Preparation and NH3-SCR catalytic performance of CeTiOx catalysts with different pore structures

-

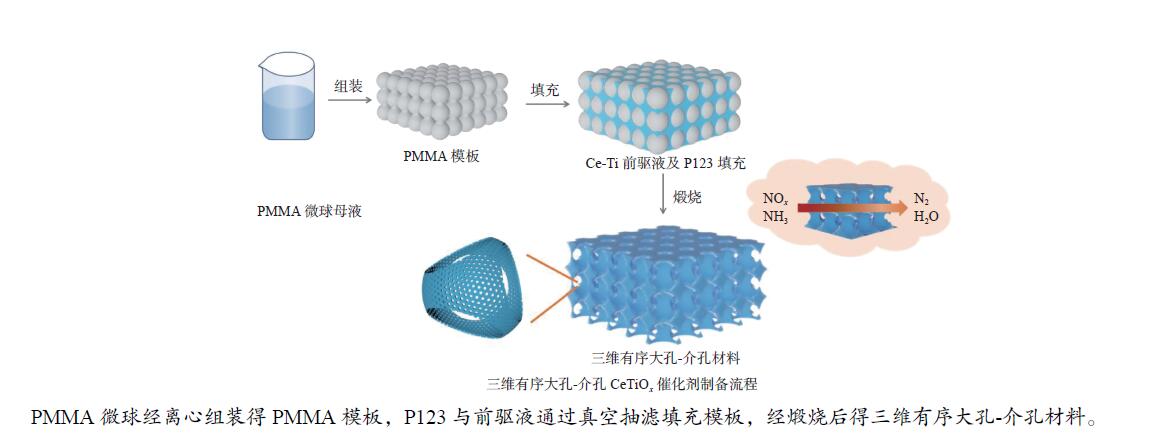

摘要: 为探究催化剂的孔结构对催化剂脱硝活性的影响,采用溶胶凝胶法分别制备了三维有序大孔-介孔(3DOM-m) CeTiOx、三维有序大孔(3DOM) CeTiOx、三维有序介孔(3DOm) CeTiOx及无序孔(DM) CeTiOx等四种不同孔结构的催化剂。NH3-SCR测试结果表明,催化剂活性依次为3DOM-m CeTiOx>3DOm CeTiOx>3DOM CeTiOx>DM CeTiOx,3DOM-m CeTiOx表现出更优异的催化活性,NO转化率在60000 h−1、250–400 ℃时超过90%。通过XRD、SEM、BET、NH3-TPD、in-situ DRIFTS等技术对催化剂进行表征分析。结果表明,催化剂的比表面积并不是决定CeTiOx脱硝活性的主导因素。3DOM-m CeTiOx具有高度有序的大孔-介孔结构、丰富的Brønsted酸酸性位点,进而提高了催化剂的脱硝活性。3DOM-m CeTiOx催化剂在NH3-SCR反应过程中同时遵循E-R机理和L-H机理。Abstract: To investigate the influence of pore structure on the catalytic activity of catalysts, four catalysts including three-dimensionally ordered macroporous-mesoporous (3DOM-m) CeTiOx, three-dimensionally ordered macroporous (3DOM) CeTiOx, three-dimensionally ordered mesoporous (3DOm) CeTiOx and disordered mesoporous (DM) CeTiOx were synthesized by the sol-gel method. The NH3-SCR denitration testing results show that the performance of the catalysts with different pore structures follows the sequence of 3DOM-m CeTiOx>3DOm CeTiOx>3DOM CeTiOx>DM CeTiOx, and the 3DOM-m CeTiOx shows an excellent catalytic activity, with more than 90% NO conversion in the range of 250–400 ℃ at a GHSV of 60000 h−1 . The characterization of catalysts by XRD, SEM, BET, NH3-TPD and in-situ DRIFTS indicates that the surface area is not the dominant factor determining the catalytic activity of CeTiOx. 3DOM-m CeTiOx has a highly ordered macroporous-mesoporous structure and abundant Bronsted acidic sites, thereby improving the denitrification activity. The NH3-SCR reaction over the 3DOM-m CeTiOx mainly follows the L-H and E-R mechanisms.

-

Key words:

- CeTiOx /

- 3DOM structure /

- ordered mesoporous structure /

- NH3-SCR

-

表 1 不同孔结构CeTiOx催化剂的结构

Table 1 Textural properties of CeTiOx catalysts with different pore structures

Catalyst Surface area

A/(m2·g−1)Pore volume v/(cm3·g−1) Average pore size d/nm 3DOM-m CeTiOx 107.3 0.217 8.1 3DOM CeTiOx 60.9 0.119 7.4 3DOm CeTiOx 257.6 0.348 5.4 DM CeTiOx 49.3 0.097 7.5 表 2 不同孔结构CeTiOx催化剂的NH3-TPD计算

Table 2 The results of NH3-TPD

Catalyst Weak acid amount/(μmol∙g−1) Medium strong acid amount/(μmol∙g−1) Total acid amount/(μmol∙g−1) 3DOM-m CeTiOx 101 35 136 3DOM CeTiOx 60 12 72 3DOm CeTiOx 71 26 97 DM CeTiOx 56 8 63 -

[1] YAN L J, LIU Y Y, LIU Y Y, et al. Scale-activity relationship of MnOx-FeOy nanocage catalysts derived from prussian blue analogues for low-temperature NO reduction: Experimental and DFT studies[J]. ACS Appl Mater Inter,2017,9(3):2581−2593. doi: 10.1021/acsami.6b15527 [2] LIU Z, SUN G X, CHEN C, et al. Fe-doped Mn3O4 spinel nanoparticles with highly exposed Feoct-O-Mntet sites for efficient selective catalytic reduction(SCR) of NO with ammonia at low temperatures[J]. ACS Catal,2020,10(12):6803−6809. doi: 10.1021/acscatal.0c01284 [3] FANG X, LIU Y J, CHENG Y, et al. Mechanism of Ce-modified birnessite-MnO2 in promoting SO2 poisoning resistance for low-temperature NH3-SCR[J]. ACS Catal,2021,11(7):4125−4135. doi: 10.1021/acscatal.0c05697 [4] CHEN Z C, REN S, WANG M M, et al. Insights into samarium doping effects on catalytic activity and SO2 tolerance of MnFeO catalyst for low-temperature NH3-SCR reaction[J]. Fuel,2022,321:124113−1124113. doi: 10.1016/j.fuel.2022.124113 [5] PAN Y J, SHEN B X, LIU L J, et al. Develop high efficient of NH3-SCR catalysts with wide temperature range by ball-milled method[J]. Fuel,2020,282:118834. doi: 10.1016/j.fuel.2020.118834 [6] YI X F, WANG J X, LIU Y Q, et al. Promotional effect of Fe and Ce co-doping on a V2O5-WO3/TiO2 catalyst for SCR of NOx with high K and Pb resistance[J]. Catal Sci Technol,2022,12(13):4169−4180. doi: 10.1039/D2CY00818A [7] 梁彦正, 王学涛, 张乾蔚, 等. 双金属Ce-Mn/ZSM-5催化剂的制备及NH3-SCR脱硝性能研究[J]. 燃料化学学报,2020,48(2):205−212.LIANG Yanzheng, WANG Xuetao, ZHANG Qianwei, et al. Performance of the modified Cu-Mn/SAPO-34 catalysts in selective catalytic reduction of NOx by NH3[J]. J Fuel Chem Technol,2020,48(2):205−212. [8] 杨洋, 胡准, 米容立, 等. Mn负载量对nMnOx/TiO2催化剂NH3-SCR催化性能的影响[J]. 分子催化,2020,34(4):313−325.YANG Yang, HU Zhun, MI Rongli, et al. Effect of Mn loading on catalytic performance of nMnOx/TiO2 in NH3-SCR reaction[J]. J Mol Catal,2020,34(4):313−325. [9] 纪生晓, 张玮坚, 郑玉婴, 等. 低温燃烧法制备Mn-CeOx催化剂及其NH3-SCR脱硝性能[J]. 燃料化学学报,2019,47(2):224−232.JI Shengxiao, ZHANG Yijian, ZHENG Yuying, et al. Low-temperature combustion synthesis of the Mn-CeOx catalyst and its performance in the selective catalytic reduction of NOx by NH3[J]. J Fuel Chem Technol,2019,47(2):224−232. [10] 于飞, 马江丽, 任德志, 等. 铁基分子筛活性位点的制备控制及对NH3-SCR活性的影响[J]. 分子催化,2022,36(4):321−329.YU Fei, MA Jiangli, REN Dezhi, et al. Effect of Iron sites and synthesis procedure of Fe-beta catalysts on NH3-SCR performance[J]. J Mol Catal,2022,36(4):321−329. [11] CHEN W, YANG S, LIU H, et al. Single-atom Ce-modified alpha-Fe2O3 for selective catalytic reduction of NO with NH3[J]. Environ Sci Technol,2022,56:10442−10453. doi: 10.1021/acs.est.2c02916 [12] 刘崇飞, 王学涛, 邢利益, 等. 双金属Cu-Ce/SAPO-34催化剂的制备及其NH3-SCR脱硝性能研究[J]. 燃料化学学报,2022,50(10):1316−1323.LIU Chongfei, WANG Xuetao, XING Liyi, et al. Study on preparation and denitrification performance of NH3-SCR of bimetallic Cu-Ce/SAPO-34 catalyst[J]. J Fuel Chem Technol,2022,50(10):1316−1323. [13] WANG J, FAN D Q, YU T, et al. Improvement of low-temperature hydrothermal stability of Cu/SAPO-34 catalysts by Cu2+ species[J]. J Catal,2015,322:84−90. doi: 10.1016/j.jcat.2014.11.010 [14] LIU C X, CHEN L, LI J H, et al. Enhancement of activity and sulfur resistance of CeO2 supported on TiO2-SiO2 for the selective catalytic reduction of NO by NH3[J]. Environ Sci Technol,2012,46(11):6182−6189. doi: 10.1021/es3001773 [15] 周国民, 李明圆, 付在国, 等. 碱金属对NH3-SCR脱硝催化剂Ce/TiO2的毒化研究[J]. 应用化工,2018,47(12):2616−2619.ZHOU Guomin, LI Mingyuan, FU Zaiguo, et al. Influence of alkali metals on Ce/TiO2 catalyst for selective catalytic reduction of no with NH3[J]. Appl Chem Ind,2018,47(12):2616−2619. [16] 耿新泽, 段钰锋, 胡鹏, 等. SCR气氛下Ce-W/TiO2催化剂的脱硝协同脱汞特性[J]. 中国环境科学,2019,39(4):1419−1426.GENG Xinze, DUAN Yufeng, HU Peng, et al. Characteristics of denitrification and mercury removal of Ce-W/TiO2 catalysts in SCR atmosphere[J]. China Environ Sci,2019,39(4):1419−1426. [17] 康海彦, 莫杜娟, 张学军, 等. CeO2-WO3催化剂表面酸性和氧化还原性能在脱硝反应中的研究[J/OL]. 燃料化学学报 (中英文), 2023, 51(6): 814–824.KANG Haiyan, MO Dujuan, ZHANG Xuejun, et al. Investigation of the surface acidity and redox on the CeO2-WO3 catalyst for selective catalytic reduction with NH3[J/OL]. J Fuel Chem Technol, 2023, 51(6): 814–824. [18] LI Q, LI X, LI W, et al. Effect of preferential exposure of anatase TiO2 {0 0 1} facets on the performance of Mn-Ce/TiO2 catalysts for low-temperature selective catalytic reduction of NOx with NH3[J]. Chem Eng J,2019,369:26−34. doi: 10.1016/j.cej.2019.03.054 [19] 赵海, 张德祥, 高晋生. 稀土掺杂铁锰脱硝催化剂的制备及其性能研究[J]. 煤炭转化,2011,34(4):72−74 + 78.ZHAO Hai, ZHANG Dexiang, GAO Jinsheng. Selective catalytic reduction of NOx with NH3 over Fe-Mn-O catalyst promoted by CeO2[J]. Coal Conversion,2011,34(4):72−74 + 78. [20] 周超, 赵阳, 徐佳, 等. pH值对浸渍法制备的铈钨钛脱硝催化剂的影响[J]. 稀土,2020,41(5):59−69.ZHOU Chao, ZHAO Yang, XU Jia, et al. Effect of pH on denitration performance of CeWTi catalyst[J]. Chin Rare Earths,2020,41(5):59−69. [21] 安志强. 二氧化钛载体制备及性能研究[D]. 南京: 南京工业大学, 2005.AN Zhiqiang. Studies on the preparation and performance of TiO2 supports[D]. Nanjing: Nanjing University of Technology, 2005. [22] ZHANG Z P, LI R M, WANG M J, et al. Two steps synthesis of CeTiOx oxides nanotube catalyst: Enhanced activity, resistance of SO2 and H2O for low temperature NH3-SCR of NOx[J]. Appl Catal B: Environ,2021,282:119542. doi: 10.1016/j.apcatb.2020.119542 [23] ZHANG Z P, CHEN L Q, LI Z B, et al. Activity and SO2 resistance of amorphous CeaTiOx catalysts for the selective catalytic reduction of NO with NH3: in situ DRIFT studies[J]. Catal Sci Technol,2016,6(19):7151−7162. doi: 10.1039/C6CY00475J [24] FEI Z Y, YANG Y R, WANG M H, et al. Precisely fabricating Ce-O-Ti structure to enhance performance of Ce-Ti based catalysts for selective catalytic reduction of NO with NH3[J]. Chem Eng J,2018,353:930−939. doi: 10.1016/j.cej.2018.07.198 [25] HUANG B J, YU D Q, SHENG Z Y, et al. Novel CeO2@TiO2 core-shell nanostructure catalyst for selective catalytic reduction of NOx with NH3[J]. J Environ Sci,2017,55(5):129−136. [26] MA K L, GUO K, LI L L, et al. Cavity size dependent SO2 resistance for NH3-SCR of hollow structured CeO2-TiO2 catalysts[J]. Catal Commun,2019,128:105719. doi: 10.1016/j.catcom.2019.105719 [27] 李丹, 王慧, 陈留平, 等. 一种无定形有序的Ce-Ti催化膜用于同时去除粉尘和氮氧化物(英文)[J]. 无机化学学报,2020,36(11):2189−2196.LI Dan, WANG Hui, CHEN Liuping, et al. Ordered mesoporous and complete amorphous Ce-Ti catalytic filter for particle separation and NOx removal[J]. Chin J Inorg Chem,2020,36(11):2189−2196. [28] HONG H, LIU J L, HUANG H W, et al. Ordered macro-microporous metal-organic framework single crystals and their derivatives for rechargeable aluminum-ion batteries[J]. J Am Chem Soc,2019,141:14764−14771. doi: 10.1021/jacs.9b06957 [29] YANG G C, PAN Q Y, YANG P, et al. Heteropolyacids supported on hierarchically macro/mesoporous TiO2: Efficient catalyst for deep oxidative desulfurization of fuel[J]. Tungsten,2022,4(1):28−37. doi: 10.1007/s42864-021-00125-2 [30] ZHOU Z M, ZENG T Y, CHENG Z M, et al. Preparation and characterization of titania-alumina mixed oxides with hierarchically macro-mesoporous structures[J]. Ind Eng Chem Res,2011,50(2):883−890. doi: 10.1021/ie101697t [31] ZHOU Z M, ZENG T Y, CHENG Z M, et al. Preparation of a catalyst for selective hydrogenation of pyrolysis gasoline[J]. Ind Eng Chem Res,2010,49:11112−11118. doi: 10.1021/ie1003043 [32] ZHOU Z M, ZENG T Y, CHENG Z M, et al. Diffusion-enhanced hierarchically macro-mesoporous catalyst for selective hydrogenation of pyrolysis gasoline[J]. AICHE J,2011,57(8):2198−2206. doi: 10.1002/aic.12421 [33] 邓权政, 毛文婷, 韩璐. 介观尺度多孔材料的电子显微学结构解析[J]. 化学学报,2022,80(8):1203−1216. doi: 10.6023/A22030136DENG Quanzheng, MAO Wenting, HAN Lu. Structural solution of porous materials on the mesostructural scale by electron microscopy[J]. Acta Chim Sin,2022,80(8):1203−1216. doi: 10.6023/A22030136 [34] WANG L Y, REN Y, YU X H, et al. Novel preparation method, catalytic performance and reaction mechanisms of PrxMn1-xOd/3DOM ZSM-5 catalysts for the simultaneous removal of soot and NOx[J]. J Catal,2023,417:226−247. doi: 10.1016/j.jcat.2022.12.004 [35] LI Y L, LI W M, YAN R, et al. Hierarchical three-dimensionally ordered macroporous Fe-V binary metal oxide catalyst for low temperature selective catalytic reduction of NOx from marine diesel engine exhaust[J]. Appl Catal B: Environ,2020,268:118455. doi: 10.1016/j.apcatb.2019.118455 [36] 宋丽云, 邓世林, 周宜芸, 等. V2O5-MoO3/TiO2催化剂的NH3-SCR性能: 载体的影响[J]. 材料导报,2023,37(6):71−76.SONG Liyun, DENG Shilin, ZHOU Yiyun, et al. NH3-SCR performance of V2O5-MoO3/TiO2 catalyst: Effect of support[J]. Mater Rep,2023,37(6):71−76. [37] ZHANG X L, HU X R, LIU S W, et al. MnOx-pillared rectorite prepared by in-situ deposition as efficient catalysts for low-temperature NH3-SCR: The influences of manganese (II) precursors[J]. J Environ Chem Eng,2022,10(2):105719. [38] PAN J H, ZHAO X S, LEE W I. Block copolymer-templated synthesis of highly organized mesoporous TiO2-based films and their photoelectrochemical applications[J]. Chem Eng J,2011,170(2-3):363−380. doi: 10.1016/j.cej.2010.11.040 [39] MU Y B, HUANG X S, TANG Z C, et al. Ordered mesoporous TiO2 framework confined CeSn catalyst exhibiting excellent high activity for selective catalytic reduction of NO with NH3 at low temperature[J]. Chem Eng J,2023,454:140−181. [40] 梅雪垒, 熊靖, 韦岳长, 等. 三维有序大孔钙钛矿型La1−xKxNiO3催化剂提高炭烟催化燃烧活性: K取代的作用(英文)[J]. 催化学报,2019,40(5):722−732. doi: 10.1016/S1872-2067(18)63269-9MEI Xuelei, XIONG Jing, WEI Yuechang, et al. Three-dimensional ordered macroporous perovskite-type La1−xKxNiO3 catalysts with enhanced catalytic activity for soot combustion: the Effect of K-substitution[J]. Chin J Catal,2019,40(5):722−732. doi: 10.1016/S1872-2067(18)63269-9 [41] 王艳, 李兆强, 赵文怡, 等. 有序介孔CeO2基催化剂用于富H2中CO优先氧化的研究[J]. 稀土,2018,39(1):1−10.WANG Yan, LI Zhaoqiang, ZHAO Wenyi, et al. Modified highly ordered mesoporous ceria-based catalysts employed for CO preferential oxidation in H2-rich stream[J]. Chin Rare Earth,2018,39(1):1−10. [42] ZHONG Y K, CHANG S, DONG G J. Preparation and characterization of a novel double-walled Na2(TiO)SiO4 nanotube by hydrothermal process with CTAB as an assistant[J]. Microporous Mesoporous Mater,2017,239:70−77. [43] XU Y, ZHOU M L, CHEN M T, et al. Simultaneous removal of NO and elemental mercury from coal-fired flue gas using natural ferruginous manganese ore at low temperature[J]. Fuel,2022,326:125118. [44] WANTANABE S G, MA X L, SONG C S. Characterization of structural and surface properties of nanocrystalline TiO2-CeO2 mixed oxides by XRD, XPS, TPR, and TPD[J]. J Phys Chem C,2009,113(32):14249−21425. doi: 10.1021/jp8110309 [45] LIU B, LIU J, MA S C, et al. Mechanistic study of selective catalytic reduction of NO with NH3 on W-Doped CeO2 catalysts: Unraveling the catalytic cycle the role of oxygen vacancy[J]. J Phys Chem C,2016,120(4):2271−2283. doi: 10.1021/acs.jpcc.5b11355 [46] WU Z B, JIANG B Q, LIU Y, et al. DRIFT study of manganese/titania-based catalysts for low-temperature selective catalytic reduction of NO with NH3[J]. Environ Sci Technol,2007,41(16):5812−5817. doi: 10.1021/es0700350 [47] LIU F D, ASAKURA K, HE H, et al. Influence of calcination temperature on iron titanate catalyst for the selective catalytic reduction of NOx with NH3[J]. Catal Today,2011,164(1):520−527. doi: 10.1016/j.cattod.2010.10.008 [48] 陈宜华, 王攀, 孟凡禹, 等. VPO/TiO2催化剂表面酸性位调控及低温NH3-SCR脱硝性能研究[J]. 中国环境科学,2023,43(4):1558−1566.CHEN Yihua, WANG Pan, MENG Fanyu, et al. The optimization of surface acidity VPO/TiO, catalyst and its low-temperature NH3-SCR denitration performance[J]. China Environ Sci,2023,43(4):1558−1566. [49] SHAN W, LIU F, HONG H, et al. A superior Ce-W-Ti mixed oxide catalyst for the selective catalytic reduction of NOx with NH3[J]. Appl Catal B: Environ,2012,115−116:100−106. doi: 10.1016/j.apcatb.2011.12.019 [50] CHEN L, LI J, GE M F. DRIFT study on cerium-tungsten/titiania catalyst for selective catalytic reduction of NOx with NH3[J]. Environ Sci Technol,2010,44:9590−9596. doi: 10.1021/es102692b [51] LIU Z M, ZHANG S X, LI J H, et al. Promoting effect of MoO3 on the NOx reduction by NH3 over CeO2/TiO2 catalyst studied with in situ DRIFTS[J]. Appl Catal B: Environ,2014,144:90−95. doi: 10.1016/j.apcatb.2013.06.036 [52] SHU Y, SUN H, QUAN X, et al. Enhancement of catalytic activity over the iron-modified Ce/TiO2 catalyst for selective catalytic reduction of NOx with ammonia[J]. J Phys Chem C,2012,116(48):25319−25327. doi: 10.1021/jp307038q [53] LIU Z, LIU Y, CHEN B, et al. Novel Fe-Ce-Ti catalyst with remarkable performance for the selective catalytic reduction of NOx by NH3[J]. Catal Sci Technol,2016,6:6688−6696. doi: 10.1039/C5CY02278A [54] CHEN W M, MA Y P, QU Z, et al. Mechanism of the selective catalytic oxidation of slip ammonia over Ru-modified Ce-Zr complexes determined by in situ diffuse reflectance infrared fourier transform spectroscopy[J]. Environ Sci Technol,2014,48(20):12199−12205. doi: 10.1021/es502369f -

下载:

下载: