Mordenite supported Ni-W self-reducing bifunctional catalyst for cellulose hydrogenolysis into ethylene glycol

-

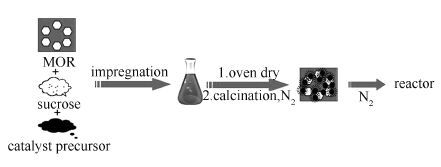

摘要: 以丝光沸石分子筛(MOR)为载体,以高温生物碳源分解产物H2或CO为还原剂,采用等体积浸渍法制备自还原型双功能催化剂Ni-W/MOR,不经过还原过程直接将其应用于纤维素水相氢解制备低碳乙二醇的研究。考察了催化剂的煅烧温度、活性金属含量配比对纤维素转化率和目标产物收率的影响。结果表明,催化剂的煅烧温度在773 K为宜;XRD表征结果说明,催化剂中活性金属结晶度和晶体的种类与催化剂的配比有关;TEM照片可直观地说明,采用上述方法制备的催化剂中活性金属在载体上具有较好的分散性,粒径均小于20 nm。当Ni、W含量分别为10%和15%,煅烧温度为773 K,反应条件为513 K、5.0 MPa、2 h时低碳多元醇总收率为56.92%,其中,乙二醇收率为52.30%。Abstract: Based on the reducing gases (H2 and CO) generated from biomass-based carbon at high clacination temperature, self-reducing bifunctional catalyst Ni-W/MOR was prepared by incipient impregnation. This series of catalysts were directly applied to cellulose hydrogenolysis to low carbon polyols in aqueous solution, omitting the catalysts reduction step. The effects of catalysts temperature of the catalyst and weight ratio of active components on conversion of cellulose and yield of target products were investigated. The optimal calcination temperature was 773 K through experimental results. XRD analysis showed that the crystallinity and species of metallic alloys were related to different weight ratios of nickel and tungsten. It was intuitively observed that the active metals showed good dispersion on the surface of MOR through TEM characterization, with particles sizes less than 20 nm. The total yield of low carbon polyols was up to 56.92%, including 52.30% of EG under the reaction condition of 5.0 MPa of H2 for 2 h reaction time and the calcination temperature of catalysts was 773 K.

-

Key words:

- mordenite /

- self-reducing catalysts /

- sugar polyols /

- hydrogenolysis /

- ethylene glycol

-

表 1 Ni-W/MOR催化剂的比表面积和孔结构

Table 1 BET results of Ni-W/MOR

Catalyst BET specific surface area A/(m2·g-1) Pore volume v/(cm3·g-1) Average pore diameter d/nm 10%Ni-15%W/MOR-773 K 61.450 0.108 3.823 10%Ni-15%W/MOR-873 K 50.360 0.103 3.821 10%Ni-15%W/MOR-973 K 41.476 0.110 3.821 25%Ni-20%W/MOR-773 K 27.082 0.237 4.125 表 2 煅烧温度对催化剂Ni-W/MOR活性的影响

Table 2 Effect of calcination temperature on catalytic activity of Ni-W/MORa

Entry Catalyst Yield w/% Conv. x/% EGb 1, 2-PG Gly Ery Sor Glu 1 10%Ni-15%W/MOR-673 K 17.91 4.15 0.37 - 1.03 4.98 82 2 10%Ni-15%W/MOR-773 K 52.30 4.31 0.31 - 2.38 9.68 100 3 10%Ni-15%W/MOR-873 K 48.89 4.62 0.33 0.76 3.02 7.89 100 4 10%Ni-15%W/MOR-973 K 44.83 4.99 0.38 1.62 6.36 9.02 100 5 10%Ni-15%W/MOR-1073 K 21.65 1.32 4.82 - 2.53 5.14 95 a: reaction condition: feedstock: cellulose 0.5 g, water 55 mL; catalyst: 0.2 g; temperature: 513 K; H2 pressure: 5.0 MPa; reaction time: 2 h; b: EG: ethylene glycol; 1, 2-PG: 1, 2-propylene glycol; Gly: glycerol; Ery: erythritol; Sor: sorbitol; Glu: glucose 表 3 Ni/W质量比对催化剂Ni-W/MOR活性的影响

Table 3 Effect of Ni/W mass ratio on catalytic activity of Ni-W/MORa

Entry Catalyst Ni/W (mass ratio) Yield w/% Conv. x/% EG 1, 2-PG Gly Ery Sor Glu 1 5%Ni-5%W/MOR-773 K 1:1 b 10.71 4.06 0.56 - 1.44 4.4 90 2 10%Ni-5%W/MOR-773 K 2:1 20.38 3.95 0.32 - 1.89 4.99 96 3 15%Ni-5%W/MOR-773 K 3:1 27.71 5.34 0.42 1.02 1.32 1.41 93 4 10%Ni-10%W/MOR-773 K 2:2 26.63 7.08 0.90 0.55 2.95 4.36 91 5 10%Ni-15%W/MOR-773 K 2:3 52.30 4.31 0.31 - 2.38 9.68 100 6 15%Ni-20%W/MOR-773 K 3:4 27.15 2.96 3.38 1.60 2.96 3.95 98 7 25%Ni-20%W/MOR-773 K 5:4 37.44 4.05 2.70 2.27 4.34 2.25 94 8 25%Ni-25%W/MOR-773 K 5:5 30.96 3.77 2.97 3.70 2.67 4.05 100 9 blank/MOR-773 K - 0.23 - 0.12 - 2.16 4.90 33 10 10%Ni-15%W/MOR-773 Kc 2:3 trace trace - - 3.04 3.80 62 11 10%Ni-15%W/MCd 2:3 36.35 2.60 - 0.90 1.12 2.37 85 a: reaction condition: feedstock: cellulose 0.5 g, water 55 mL; catalyst: 0.2 g; temperature: 513 K; H2 pressure: 5.0 MPa; reaction time: 2 h; b: Ni/W mass ratio 1:1 represents the loading of Ni and W are 5% and 5% resperctively; c: with no sucrose; d: mesoporous carbon -

[1] ROSELINDE O, MICHIEL D, JAN A G, BEAU O B, RICK V, ELENA G, JOHAN A M, ANDREAS R, BERT F S.Conversion of sugar to ethylene glycol with nickel tungsten carbide in a fed-batch reactor:High productivity and reaction network elucidation[J].Green Chem, 2014, 16(2):695-707. doi: 10.1039/C3GC41431K [2] BEAK I G, YOU S J, PARK E D.Direct conversion of cellulose into polyols over Ni/W/SiO2-Al2O3[J].Bioresouce Technol, 2012, 114:684-690. doi: 10.1016/j.biortech.2012.03.059 [3] FUKUOKA A, DHEPE P L.Catalytic conversion of cellulose into sugar alcohols[J].Angew Chem Int Ed, 2006, (31):5161-5163. [4] LUO C, WANG S, LIU H.Cellulose conversion into polyols catalyzed by reversibly formed acids and supported Ruthenium clusters in hot water[J].Angew Chem Int Ed, 2007, 46(40):7636-7639. doi: 10.1002/(ISSN)1521-3773 [5] DENG W P, TAN X, FANG W, ZHANG Q, WANG Y.Converison of cellulose into sorbitol over carbon nanotube-supported Ruthenium catalyst[J].Catal Lett, 2009, 133:167-174. doi: 10.1007/s10562-009-0136-3 [6] NIU Y F, WANG H, ZHU X L, SONG Z Q, XIE X N, LIU X, HAN J Y, GE Q F.Ru supported on zirconia-modified SBA-15 for selective converison of cellulose to hexitol[J].Microporous Mesoporous Mater, 2014, 198:215-222. doi: 10.1016/j.micromeso.2014.07.030 [7] YOU S J, BEAK I G, KIM Y T, JEONG K E, CHAE H J, KIM T W, KIM C U, KIM T J, CHUNG Y M, OH S H, PARK E D.Direct converison of cellulose into polyols or H2 over Pt/Na (H)-ZSM-5[J].Korean J Chem Eng, 2011, 28(3):744-750. doi: 10.1007/s11814-011-0019-3 [8] Sun J Y, LIU H C.Selective hydrogenolysis of biomass-derived xylitol to ethylene glycol and propylene glycol on Ni/C and basic oxide-promoted Ni/C catalysts[J].Catal Today, 2014, 234:75-82. doi: 10.1016/j.cattod.2013.12.040 [9] KATERINA F, OLIVER M, MARTIN L, PETER C.Hydrogenolysis of cellulose to valuable chemicals over actived carbon supported mono-and bimetallic nickel/tungsten catalysts[J].Green Chem, 2014, 16:3580-3588. doi: 10.1039/C4GC00664J [10] WANG A Q, ZHANG T.One-pot conversion of cellulose to ethylene glycol with multifunctional tungsten-based catalysts[J].Accounts Chem Res, 2013, 46(7):1377-1386. doi: 10.1021/ar3002156 [11] ZHAO M, CHUECH T L, HARRIS A T.SBA-15 supported Ni-Co bimetallic catalysts for enhanced hydrogen production during cellulose decomposition[J].Appl Catal B:Environ, 2011, 101(3/4):522-530. [12] JI N, ZHENG M Y, WANG A Q, ZHANG T, CHEN J G.Nickel-promoted tungsten carbide catalysts for cellulose conversion:effect of preparation methods[J].ChemSusChem, 2012, 5(5):939-944. doi: 10.1002/cssc.201100575 [13] ZHENG M Y, WANG A Q, JI N, PANG J F, WANG X D, ZHANG T.Transition metal-tungsten bimetallic catalysts for the conversion of cellulose into ethylene glycol[J].ChemSusChem, 2010, 3:63-66. doi: 10.1002/cssc.v3:1 [14] 赵冠鸿, 郑明远, 王爱琴, 张涛.磷化钨催化转化纤维素制乙二醇[J].催化学报, 2010, 31(8):928-932. doi: 10.1016/S1872-2067(10)60104-0ZHAO Guan-hong, ZHENG Min-yuan, WANG Ai-qin, ZHANG Tao.Catalytic conversion of cellulose to ethylene glycol over tungsten phosphide catalysts[J].Chin J Catal, 2010, 31(8):928-932. doi: 10.1016/S1872-2067(10)60104-0 [15] KITCHIN J R, NORSKOV J K, BARTEAU M A, CHEN J G.Modification of the surface electronic and chemical properties of Pt (111) by subsurface 3d transition metals[J].J Chem Phys, 2004, 120(21):10240-10246. doi: 10.1063/1.1737365 [16] CHEN J G, MENNING C A, ZELLNER M B.Monolayer bimetallic surfaces:Experimental and theoretical studies of trends in electronic and chemical properties[J].Surf Sci Pep, 2008, 63(5):201-254. -

下载:

下载: