Application of DFT calculation in the study of iron-based catalyst for Fischer-Tropsch synthesis

-

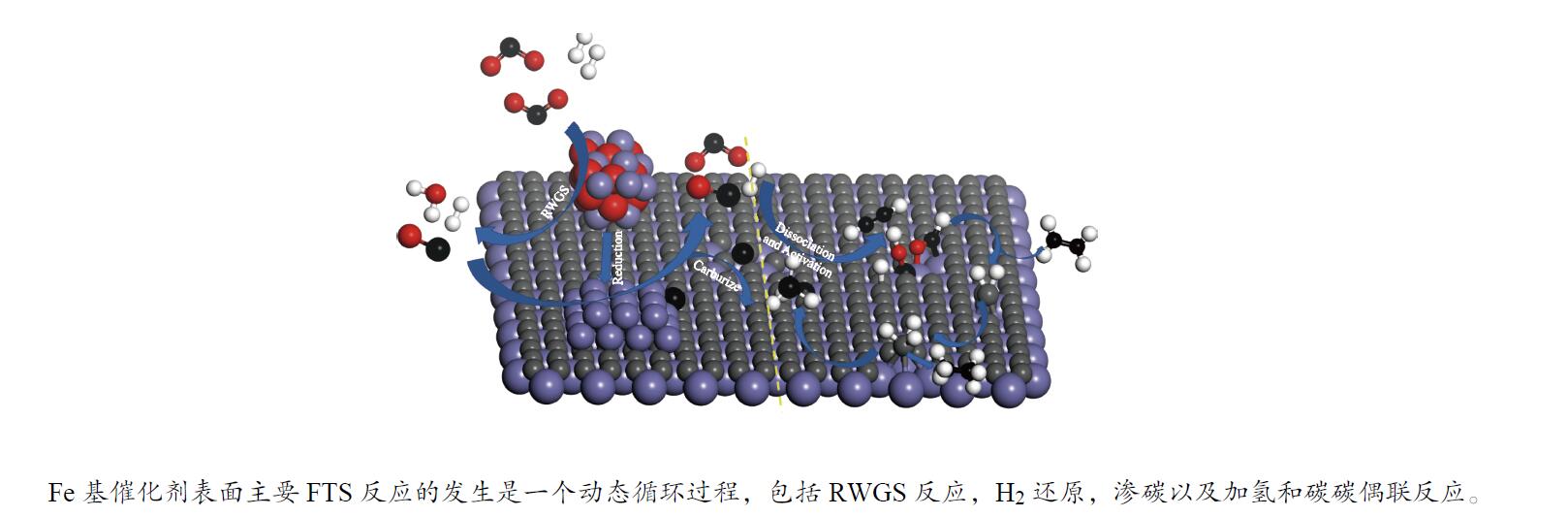

摘要: 费托合成是煤炭间接液化的关键技术。铁基催化剂是常用的FTS催化剂。受反应过程中相变复杂性和原位表征困难的限制,密度泛函理论(DFT)成为研究铁基催化剂表面物种吸附和反应的必要手段。本工作以铁碳化合物的表面化学性质作为出发点,探讨了不同碳化铁物相的形成条件及表面物种吸附性能,简述了当前DFT计算研究涉及的FTS基元反应,总结了不同机制下链引发、链增长、链终止的机理研究。结合实验研究进展,总结了助剂的加入对铁基催化剂结构和性能的调控机理,结合一些前沿研究,对目前铁基催化剂存在的问题进行总结,对表面碳在催化反应中的作用和各物相催化作用差异等问题进行了展望。Abstract: Fischer-Tropsch synthesis (FTS) is the key technology of indirect coal liquefaction. Iron-based catalysts are commonly used. Due to the complexity of phase transition and the difficulty of in-situ characterization, density functional theory (DFT) has become a necessary means to study the adsorption and reaction of surface species on iron-based catalysts. In this review, the formation of different iron carbide phases and the adsorption properties of surface species were discussed based on the surface chemical properties of iron-carbon compounds. Then, the elementary reactions involved in the current DFT calculation research are briefly described. The research of chain initiation, chain growth, and chain termination under different mechanisms is summarized. Combined with the experimental research progress, the regulation mechanism of the promoters on the structure and performance of iron-based catalysts was reviewed. Finally, the existing problems of iron-based catalysts are summarized. The role of surface carbon in the reactions and the effects of various phases are prospected combined with recent results.

-

Key words:

- FTS reaction /

- iron carbide /

- DFT calculation /

- promoters

-

图 6 η-Fe2C(011)、(110)、(211)和(121)表面CO活化途径的能量[111]

Figure 6 Energy diagram of CO activation pathway on η-Fe2C (011), (110), (211) and (121) surfaces Energy zero point is the total energy of free CO and H2 molecules Black line : mechanism I; red line : mechanism II, activate intermediates through *HCO; blue line : Mechanism II, activate intermediates through *COH[111] (with permission from ACS publications)

图 7 (a) h-Fe7C3(211)表面4F2位点CO直接或H辅助解离途径CO活化机制的能量分布,(b) h-Fe7C3(1-11)表面CO直接或H辅助解离途径的构型和能量[107, 121]

Figure 7 (a) The energy distribution of the CO activation mechanism over the 4F2 site via CO direct or H-assisted dissociation on the surface of h-Fe7C3(211). The configuration and energy of CO direct or H-assisted dissociation on (B) h-Fe7C3(111) surface[107, 121](purple : Fe atom ; gray : C atom; red : O atom ; yellow : H atom) (with permission from Molecular Catalysis and ACS publications)

图 8 (a) 三种方式下甲烷化反应中所涉及的基本步骤的TS结构,(b) 三种情况下CH4形成的能量分布[125]

Figure 8 (a) TS structure of the basic steps involved in the methanation reaction in three ways, Blue : iron atom; gray: C atom; green: C atom involved in the reaction; white: H atom; yellow: H atom involved in the reaction; (b) energy distribution of CH4 formation in three ways[125] (with permission from ACS publications)

图 9 (a) χ-Fe5C2(510)表面CH + CO → CCH + O形成途径的能量和结构:碳化物机制(红色实线)和CO插入机制(蓝色虚线)(零点能量也包括在内,蓝色:铁原子;灰色:C原子;绿色:参与反应的C原子;白色:H原子;红色:O原子)(b) C1−C1偶联反应的有效势垒(Eeff, C−C)和反应势垒(Ea),以及对χ-Fe5C2(510)和χ-Fe5C2(100)表面的反应物能(Ei + Ej)[125]

Figure 9 (a) The energy and structure of CH + CO → CCH + O formation pathway on χ-Fe5C2 (510) surface : carbide mechanism(red solid line) and CO insertion mechanism (blue dotted line). The zero energy is included (Blue: iron atom; gray: C atom; green: C atoms involved in the reaction; white: H atom; red: O atoms) (b) Effective barrier (Eeff, C−C) and the reaction barrier (Ea) for the C1−C1 coupling reaction, as well as the energies of reactant (Ei + Ej) for χ-Fe5C2(510) and χ-Fe5C2(100) surfaces[125] (with permission from ACS publications)

图 11 (a) CO和合成气预处理下Hägg碳化物的形貌(括号中给出的指标表示对应的米勒指数,指数的第二项提供了对应的表面a = Fe/C比,指数的第三项提供了每个暴露表面对总表面积的贡献);(b) 图(a)中构造的8个Wulff暴露表面对应碳化学势(μc)最稳定端的表面结构(图左括号中给出的指标表示每个表面的米勒指数,每个结构下的数字分别为对应表面a = Fe/C比,蓝球表示Fe原子,黑球表示C原子)[142]

Figure 11 (a) Morphologies of Hägg carbide under CO and syngas pretreatments (indices given in parentheses indicates the corresponding Miller index. The second number is the corresponding surface Fe/C ratio. The third number is the contribution of each plane to the total surface area). (B) The most stable terminations of the structures from Wulff construction in Figure (a) at corresponding carbon chemical potential(mc) (indices on the left of the figure indicates the Miller index of each plane. The number under each structure is the corresponding surface Fe/C ratio, blueballs for Fe atoms and black balls for C atoms)[142] (with permission from ACS publications)

图 13 (左)K在χ-Fe5C2(100)0.00上吸附后的电荷密度差图,显示以e/A3为单位的增加(橙色,红色)和减少(蓝色)区域;(a)中的采样平面穿过山谷并经过K,(b)中的采样平面穿过山谷并经过K;(右)预覆盖K的χ-Fe5C2(100)表面上O吸附电荷密度变化的(a)侧视图和(b)俯视图,红色(绿色)等值面表示增加(减少)0.015 e/A3;(c)χ-Fe5C2(100)上吸附K和吸附O相互作用时电荷密度变化的侧视图和(d)俯视图,红色(绿色)等值面表示增加(减少)0.005 e/A3,Fe和C原子分别为紫色和橙色,K和O的位置被标记[122]

Figure 13 (left) The charge density difference of K adsorbed on χ-Fe5C2 (100)0.00 shown the increase (orange, red) or decrease (blue) regions in e/A3. The sampling plane in (a) crosses the valley and through K. The sampling plane in (b) crosses the valley and through K. (right) (a) side view and (b) top view of the change of O adsorption charge density on χ-Fe5C2(100) surface pre-covered with K. The red (green) isosurface indicates an increase (or decrease) of 0.015 e/A3. (c) The side view and (d) top view of the change of charge density in the interaction between adsorbed K and adsorbed O on χ-Fe5C2(100). The red (green) isosurface indicates an increase (decrease) of 0.005 e/A3. The Fe and C atoms are purple and orange, respectively. The positions of K and O are marked[122] (with permission from ACS publications)

表 1 CO在ε-Fe2C、χ-Fe5C2、θ-Fe3C、Fe3C7不同表面最稳定吸附位点吸附能、吸附位点键长、振动频率和不同暴露表面面积占总暴露表面面积比

Table 1 Adsorption energy, bond length, vibration frequency and the ratio of different exposed surface area to the total exposed surface area of CO on the surfaces of ε-Fe2C, χ-Fe5C2, θ-Fe3C and Fe3C7

Surfaces Eads/eV Sites dC−O/Å dFe−C/Å v(C−O)/cm−1 Contributions Ref Fe (100) −1.07 − 1.32 − 1189 − [64] (110) −1.51 − 1.32 − 1172 − [65] (111) −1.17 − 1.20 − 1739 − [65] (210) −1.11 − 1.33 − 1115 − [65] (211) −1.06 − 1.28 − 1274 − [65] (310) 0.91 − 1.33 − 1134 − [65] Fe2C (011) −2.072 2F − 2.309 1940 − [62] (110) −2.074 1F-2 − 1.781 1848 0.02 [66] (211) −1.623 2F-1 − 2.329 1886 − [62] (121) −1.665 4F − 2.001 2.090 2.184 2.247 1600 0.39 [66] (101) − − − − − 0.48 [67] (001) −1.99 1F 1.140 1.760 − − [68] Fe5C2 (510) −2.05 3F1 1.201 1.941 2.067 2.052 1729 0.06 [69] (100) −1.53 T1 1.17 1.764 1940 0.07 [69] (010) −1.92 4F1 1.212 1.911 2.018 2.272 2.411 1659 0.07 [69] (001) −1.86 3F1 1.209 2.068 1.916 2.083 1680 0.12 [69] (110) −1.91 T1 1.169 1.784 1943 0.13 [69] (111) −1.51 T1 1.166 1.17 1970 0.36 [69] (11-1) −2.04 T1 1.176 1.765 1903 0.10 [70] (221) −2.00 5F2 1.298 2.097 2.040 2.207 2.039 1215 − [69] (411) −2.02 5F1 1.179 − 1879 0.06 [69] Fe3C (100) −1.77 3F 1.204 1.910 2.044 2.018 − 0.03 [70] (001) −1.79 4F 1.209 2.276 1.913 1.972 2.297 − 0.07 [71] (010) −2.03 2F 1.174 1.779 2.433 1933 0.24 [72] (111) − − − − − 0.44 [73] Fe7C3 (1-11) −3.03 B5 1.359 1.916 1.941 1.942 2.177 − − [74] (001) −2.47 3F1 1.202 1.997 1.984 1.989 − − [74] (211) −2.37 T6 − − − − [75] (11-1) −2.27 4F3 1.22 1.949 1.957 2.269 2.344 − − [75] (1-10) −2.16 2F2 1.194 1.777 2.284 − − [75] (101) −2.24 2F1 1.196 1.857 1.949 − − [75] Note: surface area contribution ratio was calculated at 550 K, 30 atm, ΔUc = −7.26 eV, H2/CO = 8 表 2 χ-Fe5C2不同表面O物种最稳定吸附构型吸附能、键长[84]

Table 2 Adsorption energy and bond length of the most stable adsorption configuration of O species on different surfaces of χ-Fe5C2[84](with permission from ACS publications)

Surface Eads /eV dFe-O /Å dC−O /Å (510) −0.99 1.870 1.875 1.910 − (001) −0.76 1.861 1.893 1.936 − (010) −0.93 1.861 1.880 1.918 − (110) −0.35 1.749 1.794 − − (11-1) −0.98 1.842 1.889 1.977 − (-411) −1.11 1.850 1.887 1.919 − (111) −0.15 1.988 − − 1.267 表 3 χ-Fe5C2不同表面H和CHx物种吸附能[85]

Table 3 Adsorption energies of H and CHx species on different surfaces of χ-Fe5C2[85](with permission from ACS publications)

Adsorbate Eads /eV (510) (021) (001) (100) H −0.69 −0.62 −0.61 −0.72 C −8.16 −8.28 −7.28 −7.06 CH −7.26 −7.21 −6.63 −6.55 CH2 −4.48 −4.48 −4.22 −4.36 CH3 −2.21 −2.10 −2.05 −2.53 表 4 碳化物机理和CO插入机理对比[86]

Table 4 Comparison of carbide mechanism and CO insertion mechanism[86](with permission from ACS publications)

Mechanism Presenter Mechanism content Merits and demerits Intermediate Carbide mechanism Fisher and Tropsch CO is first dissociated on the surface of the catalyst to form an active carbon species, which reacts with hydrogen to form methylene and then further polymerizes to form alkanes and olefins It can explain the formation of various hydrocarbons, but cannot explain the formation of oxygen-containing compounds and branched products. M-C

CO insertion mechanism

Pichler and SchulzAfter the formation of formyl group, CO and H2 are further hydrogenated to form bridged methylene species, which can be further hydrogenated to form carbonene and methyl, and CO is repeatedly inserted and hydrogenated in the intermediate to form various hydrocarbons In addition to explaining the formation process of linear hydrocarbons, it can also explain the formation process of oxygen-containing compounds, but it cannot explain the formation of branched products.

表 5 CO在四种铁碳化合物不同表面上的最稳定和最活跃位点上的解离、CO吸附位点、活化能(Ea)、反应能(ΔEr)、CO解离过渡态的键长(dC−O)汇总

Table 5 CO dissociation, CO adsorption sites, activation energy (Ea), reaction energy (ΔEr), bond length of CO dissociation transition state (dC−O) at the most stable and active sites of CO on the surfaces of four iron-carbon compounds

Surface Most stable configuration Most actived configuration sites Ea/eV ΔEr/eV dC−O/Å sites Ea/eV ΔEr/eV dC−O/Å Ref Fe2C (011) 2F 2.49 − − − − − − [104] (110) 1F-2 3.47 − − − − − − [101] (211) 2F-1 2.69 − − − − − − [101] (121) 4F 1.85 − − − − − − [101] (001) 1F −1.08 − − − − − − [72] Fe5C2 (510) 3F1 2.57 1.06 1.79 5F1 0.87 −0.91 1.72 [69] (100) 3F 1.81 0.23 − 2F1 2.45 1.12 2.00 [69] (010) 4F1 1.54 −0.09 2.00 5F1 1.49 −0.14 2.00 [69] (001) 3F1 1.89 0.86 1.99 6F1 0.80 −0.41 1.96 [69] (110) 3F 1.89 0.99 1.83 2F3 1.49 1.02 2.09 [69] (111) T1 2.95 0.95 1.94 4F1 2.00 0.31 1.94 [69] (11-1) T1 2.81 0.71 2.02 6F1 0.83 0.14 1.86 [69] (221) 5F2 0.97 −1.26 1.83 5F1 0.79 −1.43 1.75 [69] (-411) T1 2.90 0.73 1.88 4F1 1.37 −0.28 2.04 [69] Fe3C (100) 3F 1.68 −0.53 − − − − − [102] (001) 4F 1.92 0.12 − − − − − [102] (010) 2F 1.20 0.28 − − − − − [102] (111) − 0.41 −1.00 − − − − − [103] Fe7C3 (1-11) B5 0.969 −1.32 − − − − − [104] (001) 3F1 1.48 0.14 − 4F2 0.91 −1.10 − [105] (211) 4F2 2.43 0.95 − 4F1 1.93 0.26 − [105] 表 6 η-Fe2C催化剂完美和缺陷表面CO活化的活化势垒(Ea)和所涉及表面铁原子的Bader电荷(qB)[113]

Table 6 Activation barrier (Ea) of CO and the Bader charge (qB) of the involved surface Fe atoms on the perfect and defective surfaces of η-Fe2C catalyst[113](with permission from ACS publications)

Perfect surface Defective surface 011 110 211 121 011 110 211 121 Ea/eV 2.44 3.15 2.61 1.65 0.87 1.00 1.03 0.88 qB/e 0.535 0.569 0.513 0.525 0.347 0.439 0.392 0.379 表 7 χ-Fe5C2九个面CO解离IS(吸附CO和2H)的吸附能Eads和TSn对应的活化能Ea(n)[114]

Table 7 Adsorption energy Eads and TSn corresponding activation energy Ea(n) of CO dissociation IS (adsorbed CO and 2H) over nine planes of χ-Fe5C2 [114](with permission from ACS publications)

Surface Site Eads(IS) Ea(1) Ea(2) Ea(3) Ea(4) Ea(5) Ea(6) Ea(7) Ea(8) Ea(9) (001) ms −3.34 2.03 1.02 0.90 1.05 2.01 0.93 0.76 − − ma −3.17 0.83 0.92 1.27 1.22 2.19 − − 1.77 (221) ms −3.77 1.13 1.19 0.48 0.64 − − − 1.87 1.09 ma −3.73 0.99 1.24 0.33 0.88 − − − 1.56 − (510) ms −3.90 2.99 1.18 0.51 0.83 − 0.72 − − − ma −3.78 1.18 1.62 0.54 0.56 1.57 − − − − (010) ms −3.63 1.89 0.96 0.56 0.64 1.83 0.65 0.07 − − ma −3.39 1.53 0.72 0.56 0.64 1.83 0.65 0.07 1.86 − (110) ms −3.06 3.51 1.13 1.69 1.07 1.65 1.71 0.77 − − ma −2.52 1.61 0.98 0.33 0.86 2.08 0.50 0.19 − − (-411) ms −3.92 3.26 1.03 1.08 0.66 1.85 0.96 0.32 − − ma −3.31 2.11 1.03 1.32 0.87 1.94 1.32 0.36 1.47 0.49 (11-1) ms −3.48 3.64 1.01 0.99 0.19 1.52 1.12 0.23 − − ma −2.56 0.96 0.51 0.81 0.64 1.60 − 0.46 2.19 0.91 (111) ms −2.13 2.84 − 1.39 0.36 1.66 2.50 2.30 − − ma −1.86 2.01 0.73 1.74 0.55 1.16 1.59 0.71 1.13 1.82 (100) ms −2.39 3.00 1.11 1.15 0.16 1.10 1.39 0.83 − − ma −1.18 2.86 0.28 1.13 0.50 1.33 1.22 0.51 − − 表 8 θ-Fe3C九个表面H辅助机制活化能和反应能[120]

Table 8 Activation and reaction energy of H-assisted mechanisms over nine planes of θ-Fe3C[120](with permission from ACS publications)

Surface HCO-formation HCO-dissociation COH-formation COH-dissociation Ea/eV ΔEa/eV Ea/eV ΔEa/eV Ea/eV ΔEa/eV Ea/eV ΔEa/eV (100) 0.62 0.48 0.91 −0.99 1.72 1.18 0.80 −1.23 (010) 0.61 0.55 0.74 0.01 1.19 0.95 0.59 −0.67 (110) 2.52 1.04 0.68 −0.89 2.26 1.12 1.24 −0.34 (011) 2.65 1.14 1.02 −0.79 2.00 1.63 1.27 −0.64 (001) 1.04 0.52 0.56 −0.78 2.10 0.81 1.04 −0.42 (101) 2.49 2.01 0.48 −1.48 2.40 2.34 0.91 −1.97 (0-11) 0.75 0.48 0.29 −0.38 2.36 0.97 1.10 −0.95 (1-11) 1.61 1.22 0.01 −1.68 2.01 0.94 0.27 −1.51 (111) 1.30 0.86 0.45 −1.20 2.15 1.34 0.54 −1.36 表 9 χ-Fe5C2表面CHx + CHy耦合的势垒和反应能[131]

Table 9 Barrier and reaction energy of CHx + CHy coupling on χ-Fe5C2 planes[131](with permission from ACS publications)

Reaction Ea /eV ΔEr /eV (510) (021) (001) (100) (510) (021) (001) (100) C + C 1.59 1.91 1.18 1.45 1.23 1.21 0.39 0.71 C + CH 1.09 1.38 0.78 1.02 0.65 0.85 0.22 0.72 C + CH2 1.09 1.31 0.89 1.09 0.15 0.62 0.41 0.78 C + CH3 1.21 0.76 0.90 1.42 0.07 0.16 0.36 0.23 CH + CH 0.96 1.27 0.94 1.45 0.43 0.91 0.42 0.13 CH + CH2 1.03 1.63 1.10 1.58 0.64 0.72 0.52 0.11 CH + CH3 1.52 1.19 1.52 1.79 0.42 0.45 0.64 0.44 CH2 + CH2 0.98 1.17 0.60 0.30 0.02 0.16 0.17 0.69 CH2 + CH3 1.45 0.87 1.47 1.28 0.23 0.06 0.11 0.14 -

[1] POROSOFF M D, YAN B, CHEN J G. Catalytic reduction of CO2 by H2 for synthesis of CO, methanol and hydrocarbons: Challenges and opportunities[J]. Energy Environ,2016,9(1):62−73. doi: 10.1039/C5EE02657A [2] YE R P, DING J, GONG W, ARGYLE M D, ZHONG Q, WANG Y, YAO Y G. CO2 hydrogenation to high-value products via heterogeneous catalysis[J]. Nat Commun,2019,10(1):1−15. doi: 10.1038/s41467-018-07882-8 [3] PRINZ R, SPINELLI R, MAGAGNOTTI N, ROUTA J, ASIKAINEN A. Modifying the settings of CTL timber harvesting machines to reduce fuel consumption and CO2 emissions[J]. J Clean Prod,2018,197:208−217. doi: 10.1016/j.jclepro.2018.06.210 [4] FISCHER F, TROPSCH H. The preparation of synthetic oil mixtures (synthyol) from carbon monoxide and hydrogen[J]. Brennstoff-Chemie,1923,4:276−285. [5] DE BEER M, KUNENE A, NABAHO D, CLAEYS M, VAN STEEN E. Technical and economic aspects of promotion of cobalt-based Fischer-Tropsch catalysts by noble metals-a review[J]. J S Afr I Min Metell,2014,114(2):157−165. [6] SUO Y, YAO Y, ZHANG Y, XING S, YUAN Z Y. Recent advances in cobalt-based Fischer-Tropsch synthesis catalysts[J]. J Ind Eng Chem , 2022. [7] GLASSER D, HILDEBRANDT D, LIU X, LU X, MASUKU C M. Recent advances in understanding the Fischer-Tropsch synthesis (FTS) reaction[J]. Curr Opin Chem Eng,2012,1(3):296−302. doi: 10.1016/j.coche.2012.02.001 [8] ANANTHARAJ S, KUNDU S, NODA S. “The Fe Effect”: A review unveiling the critical roles of Fe in enhancing OER activity of Ni and Co based catalysts[J]. Nano Energy,2021,80:105514. doi: 10.1016/j.nanoen.2020.105514 [9] NIE X, MENG L, WANG H, CHEN Y, GUO X, SONG C. DFT insight into the effect of potassium on the adsorption, activation and dissociation of CO2 over Fe-based catalysts[J]. Phys Chem Chem Phys,2018,20(21):14694−14707. doi: 10.1039/C8CP02218F [10] VAN DYK J C, KEYSER M J, COERTZEN M. Syngas production from South African coal sources using Sasol-Lurgi gasifiers[J]. Int J Coal Geol, 2006, 65(3/4): 243–253. [11] KIM K Y, LEE H, NOH, W Y, SHIN J, HAN S J, KIM S K, LEE J S. Cobalt ferrite nanoparticles to form a catalytic Co-Fe alloy carbide phase for selective CO2 hydrogenation to light olefins[J]. ACS Catal,2020,10(15):8660−8671. doi: 10.1021/acscatal.0c01417 [12] VAN STEEN E, CLAEYS M. Fischer-Tropsch catalysts for the biomass-to-liquid (BTL)-process[J]. Chem Eng Technol,2008,31(5):655−666. doi: 10.1002/ceat.200800067 [13] XIE J, YANG J, DUGULAN A I, HOLMEN A, CHEN D, DE JONG K P, LOUWERSE M J. Size and promoter effects in supported iron Fischer-Tropsch catalysts: Insights from experiment and theory[J]. ACS Catal,2016,6(5):3147−3157. doi: 10.1021/acscatal.6b00131 [14] JÄGER C, MUTSCHKE H, HUISKEN F, ALEXANDRESCU R, MORJAN I, DUMITRACHE F, SCHNEEWEISS O. Iron-carbon nanoparticles prepared by CO2 laser pyrolysis of toluene and iron pentacarbonyl[J]. Appl Phys A,2006,85:53−62. doi: 10.1007/s00339-006-3665-2 [15] KHOURY G A, SULLIVAN P J E. Research at imperial college on the effect of elevated temperatures on concrete[J]. Fire Saf J,1988,13(1):69−72. doi: 10.1016/0379-7112(88)90034-3 [16] WANG Y, LIU S, HUANG P, XIE H, QIAO X. Structural and magnetic properties of mono-dispersed iron carbide (FexCy) nanoparticles synthesized by facile gas phase reaction[J]. Ceram Int,2019,45(8):11119−11124. doi: 10.1016/j.ceramint.2019.02.116 [17] WANG D, XIE Z, POROSOFF M D, CHEN J G. Recent advances in carbon dioxide hydrogenation to produce olefins and aromatics[J]. Chem,2021,7(9):2277−2311. doi: 10.1016/j.chempr.2021.02.024 [18] SUN J, CHEN Y, CHEN J. Towards stable Fe-based catalysts with suitable active phase for Fischer-Tropsch synthesis to lower olefins[J]. Catal Commun,2017,91:34−37. doi: 10.1016/j.catcom.2016.12.008 [19] SHROFF M D, KALAKKAD D S, COULTER K E, KOHLER S D, HARRINGTON M S, JACKSON N B, DATYE A K. Activation of precipitated iron Fischer-Tropsch synthesis catalysts[J]. J Catal,1995,156(2):185−207. doi: 10.1006/jcat.1995.1247 [20] 梁洁, 王欣宇, 高新华, 田菊梅, 段斌, 张伟, 江永军, Prasert Reubroycharoen, 张建利, 赵天生. Fe基催化剂物相演变及CO2加氢反应性能影响[J]. 燃料化学学报, 2022, 50(12): 1573–1580.LIANG Jie, WANG Xin-yu, GAO Xin-hua, TIAN Ju-mei, DUAN Bin, ZHANG Wei, JIANG Yong-jun, REUBROYCHAROEN Prasert, ZHANG Jian-li, ZHAO Tian-sheng. Effect of Na promoter and reducing atmosphere on phase evolution of Fe-based catalyst and its CO2 hydrogenation performance[J] J Fuel Chem Technol, 2022, 50(12): 1573–1580. [21] ALAYAT A, MCLLROY D N, MCDONALD A G. Effect of synthesis and activation methods on the catalytic properties of silica nanospring (NS)-supported iron catalyst for Fischer-Tropsch synthesis[J]. Fuel Process Technol,2018,169:132−141. doi: 10.1016/j.fuproc.2017.09.011 [22] TAHARI M N A, SALLEH F, SAHARUDDIN T S T, SAMSURI A, SAMIDIN S, YARMO M A. Influence of hydrogen and carbon monoxide on reduction behavior of iron oxide at high temperature: Effect on reduction gas concentrations[J]. Int J Hydrogen Energy,2021,46(48):24791−24805. doi: 10.1016/j.ijhydene.2020.06.250 [23] MA Z, ZHOU C, WANG D, WANG Y, HE W, TAN Y, LIU Q. Co-precipitated Fe-Zr catalysts for the Fischer-Tropsch synthesis of lower olefins (C2=−C4=): Synergistic effects of Fe and Zr[J]. J Catal,2019,378:209−219. doi: 10.1016/j.jcat.2019.08.037 [24] GAO R, LIU X, CAO Z, LIU X W, LU K, MA D, WEN X D. Carbon permeation: the prerequisite elementary step in iron-catalyzed Fischer-Tropsch synthesis[J]. J Catal,2019,149:645−664. [25] RUNXIA H. E, JIANG H, FANG W U, KEDUAN Z H I, NA W A N G, CHENLIANG Z H O U, QUANSHENG L I U. Effect of doping rare earth oxide on performance of copper-manganese catalysts for water-gas shift reaction[J]. J Rare Earth,2014,32(4):298−305. doi: 10.1016/S1002-0721(14)60071-5 [26] TANG L, HE L, WANG, Y, CHEN B, XU W, DUAN, X, LU A H. Selective fabrication of χ-Fe5C2 by interfering surface reactions as a highly efficient and stable Fischer-Tropsch synthesis catalyst[J]. Appl Catal B: Environ,2021,284:119753. doi: 10.1016/j.apcatb.2020.119753 [27] LIGER E, CHARLET L, VAN CAPPELLEN P. Surface catalysis of uranium (VI) reduction by iron (II)[J]. Geochim Cosmochim Acta, 1999, 63(19/20): 2939–2955. [28] KIM D H, HAN S W, YOON H S, KIM Y D. Reverse water gas shift reaction catalyzed by Fe nanoparticles with high catalytic activity and stability[J]. J Ind Eng Chem,2015,23:67−71. doi: 10.1016/j.jiec.2014.07.043 [29] TRAN F, BLAHA P, SCHWARZ K, NOVÁK P. Hybrid exchange-correlation energy functionals for strongly correlated electrons: Applications to transition-metal monoxides[J]. Phys Rev B,2006,74(15):155108. doi: 10.1103/PhysRevB.74.155108 [30] MENG Y, LIU X W, HUO C F, GUO W P, CAO D B, PENG Q, WEN X D. When density functional approximations meet iron oxides[J]. J Chem Theory Comput,2016,12(10):5132−5144. doi: 10.1021/acs.jctc.6b00640 [31] WEZENDONK T A, SUN X, DUGULAN A I, VAN HOOF A J, HENSEN E J, KAPTEIJN F, GASCON J. Controlled formation of iron carbides and their performance in Fischer-Tropsch synthesis[J]. J Catal,2018,362:106−117. doi: 10.1016/j.jcat.2018.03.034 [32] AMAYA-RONCANCIO S, LINARES D H, DUARTE H A, SAPAG K. DFT study of hydrogen-assisted dissociation of CO by HCO, COH, and HCOH formation on Fe(100)[J]. J Phys Chem C,2016,120(20):10830−10837. doi: 10.1021/acs.jpcc.5b12014 [33] LIU J, ZHANG G, JIANG X, WANG J, SONG C, GUO X. Insight into the role of Fe5C2 in CO2 catalytic hydrogenation to hydrocarbons[J]. Catal Today,2021,371:162−170. doi: 10.1016/j.cattod.2020.07.032 [34] QIN S, ZHANG C, XU J, YANG Y, XIANG H, LI Y. Fe-Mo interactions and their influence on Fischer-Tropsch synthesis performance[J]. Appl Catal A: Gen,2011,392(1/2):118−126. doi: 10.1016/j.apcata.2010.10.032 [35] DLAMINI H, MOTJOPE T, JOORST G, TER STEGE G, MDLELENI M. Changes in physico-chemical properties of iron-based Fischer–Tropsch catalyst induced by SiO2 addition[J]. Catal Lett,2002,78:201−207. doi: 10.1023/A:1014953201451 [36] LU K, HUO C F, GUO W P, LIU X W, ZHOU Y, PENG Q, WEN X D. Development of a reactive force field for the Fe-C interaction to investigate the carburization of iron[J]. Phys Chem Chem Phys,2018,20(2):775−783. doi: 10.1039/C7CP05958B [37] LIU Q Y, SHANG C, LIU Z P. In situ active site for CO activation in Fe-catalyzed Fischer-Tropsch synthesis from machine learning[J]. J Am Chem Soc,2021,143(29):11109−11120. doi: 10.1021/jacs.1c04624 [38] 王健. 费托合成催化剂活性相调控及其反应性能研究[D]. 天津: 天津大学, 2019.WANG Jian. Modulation of active phase and influences on catalytic performance for Fischer-Tropsch synthesis[D]. Tianjin: Tianjin University, 2019. [39] CHANG Q, ZHANG C, LIU C, WEI Y, CHERUVATHUR A V, DUGULAN A I, LI Y. Relationship between iron carbide phases (ε-Fe2C, Fe7C3, and χ-Fe5C2) and catalytic performances of Fe/SiO2 Fischer-Tropsch catalysts[J]. ACS Catal,2018,8(4):3304−3316. doi: 10.1021/acscatal.7b04085 [40] TAN P. Active phase, catalytic activity, and induction period of Fe/zeolite material in nonoxidative aromatization of methane[J]. J Catal,2016,338:21−29. doi: 10.1016/j.jcat.2016.01.027 [41] FANG C M, VAN HUIS M A, ZANDBERGEN H W. Structure and stability of Fe2C phases from density-functional theory calculations[J]. Scr Mater,2010,63(4):418−421. doi: 10.1016/j.scriptamat.2010.04.042 [42] 宋楠. 低温费-托合成Fe2C催化剂上合成气转化反应机理研究[D]. 上海: 华东理工大学, 2020.SONG Nan, A Theoretical study of the syngas conversion mechanism on Fe2C catalysts for low-temperature Fischer-Tropsch synthesis[D]. Shanghai: East China University of Science and Technology, 2020. [43] LAI J, HUANG B, TANG Y, LIN F, ZHOU P, CHEN X, GUO S. Barrier-free interface electron transfer on PtFe-Fe2C janus-like nanoparticles boosts oxygen catalysis[J]. Chem,2018,4(5):1153−1166. doi: 10.1016/j.chempr.2018.02.010 [44] ZUO L, ZHANG Y D, HU Z C, FARAOUN H I, ZHAO X, ESLING C. Microstructural modification of metallic materials by electromagnetic processing and the theoretical interpretation[C]. Adv Mat Res. Trans Tech Publications Ltd, 2007, 29: 123–126. [45] SCHNEIDER A, INDEN G, GRABKE H J, WEI Q, PIPPEL E, WOLTERSDORF J. Effect of H2S on formation and decomposition of Fe3C and Fe5C2 under metal dusting conditions[J]. Steel Res Int,2000,71(5):179−184. doi: 10.1002/srin.200005710 [46] YANG C, ZHAO H, HOU Y, MA D. Fe5C2 nanoparticles: A facile bromide-induced synthesis and as an active phase for Fischer-Tropsch synthesis[J]. J Am Chem Soc,2012,134(38):15814−15821. doi: 10.1021/ja305048p [47] CHA S, KIM H, CHOI H, KIM C S, HA K S. Effects of silica shell encapsulated nanocrystals on active χ-Fe5C2 phase and Fischer-Tropsch synthesis[J]. J Nanomater,2022,12(20):3704. doi: 10.3390/nano12203704 [48] GAO Y, LIU S, ZHAO Z, TAO H, SUN Z. Heterogeneous catalysis of CO2 hydrogenation to C2 + products[J]. Acta Phys -Chim Sin,2018,34(8):858−872. doi: 10.3866/PKU.WHXB201802061 [49] CAO D B, ZHANG F Q, LI Y W, WANG J, JIAO H. Structures and energies of coadsorbed CO and H2 on Fe5C2(001), Fe5C2(110), and Fe5C2(100)[J]. J Phys Chem B,2005,109(21):10922−10935. doi: 10.1021/jp050940b [50] VENEGAS R, ZÚÑIGA C, ZAGAL J H, TORO-LABBÉ A, MARCO J F, MENÉNDEZ N, RECIO F J. Fe3O4 templated pyrolyzed Fe-N-C catalysts. Understanding the role of N-functions and Fe3C on the ORR activity and mechanism[J]. ChemElectroChem,2022,9(11):e202200115. [51] HU Y, JENSEN J O, ZHANG W, HUANG Y, CLEEMANN L N, XING W, LI Q. Direct synthesis of Fe3C-functionalized graphene by high temperature autoclave pyrolysis for oxygen reduction[J]. ChemSusChem,2014,7(8):2099−2103. doi: 10.1002/cssc.201402183 [52] LIU Y, CHEN J F, BAO J, ZHANG Y. Manganese-modified Fe3O4 microsphere catalyst with effective active phase of forming light olefins from syngas[J]. ACS catal,2015,5(6):3905−3909. doi: 10.1021/acscatal.5b00492 [53] TSUZUKI A, SAGO S, HIRANO S I, NAKA S. High temperature and pressure preparation and properties of iron carbides Fe7C3 and Fe3C[J]. J Mater Sci,1984,19(8):2513−2518. doi: 10.1007/BF00550805 [54] ZHANG J, ABBAS M, ZHAO, W, CHEN J. Enhanced stability of a fused iron catalyst under realistic Fischer-Tropsch synthesis conditions: insights into the role of iron phases (χ-Fe5C2, θ-Fe3C and α-Fe)[J]. Catal Sci Technol,2022,12(13):4217−4227. [55] ZHANG M, GUAN X, YU Y. Theoretical insights into the removal pathways of adsorbed oxygen on the surface of χ-Fe5C2 (510)[J]. Chem Eng Sci,2023,271:118576. [56] LI W Q, ARCE-RAMOS J M, SULLIVAN M B, POH, C K, CHEN L, BORGNA A, ZHANG J. Mechanistic insights into selective ethylene formation on the χ-Fe5C2 (510) surface[J]. J Catal,2023,421:185−193. [57] DAVIS B H, XU L, BAO S. Role of CO2 oxygenates and alkenes in the initiation of chain growth during the Fischer-Tropsch synthesis[J]. Stud Surf Sci Catal, 1997, 107: 175−180. [58] DE SMIT E, CINQUINI F, BEALE A M, SAFONOVA O V, VAN BEEK W, SAUTET P, WECKHUYSEN B M. Stability and reactivity of ϵ-χ-θ iron carbide catalyst phases in Fischer-Tropsch synthesis: Controlling μC[J]. J Am Chem Soc,2010,132(42):14928−14941. doi: 10.1021/ja105853q [59] LIU X, LIU J, YANG Y, LI Y W, WEN X. Theoretical perspectives on the modulation of carbon on transition-metal catalysts for conversion of carbon-containing resources[J]. ACS Catal,2021,11(4):2156−2181. doi: 10.1021/acscatal.0c04739 [60] NØRSKOV J K, STUDT F, ABILD-PEDERSEN F, BLIGAARD T. Fundamental Concepts in Heterogeneous Catalysis[M]. Hoboken: John Wiley and Sons, 2014. [61] YU X, ZHANG X, WANG H, FENG G. High coverage water adsorption on the CuO(111) surface[J]. Appl Surf Sci,2017,425:803−810. doi: 10.1016/j.apsusc.2017.07.086 [62] HAMMER B, NøRSKOV J K. Electronic factors determining the reactivity of metal surfaces[J]. Surf Sci,1995,343(3):211−220. doi: 10.1016/0039-6028(96)80007-0 [63] WANG T, TIAN X, LI Y W, WANG J, BELLER M, JIAO H. High coverage CO activation mechanisms on Fe(100) from computations[J]. J Phys Chem C,2014,118(2):1095−1101. [64] LI T, WEN X, LI Y W, JIAO H. Mechanistic insight into CO activation, methanation and CC bond formation from coverage dependent CO hydrogenation on Fe(110)[J]. Surf Sci,2019,689:121456. doi: 10.1016/j.susc.2019.121456 [65] WANG T, TIAN X X, LI Y W, WANG J, BELLER M, JIAO H. Coverage-dependent CO adsorption and dissociation mechanisms on iron surfaces from DFT computations[J]. ACS Catal,2014,4(6):1991−2005. [66] HE S, WANG W, SHEN Z, LI G, KANG J, LIU Z, WANG Y. Carbon nanotube-supported bimetallic Cu-Fe catalysts for syngas conversion to higher alcohols[J]. Mol Catal,2019,479:110610. doi: 10.1016/j.mcat.2019.110610 [67] LYU S, WANG L, LI Z, YIN S, CHEN J, ZHANG Y, WANG Y. Stabilization of ε-iron carbide as high-temperature catalyst under realistic Fischer–Tropsch synthesis conditions[J]. Nat Commun,2020,11(1):6219. doi: 10.1038/s41467-020-20068-5 [68] REDA M, HANSEN H A, VEGGE T. DFT study of the oxygen reduction reaction on carbon-coated iron and iron carbide[J]. ACS Catal,2018,8(11):10521−10529. doi: 10.1021/acscatal.8b02167 [69] HE Y, ZHAO P, MENG Y, GUO W, YANG Y, LI Y W, WEN X D. Hunting the correlation between Fe5C2 surfaces and their activities on CO: The descriptor of bond valence[J]. J Phys Chem C,2018,122(5):2806−2814. doi: 10.1021/acs.jpcc.7b11430 [70] BROOS R J, ZIJLSTRA B, FILOT I A, HENSEN E J. Quantum-chemical DFT study of direct and H-and C-assisted CO dissociation on the χ-Fe5C2 Hägg carbide[J]. J Phys Chem C,2018,122(18):9929−9938. doi: 10.1021/acs.jpcc.8b01064 [71] CANO L A, BLANCO A G, LENER G, MARCHETTI S G, SAPAG K. Effect of the support and promoters in Fischer-Tropsch synthesis using supported Fe catalysts[J]. Catal Today,2017,282:204−213. doi: 10.1016/j.cattod.2016.06.054 [72] YU X, ZHANG X, MENG Y, ZHAO Y, LI Y, XU W, LIU Z. CO adsorption, dissociation and coupling formation mechanisms on Fe2C(001) surface[J]. Appl Surf Sci,2018,434:464−472. doi: 10.1016/j.apsusc.2017.10.225 [73] 韩光秀. χ-Fe5C2晶面对CO2吸附活化及加氢转化影响的密度泛函理论研究[D]. 大连: 大连理工大学, 2022.HAN Guang-xiu. DFT study of the effect of crystal plane on CO2 adsorption, activation, and hydrogenation over χ-Fe5C2 catalyst[D]. Dalian: Dalian University of Technology, 2022. [74] YONG Z, ZHU Z, WANG Z, HU J, PAN Q. One-dimensional carbon nanotube-FexCy nanocrystal composite[J]. Nanotechnology,2007,18(10):105602. doi: 10.1088/0957-4484/18/10/105602 [75] LIU X W, HUO C F, LI Y W, WANG J, JIAO H. Energetics of carbon deposition on Fe(100) and Fe(110) surfaces and subsurfaces[J]. Surf Sci, 2012, 606(7/8): 733–739. [76] SALEH A A, CASILLAS G, PERELOMA E V, CARPENTER K R, KILLMORE C R, GAZDER A A. A transmission Kikuchi diffraction study of cementite in a quenched and tempered steel[J]. Mater Charact,2016,114:146−150. doi: 10.1016/j.matchar.2016.02.016 [77] LIAO X Y, WANG S G, MA Z Y, WANG J, LI Y W, JIAO H. Density functional theory study of CO adsorption on the (100), (001) and (010) surfaces of Fe3C[J]. J Mol Catal A: Chem, 2007, 269(1/2): 169–178. [78] FU J, SUN D, CHEN Z, ZHANG J, DU H. First-Principles Investigation of CO Adsorption on h-Fe7C3 Catalyst[J]. Crystals,2020,10(8):635. doi: 10.3390/cryst10080635 [79] ZHANG M, REN J, YU Y. Investigating the CO activation mechanism on hcp-Fe7C3(211) via density functional theory[J]. Mol Catal,2021,505:111506. doi: 10.1016/j.mcat.2021.111506 [80] PETERSEN M A, VAN DEN BERG J A, VAN RENSBURG W J. Role of step sites and surface vacancies in the adsorption and activation of CO on χ-Fe5C2 surfaces[J]. J Phys Chem C,2010,114(17):7863−7879. doi: 10.1021/jp911725u [81] BAI Y, LIU J, WANG T, SONG Y F, YANG Y, LI Y W, WEN X. Theoretical study about adsorbed oxygen reduction over χ-Fe5C2: Formation of H2O and CO2[J]. Mol Catal,2022,524:112236. doi: 10.1016/j.mcat.2022.112236 [82] BENZIGER J, MADIX R J. The effects of carbon, oxygen, sulfur and potassium adlayers on CO and H2 adsorption on Fe(100)[J]. Surf Sci,1980,94(1):119−153. doi: 10.1016/0039-6028(80)90160-0 [83] SEIP U, BASSIGNANA I C, KÜPPERS J, ERTL G. A TDS and HREELS study of CO adsorbed on a potassium promoted Fe(111) surface[J]. Surf Sci,1985,160(2):400−418. doi: 10.1016/0039-6028(85)90783-6 [84] BłOŃSKI P, KIEJNA A, HAFNER J. Theoretical study of oxygen adsorption at the Fe(110) and(100) surfaces[J]. Surf Sci,2005,590(1):88−100. doi: 10.1016/j.susc.2005.06.011 [85] NIE X, WANG H, JANIK M J, CHEN Y, GUO X, SONG C. Mechanistic insight into C–C coupling over Fe-Cu bimetallic catalysts in CO2 hydrogenation[J]. J Phys Chem C,2017,121(24):13164−13174. doi: 10.1021/acs.jpcc.7b02228 [86] CHENG J, HU P, ELLIS P, FRENCH S, KELLY G, LOK C M. Some understanding of Fischer-Tropsch synthesis from density functional theory calculations[J]. Top Catal,2010,53:326−337. doi: 10.1007/s11244-010-9450-7 [87] HAN Y F. Application of DFT modeling in Fischer-Tropsch synthesis over Co-based catalysts[J]. Chem Modell,2015,12:184. [88] YIN J, HE Y, LIU X, ZHOU X, HUO C F, GUO, WEN X D. Visiting CH4 formation and C1 + C1 couplings to tune CH4 selectivity on Fe surfaces[J]. J Catal,2019,372:217−225. doi: 10.1016/j.jcat.2019.03.007 [89] 马文平, 刘全生, 赵玉龙, 周敬来, 李永旺. 费托合成反应机理的研究进展[J]. 内蒙古工业大学学报(自然科学版),1999,(2):43−49.MA Wen-ping, LIU Quan-sheng, ZHAO Yu-long, ZHOU Jing-lai, LI Yong-wang. Research progress of Fischer-Tropsch synthesis reaction mechanism(science edition)[J]. J Inner Mongolia Univ Technol (Nat Sci Ed),1999,(2):43−49. [90] YAO Z, GUO C, MAO Y, HU, P. Quantitative determination of C-C coupling mechanisms and detailed analyses on the activity and selectivity for Fischer-Tropsch synthesis on Co(0001): Microkinetic modeling with coverage effects[J]. ACS Catal,2019,9(7):5957−5973. doi: 10.1021/acscatal.9b01150 [91] LIU H, ZHANG R, LING L, WANG Q, WANG B, LI, D. Insight into the preferred formation mechanism of long-chain hydrocarbons in Fischer-Tropsch synthesis on Hcp Co (10-11) surfaces from DFT and microkinetic modeling[J]. Catal Sci Technol,2017,7(17):3758−3776. [92] WANG H, NIE X, CHEN Y, GUO X, SONG C. Facet effect on CO2 adsorption, dissociation and hydrogenation over Fe catalysts: Insight from DFT[J]. J CO2 Util,2018,26:160−170. doi: 10.1016/j.jcou.2018.05.003 [93] CAO D B, LI Y W, WANG J, JIAO H. Chain growth mechanism of Fischer-Tropsch synthesis on Fe5C2(001)[J]. J Mol Catal A: Chem,2011,346(1/2):55−69. doi: 10.1016/j.molcata.2011.06.009 [94] PETERSEN M A, VAN RENSBURG W J. CO dissociation at vacancy sites on Hägg iron carbide: Direct versus hydrogen-assisted routes investigated with DFT[J]. Top Catal, 2015, 58(10/11): 665–674. [95] ZHANG Q, KANG J, WANG Y. Development of novel catalysts for FischerT-ropsch synthesis: Tuning the product selectivity[J]. ChemCatChem,2010,2(9):1030−1058. doi: 10.1002/cctc.201000071 [96] PAN X, JIAO F, MIAO D, BAO X. Oxide-zeolite-based composite catalyst concept that enables syngas chemistry beyond Fischer-Tropsch synthesis[J]. Chem Rev,2021,121(11):6588−6609. doi: 10.1021/acs.chemrev.0c01012 [97] BILOEN P, HELLE J N, SACHTLER W M H. Incorporation of surface carbon into hydrocarbons during Fischer-Tropsch synthesis: Mechanistic implications[J]. J Catal,1979,58(1):95−107. doi: 10.1016/0021-9517(79)90248-3 [98] PICHLER H, SCHULZ H. New insights in the area of the synthesis of hydrocarbons from CO and H2[J]. Chem Ing Technol,1970,12(18):1160−1174. [99] GAUBE J, KLEIN H F. Further support for the two-mechanisms hypothesis of Fischer-Tropsch synthesis[J]. Appl Catal A: Gen, 2010, 374(1/2): 120–125. [100] LIU J, ZHANG A, LIU M, HU S, DING F, SONG C, GUO X. Fe-MOF-derived highly active catalysts for carbon dioxide hydrogenation to valuable hydrocarbons[J]. J CO2 Util,2017,21:100−107. doi: 10.1016/j.jcou.2017.06.011 [101] LU W, HERBIG M, LIEBSCHER C H, MORSDORF L, MARCEAU R K, DEHM G, RAABE D. Formation of eta carbide in ferrous martensite by room temperature aging[J]. Acta Mater,2018,158:297−312. doi: 10.1016/j.actamat.2018.07.071 [102] WANG Y, LI Y, HUANG S, WANG J, WANG H, LV J, MA X. Insight into CH4 formation and chain growth mechanism of Fischer-Tropsch synthesis on θ-Fe3C (031)[J]. Chem Phys Lett,2017,682:115−121. doi: 10.1016/j.cplett.2017.06.006 [103] TIAN X, WANG T, YANG Y, LI Y W, WANG J, JIAO H. Structures and energies of Cu clusters on Fe and Fe3C surfaces from density functional theory computation[J]. Phys Chem Chem Phys,2014,16(48):26997−27011. doi: 10.1039/C4CP04012K [104] DUAN Y, SUN H, LU W. Theoretical study of CO adsorption and activation on h-Fe7C3(11-1) for Fischer-Tropsch synthesis[J]. Mol Catal,2022,532:112732. doi: 10.1016/j.mcat.2022.112732 [105] CHUN H J, KIM Y T. Theoretical study of CO adsorption and activation on orthorhombic Fe7C3(001) surfaces for Fischer-Tropsch synthesis using density functional theory calculations[J]. Energies,2021,14(3):563. doi: 10.3390/en14030563 [106] CHEN Y, MA L, ZHANG R, YE R, LIU W, WEI J, LIU J. Carbon-supported Fe catalysts with well-defined active sites for highly selective alcohol production from Fischer-Tropsch synthesis[J]. Appl Catal B: Environ,2022,312:121393. doi: 10.1016/j.apcatb.2022.121393 [107] RIVERA DE LA CRUZ J G, SABBE M K, REYNIERS M F. First principle study on the adsorption of hydrocarbon chains involved in Fischer-Tropsch synthesis over iron carbides[J]. J Phys Chem C,2017,121(45):25052−25063. doi: 10.1021/acs.jpcc.7b05864 [108] DENG C M, HUO C F, BAO L L, FENG G, LI Y W, WANG J, JIAO H. CO Adsorption on Fe4C(100), (110), and (111) Surfaces in Fischer-Tropsch Synthesis[J]. J Phys Chem C,2008,112(48):19018−19029. doi: 10.1021/jp805702n [109] RAO K R P M, HUGGINS F E, MAHAJAN V, HUFFMAN G P, BUKUR D B, RAO V U S. Mössbauer study of CO-precipitated Fischer-Tropsch iron catalysts[J]. Hyperfine Interact,1994,93:1751−1754. doi: 10.1007/BF02072940 [110] WANG H, NIE X, LIU Y, JANIK M J, HAN X, DENG Y, GUO X. Mechanistic insight into hydrocarbon synthesis via CO2 hydrogenation on χ-Fe5C2 catalysts[J]. ACS Appl Mater Inter,2022,14(33):37637−37651. doi: 10.1021/acsami.2c07029 [111] CAO J, SONG N, CHEN W, CAO Y, QIAN G, DUAN X, ZHOU X. Role of C-defective sites in CO adsorption over ϵ-Fe2C and η-Fe2C Fischer-Tropsch catalysts[J]. Chem Asian J,2020,15(23):4014−4022. doi: 10.1002/asia.202000995 [112] CHEN B, WANG D, DUAN X, LIU W, LI Y, QIAN G, CHEN D. Charge-tuned CO activation over a χ-Fe5C2 Fischer-Tropsch catalyst[J]. ACS Catal,2018,8(4):2709−2714. doi: 10.1021/acscatal.7b04370 [113] HENKELMAN G, ARNALDSSON A, JÓNSSON H. A fast and robust algorithm for Bader decomposition of charge density[J]. Comp Mater Sci,2006,36(3):354−360. doi: 10.1016/j.commatsci.2005.04.010 [114] HE Y, ZHAO P, YIN J, GUO W, YANG Y, LI Y W, WEN X D. CO direct versus H-assisted dissociation on hydrogen coadsorbed χ-Fe5C2 Fischer-Tropsch catalysts[J]. J Phys Chem C,2018,122(36):20907−20917. doi: 10.1021/acs.jpcc.8b06988 [115] SORESCU D C. Plane-wave density functional theory investigations of the adsorption and activation of CO on Fe5C2 surfaces[J]. J Phys Chem C,2009,113(21):9256−9274. doi: 10.1021/jp811381d [116] OZBEK M O, NIEMANTSVERDRIET J W H. Elementary reactions of CO and H2 on C-terminated χ-Fe5C2(001) surfaces[J]. J Catal,2014,317:158−166. doi: 10.1016/j.jcat.2014.06.009 [117] WEI J, SUN J, WEN Z, FANG C, GE Q, XU H. New insights into the effect of sodium on Fe3O4-based nanocatalysts for CO2 hydrogenation to light olefins[J]. Catal Sci Technol,2016,6(13):4786−4793. doi: 10.1039/C6CY00160B [118] LIU W H, ZENG W, LIU F S, TANG B, LIU Q J, WANG W D. The mechanical and electronic properties of o-Fe2C, h-Fe3C, t-Fe5C2, m-Fe5C2 and h-Fe7C3 compounds: First-principles calculations[J]. Phys B Condens Matter,2021,606:412825. doi: 10.1016/j.physb.2021.412825 [119] FARAOUN H I, ZHANG Y D, ESLING C, AOURAG H Crystalline, electronic, and magnetic structures of o-Fe3C, χ-Fe5C2, and η-Fe2C from first principle calculation[J]. J Appl Phys, 2006, 0512: 10.1063 [120] BROOS R J, KLUMPERS B, ZIJLSTRA B, FILOT I A, HENSEN E J. A quantum-chemical study of the CO dissociation mechanism on low-index Miller planes of θ-Fe3C[J]. Catal Today,2020,342:152−160. doi: 10.1016/j.cattod.2019.02.015 [121] BRODEN G, GAFNER G, BONZEL H P. Co adsorption on potassium promoted Fe(110)[J]. Surf Sci,1979,84(2):295−314. doi: 10.1016/0039-6028(79)90139-0 [122] PETERSEN M A, CARIEM M J, CLAEYS M, VAN STEEN E. A DFT perspective of potassium promotion of χ-Fe5C2 (100)[J]. Appl Catal A: Gen,2015,496:64−72. doi: 10.1016/j.apcata.2015.02.008 [123] CAMERON S D, DWYER D J. Charge transfer effects on CO bond cleavage: CO and potassium on Fe (100)[J]. Surf Sci,1988,198(3):315−330. doi: 10.1016/0039-6028(88)90371-8 [124] GRAF B, MUHLER M. The influence of the potassium promoter on the kinetics and thermodynamics of CO adsorption on a bulk iron catalyst applied in Fischer-Tropsch synthesis: A quantitative adsorption calorimetry, temperature-programmed desorption, and surface hydrogenation study[J]. Phys Chem Chem Phys,2011,13(9):3701−3710. doi: 10.1039/C0CP01875A [125] PHAM T H, QI Y, YANG J, DUAN X, QIAN G, ZHOU X, YUAN W. Insights into Hägg iron-carbide-catalyzed Fischer-Tropsch synthesis: Suppression of CH4 formation and enhancement of C-C coupling on χ-Fe5C2 (510)[J]. ACS Catal,2015,5(4):2203−2208. doi: 10.1021/cs501668g [126] DENG L J, HUO C F, LIU X W, ZHAO X H, LI Y W, WANG J, JIAO H. Density functional theory study on surface CxHy formation from CO activation on Fe3C(100)[J]. J Phys Chem C,2010,114(49):21585−21592. doi: 10.1021/jp108480e [127] HUO C F, LI Y W, WANG J, JIAO H. Insight into CH4 formation in iron-catalyzed Fischer-Tropsch synthesis[J]. J Am Chem Soc,2009,131(41):14713−14721. doi: 10.1021/ja9021864 [128] FAN H, SONG J, WANG Y, WANG Y, JIN Y, LIU S, LI T, LI Q, SHAO C, LIU W. Inhabiting inactive transition by coupling function of oxygen vacancies and Fe-C bonds achieving long cycle life of an iron-based anode[J]. Adv Mater,2023,2303360. [129] LI T, WEN X, LI Y W, JIAO H. Successive dissociation of CO, CH4, C2H6, and CH3CHO on Fe(110): Retrosynthetic understanding of FTS mechanism[J]. J Phys Chem C,2018,122(50):28846−28855. doi: 10.1021/acs.jpcc.8b10310 [130] SCHWEICHER J, BUNDHOO A, KRUSE N. Hydrocarbon chain lengthening in catalytic CO hydrogenation: evidence for a CO-insertion mechanism[J]. J Am Chem Soc,2012,134(39):16135−16138. [131] YIN J, LIU X, LIU X W, WANG H, WAN H, WANG S, WEN X D. Theoretical exploration of intrinsic facet-dependent CH4 and C2 formation on Fe5C2 particle[J]. Appl Catal B: Environ,2020,278:119308. doi: 10.1016/j.apcatb.2020.119308 [132] PHAM T H, CAO J, SONG N, CAO Y, CHEN B, QIAN G, DUAN X. Mechanistic aspects of facet-dependent CH4/C2 + selectivity over a χ-Fe5C2 Fischer-Tropsch catalyst[J]. Green Energy Environ, 2022, 7(3): 449–456. [133] YANG Y, YAN M F, ZHANG Y X, LI D Y, ZHANG C S, ZHU Y D, WANG Y X. Catalytic growth of diamond-like carbon on Fe3C-containing carburized layer through a single-step plasma-assisted carburizing process[J]. Carbon,2017,122:1−8. [134] DE LA CRUZ J G R, SABBE M K, REYNIERS M F. First principle study of chain termination reactions during Fischer-Tropsch Synthesis on χ-Fe5C2(010)[J]. Mol Catal,2018,453:55−63. doi: 10.1016/j.mcat.2018.04.032 [135] VAN SANTEN R A, MARKVOORT A J. Chain growth by CO insertion in the Fischer-Tropsch reaction[J]. ChemCatChem,2013,5(11):3384−3397. [136] KLEIS J, GREELEY J, ROMERO N A, MOROZOV V A, FALSIG H, LARSEN A H, JACOBSEN K W. Finite size effects in chemical bonding: From small clusters to solids[J]. Catal Lett,2011,141:1067−1071. doi: 10.1007/s10562-011-0632-0 [137] LIU J X, WANG P, XU W, HENSEN E. Particle size and crystal phase effects in Fischer-Tropsch catalysts[J]. Eng Proc,2017,3(4):467−476. [138] MABASO E I, VAN STEEN E, CLAEYS M. Fischer-Tropsch synthesis on supported iron crystallites of different size[J]. Dgmk Tagungsbericht, 2006, (4): 93−100.. [139] PARK J Y, LEE Y J, KHANNA P K, JUN K W, BAE J W, KIM Y. H. Alumina-supported iron oxide nanoparticles as Fischer-Tropsch catalysts: Effect of particle size of iron oxide[J]. J Mol Catal A: Chem,2010,323(1/2):84−90. doi: 10.1016/j.molcata.2010.03.025 [140] LV Z Q, SUN S H, JIANG P, WANG B Z, FU W T. First-principles study on the structural stability, electronic and magnetic properties of Fe2C[J]. Comput Mater Sci,2008,42(4):692−697. doi: 10.1016/j.commatsci.2007.10.007 [141] ZHAO S, LIU X W, HUO C F, LI Y W, WANG J, JIAO H. Determining surface structure and stability of ε-Fe2C, χ-Fe5C2, θ-Fe3C and Fe4C phases under carburization environment from combined DFT and atomistic thermodynamic studies[J]. Catal Struct React,2015,1(1):44−60. [142] ZHAO S, LIU X W, HUO C F, LI Y W, WANG J, JIAO H. Surface morphology of Hägg iron carbide (χ-Fe5C2) from ab initio atomistic thermodynamics[J]. J Catal,2012,294:47−53. doi: 10.1016/j.jcat.2012.07.003 [143] LIANG B, DUAN H, SUN T, MA J, LIU X, XU J, ZHANG T. Effect of Na promoter on Fe-based catalyst for CO2 hydrogenation to alkenes[J]. ACS Sustainable Chem Eng,2018,7(1):925−932. [144] WAN H J, WU B S, ZHANG C H, XIANG H W, LI Y W, XU B F, YI F. Study on Fe-Al2O3 interaction over precipitated iron catalyst for Fischer-Tropsch synthesis[J]. Catal Commun,2007,8(10):1538−1545. doi: 10.1016/j.catcom.2007.01.002 [145] XU Y, SHI C, LIU B, WANG T, ZHENG J, LI W, LIU X. Selective production of aromatics from CO2[J]. Catal Sci Technol,2019,9(3):593−610. doi: 10.1039/C8CY02024H [146] BLIGAARD T, NøRSKOV J K, DAHL S, MATTHIESEN J, CHRISTENSEN C H, SEHESTED J. The Brønsted-Evans-Polanyi relation and the volcano curve in heterogeneous catalysis[J]. J Catal,2004,224(1):206−217. doi: 10.1016/j.jcat.2004.02.034 [147] AI X, XIE H, CHEN S, ZHANG G, XU B, ZHOU G. Highly dispersed mesoporous Cu/γ-Al2O3 catalyst for RWGS reaction[J]. Int J Hydrogen Energy,2022,47(33):14884−14895. doi: 10.1016/j.ijhydene.2022.03.002 [148] GRZYBEK T, KLINIK J, PAPP H, BAERNS M. Characterization of Cu and K containing Fe/Mn oxide catalysts for Fischer-Tropsch synthesis[J]. Chem Eng Technol,1990,13(1):156−161. doi: 10.1002/ceat.270130122 [149] KUMAR K L, NAIDU B N, SAINI H, GHOSH K, PRASAD V V D N, MONDAL P. Insights of precursor phase transition of (Cu-Zn-Al)/γ-Al2O3 hybrid catalyst for one step dimethyl ether synthesis from syngas[J]. Catal Today,2022,404:169−181. doi: 10.1016/j.cattod.2022.03.018 [150] TIAN X, WANG T, YANG Y, LI Y W, WANG J, JIAO H. Surface morphology of Cu adsorption on different terminations of the Hägg iron carbide (χ-Fe5C2) Phase[J]. J Phys Chem C,2015,119(13):7371−7385. doi: 10.1021/acs.jpcc.5b01324 [151] TIAN X, WANG T, YANG Y, LI Y W, WANG J, JIAO H. Copper promotion in CO adsorption and dissociation on the Fe(100) surface[J]. J Phys Chem C,2014,118(35):20472−20480. doi: 10.1021/jp506794w [152] TIAN X, WANG T, YANG Y, LIU G, TSANG S C E. Selective C2 + alcohol synthesis from direct CO2 hydrogenation over a Cs-promoted Cu-Fe-Zn catalyst[J]. ACS Catal,2020,10(9):5250−5260. doi: 10.1021/acscatal.0c01184 [153] ATHARIBOROUJENY M, RAUB A, IABLOKOV V, CHENAKIN S, KOVARIK L, KRUSE N. Competing mechanisms in CO hydrogenation over Co-MnOx catalysts[J]. ACS Catal,2019,9(6):5603−5612. doi: 10.1021/acscatal.9b00967 [154] LIU X, XU M, CAO C, YANG Z, XU J. Effects of zinc on χ-Fe5C2 for carbon dioxide hydrogenation to olefins: Insights from experimental and density function theory calculations[J]. Chin J Chem Eng,2023,54:206−214. doi: 10.1016/j.cjche.2022.03.027 [155] KHODAEI M, ENAYATI M H, KARIMZADEH F. Mechanochemical behavior of Fe2O3-Al-Fe powder mixtures to produce Fe3Al-Al2O3 nanocomposite powder[J]. J mater Sci,2008,43:132−138. doi: 10.1007/s10853-007-2123-7 [156] HUANG B, ISHIHARA K N, SHINGU P H. Metastable phases of Al-Fe system by mechanical alloying[J]. MSEA, 1997, 231(1/2): 72–79. [157] PIJOLAT M, PERRICHON V, BUSSIERE P. Study of the carburization of an iron catalyst during the Fischer-Tropsch synthesis: Influence on its catalytic activity[J]. J Catal,1987,107(1):82−91. doi: 10.1016/0021-9517(87)90274-0 [158] ORDOMSKY V V, LEGRAS B, CHENG K, PAUL S, KHODAKOV A Y. The role of carbon atoms of supported iron carbides in Fischer-Tropsch synthesis[J]. Catal Sci Technol,2015,5(3):1433−1437. doi: 10.1039/C4CY01631A [159] ZHANG H, SONG X, ZHAO C, HU D, ZHANG W, JIA M. N-doped porous carbon-FexC nanoparticle composites as catalysts for Friedel-Crafts acylation[J]. ACS Appl Nano Mater,2020,3(7):6664−6674. doi: 10.1021/acsanm.0c01107 [160] TORRES GALVIS H M, BITTER J H, KHARE C B, RUITENBEEK M, DUGULAN A I, DE JONG K P. Supported iron nanoparticles as catalysts for sustainable production of lower olefins[J]. Science,2012,335(6070):835−838. doi: 10.1126/science.1215614 [161] SCHULTE H J, GRAF B, XIA W, MUHLER M. Nitrogen-and oxygen-functionalized multiwalled carbon nanotubes used as support in iron-catalyzed, high-temperature Fischer-Tropsch synthesis[J]. ChemCatChem,2012,4(3):350−355. doi: 10.1002/cctc.201100275 [162] XIONG H, MOTCHELAHO M A, MOYO M, JEWELL L L, COVILLE N J. Fischer-Tropsch synthesis: Iron-based catalysts supported on nitrogen-doped carbon nanotubes synthesized by post-doping[J]. Appl Catal A: Gen,2014,482:377−386. doi: 10.1016/j.apcata.2014.06.019 [163] WANG F, WANG Y, HAN K, YU H. Efficient elimination of formaldehyde over Pt/Fe3O4 catalyst at room temperature[J]. J Environ Chem Eng,2020,8(4):104041. [164] KOVALCHUK V I, KUZNETSOV B N. Hydrocarbon synthesis from CO and H2 on (Fe + Pt) SiO2 catalysts[J]. J Mol Catal A: Chem,1995,102(2):103−110. doi: 10.1016/1381-1169(95)90045-4 [165] LI S, KRISHNAMOORTHY S, LI A, MEITZNER G D, IGLESIA E. Promoted iron-based catalysts for the Fischer-Tropsch synthesis: Design, synthesis, site densities, and catalytic properties[J]. J Catal,2002,206(2):202−217. doi: 10.1006/jcat.2001.3506 [166] HE Y, ZHAO P, GUO W, YANG Y, HUO C F, LI Y W, WEN X D. Hägg carbide surfaces induced Pt morphological changes: A theoretical insight[J]. Catal Sci Technol,2016,6(17):6726−6738. doi: 10.1039/C6CY00764C [167] LU Y, CAO B, YU F, LIU J, BAO Z, GAO J. High selectivity higher alcohols synthesis from syngas over three-dimensionally ordered macroporous Cu-Fe catalysts[J]. ChemCatChem,2014,6(2):473−478. doi: 10.1002/cctc.201300749 [168] ZHAO S, LIU X W, HUO C F, LI Y W, WANG J, JIAO H. The role of potassium promoter in surface carbon hydrogenation on Hägg carbide surfaces[J]. Appl Catal A: Gen,2015,493:68−76. doi: 10.1016/j.apcata.2015.01.006 [169] ZHAO S, LIU X W, HUO C F, LI Y W, WANG J, JIAO H. Potassium promotion on CO hydrogenation on the χ-Fe5C2(111) surface with carbon vacancy[J]. Appl Catal A: Gen,2017,534:22−29. doi: 10.1016/j.apcata.2017.01.012 [170] ZHAO S, LIU X W, HUO C F, WEN X D, GUO W, CAO D, JIAO H. Morphology control of K2O promoter on Hägg carbide (χ-Fe5C2) under Fischer–Tropsch synthesis condition[J]. Catal Today,2016,261:93−100. doi: 10.1016/j.cattod.2015.07.035 [171] ZHAO S, LIU X W, HUO C F, WEN X D, GUO W, CAO D, JIAO H. Highly activated K-doped iron carbide nanocatalysts designed by computational simulation for Fischer-Tropsch synthesis[J]. J Mater Chem A,2014,2(35):14371−14379. doi: 10.1039/C4TA02413C [172] HE Y, ZHAO P, LIU J, GUO W, YANG Y, LI Y W, WEN X D. Suppression by Pt of CO adsorption and dissociation and methane formation on Fe5C2(100) surfaces[J]. Phys Chem Chem Phys,2018,20(39):25246−25255. doi: 10.1039/C8CP04670K -

下载:

下载: