Effect of vermiculite on the slagging characteristics of high sodium and high calcium Zhundong coal

-

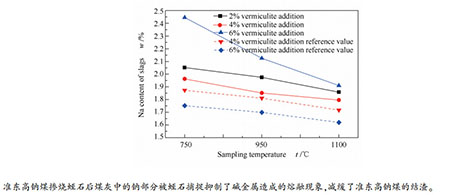

摘要: 采用一维沉降炉,辅以灰熔点仪的实验方法,将蛭石与高钠高钙准东煤掺混燃烧,研究其对高钠高钙准东煤结渣特性的影响。结果表明,随着蛭石掺烧量的提高,灰熔点温度呈现先降低后升高的趋势,当掺烧量为6%时灰熔点温度最低;蛭石掺烧量越高,高钠高钙准东煤结渣情况改善越明显,当掺烧量达到4%时,渣样变得疏松多孔,质地变脆,渣样与沉积探针之间的黏附性较弱,极易通过吹灰除去,建议蛭石掺烧量为4%;煤灰中原始矿物质以石英、钙铝黄长石或钙黄长石以及辉石类的低熔点矿物质为主,掺烧蛭石后,含钠的绿辉石矿物质被转化为韭闪石,含铁的斜辉石、赤铁矿等矿物质被转化为铁橄榄石,渣样中的矿物质均以高熔点的镁橄榄石为主;蛭石具有固钠的作用,取样温度越低,蛭石掺混量越高,其固钠效果越明显。Abstract: The effect of vermiculite on the slagging characteristics of high-sodium and high-calcium Zhundong coal was studied by a drop-tube furnace and with ash fusion tester. The results show that with the increase of the amount of vermiculite blended, the ash melting point temperature first decreases and then increases. When the ratio of blending is 6%, the ash fusion point temperature is the lowest. The higher the blending ratio is, the more obvious the improvement of the slagging condition of Zhundong coal is. When the ratio of blending is 4%, the slag sample becomes loose and porous, the texture turns to be brittle, and the adhesion between the slag sample and the deposition probe is weak, being easy to be removed by soot blowing. It is recommended that the amount of vermiculite blended should be 4%. The original mineral in coal ash is mainly composed of quartz, gehlenite and low fusion point minerals of pyroxene. After blending vermiculite, the omphacite, sodium-containing minerals, is converted into pargasite, and the iron-bearing minerals such as augite and hematite are converted into forsterite ferroan, and the minerals in the slag sample are mainly forsterite, which has a high fusion point. Sodium can be captured by vermiculite. With the sampling temperature decreasing and the vermiculite blending ratio increasing, the effect of sodium capture becomes more and more obvious.

-

图 4 纯蛭石1100 ℃时的微观形貌照片

Figure 4 SEM pictures of vermiculite at 1100 ℃

(a): 50×; (b) : 800×, 1 area in Figure 4(a)

图 7 天池能源煤掺烧不同比例蛭石的XRD谱图

Figure 7 XRD patterns of slag with different additional ratios of vermiculite

(a): raw coal; (b): 1%vermiculite; (c): 2%vermiculite; (d): 4%vermiculite; (e): 6%vermiculite 1: SiO2(Quartz or Silicon Sulfate); 2: Ca2Al2SiO7(Gehlenite); 3: Fe2O3(Hematite); 4: CaSO4(Anhydrite or Calcium Sulfate); 5: CaO(Lime); 6: Mg2SiO4(Forsterite)or Mg1.8Fe0.2SiO4(Forsterite ferroan); 7: (Na, Ca)(Al, Mg)Si2O6(Omphacite); 8: NaCa2Mg4Al(Si6Al2)O22(OH)2(Pargasite); 9: Ca2(Mg0.75Al0.25)(Si1.75Al0.25O7)(Akermanite); 10: Al2O3(Aluminum Oxide); 11: Ca(Mg, Fe, Al)(SiAl)2O6(Augite); 12: CaMgSi2O6(Diopside); 13: Ca2Fe1.052Al0.665Mg0.133Si0.133O5(Brownmillerite); 14: Ca(Al2Si2O)(Anorthite)

图 8 钠含量随温度及蛭石添加量的变化

Figure 8 Diagram of sodium contents with the changes of temperature and vermiculite addition

— ■ —: 2% vermiculite addition; — ● —: 4% vermiculite addition; — ▲ —: 6% vermiculite addition; --▼--: 4% vermiculite addition reference value; --◆--: 6% vermiculite addition reference value

表 1 天池能源煤的元素分析与工业分析

Table 1 Proximate analysis and ultimate analyses of raw coal

Ultimate analysis w/% Proximate analysis w/% C H O N S Ad Vd FCd Mar 67.50 4.00 20.69 0.70 0.57 6.54 35.75 57.71 24.05 表 2 煤灰与蛭石的成分分析

Table 2 Composition analysis of coal ash and vermiculite

Experiment sample Composition w/% CaO MgO Na2O K2O Fe2O3 Al2O3 SiO2 SO3 TiO2 Cl others Coal ash 24.20 8.39 5.36 0.62 5.05 13.50 15.70 21.30 0.84 1.97 3.07 Vermiculite 3.67 22.80 1.50 7.66 5.85 13.40 39.90 1.16 1.56 0.23 2.27 表 3 沉降炉运行参数

Table 3 Operation parameters of drop-tube furnace

Items Dimension Numerical value Furnace temperature ℃ 1300 Feeding rate (g·min-1) 1.2 Primary air (m3·h-1) 0.15 Secondary air (m3·h-1) 0.9 Excess air ratio - 1.2 Outlet oxygen - 0.05 -

[1] 严陆光, 夏训诚, 吕绍勤, 吴甲春, 林闽, 黄常纲.大力推进新疆大规模综合能源基地的发展[J].电工电能新技术, 2011, 30(1):1-7. doi: 10.3969/j.issn.1003-3076.2011.01.001YAN Lu-guang, XIA Xun-cheng, LYU Shao-qin, WU Jia-chun, LIN Min, HUANG Chang-gang. Great promotion of development of large scale integrative energy base in Xinjiang[J]. Adv Technol Elect Eng Energy, 2011, 30(1):1-7. doi: 10.3969/j.issn.1003-3076.2011.01.001 [2] 宋汉疆.新疆准东煤田煤炭综合利用问题探讨[J].西部探矿工程, 2008, 20(9):149-151. doi: 10.3969/j.issn.1004-5716.2008.09.053SONG Han-jiang. Study of comprehensive utilization problem of Xinjiang Zhundong coal[J]. West China Expor Eng, 2008, 20(9):149-151. doi: 10.3969/j.issn.1004-5716.2008.09.053 [3] 杨忠灿, 刘家利, 姚伟.准东煤灰沾污指标研究[J].洁净煤技术, 2013, 19(2):81-84. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201302022YANG Zhong-can, LIU Jia-li, YAO Wei. Fouling index of Zhundong coal ash[J]. Clean Coal Technol, 2013, 19(2):81-84. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201302022 [4] 张守玉, 陈川, 施大钟, 吕俊复, 王健, 郭熙, 董爱霞, 熊绍武.高钠煤燃烧利用现状[J].中国电机工程学报, 2013, 33(5):1-12, 17. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201305001ZHANG Shou-yu, CHEN Chuan, SHI Da-zhong, LYU Jun-fu, WANG Jian, GUO Xi, DONG Ai-xia, XIONG Shao-wu. Situation of combustion utilization of high sodium coal[J]. Proc CSEE, 2013, 33(5):1-12, 17. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201305001 [5] 董明钢.高钠煤对锅炉受热面结渣、沾污和腐蚀的影响及预防措施[J].热力发电, 2008, 37(9):35-39. doi: 10.3969/j.issn.1002-3364.2008.09.010DONG Ming-gang. Influence of high-sodium coal upon slagging, contamination, and corrosion on the heating surface of boilers[J]. Therm Power Gen, 2008, 37(9):35-39. doi: 10.3969/j.issn.1002-3364.2008.09.010 [6] HAO Z, ZHOU B, LI L, ZHANG H. Experimental measurement of the effective thermal conductivity of ash deposit for high sodium coal (Zhun Dong coal) in a 300 KW test furnace[J]. Energy Fuels, 2013, 27(11):7008-7022. doi: 10.1021/ef4012017 [7] LI G, WANG CA, YAN Y, JIN X, LIU Y, CHE D. Release and transformation of sodium during combustion of Zhundong coals[J]. J Energy Inst, 2016, 89(1):48-56. doi: 10.1016/j.joei.2015.01.011 [8] 沈铭科, 邱坤赞, 黄镇宇, 王智化, 刘建忠.准东煤掺烧高岭土对固钠率及灰熔融特性影响研究[J].燃料化学学报, 2015, 43(9):1044-1051. doi: 10.3969/j.issn.0253-2409.2015.09.004SHEN Ming-ke, QIU Kun-zan, HUANG Zhen-yu, WANG Zhi-hua, LIU Jian-zhong. Influence of kaolin on sodium retention and ash fusion characteristic during combustion of Zhundong coal[J]. J Fuel Chem Technol, 2015, 43(9):1044-1051. doi: 10.3969/j.issn.0253-2409.2015.09.004 [9] 张利孟, 董信光, 刘科, 谭厚章, 王学斌, 魏博.高岭土对准东煤结渣特性及矿物质演变的影响[J].燃料化学学报, 2015, 43(10):1176-1181. doi: 10.3969/j.issn.0253-2409.2015.10.004ZHANG Li-meng, DONG Xin-guang, LIU Ke, TAN Hou-zhang, WANG Xue-bin, WEI Bo. Effect of kaolin on ash slagging and mineral conversion of Zhundong coal[J]. J Fuel Chem Technol, 2015, 43(10):1176-1181. doi: 10.3969/j.issn.0253-2409.2015.10.004 [10] 王学斌, 魏博, 张利孟, 谭厚章, 徐通模.温度和SiO2添加物对准东煤中碱金属的赋存形态及迁徙特性的影响[J].热力发电, 2014, 43(8):84-88. doi: 10.3969/j.issn.1002-3364.2014.08.084WANG Xue-bin, WEI Bo, ZHANG Li-meng, TAN Hou-zhang, XU Tong-mo. Effect of temperature and silicon additives on occurrence and transformation characteristics of alkali metal in Zhundong coal[J]. Therm Power Gen, 2014, 43(8):84-88. doi: 10.3969/j.issn.1002-3364.2014.08.084 [11] 马尚文, 刘霞, 许洁, 阿更兄. SiO2含量对煤灰熔融特性的影响[J].广东化工, 2013, 40(13):81-82. doi: 10.3969/j.issn.1007-1865.2013.13.039MA Shang-wen, LIU Xia, XU Jie, A Geng-xiong. The effect of SiO2 on fusion temperature of coal ash[J]. Guangdong Chem Ind, 2013, 40(13):81-82. doi: 10.3969/j.issn.1007-1865.2013.13.039 [12] 王云刚, 赵钦新, 马海东, 姜薇薇.准东煤灰熔融特性试验研究[J].动力工程学报, 2013, 33(11):841-846. http://d.old.wanfangdata.com.cn/Periodical/dlgc201311003WANG Yun-gang, ZHAO Qin-xin, MA Hai-dong, JIANG Wei-wei. Experimental study on ash fusion characteristics of Zhundong coal[J]. J Chin Soc Power Eng, 2013, 33(11):841-846. http://d.old.wanfangdata.com.cn/Periodical/dlgc201311003 [13] 张雪慧, 魏博, 马瑞, 阮仁晖, 谭厚章.准东地区粉煤灰改性做高碱煤缓焦剂的熔融性能评估[J].热力发电, 2019, 48(1):43-48. http://d.old.wanfangdata.com.cn/Periodical/rlfd201901008ZHANG Xue-hui, WEI Bo, MA Rui, RUAN Ren-hui, TAN Hou-zhang. The evaluation of fusion characteristics on the high alkali coal slagging inhibitor by modified fly ash from Zhundong area[J]. Therm Power Gen, 2019, 48(1):43-48. http://d.old.wanfangdata.com.cn/Periodical/rlfd201901008 [14] 魏博, 王学斌, 张利孟, 谭厚章, 徐通模.掺烧废弃硅粉对准东煤钠迁徙及灰熔融影响的实验研究[J].中国电力, 2014, 47(10):98-102. doi: 10.3969/j.issn.1007-3361.2014.10.037WEI Bo, WANG Xue-bin, ZHANG Li-meng, TAN Hou-zhang, XU Tong-mo. Experimental study on effect of sodium migration and ash fusion of Zhundong coal[J]. Electr Pow, 2014, 47(10):98-102. doi: 10.3969/j.issn.1007-3361.2014.10.037 [15] YAO Y, JIN J, LIU D, WANG Y, KOU X, LIN Y. Evaluation of vermiculite in reducing ash deposition during the combustion of high-calcium and high-sodium Zhundong coal in a drop-tube furnace[J]. Energy Fuels, 2016, 30(4):3488-3494. doi: 10.1021/acs.energyfuels.6b00078 [16] 高姗姗, 金晶, 刘敦禹, 王永贞, 姚宇翔, 寇学森.蛭石复合添加剂对准东煤灰特性影响[J].化工进展, 2017, 36(9):3280-3286. http://d.old.wanfangdata.com.cn/Periodical/hgjz201709019GAO Shan-shan, JIN Jing, LIU Dun-yu, WANG Yong-zhen, YAO Yu-xiang, KOU Xue-sen. Effect of vermiculite composite additives on the anti-slagging behavior during combustion of Zhundong coal[J]. Chem Ind Eng Prog, 2017, 36(9):3280-3286. http://d.old.wanfangdata.com.cn/Periodical/hgjz201709019 [17] 付子文, 王长安, 车得福, 翁青松.成灰温度对准东煤灰理化特性影响的实验研究[J].工程热物理学报, 2014, 35(3):609-613. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gcrwlxb201403043FU Zi-wen, WANG Chang-an, CHE De-fu, WENG Qing-song. Experimental study on the effect of ashing temperature on physicochemical properties of Zhundong coal ashes[J]. J Eng Thermophys, 2014, 35(3):609-613. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gcrwlxb201403043 -

下载:

下载: