Preparation of flotation refined carbon from gasification slag

-

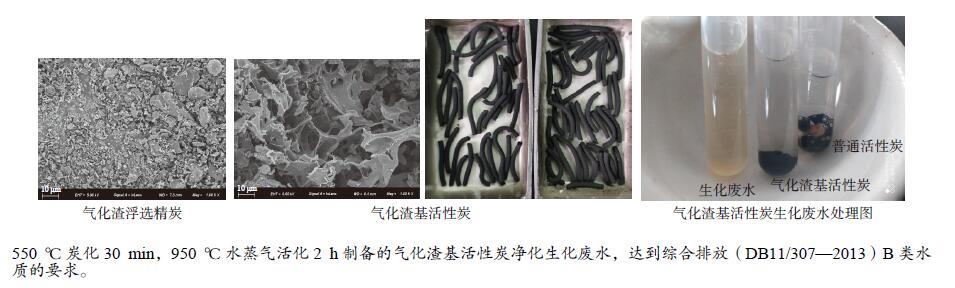

摘要: 煤气化灰渣高效环保资源化利用是目前煤化工固废领域研究的热点。利用气化灰渣浮选精炭为原料,配以适宜比例的长焰煤和70%沥青含量的高温煤焦油黏结剂并辅加活性剂开展了制备活性炭的研究,在管式炉中考察了活化温度和活化时间对活性炭产品表面性质及抗压强度的影响规律。采用红外、N2吸附-脱附、扫描电镜、碘吸附等手段对成型活性炭的孔径分布和吸附性能进行了分析表征,将活性炭产品用于生化废水进行COD脱除效果的检验。结果表明,针对气化灰渣浮选精炭原料体系,选择适宜的活化温度和活化时间是有效成孔与扩孔的关键因素,经550 ℃炭化30 min,950 ℃水蒸气活化2 h制备的成型活性炭表观形貌呈现有机炭质组分与矿物的交错赋存形态,表面含氧官能团丰富,比表面积566 m2/g,孔容0.5611 mL/g,平均孔径5.1 nm,孔径分布较为集中,具有一定的中孔结构,碘值650 mg/g和亚甲蓝值128 mg/g均达到了《工业水处理用活性炭技术指标》的行业标准要求。这种浮选精炭基活性炭用于生化废水净化,处理时间为60 min,固液比0.6 g/L,COD可降至30 mg/L,达到水污染物综合排放标准(DB11/307—2013)B类水质的要求。Abstract: Highly efficient and environmentally friendly utilization of coal gasification slag is a hot research subject in the coal chemical industry at present. The preparation of activated carbon with a flotation refined carbon from gasification slag, a long flame coal, a high temperature coal tar containing 70% asphalt and an active agent in proper proportion was carried out. The influence of activation temperature and time on the surface properties and compressive strength of the produced activated carbon was investigated in a tube furnace. The oxygen functional group, pore structure and absorption performance of the produced activated carbon were characterized by FT-IR, N2 adsorption-desorption, SEM and iodine adsorption. The COD removal from biochemical waste water by the produced activated carbon was verified. The results show that the key factors for the effective formation and expansion of pore are the suitable activation temperature and time for the floatation refined carbon from gasification slag as the feedstock. The activated carbon prepared by carbonization at 550 ℃ for 30 min and steam activation at 950 ℃ for 2 h exhibits a crisscross morphology of organic carbon components and minerals. The surface area, pore capacity and average pore diameter are 566 m2/g, 0.5611 mL/g and 5.1 nm, respectively, with the characteristics of a concentrated pore distribution and a certain quantity of mesopore. Both iodine value (650 mg/g) and methylene blue value (128 mg/g) meet the requirements of the Chinese standard “Technical Specifications and Test Methods of Activated Carbon for Purification of Industrial Wastewater”. The COD in biochemical waste water treated by the activated carbon for 60 min with a solid-to-liquid ratio of 0.6 g/L can be reduced to lower than 30 mg/L, meeting the B class water quality of the Chinese standard “Integrated Discharge Standard of Water Pollutants” (DB11/307—2013).

-

Key words:

- gasification slag /

- floating refined carbon /

- activated carbon /

- activation /

- pore structure

-

表 1 原料的性质分析

Table 1 Analysis data of properties of raw materials

Sample Proximate analysis w/% Elementary analysis wdaf/% CRC Mad Ad Vd FCd C H N S O* Gasification slag 1.92 53.25 2.11 44.64 95.48 0.72 0.75 0.63 2.42 1 Fine carbon 7.84 12.50 3.95 83.55 96.53 0.62 0.73 0.42 1.70 1 Coal 17.46 5.13 47.14 47.73 74.97 5.16 1.00 0.20 18.67 1 *: by difference 表 2 精炭和活性炭产物比表面积与孔结构

Table 2 Surface and pore structure data of refined carbon and produced activated carbon

Sample Iodine value /(mg·g−1) Methylene blue value /(mg·g−1) BET surface area /(m2·g−1) BET surface area of mesopore /(m2·g−1) Pore volume /(mL·g−1) Pore volume of mesopore /(mL·g−1) Average pore size /nm Refined carbon 292 38 283 104.22 0.2676 0.1196 3.7 Activated product 650 128 566 271.68 0.5611 0.3303 5.1 -

[1] 王国法. 碳中和目标下, 煤炭的坚守与转身[N]. 中国煤炭报, 2021-02-06.WANG Guo-fa. Adherence and changing of coal under the goal of carbon neutrality[N]. China Coal News, 2021-02-06. [2] 王晓磊, 陈贵锋, 李文博, 黄澎, 王乃继. 双碳背景下煤炭清洁高效利用方向构建[J]. 煤质技术,2021,36(6):1−5.WANG Xiao-lei, CHEN Gui-feng, LI Wen-bo, HUANG Peng, WANG Nai-ji. Construction of clean efficient utilization direction of coal under the background of Double Carbon[J]. Coal Quality Technol,2021,36(6):1−5. [3] 张抗, 苗淼, 张立勤. “双碳”目标与中国能源转型思考 (二)—能源转型中的化石能源[J]. 中外能源,2022,27(4):1−6.ZHANG Kang, MIAO Miao, ZHANG Li-qin. Carbon peaking and carbon neutrality goals and reflections on China′s energy transition part Ⅱ[J]. Sino-Global Energy,2022,27(4):1−6. [4] 门卓武, 李初福, 李井峰. 现代煤化工技术开发的机遇与方向[J]. 能源科技,2020,18(8):60−62.MEN Zhuo-wu, LI Chu-fu, LI Jing-feng. Opportunities for and directions of modern coal chemical technology development[J]. Energy Sci Technol,2020,18(8):60−62. [5] 徐振刚. 中国现代煤化工近25年发展回顾·反思·展望[J]. 煤炭科学技术,2020,48(8):1−25. doi: 10.13199/j.cnki.cst.2020.08.001XU Zhen-gang. Review, rethink and prospect of China’s modern coal chemical industry development in recent 25 years[J]. Coal Sci Technol,2020,48(8):1−25. doi: 10.13199/j.cnki.cst.2020.08.001 [6] 朱菊芬, 李健, 闫龙, 尚军飞, 王玉飞, 李强, 王建友. 煤气化渣资源化利用研究进展及应用展望[J]. 洁净 煤技术,2021,27(6):11−21.ZHU Ju-fen, LI Jian, YAN Long, SHANG Jun-fei, WANG Yu-fei, LI Qiang, WANG Jian-you. Research progress and application prospect of coal gasification slag resource utilization[J]. Clean Coal Technol,2021,27(6):11−21. [7] 申改燕, 李金洲, 王敬. 关于煤化工气化炉渣资源化利用技术的探讨[J]. 能源与节能,2020,(7):58−60.SHEN Gai-yan, LI Jin-zhou, WANG Jing. Discussion on resource utilization technology of coal chemical gasification slag[J]. Energy Energy Conservation,2020,(7):58−60. [8] 史兆臣, 戴高峰, 王学斌, 董永胜, 李攀, 于伟, 谭厚章. 煤气化细渣的资源化综合利用技术研究进展[J]. 华电技术,2020,42(7):63−73.SHI Zhao-chen, DAI Gao-feng, WANG Xue-bin, DONG Yong-sheng, LI Pan, YU Wei, TAN Hou-zhang. Review on the comprehensive resources utilization technology of coal gasification fine slag[J]. Huadian Technol,2020,42(7):63−73. [9] 傅博, 马梦凡, 申旺, 程臻赟, 江尧. 气化渣对硅酸盐水泥强度和微观结构的影响研究[J]. 硅酸盐通报,2020,39(8):2523−2527.FU Bo, MA Meng-fan, SHEN Wang, CHENG Zhen-yun, JIANG Yao. Influence of coal gasification slag on strength and microstructure of Portland cement[J]. Bull Chin Ceram Soc,2020,39(8):2523−2527. [10] 张成, 裴超. 煤气化渣生产蒸压砖的技术研究[J]. 砖瓦世界,2019,(10):49−52.ZHANG Cheng, PEI Chao. Technological research on production of autoclaved bricks from coal gasification slag[J]. Brick Tile World,2019,(10):49−52. [11] 吴昊东, 邵丰华, 吕鹏, 白永辉, 宋旭东, 王焦飞, 郭庆华, 王学斌, 于广锁. 气流床煤气化细渣结构、 性质与其粒度分布关系研究[J]. 燃料化学学报,2022,50(5):513−520.WU Hao-dong, SHAO Feng-hua, LÜ Peng, BAI Yong-hui, SONG Xu-dong, WANG Jiao-fei, GUO Qing-hua, WANG Xue-bin, YU Guang-suo. Study on the relationship between structure, properties and size distribution of fine slag from entrained flow gasification[J]. J Fuel Chem Technol,2022,50(5):513−520. [12] GUO F, ZHAO X, GUO Y, ZHANG Y, WU J. Fractal analysis and pore structure of gasification fine slag and its flotation residual carbon[J]. Colloids Surf A,2020,585:124148. doi: 10.1016/j.colsurfa.2019.124148 [13] 胡俊阳, 黄阳, 王维清, 冯启明, 徐中慧. 煤气化炉 渣浮选精炭在染色废水中的应用[J]. 环境工程,2018,36(3):59−63,137.HU Jun-yang, HUANG Yang, WANG Wei-qing, FENG Qi-ming, XU Zhong-hui. Application of concentrate carbon from coal gasification slag by flotation on dyeing wastewater[J]. Environ Eng,2018,36(3):59−63,137. [14] 朱仁帅, 吕飞勇, 汤茜, 孙帅, 张香兰. 利用水煤浆气化炉飞灰合成吸附材料的研究[J]. 粉煤灰综合利用,2017,(3):12−15.ZHU Ren-shuai, LV Fei-yong, TANG Xi, SUN Shuai, ZHANG Xiang-lan. Study on synthesis of adsorbent from fly ash of coal-water slurry gasifier[J]. Fly Ash Compr Util,2017,(3):12−15. [15] LIU S, CHEN X, AI W, WEI C. A new method to prepare mesoporous silica from coal gasification fine slag and its application in methylene blue adsorption[J]. J Clean Prod,2019,212:1062−1071. doi: 10.1016/j.jclepro.2018.12.060 [16] 王云海, 陈庆云, 赵景联. 一种基于煤气化灰渣的水处理吸附剂及其制备方法: N107081140A[P]. 2017-08-22.WANG Yun-hai, CHEN Qing-yun, ZHAO Jing-lian. A coal gasification ash-based water treatment adsorbent and its preparation method: CN107081140A[P]. 2017-08-22. [17] 魏存弟, 艾卫东, 魏际伦, 蒋引珊, 杨殿范, 夏茂盛. 利用煤气化细渣制备吸附材料的方法及制得的吸附材料: CN107855103A[P]. 2018-03-30.WEI Cun-di, AI Wei-dong, WEI Ji-lun, JIANG Yin-shan, YANG Dian-fan, XIA Mao-sheng. Method for preparing of adsorption material from coal gasification fine slag and its adsorption material: CN107855103A[P]. 2018-03-30. [18] 顾彧彦, 乔秀臣. 煤气化细渣制备碳硅复合材料吸附去除水中Pb2 + [J]. 化工环保,2019,39(1):87−93.GU Yu-yan, QIAO Xiu-chen. Adsorption of Pb2 + from water by carbon-silica composite prepared from coal gasification fine slag[J]. Environ Prot Chem Ind.,2019,39(1):87−93. [19] 吴思萍, 赵凯, 董永胜, 王学斌, 白永辉, 刘莉君, 于伟. 气化细渣浮选脱碳研究进展[J]. 华电技术,2020,42(7):81−86.WU Si-ping, ZHAO Kai, DONG Yong-sheng, WANG Xue-bin, BAI Yong-hui, LIU Li-jun, YU Wei. Research progress on floating decarbonization of gasified fine slag[J]. Huadian Technol,2020,42(7):81−86. [20] GB 474—2008, 煤样的制备方法[S]. 北京: 中国标准出版社, 2008.GB 474—2008, Method for preparation of coal samples[S]. Beijing: Standards Press of China, 2008. -

下载:

下载: