| [1] |

KOPYSCINSKI J, SCHILDHAUER T J, BIOLLAZ S M A. Production of synthetic natural gas from coal and dry biomass-a technology review from 1950 to 2009[J]. Fuel, 2010, 89(8):1763-1783. doi: 10.1016/j.fuel.2010.01.027

|

| [2] |

李安学, 王立夫, 左玉帮.煤制天然气工厂建设若干问题的探讨[J].化工进展, 2013, 32(12):2877-2881. http://www.wenkuxiazai.com/doc/2a4be0c4f90f76c661371ad0-4.htmlLI An-xue, WANG Li-fu, ZUO Yu-bang. Research of some issues on the construction of coal-to-SNG plants[J]. Chem Ind Eng Process (China), 2013, 32(12):2877-2881. http://www.wenkuxiazai.com/doc/2a4be0c4f90f76c661371ad0-4.html

|

| [3] |

何忠, 崔晓曦, 范辉, 常瑜, 李忠.煤制天然气工艺技术和催化剂的研究进展[J].化工进展, 2011, 30(SI):388-392. http://industry.wanfangdata.com.cn/dl/Detail/Conference?id=Conference_7549174HE Zhong, CUI Xiao-xi, FAN Hui, CHANG Yu, LI Zhong. Research of coal-to-synthetic natural gas technology and catalyst[J]. Chem Ind & Eng Pro (China), 2011, 30(SI):388-392. http://industry.wanfangdata.com.cn/dl/Detail/Conference?id=Conference_7549174

|

| [4] |

TADA S, SHIMIZU T, KAMEYAMA H. Ni/CeO2catalysts with high CO2 methanation activity and high CH4 selectivity at low temperatures[J]. Int J Hydrogen Energy, 2012, 37(7):5527-5531. doi: 10.1016/j.ijhydene.2011.12.122

|

| [5] |

YAN X L, LIU Y, ZHAO B R. Methanation over Ni/SiO2:Effect of the catalyst preparation methodologies[J]. Int J Hydrogen Energy, 2013, 38(5):2283-2291. doi: 10.1016/j.ijhydene.2012.12.024

|

| [6] |

LU B, KAWAMOTO K. Preparation of the highly loaded and well-dispersed NiO/SBA-15 for methanation of producer gas[J]. Fuel, 2013, 103(1):699-704. https://www.sciencedirect.com/science/article/pii/S0016236112007223

|

| [7] |

张加赢, 辛忠, 孟鑫, 陶淼.基于MCM-41的镍基甲烷化催化剂活性与稳定性[J].化工学报, 2014, 65(1):160-168. http://industry.wanfangdata.com.cn/jt/Detail/Periodical?id=Periodical_hgxb201401021ZHANG Jia-ying, XIN Zhong, MENG Xin, TAO Miao. Activity and stability of nickel based MCM-41 methanation catalysts for production of synthetic natural gas[J]. CIESC J, 2014, 65(1):160-168. http://industry.wanfangdata.com.cn/jt/Detail/Periodical?id=Periodical_hgxb201401021

|

| [8] |

赵化龙, 赵彬然, 闫晓亮, 刘媛, 王勇, 刘昌俊.介质阻挡放电等离子体处理载体对CO甲烷化Ni-SiO2催化剂性能的改进[J].化工学报, 2013, 64(1):283-288. http://www.whxb.pku.edu.cn/CN/abstract/abstract21405.shtmlZHAO Hua-long, ZHAO Bin-ran, YAN Xiao-liang, LIU Yuan, WANG Yong, LIU Chang-jun. Ni/SiO2catalyst for CO methanation with support treated by dielectric barrier discharge plasma[J]. CIESC J, 2013, 64(1):283-288. http://www.whxb.pku.edu.cn/CN/abstract/abstract21405.shtml

|

| [9] |

莫文龙, 马凤云, 刘月娥, 刘景梅, 钟梅, 艾沙·努拉洪.焙烧温度对CO2-CH4重整制合成气NiO/γ-Al2O3催化剂性能的影响[J].无机材料学报, 2016, 31(3):234-240. http://www.cqvip.com/QK/93432X/201603/668250693.htmlMO Wen-long, MA Feng-yun, LIU Yue-e, LIU Jing-mei, ZHONG Mei, Aisha·nulahong. Influence of calcination temperature on the performance of NiO/γ-Al2O3 catalyst for CO2-CH4 reforming to produce syngas[J]. J Inorg Mater, 2016, 31(3):234-240. http://www.cqvip.com/QK/93432X/201603/668250693.html

|

| [10] |

贺龙, 王永刚, 公维博, 许德平, 杨芳芳, 张海永.焙烧温度对浆态床甲烷化催化剂的影响[J].煤炭转化, 2012, 35(4):72-76. http://www.cqvip.com/QK/92653A/201204/43605180.htmlHE Long, WANG Yong-gang, GONG Wei-bo, XU De-ping, YANG Fang-fang, ZHANG Hai-yong. Influence of calcination temperature on the performance of methanation in slurry bed reactor[J]. Coal Conver, 2012, 35(4):72-76. http://www.cqvip.com/QK/92653A/201204/43605180.html

|

| [11] |

殷海荣, 王明华, 章春香.球磨时间对钛酸钡介电性能的影响[J].中国陶瓷, 2007, 43(2):47-49+55. http://mall.cnki.net/magazine/Article/ZGTC200702015.htmYIN Hai-rong, WANG Ming-hua, ZHANG Chun-xiang. Influence of milling time on dielectric properties of barium titan ate[J]. Chin Cera, 2007, 43(2):47-49+55. http://mall.cnki.net/magazine/Article/ZGTC200702015.htm

|

| [12] |

尤金发. 机械活化前驱体法制备异向生长的碳酸钡[D]. 泉州: 华侨大学, 2013.YOU Jin-fa. Preparation of heterogeneous growth of barium carbonate by mechanical activation precursor method[D]. Quanzhou: Huaqiao University, 2013.

|

| [13] |

刘吉, 王东旭, 肖显斌, 陈旭娇, 覃吴, 董长青.焙烧温度对Ni/γ-Al2O3还原条件及催化甲苯水蒸气重整反应的影响[J].燃料化学学报, 2014, 42(10):1225-1232. doi: 10.3969/j.issn.0253-2409.2014.10.011LIU Ji, WANG Dong-xu, XIAO Xian-bin, CHEN Xu-jiao, QIN Wu, DONG Chang-qing. Effect of calcination temperature on Ni/γ-Al2O3 reduction and catalytic steam reforming of toluene[J]. J Fuel Chem Technol, 2014, 42(10):1225-1232. doi: 10.3969/j.issn.0253-2409.2014.10.011

|

| [14] |

OH Y S, ROH H S, JUN K W, BAEK Y S. A highly active catalyst, Ni/Ce-ZrO2/theta-Al2O3, for on-site H2 generation by steam methane reforming. pretreatment effect[J]. Int J Hydrogen Energy, 2003, 28(12):1387-1392. doi: 10.1016/S0360-3199(03)00029-6

|

| [15] |

LI H T, XU Y L, GAO C G, ZHAO Y X. Structural and textural evolution of Ni/γ-A12O3 catalyst under hydrothermal conditions[J]. Catal Today, 2010, 158(3/4):475-480. http://downloads.hindawi.com/journals/jnm/2017/8707289.xml

|

| [16] |

申文龙. 煤合成气甲烷化镍基催化剂的研究[D]. 湘潭: 湘潭大学, 2013. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2211575SHEN Wen-long. Research on Ni-based catalysts for methanation of coal syngas[D]. Xiangtan: Xiangtan University, 2013. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2211575

|

| [17] |

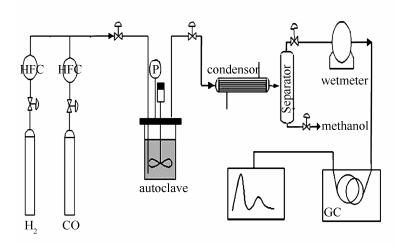

黄国宝, 王志青, 李庆峰, 黄戒介, 房倚天.液相中镍催化剂催化合成气甲烷化的初步研究[J].燃料化学学报, 2015, 42(8):952-957. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18470.shtmlHUANG Guo-bao, WANG Zhi-qing, LI Qing-feng, HUANG Jie-jie, FANG Yi-tian. Syngas methanation over nickel catalyst in liqiud-phase[J]. J Fuel Chem Technol, 2015, 42(8):952-957. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18470.shtml

|

下载:

下载: