-

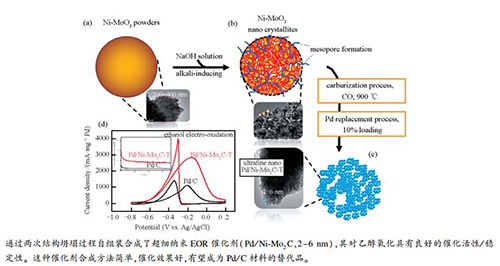

摘要: 本研究采用简易的碱性诱导自组装的方法制备了一种新型纳米Pd/Ni-Mo2C(2-6 nm)催化剂。该催化剂在碱性体系中对乙醇的电催化氧化展现出优异的性能。催化活性为2832.2 mA/mgPd,剩余电流密度为447.8 mA/mgPd,分别是质量分数10%商业Pd/C催化剂(1107.6和96.1 mA/mgPd)的2.6和4.7倍。Abstract: Herein, a new superfine nano Pd/Ni-Mo2C (2-6 nm) catalyst is developed via a facile, alkali-induced self-assembly strategy. The catalyst exhibits excellent performance towards ethanol electro-catalytic oxidation in alkaline system, with an activity of 2832.2 mA/mgPd and a residual current density of 447.8 mA/mgPd, which is 2.6 and 4.7 times enhancements compared with the commercial 10% Pt/C catalyst (1107.6 and 96.1 mA/mgPd).

-

Key words:

- molybdenum carbide /

- nickel /

- alkali treatment /

- palladium /

- ethanol oxidation

-

Figure 1 (a) Digital photo of the precursor powder, ((b), (c)) TEM images of Ni-MoO3 and ((d), (e)) TEM images of Ni-MoO3-T (the inset (in Figure 1(d)) shows its particle size distribution)

Figure 4 (a) TEM images of Pd/Ni-Mo2C-T, (b) particle size distribution of Pd/Ni-Mo2C-T, (c) elemental mapping images of Pd/Ni-Mo2C-T, (d) HRTEM images of Pd/Ni-Mo2C-T and (e) EDX analysis of Pd/Ni-Mo2C-T (the inset (in Figure 4(a)) shows the colour change of catalyst before and after loading palladium)

Figure 5 (a) Cyclic voltammograms (CV) of Pd/Ni-Mo2C, Pd/Ni-Mo2C-T and Pd/C in presence of 1 mol/L KOH and 1 mol/L C2H5OH with a scan rate of 50 mV/s at 30 ℃, (b) Chronoamperometry curves (CA) of the samples in presence of 1 mol/L KOH and 1 mol/L C2H5OH at -0.05 V for 1800 s at 30 ℃, (c) CV curves of Pd/Ni-Mo2C-T catalyst in presence of 1 mol/L KOH and 1 mol/L C2H5OH with different scan rates from 100 to 500 mV/s at 30 ℃ and (d) the relation of Ip-v1/2

Figure 6 (a) LSV curves of Pd/Ni-Mo2C catalyst in presence of 1 mol/L KOH and 1 mol/L C2H5OH at 298-313 K, (b) the relationship of lgi-1/T for Pd/Ni-Mo2C catalyst, (c) LSV curves of Pd/Ni-Mo2C catalyst in presence of 1 mol/L KOH and 1 mol/L C2H5OH at 298-313 K, and (d) the relationship of lgi-1/T for Pd/Ni-Mo2C-T catalyst

Table 1 Catalytic performance characteristics of different catalysts for ethanol electro-catalytic in alkaline condition

Catalyst Onset potential /V Peak current /(mA·mg-1 Pd) Residual current /(mA·mg-1 Pd) 10%Pd/C -0.561 1107.6 96.1 Pd/Ni-Mo2C -0.606 2232.3 124.9 Pd/Ni-Mo2C-T -0.628 2832.2 447.8 -

[1] WU T, MA Y, QU Z B, FAN J C, LI Q X, SHI P H, XU Q J, MIN Y L. Black phosphorus-graphene heterostructure-supported Pd nanoparticles with superior activity and stability for ethanol electro-oxidation[J]. ACS Appl Mater Interf, 2019, 11:5136-5145. doi: 10.1021/acsami.8b20240 [2] ZHANG H C, SHANG Y Y, ZHAO J, WANG J J. Enhanced electrocatalytic activity of ethanol oxidation reaction on palladium-silver nanoparticles via removable surface ligands[J]. ACS Appl Mater Interf, 2017, 9(19):16635-16643. doi: 10.1021/acsami.7b01874 [3] YANG H L, ZHANG X Y, ZOU H, YU Z N, LI S W, SUN J H, CHEN S D, JIN J, MA J T. Palladium nanoparticles anchored on three-dimensional nitrogen-doped carbon nanotubes as a robust electrocatalyst for ethanol oxidation[J]. ACS Sustainable Chem Eng, 2018, 6(6):7918-7923. doi: 10.1021/acssuschemeng.8b01157 [4] MARTIN R, JAKUB D, BJOÖRN R, FINN R, DAVID A H, FRANCESCO C, ROBERTO F, JOCHIM S, OLAF M M. Structural reorganization of Pt(111) electrodes by electrochemical oxidation and reduction[J]. J Am Chem Soc, 2017, 139(12):4532-4539. doi: 10.1021/jacs.7b01039 [5] MOHAMMAD S A, SEUNGWON J. Electrochemical activity evaluation of chemically damaged carbon nanotube with palladium nanoparticles for ethanol oxidation[J]. J Power Sources, 2015, 282:479-488. doi: 10.1016/j.jpowsour.2015.02.072 [6] LEANDRO L C, FLAVIO C, AURO A T. Nickel palladium electrocatalysts for methanol, ethanol, and glycerol oxidation reactions[J]. Int J Hydrogen Energy, 2017, 42:16118-16126. doi: 10.1016/j.ijhydene.2017.05.124 [7] RAJESH K, RALUCA S, RAJESH K S, EDNAN J, DINESH P S, VIDHU S T, ALFREDO R V, EVERSON T S G da S, JAQUELINE R M, LAURO T K, STANISLAV A M. Controlled density of defects assisted perforated structure in reduced graphene oxide nanosheets-palladium hybrids for enhanced ethanol electro-oxidation[J]. Carbon, 2017, 117:137-146. doi: 10.1016/j.carbon.2017.02.065 [8] LEVY R B, BOUDART M. Platinum-like behavior of tungsten carbide in surface catalysis[J]. Science, 1973, 181(4099):547-549. doi: 10.1126/science.181.4099.547 [9] LIU Y, THOMAS G K, JINGGUANG G C, WILLIAM E M. Metal carbides as alternative electrocatalyst supports[J]. ACS Catal, 2013, 3:1184-1194. doi: 10.1021/cs4001249 [10] AKHAIRI M A F, KAMARUDIN S K. Catalysts in direct ethanol fuel cell (DEFC):An overview[J]. Int J Hydrogen Energy, 2016, 41:4214-4228. doi: 10.1016/j.ijhydene.2015.12.145 [11] WANG H, SUN C, CAO Y J, ZHU J T, CHEN Y, GUO J, ZHAO J, SUN Y H, ZOU G F. Molybdenum carbide nanoparticles embedded in nitrogen-doped porous carbon nanofibers as a dual catalyst for hydrogen evolution and oxygen reduction reactions[J]. Carbon, 2017, 114:628-634. doi: 10.1016/j.carbon.2016.12.081 [12] LIN L L, SHENG W C, YAO S Y, MA D, JINGGUANG G C. Pt/Mo2C/C-cp as a highly active and stable catalyst for ethanol electrooxidation[J]. J Power Sources, 2017, 345:182-189. doi: 10.1016/j.jpowsour.2017.02.001 [13] WAN C, YAGYA N R, BRIAN M L. Multiple phases of molybdenum carbide as electrocatalysts for the hydrogen evolution reaction[J]. Angew Chem Int Ed, 2014, 53(25):6407-6410. doi: 10.1002/anie.201402998 [14] JAEHO J, YEREUM P, SEUNGHYUK C, JINHEE L, SUNG S L, BYOUNG H L, YOUNG J S, JEONG H C, YUN H J, SUNGJOO L. Epitaxial synthesis of molybdenum carbide and formation of a Mo2C/MoS2 hybrid structure via chemical conversion of molybdenum disulfide[J]. ACS Nano, 2018, 12(1):338-346. doi: 10.1021/acsnano.7b06417 [15] ZHONG Z W, LIU N, CHEN H Y, FU X H, YANG L C, GAO Q S. Molybdenum carbide supported by N-doped carbon:Controlled synthesis and application in electrocatalytic hydrogen evolution reaction[J]. Mater Lett, 2016, 176:101-105. doi: 10.1016/j.matlet.2016.04.089 [16] MU Y P, ZHANG Y, FANG L, LIU L, ZHANG H J, WANG Y. Controllable synthesis of molybdenum carbide nanoparticles embedded in porous graphitized carbon matrixes as efficient electrocatalyst for hydrogen evolution reaction[J]. Electrochim Acta, 2016, 215:357-365. doi: 10.1016/j.electacta.2016.08.104 [17] AYAZ H, VALDECIR A P, ALEJO C, EDSON A T. Molybdenum carbide-based electrocatalysts for CO tolerance in proton exchange membrane fuel cell anodes[J]. Electrochim Acta, 2014, 142:307-316. doi: 10.1016/j.electacta.2014.07.142 [18] LIN H L, LIU N, SHI Z P, GUO Y L, TANG Y, GAO Q S. Cobalt-doping in molybdenum-carbide nanowires toward efficient electrocatalytic hydrogen evolution[J]. Adv Funct Mater, 2016, 26(31):5590-5598. doi: 10.1002/adfm.v26.31 [19] XIONG K, LI L, ZHANG L, DING W, PENG L S, WANG Y, CHEN S G, TAN S Y, WEI Z D. Ni-doped Mo2C nanowires supported on Ni foam as a binder-free electrode for enhancing the hydrogen evolution performance[J]. J Mater Chem A, 2015, 3:1863-1867. doi: 10.1039/C4TA05686H [20] XU X B, FARHAT N, WANG X. Ni-Decorated molybdenum carbide hollow structure derived from carbon-coated metal-organic framework for electrocatalytic hydrogen evolution reaction[J]. Chem Mater, 2016, 28(17):6313-6320. doi: 10.1021/acs.chemmater.6b02586 [21] SUYLAN L A D, ANDRE L L M, CARLSON P S. Synthesis and characterization of molybdenum carbide doped with nickel[J]. Mater Chem Phys, 2018, 216:243-249. doi: 10.1016/j.matchemphys.2018.05.074 [22] TEODÓRA N K, DÁVID H, ALEX L A DE L, IMRE M S. Thermal decomposition of ammonium molybdates[J]. J Therm Anal Calorim, 2016, 124(2):1013-1021. doi: 10.1007/s10973-015-5201-0 [23] CUI G F, SHEN P K, MENG H, ZHAO J, WU G. Tungsten carbide as supports for Pt electrocatalysts with improved CO tolerance in methanol oxidation[J]. J Power Sources, 2011, 196(15):6125-6130. doi: 10.1016/j.jpowsour.2011.03.042 [24] MA C A, CHEN Z Y, ZHAO F M. Synthesis of ultrafine mesoporous tungsten carbide by high-energy ball milling and its electrocatalytic activity for methanol oxidation[J]. Chin J Chem, 2011, 29:611-616. doi: 10.1002/cjoc.v29.4 [25] XU L J, DU J J, TANG J X, ZHANG J D. Electrochemical behavior of electrodeposited Ni-Cr alloys[J]. Mater Prot, 2008, 41(2):23-25. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=407c0fdbbd640150534027f37847cc34 -

下载:

下载: