-

摘要: 采用13C-NMR技术表征出汪清三个矿区油页岩的碳原子化学结构, 并获得碳骨架结构的12个重要参数。利用热重和傅里叶红外联用技术 (TG-FTIR) 得出了在50℃/min升温速率和热解终温600℃下油页岩热解时轻质气体的生成规律。采用基于燃料化学结构的FLASHCHAIN模型对热解产物的析出进行了模拟, 并与实验结果相比较。结果表明, FLASHCHAIN模型用来模拟汪清油页岩热解时, 在520℃之前有较好的效果, 当温度高于520℃时, 由于二次热解反应及页岩中矿物质分解对热解过程的影响, 导致模型的预测值与实验值存在一定的误差, 且随着温度的升高两者之间的误差也随之加大。

-

关键词:

- 油页岩 /

- 13C-NMR /

- 热重红外 /

- FLASHCHAIN

Abstract: The carbon atom chemical structure of three Wangqing oil shales was characterized by 13C-NMR techniques, and twelve important parameters of the carbon skeleton structure were obtained.Thermogravimetric-Fourier transform infrared spectroscopy (TG-FTIR) tests were used to obtain the formation of light gases during pyrolysis at 50℃/min and the final temperature of 600℃.The FLASHCHAIN model, which was established based on the structure of fuel, was employed to simulate the evolution of pyrolysis products and compared with the experimental tests.The results show that the model has a good simulation below 520℃, some errors occur above 520℃ due to the influence of secondary pyrolysis reactions and decomposition of minerals in the shale.The errors increase gradually with the increasing pyrolysis temperature.-

Key words:

- oil shale /

- 13C-NMR /

- TG-FTIR /

- FLASHCHAIN

-

表 1 油页岩样品的工业分析、元素分析和原子比

Table 1 Proximate analysis, ultimate analysis and atomic ratio of oil shale samples

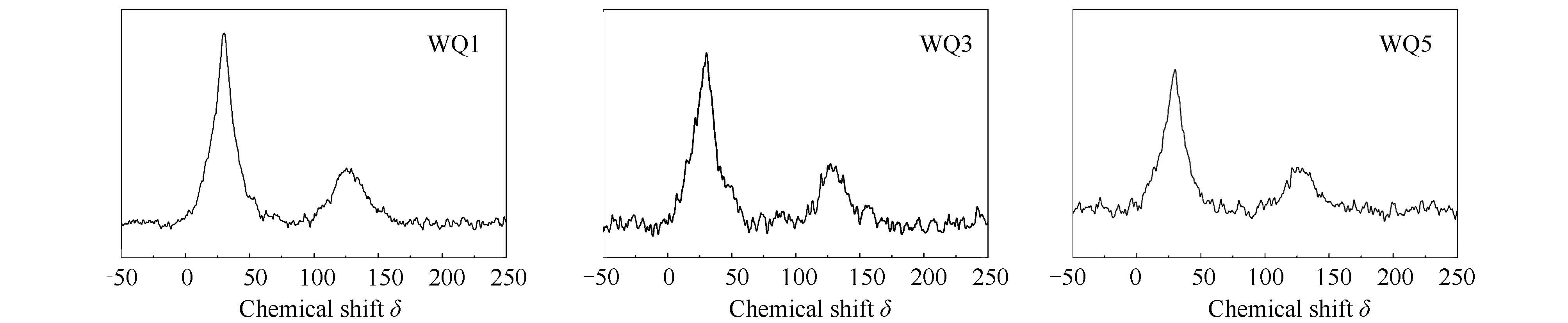

Sample Proximate analysis wad/% Ultimate analysis wad/% Atomic ratio M V A FC C H O N S H/C O/C WQ1 2.22 17.60 78.18 2.00 14.30 1.07 5.76 0.69 0.26 0.90 0.30 WQ3 1.78 15.02 81.17 2.03 11.23 1.41 5.44 0.55 0.20 1.51 0.36 WQ5 1.86 16.11 80.28 1.75 12.03 1.50 5.56 0.63 0.21 1.50 0.35 表 2 碳化学位移归属

Table 2 Assignments for peaks in 13C-NMR spectra

Chemical shift δ Carbon functionality WQ1 WQ3 WQ5 14-16 aliphatic methyl 2.48 2.22 3.02 16-22 aromatic methyl 7.75 6.06 9.94 22-36 methylene and aliphatic C (2) carbon 47.43 34.05 58.36 36-50 methine and quaternary carbon 18.91 12.97 21.49 50-55 oxy-methylene 2.79 2.32 1.57 55-75 oxy-methine 3.10 0.72 0.69 75-90 oxy-quaternary 0.31 0.75 0.00 100-129 ortho-oxyaromatic protonated 20.46 11.89 21.70 129-137 bridgehead aromatic carbon 8.06 6.84 10.59 137-148 aromatic branched 6.20 4.56 6.38 148-164 oxy-aromatic carbon 2.79 2.69 2.09 164-188 carboxyl 0.31 0.31 0.00 188-220 carbonyl 0.62 0.00 0.00 表 3 油页岩样品碳骨架结构参数

Table 3 Carbon structural parameters of oil shale sample

Sample fa f′a fac faH faN faP faS faB fal falH fal* falO WQ1 35.18 35.18 0 15.90 19.28 2.17 4.82 6.27 64.82 56.14 8.68 4.82 WQ3 36.07 36.07 0 13.39 22.68 3.03 5.13 7.70 63.93 56.36 7.57 4.27 WQ5 35.64 35.64 0 15.25 20.39 1.47 4.48 7.44 64.36 57.72 6.64 1.59 note:fa: total aromatic carbon;f′a: aromatic carbons;fac: carbonyl carbon;faH: protonated aromatic carbon;faN: non-protonated aromatic carbon;faP: phenolic hydroxyl carbon;faS: alkyl substituted aromatic carbon;faB: bridgehead aromatic carbon;fal: totalaliphatic carbon;falH: methylene or methane carbon;fal* : methyl and quaternary carbon;falO: oxygen-kinked aliphatic carbon 表 4 结构参数的命名及计算公式

Table 4 Nomenclature and equations of structural parameters

No. Symbol Structural parameter Equation 1 xb ratio of aromatic bridging carbons and

aromatic ring carbons${x_{\rm{b}}}=\frac{{f_{\rm{a}}^{\rm{B}}}}{{{{f'}_{\rm{a}}}}}$ 2 Ca carbons of aromatic cluster ${x_{\rm{b}}}=\frac{{1 -tan{\rm{h}}\frac{{\left ({{C_{\rm{a}}} -{C_0}} \right)}}{m}}}{2}{{x'}_{\rm{b}}} + \frac{{1 + tan{\rm{h}}\left ({\frac{{{C_{\rm{a}}} -{C_0}}}{m}} \right)}}{2}{{x''}_{\rm{b}}}$ 3 Ccl cluster carbons ${C_{{\rm{cl}}}}={C_{\rm{a}}} + {C_{{\rm{al}}}}$ 4 Cal aliphatic carbons ${C_{{\rm{al}}}}={C_{\rm{a}}}\frac{{{f_{{\rm{al}}}}}}{{{f_{\rm{a}}}}}$ 5 Cp circumferential carbons ${C_{\rm{p}}}={C_{{\rm{cl}}}}\left ({f_{\rm{a}}^{\rm{H}} + f_{\rm{a}}^{\rm{S}} + f_{\rm{a}}^{\rm{B}}} \right)$ 6 Ra aromatic rings ${R_{\rm{a}}}=\frac{1}{2}\left ({{C_{\rm{a}}} -{C_{\rm{p}}}} \right) + 1$ 表 5 油页岩样品的团簇结构参数

Table 5 Structural parameters of oil shale aromatic cluster

Sample xb Ca Ccl Cal Cp Ra WQ1 0.1714 8.53 24.37 15.84 6.15 2.19 WQ3 0.2134 10.64 29.50 18.86 7.73 2.46 WQ5 0.2087 10.40 29.18 18.78 7.93 2.24 -

[1] 刘招君, 柳蓉.中国油页岩特征及开发利用前景分析[J].地学前缘, 2005, 12(3):315-322. http://www.cnki.com.cn/Article/CJFDTOTAL-DXQY200503044.htmLIU Zhao-jun, LIU Rong.Oil shale resource state and evaluating system[J].Earth Science Frontiers, 2005, 12(3):315-323. http://www.cnki.com.cn/Article/CJFDTOTAL-DXQY200503044.htm [2] HOU X L.Prospect of oil shale and shale oil industry.Proceedings international conference on oil shale oil[M].Beijing:Chemical Industry Press, 1988:7-15. [3] QIAN J L, YIN L.Oil shale-petroleum alternative[M].Beijing:China Petrochemical Press, 2008:30-34. [4] NIKSA S.FLASHCHAIN theory for rapid coal devolatilization.1.Formulation[J].Energy Fuels, 1991, 5(5):647-665. doi: 10.1021/ef00029a006 [5] NIKSA S.FLASHCHAIN theory for rapid coal devolatilization.2.Impact of operating conditions[J].Energy Fuels, 1991, 5(5):665-673. doi: 10.1021/ef00029a007 [6] NIKSA S.FLASHCHAIN theory for rapid coal devolatilization.3.Modeling the Behavior of Various Coals[J].Energy Fuels, 1991, 5(5):673-683. doi: 10.1021/ef00029a008 [7] NIKSA S.FLASHCHAIN theory for rapid coal devolatilization.4.Predicting ultimate yields from ultimate analyses alone[J].Energy Fuels, 1994, 8(3):659-670. doi: 10.1021/ef00045a022 [8] NIKSA S.FLASHCHAIN Theory for rapid coal devolatilization.5.Interpredicting rates of devolatilization for various coal types and operating conditions[J].Energy Fuels, 1994, 8(3):671-679. doi: 10.1021/ef00045a023 [9] NIKSA S.FLASHCHAIN theory for rapid coal devolatilization.6.Predicting the evolution of fuel nitrogen from various coals[J].Energy Fuels, 1995, 9(3):467-478. doi: 10.1021/ef00051a011 [10] NIKSA S.FLASHCHAIN theory for rapid coal devolatilization.7.Predicting the release of oxygen species from various coals[J].Energy Fuels, 1996, 10(1):173-187. doi: 10.1021/ef950067l [11] SOLOMON P R, HAMBIEN D G, CARANGRLO R M.General model of coal devolatilization[J].Energy Fuels, 1988, 2(4):405-422. doi: 10.1021/ef00010a006 [12] GRANT D M, PUGMIRE R J, FLETCHER T H.Chemical model of coal devolatilization using percolation lattice statistics[J].Energy Fuels, 1989, 3(2):175-186. doi: 10.1021/ef00014a011 [13] FLETCHER T H, KERSTEIN A R, PUGMIRE R J.Chemical percolation model for devolatilization.2.Temperature and heating rate effects on product yields[J].Energy Fuels, 1990, 4(1):54-60. doi: 10.1021/ef00019a010 [14] THOMAS FLETCHER.Chemical percolation model for devolatilization[J].Energy Fuels, 1992, 6(1):414-431. [15] JUPUDI R S, ZAMANSKY V, FLETCHER T H.Prediction of light gas composition in coal devolatilization[J].Energy Fuels, 2009, 23(6):3063-3067. doi: 10.1021/ef9001346 [16] NIKSA S.Predicting the rapid devolatilization of diverse forms of biomass with bio-FLASHCHAIN[J].Proc Combust Inst, 2000, 28(2):2727-2733. doi: 10.1016/S0082-0784(00)80693-1 [17] CHEN Y, CHARPENAY S, JENSEN A.Modeling of biomass pyrolysis kinetics[J].Symp (Int) Combust, 1998, 27(1):1327-1334. doi: 10.1016/S0082-0784(98)80537-7 [18] FLETCHER T H, HARLAND R, WEBSTER J.Prediction of tar and light gas during pyrolysis of black liquor and biomass[J].Energy Fuels, 2012, 26(6):3381-3387. doi: 10.1021/ef300574n [19] DOMINIC B.An advanced model of coal devolatilization based on chemical structure[D].Provo:Brigham Young University, 1999:39-40. [20] 秦匡宗, 劳永新.茂名和抚顺油页岩组成结构的研究I.有机质的芳碳结构[J].燃料化学学报, 1985, 13(2):133-140.QIN Kuang-zong, LAO Yong-xin.Investigation on the constitution and structure of Maoming and Fushun oil shale I.The structural components of the organic matter[J].J Fuel Chem Technol, 1985, 13(2):133-140. [21] TONG J, HAN X, WANG S.Evaluation of structural characteristics of huadian oil shale kerogen using direct techniques (Solid-State 13C-NMR, XPS, FT-IR and XRD)[J].Energy Fuels, 2011, 25(9):4006-4013. doi: 10.1021/ef200738p [22] SOLUM M S, PUGMIRE R J, GRANT D M.13C solid-state NMR argonne premium coals[J].Energy Fuels, 1989, 3(2):187-193. doi: 10.1021/ef00014a012 -

下载:

下载: