Structure and hydrogen evolution performance of nano-porous PtCu/C membrane catalysts

-

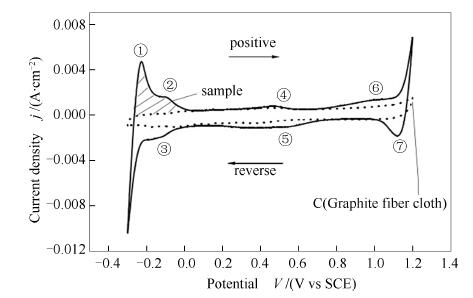

摘要: 采用离子束溅射(Ion Beam Sputtering, IBS)与Pt、Cu移动双靶技术,结合真空退火及酸蚀处理等后处理工艺,制备出PtCu/C薄膜催化剂。采用高分辨透射电镜(HRTEM & STEM)、原子力显微镜测试(AFM)、X射线衍射(XRD)测试薄膜催化剂的表面形貌及组织结构。通过循环伏安法(CV)和线性扫描伏安法(LSV)测试薄膜催化剂的电化学析氢性能。结果表明,经过真空退火(400 ℃保温1 h)及酸蚀处理(1 mol/L HNO3,50 ℃,120 h)后的薄膜催化剂出现类蜂窝状纳米多孔结构,其电化学析氢交换电流密度达到0.004 27 A/cm2,相较于未后处理样品的铂载量降低8.77%,催化性能提升20.62%。Abstract: PtCu/C membrane catalysts were prepared by ion beam sputtering (IBS) with moving bimetallic Pt and Cu targets; they were post-processed by vacuum annealing in combination with acid etching. High resolution transmission electron microscopy (HRTEM & STEM) and atomic force microscope (AFM) were employed to characterize the surface morphology of post-processed samples; the alloying degree of Pt and Cu was determined by the X-ray diffraction (XRD). Through cyclic voltammetry (CV) and linear sweep voltammetry (LSV), the electrochemical hydrogen evolution properties of the PtCu/C membrane catalysts were investigated. The results indicated that the PtCu/C membrane catalyst annealed at 400 ℃ and etched by HNO3 exhibits honeycomb nano-porous structure; the loading of Pt is reduced by about 8.77%, whereas the catalytic activity is enhanced by about 20.62%, in comparison compared with the original PtCu/C membrane catalyst.

-

Key words:

- ion beam sputtering /

- PtCu/C /

- membrane /

- post-processing /

- catalytic activity

-

表 1 薄膜镀制参数

Table 1 Parameters for Ion Beam Sputtering (IBS)

Distance of movement d/mm Time t/s Screen voltageV/kV Beam currentI/mA Acceleration voltageV/kV Cleaning 0 300 0.8 70 200 Sputtering 20-50 600 2.6 70 140 表 2 样品后处理参数

Table 2 post-Processing conditions of samples

Sample Annealing temperature t/℃ Etching time t/h a - - b 400 - c - 120 d 400 120 表 3 样品a、d及Pt/C金属载量及i0值

Table 3 Metal loadings in the membrane and i0 values of various samples

Sample Pt/(mg·cm-2) Cu/(mg·cm-2) Pt/Cu(mol ratio) i0/(A·cm-2) a 0.057 0.051 0.36 0.00354 Pt/C 0.138 - - 0.00390 d 0.052 0.023 0.72 0.00427 表 4 AFM检测的高度参数

Table 4 Height parameters for various samples

Sample Sq /nm Ssk Sku Sp /nm Sv /nm Sz /nm Sa /nm a 0.52 1.04 9.14 6.54 2.07 8.61 0.40 d 10.90 0.14 2.71 37.50 30.80 68.30 8.76 -

[1] LI W Z, XIN Q, YAN Y S. Nanostructured Pt-Fe/C cathode catalysts for direct methanol fuel cell: The effect of catalyst composition[J]. Int J Hygrogen Energy, 2010, 35(6): 2530-2538. doi: 10.1016/j.ijhydene.2010.01.013 [2] 贾羽洁, 蒋剑春, 孙康, 陆天虹. Pt/Au原子比对活性炭负载Au-Pt直接甲酸燃料电池阴极催化剂性能的影响[J]. 燃料化学学报, 2011, 39(10): 792-795. doi: 10.1016/S1872-5813(11)60046-7JIA Yu-jie, JIANG Jian-chun, SUN Kang, LU Tian-hong. Effect of Pt/Au atomic ratio in active-carbon-supported Au-Pt catalyst on its cathodic performance in direct formic acid fuel cells[J]. J Fuel Chem Technol, 2011, 39(10): 792-795. doi: 10.1016/S1872-5813(11)60046-7 [3] JOO J, KIM P, KIM W, KIM Y, YI J. Effect of the preparation conditions of carbon-supported Pt catalyst on PEMFC performance[J]. J Appl Electrochem, 2009, 39(1): 135-140. doi: 10.1007/s10800-008-9645-9 [4] 张熙贵, 王涛, 夏保佳, 钦佩, 徐乃欣. PEMFC氧电极的研究--助催化元素Ni和Co对Pt/C电催化剂性能的影响[J]. 燃料化学学报, 2003, 31(5): 411-414. http://rlhxxb.sxicc.ac.cn/CN/volumn/volumn_1232.shtml#ZHANG Xi-gui, WANG Tao, XIA Bao-jia, QIN Pei, XU Nai-xin. Study on oxygen electrode of PEMFC-effect of Ni, Co on properties of Pt/C electro-catalyst[J]. J Fuel Chem Technol, 2003, 31(5): 411-414. http://rlhxxb.sxicc.ac.cn/CN/volumn/volumn_1232.shtml# [5] 刘明义, 何源清, 毛宗强, 谢晓峰. 质子交换膜燃料电池阳极电催化剂CO中毒机理[J].电源技术, 2002, 26(z1): 247-249. http://www.cnki.com.cn/Article/CJFDTOTAL-DYJS2002S1016.htmLIU Ming-yi, HE Yuan-qin, MAO Zong-qiang, XIE Xiao-feng. CO-poisoning mechanism of anodic electrocatalyst in proton-exchange membrane fuel cell[J]. Chin J Power Sources, 2002, 26(z1): 247-249. http://www.cnki.com.cn/Article/CJFDTOTAL-DYJS2002S1016.htm [6] 徐云飞. 质子交换膜燃料电池Pt-Ru/C催化剂的研究[D]. 天津: 天津大学, 2007.XU Yun-fei, Study of Pt-Ru/C catalyst of proton-exchange membrane fuel cell[D]. Tianjing: Tianjing University, 2007. [7] 麻博远, 赵星. Pt-Ru二元合金催化剂CO"中毒"问题的理论研究[J]. 辽宁工业大学学报, 2008, 28(4): 274-277. http://www.cnki.com.cn/Article/CJFDTOTAL-LNGX200804017.htmMA Bo-yuan, ZHAO Xing. Theoretical study on CO poisoning of Pt-Ru catalysts[J]. J Liaoning Univ Technol, 2008, 28(4): 274-277. http://www.cnki.com.cn/Article/CJFDTOTAL-LNGX200804017.htm [8] 李莉, 王恒秀, 徐柏庆, 李晋鲁, 陆天虹, 毛宗强. PEMFC催化剂的研究:自制抗CO中毒Pt-Ru/C电催化剂的性质[J]. 化学学报, 2003, 61(6): 818-823. http://www.cnki.com.cn/Article/CJFDTOTAL-HXXB200306003.htmLI Li, WANG Heng-xiu, XU Bo-qing, LI Jin-lu, LU Tian-hong, MAO Zong-qiang. Study of PEMFC electro-catalysts: Characteristics of a homemade CO-tolerant Pt-Ru/C catalyst[J]. Acta Chim Sin, 2003, 61(6): 818-823. http://www.cnki.com.cn/Article/CJFDTOTAL-HXXB200306003.htm [9] WANG H, WANG R F, LI H, WANG Q F, KANG J, LEI Z Q. Facile synthesis of carbon-supported pseudo-core@shell PdCu@Pt nanoparticles for direct methanol fuel cells[J]. Int J Hydrogen Energy, 2011, 36(1): 839-848. doi: 10.1016/j.ijhydene.2010.09.033 [10] ADILBISH G, LEE J W, JANG Y S, LEE H G, YU Y T. Preparation of Pt/C electrode with double catalyst layers by electrophoresis deposition method for PEMFC[J]. Int J Hydrogen Energy, 2014, 39(7): 3381-3386. doi: 10.1016/j.ijhydene.2013.11.044 [11] MICHEAUD C, BAZIN D, GUERIN M, MARECOT P, BARBIER J. Study of supported bimetallic Pd-Pt catalysts characterization and catalytic activity for toluene hydrogenation[J]. React Kinet Catal Lett, 2000, 69(2): 209-216. doi: 10.1023/A:1005623127174 [12] 徐丹, 贾丽华, 郭祥峰. Cu 掺杂对介孔 VOx-TiO2催化苯羟基化制苯酚的影响[J]. 催化学报, 2013, 34(2): 341-350. doi: 10.1016/S1872-2067(11)60487-7XU Dan, JIA Li-hua, GUO Xiang-feng. Cu-doped mesoporous VOx-TiO2 in catalytic hydroxylation of benzene to phenol[J]. Chin J Catal, 2013, 34(2): 341-350. doi: 10.1016/S1872-2067(11)60487-7 [13] PODLOVCHENKO B I, MAKSIMOV Y M, MASLAKOV K I. Electrocatalytic properties of Au electrodes decorated with Pt submonolayers by galvanic displacement of copper adatoms[J]. Electrochim Acta, 2014, 130: 351-360. doi: 10.1016/j.electacta.2014.02.148 [14] FENG L G, YANG J, HU Y, ZHU J B, LIU C P, XING W. Electrocatalytic properites of PdCeOx/C anodic catalyst for formic acid electrooxidation[J]. Int J Hydrogen Energy, 2012, 37: 4812-4818. doi: 10.1016/j.ijhydene.2011.12.114 [15] LIAO M Y, WANG Y L, CHEN G Q, ZHOU H, LI Y H, ZHONG C J, CHEN B H. Reducing Pt use in the catalysts for formic acid electrooxidation via nanoengineered surface structure[J]. J Power Sources, 2014, 257: 45-51. doi: 10.1016/j.jpowsour.2014.01.103 [16] HUANG N, YANG B, SHEN M Z, HAO X Y. Effects of acid treatment on the electrocatalysis properties of PtCuLaOx/C composite membrane materials[J]. Rare Met Mater Eng, 2013, 42(9): 1795-1799. doi: 10.1016/S1875-5372(14)60007-2 [17] 张云洞, 刘洪祥. 离子束溅射沉积干涉光学薄膜技术[J].光电工程, 2001, 28(5): 69-72. http://www.cnki.com.cn/Article/CJFDTOTAL-GDGC200105018.htmZHANG Yun-dong, LIU Hong-xiang. Production of optical coatings with ion beam sputter deposition technique[J]. Opto-Electron Eng, 2001, 28(5): 69-72. http://www.cnki.com.cn/Article/CJFDTOTAL-GDGC200105018.htm [18] FEDER R, FROST F, NEUMANN H, BUNDESMANN C, RAUSCHENBACH B. Systematic investigations of low energy Arion beam sputtering of Si and Ag[J]. Nucl Instrum Methods Phys Res, Sect B, 2013, 317: 137-142. doi: 10.1016/j.nimb.2013.01.056 [19] LIANG X, WANG X, MIAO E L, ZHENG J J, WANG F, WANG G W, GU Y Q. An investigation on the removal characteristics of compound materials during ion beam sputtering using the Kinetic Monte Carlo method[J]. Nucl Instrum Methods Phys Res, Sect B, 2014, 323: 1-6. doi: 10.1016/j.nimb.2014.01.010 [20] FUH Y K, WANG C H. In situ roughness monitoring of sputtered Pt thin film under dynamic turbulence using adaptive optics[J]. Optik, 2014, 25(9): 2086-2089. https://www.researchgate.net/publication/261763914_In_situ_roughness_monitoring_of_sputtered_Pt_thin_film_under_dynamic_turbulence_using_adaptive_optics [21] TAKASHI N, TAKUO N, TSUTOMU M, HIROSHI I. Effect of current density on electrochemical shape control of Pt nanoparticles[J]. Electrochim Acta, 2014, 129: 152-159. doi: 10.1016/j.electacta.2014.02.105 [22] LI Y S, HAO F R, WANG Y H, ZHANG Y H, GE C W, LU T H. Facile synthesis of octahedral Pt-Pd nanoparticles stabilized by silsesquioxane for the electrooxidation of formic acid[J]. Electrochim Acta, 2014, 133: 302-307. doi: 10.1016/j.electacta.2014.04.030 [23] 黄能. 后处理对铂基掺稀土氧化物薄膜电极催化性能的影响[D]. 昆明: 昆明理工大学, 2013.HUANG Neng. Effect of postprocessing on the catalytic performance of Pt based rare earth oxide thin film electrodes[D]. Kunming: Kunming University of Science and Technology, 2013. -

下载:

下载: