Particle size classification and CO2 gasification of the char fines from fluidized bed gasification of Shenhua coal

-

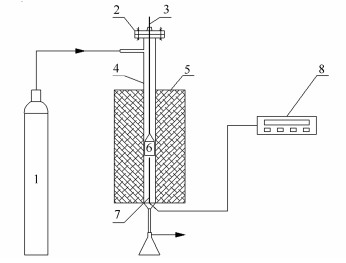

摘要: 按粒径将神华煤流化床气化带出细粉(简称细粉) 依次筛分为七个组分。采用工业分析仪、元素分析仪、热重分析仪、X射线粉末衍射仪、物理吸附仪等对各组分细粉的基本物化特性、CO2恒温和程序升温气化行为进行了考察。在此基础上, 对气化活性差异及其原因进行初步探索。结果表明, 细粉经历部分气化后, 由于挥发分的析出, 细粉的固定碳含量较原煤高, 但较相应半焦低。细粉的粒径分布范围较宽, 呈近似"M"形分布。随细粉粒径减小, 灰分含量增大, 而含碳量减少。CO2恒温气化与程序升温气化获得的气化反应活性顺序一致:均随细粉粒径的减小先逐渐降低而后又逐渐升高。不同细粉气化反应活性的差异与其自身的石墨化程度及灰分含量有关, 而在研究实验条件下与孔径结构关系不大。Abstract: The char fines from fluidized bed gasification (fines for short) are classified into 7 components based on particle size. The basic physicochemical properties, the constant and programmed increasing temperature CO2 gasification behaviors were investigated by coal quality analyzer, elemental analyzer, X-ray powder diffractometer, gas sorption analyzer and thermogravimetric analyzer. The difference of gasification reactivity and its reasons were discussed. The results show that after partial gasification, fixed carbon of the fines is higher than that of its parent coal but lower than the corresponding coal char because of the escape of volatiles. The particle size distribution of fines is very wide and multimodal distribution with the shape of "M". In addition, the ash content of fines approximately increases with decreasing particle size. However, the carbon content decreases with decreasing particle size. Both the constant and programmed increasing temperature CO2 gasification show the same result. The gasification reactivity firstly decreases and then gradually increases with decreasing particle size. Furthermore, the carbon crystalline structure and ash content are contributed to the difference in gasification reactivity of fines, and the different reactivity is not related to the pore structure in this experimental condition.

-

图 4 30 ℃/min升温速率下两种神华细粉的气化反应速率

Figure 4 Gasification curves of Shenhua fines at a heating rate of 30 ℃/min (a): gasification curves; (b): the partial enlarged drawing of gasification curves

■: F(d > 2); ○: F(0.9-2); ▲: F(0.5-0.9); ▽: F(0.098-0.5); ◇: F(0.038 5-0.098); ◁: F(0.001-0.038 5); ▶: F(d < 0.001)

表 1 样品的工业分析和元素分析

Table 1 Proximate and ultimate analyses of samples

Sample Proximate analysis wad/% Ultimate analysis wad/% V M A FC C H O* N S SH Coal 28.93 2.49 16.84 51.74 56.30 - - - 0.33 F(d > 2) 2.20 0.91 12.16 84.73 77.50 0.62 8.16 0.60 0.05 F(0.9-2) 2.29 0.77 10.85 86.10 78.05 - - - 0.04 F(0.5-0.9) 1.77 0.65 11.37 86.21 76.15 0.20 11.08 0.52 0.03 F(0.098-0.5) 2.06 0.60 11.45 85.89 75.45 - - - 0.04 F(0.0385-0.098) 3.12 0.63 18.98 77.27 71.45 - - - 0.07 F(0.001-0.0385) 2.48 0.60 17.66 79.26 70.90 - - - 0.06 F(d < 0.001) 3.47 0.63 25.28 70.62 67.00 0.33 6.22 0.50 0.04 FSH 3.00 0.87 17.97 78.16 69.15 - - - 0.02 CSH 1.19 0.59 10.87 87.35 75.40 - - - 0.15 O*: by difference;-:not detected 表 2 三类细粉的灰成分分析

Table 2 Ash composition analysis of the three fines

Sample Content w / % SiO2 Al2O3 Fe2O3 CaO MgO TiO2 K2O Na2O SO3 P2O5 F(d > 2) 5.83 1.83 1.03 1.05 0.14 0.08 0.031 0.062 0.22 0.030 F(0.5-0.9) 6.02 2.04 1.09 1.39 0.17 0.075 0.065 0.089 0.15 0.041 F(d < 0.001) 8.91 3.25 1.46 4.24 0.28 0.14 0.12 0.18 0.25 0.06 表 3 各类细粉在950 ℃温度下的反应性指数RS值

Table 3 Reactivity indexes of different fines at 950 ℃

Sample F(d > 2) F(0.9-2) F(0.5-0.9) F(0.098-0.5) F(0.038 5-0.098) F(0.001-0.098) F(d < 0.001) Rs/min-1 0.025 7 0.021 9 0.020 9 0.023 5 0.027 5 0.032 8 0.041 4 表 4 30 ℃/min升温速率下细粉的特征气化温度

Table 4 Initial, peak and final temperature of the fines and the corresponding char at 30 ℃/min

Sample Temperature t/℃ tinitial tpeak tfinal F(d > 2) 857 1 091 1 191 F(0.9-2) 855 1 100 1 192 F(0.5-0.9) 861 1 102 1 207 F(0.098-0.5) 856 1 098 1 207 F(0.0385-0.098) 839 1 085 1 221 F(0.001-0.0385) 838 1 083 1 194 F(d < 0.001) 785 1 074 1 178 表 5 三类脱灰后细粉的晶体结构参数

Table 5 Crystal structure parameters of three demineralized coal fines

Sample d002, P /nm Lc, P /nm d002, G /nm Lc, G /nm Xp XG d002, a /nm Lc, a /nm DF(d > 2) 43.90 172.00 35.80 156.80 0.15 0.85 37.10 159.10 DF(0.5-0.9) 44.40 182.60 35.90 158.50 0.14 0.86 37.10 162.00 DF(d < 0.001) 44.50 158.70 35.90 155.00 0.15 0.85 37.30 155.30 表 6 三类细粉的孔结构

Table 6 Pore structure analysis of the three fines

Sample area BET surface area A/(m2·g-1) Micropore area A/(m2·g-1) Total pore volume v/(cm3·g-1) Micropore volume v/(cm3·g-1) F(d > 2) 224 145 0.145 6 0.058 4 F(0.5-0.9) 269 153 0.213 5 0.062 1 F(d < 0.001) 221 109 0.193 1 0.044 5 -

[1] JING X L, WANG Z Q, YU Z L, ZHANG Q, LI C Y, FANG Y T. Experimental and kinetic investigations of CO2 gasification of fine chars separated from a pilot-scale fluidized-bed gasifier[J]. Energy Fuels, 2013, 27(5): 2422-2430. doi: 10.1021/ef4002296 [2] 屈利娟.流化床煤气化技术的研究进展[J].煤炭转化, 2007, 30(2): 81-85. http://www.cnki.com.cn/Article/CJFDTOTAL-MTZH200702019.htmQU Li-juan. Process of research in the fluidized bed coal gasification technology[J]. Coal Convers, 2007, 30(2): 81-85. http://www.cnki.com.cn/Article/CJFDTOTAL-MTZH200702019.htm [3] 王志雨.多段分级转化流化床煤气化炉气固流动特性的基础研究.太原:中国科学院山西煤炭化学研究所, 2013.WANG Zhi-yu. Fundamental research on the hydrodynamic characteristics of multi-stage conversion fluidized bed gasifier. Taiyuan: Institute of Coal Chemistry, Chinese Academy of Sciences, 2013. [4] 许世森, 张东亮, 任永强.大规模煤气化技术.北京:化学工业出版社, 2006.XU Shi-sen, ZHANG Dong-liang, REN Yong-qiang. Large-scale coal gasification technology[M]. Beijing: Chemical Industry Press, 2006. [5] KELEBOPILE L, SUN R, LIAO J. Fly ash and coal char reactivity from thermo-gravimetric (TGA) experiments[J]. Fuel Process Technol, 2011, 92(6): 1178-1186. doi: 10.1016/j.fuproc.2011.01.007 [6] GU J, WU S, WU Y, LI Y, GAO J. Differences in gasification behaviors and related properties between entrained gasifier fly ash and coal char[J]. Energy Fuels, 2008, 22(6): 4029-4033. doi: 10.1021/ef800527x [7] 房倚天, 吴晋沪, 张建民, 王洋.流化床气化炉飞灰气化反应性的研究: Ⅱ飞灰气化动力学的研究[J].燃料化学学报, 1996, 24(3): 225-232. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX603.007.htmFANG Yi-tian, WU Jin-hu, ZHANG Jian-min, WANG Yang. Study on gasification reactivity of fly ash from a fluidized bed gasifier: Ⅱ study on gasification reaction kinetics of fly ash[J]. J Fuel Chem Technol, 1996, 24(3): 225-232. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX603.007.htm [8] 李风海, 李振珠, 黄戒介, 房倚天.神木煤流化床气化带出细粉的特性[J].燃料化学学报, 2014, 42(10): 1153-1159. doi: 10.1016/S1872-5813(14)60046-3LI Feng-hai, LI Zhen-zhu, HUANG Jie-jie, FANG Yi-tian. Characteristics of fine chars from fluidized bed gasification of Shenmu coal[J]. J Fuel Chem Technol, 2014, 42(10): 1153-1159. doi: 10.1016/S1872-5813(14)60046-3 [9] 张骁博, 赵虹, 杨建国.不同粒径煤粉煤质变化及燃烧特性研究[J].煤炭学报, 2011, 36(6): 999-1003. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201106022.htmZHANG Xiao-bo, ZHAO hong, YANG jian-guo. Study on the variation of coal properties for different coal diameters and its effects on combustion characteristics[J]. Coal Convers, 2011, 36(6): 999-1003. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201106022.htm [10] TAKARADA T, TAMAI Y, TOMITA A. Reactivities of 34 coals under stream gasification[J]. Fuel, 1985, 64(10): 1438-1442. doi: 10.1016/0016-2361(85)90347-3 [11] 胡荣祖, 史启祯.热分析动力学[M].北京:科学出版社, 2001.HU Rong-zu, SHI Qi-zhen. Thermal analysis kinetics[M]. Beijing: Science Press, 2001. [12] 景旭亮, 王志青, 房倚天.流化床气化炉半焦细粉水蒸气再气化特性及动力学研究[J].燃料化学学报, 2013, 41(4): 400-406. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18158.shtmlJING Xu-liang, WANG Zhi-qing, FANG Yi-tian. Steam re-gasification properties and kinetics of coal char fines derived from fluidized bed gasifier[J]. J Fuel Chem Technol, 2013, 41(4): 400-406. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18158.shtml [13] ZHANG L, HUANG J, FANG Y, WANG Y. Gasification reactivity and kinetics of typical Chinese anthracite chars with stream and CO2[J]. Energy Fuels, 2006, 20(3): 1201-1210. doi: 10.1021/ef050343o [14] 任海军, 张永奇, 房倚天, 黄戒介, 汪洋.褐煤焦中的矿物质对气化动力学的影响[J].化学工程, 2010, 38(10): 132-135. http://www.cnki.com.cn/Article/CJFDTOTAL-IMIY201010030.htmREN Hai-jun, ZHANG Yong-qi, FANG Yi-tian, HUANG Jie-jie, WANG-Yang. Effect of minerals in lignite char on kinetics of stream gasification[J]. Chem Eng (China), 2010, 38(10): 132-135. http://www.cnki.com.cn/Article/CJFDTOTAL-IMIY201010030.htm [15] WU S Y, GU J, ZHANG X, WU Y Q, GAO J S. Variation of carbon crystalline structures and CO2 gasification reactivity of Shenfu coal chars at elevated temperatures[J]. Energy Fuels, 2008, 22(1): 199-206. doi: 10.1021/ef700371r [16] ZHU W K, SONG W L, LIN W G. Effect of the coal particle size on pyrolysis and char reactivity for two types of coal and demineralized coal[J]. Energy Fuels, 2008, 22(4): 2482-2487. doi: 10.1021/ef800143h -

下载:

下载: