36O2 0.14 0.18 0.18 - Others 5.066 2-ethoxytetrahydrofuran C6H12O2 2.98 2.74 2.42 3.25 8.240 2H-pyran, 2-ethoxytetrahydro- C7H14O2 0.58 0.50 0.59 0.81 8.390 furan, tetrahydro-2-methyl- C5H10O - - 0.18 0.26 18.250 2, 2-diethoxytetrahydrofuran C8H16O3 0.21 0.23 0.18 - 9.869 benzaldehyde C7H6O 0.39 1.01 1.24 1.16 16.364 pentanal, 5-[(tetrahydro-2H-pyran-2-yl) oxy]- C10H18O3 1.28 - 1.18 - 18.784 acrolein, 3-ethoxy-, diethyl acetal C9H18O3 0.43 0.48 - - 21.658 tridecanal C13H26O 0.37 0.37 0.32 0.67 13.110 mequinol C7H8O2 - 0.37 - - 15.635 phenol, 2-ethoxy- C8H10O2 0.31 0.30 0.30 - 23.102 phenol, 2, 4-bis (1, 1-dimethylethyl)- C14H22O 1.28 1.26 1.03 1.45 8.495 benzene, (1-methylethyl)- C9H12 11.02 10.81 14.92 17.93 10.476 .alpha.-methylstyrene C9H10 0.48 0.46 0.68 0.75 15.817 benzene, [1-[[1-(1-methylethyl)-3-butenyl]oxy]ethyl]- C15H22O 1.04 1.30 - 1.13 -: not detected or less than 0.1% -

[1] 中国农业部/美国能源部.中国生物质资源可获得性评价[M].北京:中国环境科学出版社, 1998.Chinese Ministry of Agriculture & US Department Energy. Chinese Biomass Resources Availability Evaluation[M]. Beijing:China Environmental Science Press, 1998. [2] 宋春财, 王刚, 胡浩权.生物质热化学液化技术研究进展[J].太阳能学报, 2004, 25(2):242-248. http://www.cnki.com.cn/Article/CJFDTOTAL-TYLX200402022.htmSONG Chun-cai, WANG Gang, HU Hao-quan. Progress in thermochemical liquefaction of biomass[J]. Acta Energ Sol Sin, 2004, 25(2), 242-248. http://www.cnki.com.cn/Article/CJFDTOTAL-TYLX200402022.htm [3] 日本能源学会.生物质和生物能源手册[M].北京:化学工业出版社, 2007.Japan Institute of Energy. Manual of Biomass and Bioenergy[M]. Beijing:Chemical Industry Press, 2007. [4] 邓可蕴. 21世纪我国生物质能发展战略[J].中国电力, 2000, 33(9):82-84. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDL200009025.htmDENG Ke-yun. Development strategy of China's bio energy in 21st century[J]. Electr Power, 2000, 33(9):82-84. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDL200009025.htm [5] 骆仲泱, 周劲松, 王树荣, 余春江, 方梦祥, 岑可法.中国生物质能利用技术评价[J].中国能源, 2004, 26(9):39-42. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGLN200409013.htmLUO Zhong-yang, ZHOU Jin-song, WANG Shu-rong, YU Chun-jiang, FANG Meng-xiang, CEN Ke-fa. Review of the technologies of biomass energy utilization in China[J]. Energy China, 2004, 26(9):39-42. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGLN200409013.htm [6] 曹湘洪.我国生物能源产业健康发展的对策思考[J].化工进展, 2007, 26(7):905-913. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ200707002.htmCAO Xiang-hong. Thoughts on the countermeasures towards the healthy development of Chinese bio-energy industry[J]. Chem Ind Eng Prog, 2007, 26(7):905-913. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ200707002.htm [7] 国家自然科学基金委员会.国家自然科学基金"十三五"发展规划[Z]. 2016, 06.The National Natural Science Foundation of China. The National Natural Science Foundation of the "13th Five-Year" development plan[Z]. 2016, 06. [8] YAMAZAKI J, MINAMI E, SAKA S. Liquefaction of beech wood in various supercritical alcohols[J]. Wood Sci, 2006, 52(6):527-532. doi: 10.1007/s10086-005-0798-4 [9] MAZAHERI H, LEE K T, BHATIA S, MOHAMED A R. Sub/supercritical liquefaction of oil palm fruit press fiber for the production of bio-oil:Effect of solvents[J]. Bioresour Technol, 2010, 101(19):7641-7647. doi: 10.1016/j.biortech.2010.04.072 [10] 郑朝阳, 解新安, 陶红秀, 郑璐丝, 李雁.亚/超临界乙醇液化秸秆纤维素解聚反应研究与机理初探[J].燃料化学学报, 2012, 40(5):526-532. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17938.shtmlZHENG Chao-yang, XIE Xin-an, TAO Hong-xiu, ZHENG Lu-si, LI Yan. Depolymerization of stalk cellulose during its liquefaction in sub-and supercritical ethanol[J]. J Fuel Chem Technol, 2012, 40(5):526-532. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17938.shtml [11] 陶红秀, 解新安, 郑朝阳, 汤成正, 战晓青.玉米秸秆纤维素在亚/超临界乙醇中的液化行为研究[J].西北农林科技大学学报(自然科学版), 2014, 42(1):196-204. http://www.cnki.com.cn/Article/CJFDTOTAL-XBNY201401031.htmTAO Hong-xiu, XIE Xin-an, ZHENG Chao-yang, ZHAN Xiao-qing. Liquefaction of cornstalk cellulose in sub/super-critical ethanol[J]. J Northwest Univ A&F (Nat Sci Ed), 2014, 42(1):196-204. http://www.cnki.com.cn/Article/CJFDTOTAL-XBNY201401031.htm [12] 陈晓菲.稻秆粉末醇解产物的分析和醇解机理研究[D].武汉:武汉科技大学, 2008.CHEN Xiao-fei. Analysis of the products from alkanolysis of the rice-stalk powder and related mechanism study[D].Wuhan:Wuhan University of Science and Technology, 2008. [13] MURNIEKS R, KAMPARS V, MALINS K, APSENIECE L. Hydrotreating of wheat straw in toluene and ethanol[J]. Bioresour Technol, 2014, 163:106-111. doi: 10.1016/j.biortech.2014.04.022 [14] 唐仕荣.玉米秆超临界乙醇解聚产物分析[J].安徽农业科学, 2009, 37(11):4869-4870. http://www.cnki.com.cn/Article/CJFDTOTAL-AHNY200911014.htmTANG Shi-rong. Analysis of depolymerization product of cornstalk in supercritical ethanol[J]. J Anhui Agri Sci, 2009, 37(11):4869-4870. http://www.cnki.com.cn/Article/CJFDTOTAL-AHNY200911014.htm [15] ZHENG C, TAO H, XIE X. Distribution and characterizations of liquefaction of celluloses in sub-and super-critical ethanol[J]. Bioresour, 2013, 8(1):648-662. https://www.researchgate.net/publication/270503466_Distribution_and_Characterizations_of_Liquefaction_of_Celluloses_in_Sub-_and_Super-Critical_Ethanol [16] 朱明江.自旋捕捉剂修饰及生物学效应研究[D].浙江:浙江大学, 2010.ZHU Ming-jiang. The modificatios of spin trappers and their application in vivo[D]. Zhejiang:Zhejiang University, 2010. [17] 刘扬, 徐广智, 赵瑶兴, 孙祥玉.电极过程自由基中间体的ESR研究-取代苯基重氮盐的电解还原[J].波谱学杂志, 1987, 4(1):29-33. http://www.cnki.com.cn/Article/CJFDTOTAL-PPXZ198701006.htmLIU Yang, XU Guang-zhi, ZHAO Yao-xing, SUN Xiang-yu. ESR study of the ferr radical intermediates formed during the electrolytic process-electrolytic reduction of substituted phenyldiazonium salts[J]. Chin J Magn Reson, 1987, 4(1):29-33. http://www.cnki.com.cn/Article/CJFDTOTAL-PPXZ198701006.htm [18] 刘扬, 徐广智, 赵瑶兴, 孙祥玉.甲苯基重氮盐及其与冠醚络合物光解活泼自由基的ESR研究[J].物理化学学报, 1989, 5(2):135-140. http://www.cnki.com.cn/Article/CJFDTOTAL-WLHX198902001.htmLIU Yang, XU Guang-zhi, ZHAO Yao-xing, SUN Xiang-yu.ESR study on the free radical intermediates formed during the photolysis of methyl[J]. Acta Phys-Chim Sin, 1989, 5(2):135-140. http://www.cnki.com.cn/Article/CJFDTOTAL-WLHX198902001.htm [19] 黄忠喜.负载钴催化剂催化原子转移自由基聚合研究[D].上海:上海交通大学, 2008.HUANG Zhong-xi. Atom transfer radical polymerization catalyzed by immobilized cobalt catalyst[D].Shanghai:Shanghai Jiaotong University, 2008. [20] 魏巍, 解新安, 汤成正, 李雁, 李璐, 王娅莉, 魏星, 樊荻.亚/超临界乙醇中烃基和氢自由基作用下的纤维素液化行为[J].燃料化学学报, 2016, 44(4):415-421. doi: 10.1016/S1872-5813(16)30021-4LI Wei, XIE Xin-an, TANG Cheng-zheng, LI Yan, LI Lu, WANG Ya-li, WEI Xing, FAN Di. Effects of hydroxyl and hydrogen free radicals on the liquefaction of cellulose in sub/supercritical ethanol[J]. J Fuel Chem Technol, 2016, 44(4):415-421. doi: 10.1016/S1872-5813(16)30021-4 [21] GB/T 2677.1, 造纸原料分析用试样的采取[S].GB/T 2677.1, Fibrous raw material of sampling for analysis[S]. [22] GB/T 2677.10-95, 造纸原料综纤维素含量的测定[S].GB/T 2677.10-95, Fibrous raw material-determination of holocellulose[S]. [23] GUO Z, BAI Z, BAI J, WANG Z, LI W. Co-liquefaction of lignite and sawdust under syngas[J]. Fuel Process Technol, 2011, 92(1):119-125. doi: 10.1016/j.fuproc.2010.09.014 [24] 邵千钧, 彭锦星, 修树东, 文先红.竹子在超临界甲醇中的热解油产物分析[J].太阳能学报, 2007, 28(9):984-987. http://www.cnki.com.cn/Article/CJFDTOTAL-TYLX200709011.htmSHAO Qian-jun, PENG Jin-xing, XIU Shu-dong, WEN Xian-hong. Analysis of oil products by pyrolysis of bamboo in supercritical methanol[J]. Acta Energ Sol Sin, 2007, 28(9):984-987. http://www.cnki.com.cn/Article/CJFDTOTAL-TYLX200709011.htm [25] SHARYPOV V I, KUZNETSOV B N. Catalytic hydroliquefaction of barzass liptobiolitic coal in a petroleum residue as a solvent[J]. Fuel, 2006, 85(7):918-922. https://www.researchgate.net/profile/A_Startsev/publication/239142291_Catalytic_hydroliquefaction_of_Barzass_liptobiolitic_coal_in_a_petroleum_residue_as_a_solvent/links/558e189f08ae47a3490bdf8c.pdf?inViewer=0&pdfJsDownload=0&origin=publication_detail [26] PÜTÜN A E, ÖZCAN A, PÜTÜN E. Pyrolysis of hazelnut shells in a fixed-bed tubular reactor:Yields and structural analysis of bio-oil[J]. J Anal Appl Pyrolysis, 1999, 52(1):33-49. doi: 10.1016/S0165-2370(99)00044-3 [27] 武景丽, 汪丛伟, 阴秀丽, 吴创之, 马隆龙, 周肇秋, 陈汉平.基于TG-FTIR的生物油重质组分热解特性研究[J].太阳能学报, 2010, 31(1):113-117. http://www.cnki.com.cn/Article/CJFDTOTAL-TYLX201001023.htmWU Jing-li, WANG Cong-wei, YIN Xiu-li, WU Chuang-zhi, MA Long-long, ZHOU Zhao-qiu, CHEN Han-ping. Study on pyrolysis of heavy fractions of bio-oil by using TG-FTIR analysis[J]. Acta Energ Sol Sin, 2010, 31(1):113-117. http://www.cnki.com.cn/Article/CJFDTOTAL-TYLX201001023.htm [28] SOARES S, RICARDO N M P S, JONES S, HEATLEY F. High temperature thermal degradation of cellulose in air studied using FTIR and 1H and 13C solid-state NMR[J]. Eur Polym J, 2001, 37(4):737-745. doi: 10.1016/S0014-3057(00)00181-6 [29] TANG C, TAO H, ZHAN X, XIE X. Mechanism of esters formation during cellulose liquefaction in sub-and supercritical ethanol[J]. BioResources, 2014, 9(3):4946-4957. [30] 陶红秀, 解新安, 汤成正, 田文广.玉米秸秆纤维素在亚/超临界乙醇中液化生成酮类化合物的机理探讨[J].燃料化学学报, 2013, 41(1):60-66. doi: 10.1016/S1872-5813(13)60010-9TAO Hong-xiu, XIE Xin-an, TANG Cheng-zheng, TIAN Wen-guang. Mechanism of ketones formation from cellulose liquefaction in sub-and supercritical ethanol[J]. J Fuel Chem Technol, 2013, 41(1):60-66. doi: 10.1016/S1872-5813(13)60010-9 -

下载:

下载: