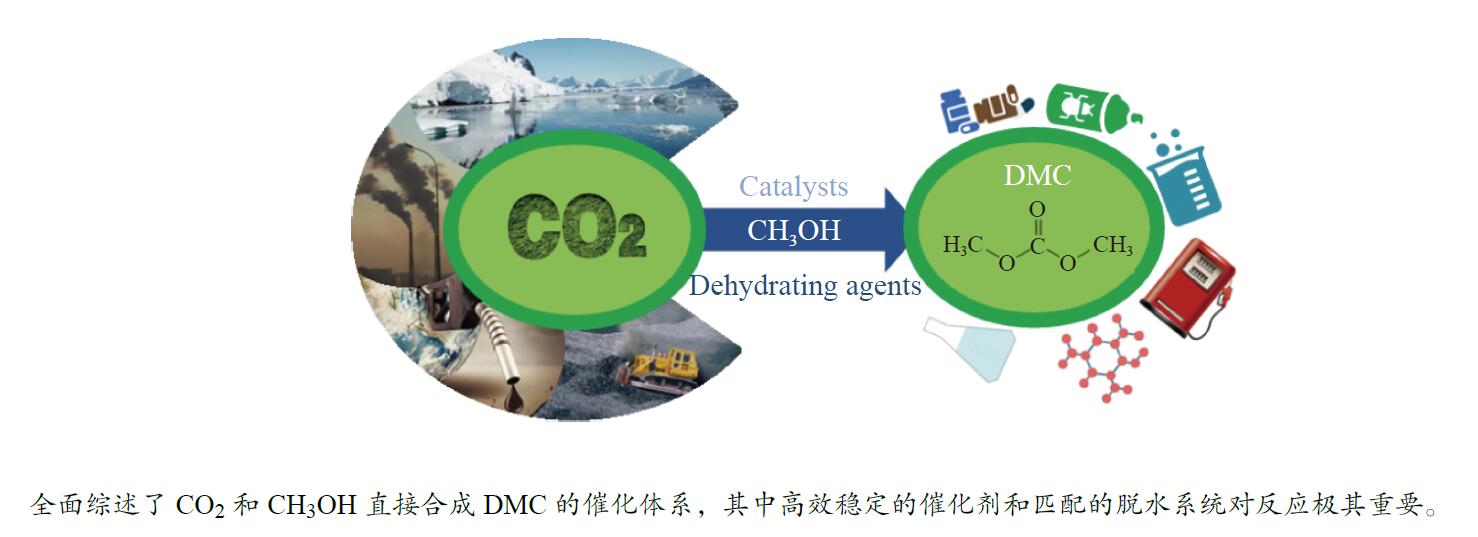

Catalytic systems for the direct synthesis of dimethyl carbonate from carbon dioxide and methanol containing dehydrating agent, a review

-

摘要: 碳酸二甲酯(DMC)是一种用途广泛的环境友好型绿色化学品,利用CO2和CH3OH直接合成DMC是近年来CO2清洁转化的一个研究重点。设计高效稳定的催化剂和反应工艺促进CO2的转化,是DMC直接合成法能否工业化的技术关键。本工作综述了CO2和CH3OH直接合成DMC催化体系的研究进展,介绍了不同类型催化剂的反应机理,主要包括离子液体催化剂、碱金属碳酸盐催化剂、过渡金属氧化物催化剂等,阐述了各种脱水剂的脱水原理和对反应的促进作用,对不同催化-脱水体系的优势及缺点进行分析。据此预测,开发高效稳定的催化剂和对水选择渗透性强的膜材料,构建和实施新型的脱水工艺,将是今后DMC直接合成的研究重点。Abstract: Dimethyl carbonate (DMC) is a widely used environment-friendly green chemical, and the direct synthesis of DMC from CO2 and CH3OH has become one of the research focuses on the clean conversion of CO2 in recent years. The design of efficient and stable catalysts and reaction processes to promote the conversion of CO2 is the key to realize the direct synthesis of DMC in industry. In this paper, the research progress of catalytic systems for the direct synthesis of DMC from CO2 and CH3OH is reviewed and the reaction mechanism of different types of catalysts is summarized, mainly including the ionic liquid catalyst, alkali metal carbonate catalyst, transition metal oxide catalyst, etc. The operation principle of various dehydrating agents and their promoting effect on the production of DMC are expounded, while the advantages and disadvantages of different catalytic-dehydration systems are analyzed. It is predicted that the development of efficient and stable catalysts and membrane materials with strong permeability to water as well as the construction and implementation of new dehydration processes will be the focus of future research on the direct synthesis of DMC from CO2 and CH3OH.

-

Key words:

- carbon dioxide /

- methanol /

- dimethyl carbonate /

- catalysts /

- dehydrating agents

-

图 7 (a) 催化活性与催化剂中等强度酸性位点数量关系,(b) 催化活性与催化剂中等强度碱性位点数量关系[39]

Figure 7 Relationship between the catalytic activity and the number of acidic sites in the catalyst (a) as well as the relationship between the catalytic activity and the number of basic sites in the catalyst (b) in the synthesis of DMC from CO2 and CH3OH[39] (with permission from Elsevier)

表 1 DMC合成方法

Table 1 Summary of DMC synthesis methods

Synthesis method Advantage Disadvantage Current status Phosgene method 1. The method is easy to operate. 2. The method has a high DMC yield and can generate considerable returns 1. Phosgene is highly toxic and is classified as a Class A deadly compound. 2. Phosgene and by-product HCl are demanding on the equipment The method has been phased out Indirect vapor phase methanol oxidative carbonylation 1. The reaction conditions are mild.

2. Product purity is higher than 99% and selectivity is higher than 96%1. This method uses an expensive Pd catalyst. 2. NO/O2 mixtures pose an explosion risk.

3. The intermediate product methyl nitrite is highly toxicThe method has been phased out Direct vapor phase methanol oxidative carbonylation 1. Raw materials are low cost and less toxic. 2. By-products (CO2 and H2O) are non-toxic and easy to handle. 3. High product quality 1. The methanol conversion rate is low, and the by-product water is easy to inactivate the catalyst. 2. The cost of this method is higher than that of liquid phase methanol oxidative carbonylation The method has been industrially applied Oxidative carbonylation of liquid phase methanol 1. High safety, simple process, no environmental pollution. 2. The product has high purity and selectivity of more than 98% 1. Cl− leakage can easily inactivate the catalyst and corrode the equipment. 2. Water can severely reduce catalyst lifetime. 3. There are serious safety risks in the reaction system The method has fewer industrial applications Transesterification method 1. The reaction conditions are mild, the process is simple, and the catalytic efficiency and product purity are high. 2. Ethylene glycol is a co-produced high value-added chemical product 1. This method uses high-cost propylene oxide and ethylene oxide . 2. Ethylene oxide is flammable and explosive, with geographical restrictions The method has been industrially applied Urea alcohol hydrolysis 1. Low cost of raw materials.

2. No CH3OH-H2O-DMC ternary azeotrope is generated during the reaction1. The reaction conditions are harsh, the single-pass conversion rate is low, and the reaction selectivity is poor. 2. It is necessary to solve the problems of environmental pollution, production safety, and catalyst inactivation The method urgently

needs to be developedCO2-CH3OH direct synthesis method 1. Raw materials are cheap, safe and accessible. 2. The reaction has high atomic utilization and few by-products 1. The reaction is limited by thermodynamic equilibrium. 2. The yield of this method is extremely low The method urgently needs to be developed 表 2 CO2和CH3OH合成DMC反应中化合物的热力学数据和比热容系数(298.15 K, 1.0 × 105 Pa)

Table 2 Thermodynamic data and specific heat capacity coefficients of various compounds in the synthesis of DMC from CO2 and CH3OH at 298.15 K and 1.0×105 Pa

Compound Thermodynamic data $\Delta { {}_{f}{}^{}{H}_{{\rm{m}}}^{\Theta } }^{}$ /(kJ∙mol−1) $\Delta {S}_{{\rm{m,B}}}^{\Theta }$ /(J∙mol−1∙K−1) AC BC /( × 10−2) DC ( × 10−4) CO2 −393.51 213.785 3.0050 0.6600 −0.0405 CH3OH −238.4 127.19 19.8589 −13.0668 3.3636 H2O −285.83 69.95 3.4700 0.1450 0.1405 DMC −608.74 235.8 19.0701 −6.3248 1.5830 表 3 离子液体催化剂上CO2和CH3OH合成DMC催化性能[21]

Table 3 Catalytic performance of various ionic liquids (ILs) for the synthesis of DMC from CO2 and CH3OH[21]

Ionic liquid A /mmol x /% s /% CH 1.63 0.6 95.2 CC − − − EmimOH 0.31 0.1 87.0 BmimOH trace − − KOH − − − EtmimOH 0.62 0.2 77.6 EtmimBr − − − CH/CaO 1.56 0.5 93.0 CH/CH3I 8.19 2.7 98.8 notes: A, amount of DMC produced; x, conversion of CH3OH; s, selectivity of DMC 表 4 [CnCmIm][HCO3]催化剂上CO2和CH3OH合成DMC催化性能[22]

Table 4 Catalytic performance of [CnCmIm][HCO3] catalysts for the synthesis of DMC from CO2 and CH3OH[22]

Entry Catalyst Base x /% s /% 1 [C1C4Im][HCO3] DBU 48 >99 2 [C1C4Im][HCO3] BABCO 24 82 3 [C1C4Im][HCO3] HTMP 36 >99 4 [C1C4Im][HCO3] Na2CO3 22 97 5 [C1C4Im][HCO3] NaHCO3 24 >99 6 [C1C4Im][HCO3] K2CO3 61 54 7 [C1C4Im][HCO3] KHCO3 24 >99 8 [C1C4Im][HCO3] Cs2CO3 45 >99 9a [C1C4Im][HCO3] Cs2CO3 26 >99 10b [C1C4Im][HCO3] Cs2CO3 37 >99 11c,d [C1C4Im][HCO3] Cs2CO3 74 97 12d [C1C4Im][HCO3] Cs2CO3 54 >99 13 [C1C4Im][HCO3] Cs2CO3 82 94 14 [C1C4Im][HCO3] None 14 >99 15 [C1C2Im][HCO3] Cs2CO3 36 >99 16 [C1C6Im][HCO3] Cs2CO3 47 >99 17 [C1C4Im][HCO3] Cs2CO3 16 >99 Reaction conditions: 5 mmol methanol, 5 mmol [CnCmIm][HCO3], 5 mmol base, 10 mL CH2Br2, 1.0×106 Pa CO2, 25 °C, reaction time of 24 h. DBU, 1,8-diazadicyclo[5.4.0]undecy-7-ene; BABCO, 1,4-diazadicyclo[2.2.2]octane; HTMP, 2,2,6,6-tetramethylpiperidine. (a) 0.25 mmol [CnCmIm][HCO3]; (b) 2.5 mmol [CnCmIm][HCO3]; (c) 20 mmol Cs2CO3; (d) reaction at 50 ℃ 表 5 碱金属碳酸盐催化剂上CO2和CH3OH合成DMC催化性能

Table 5 Catalytic performance of alkali metal carbonate catalysts for the synthesis of DMC from CO2 and CH3OH

Entry Catalyst t /℃ p / × 106 Pa x /% s /% References 1 K2CO3 70 8.0 4.1 81.8 [28] 2 KHCO3 70 8.0 2.0 74.1 [28] 3 Na2CO3 70 8.0 0.98 62.6 [28] 4 (NH4)2CO3 70 8.0 trace − [28] 5 Li2CO3 70 8.0 0.54 57.6 [28] 6 K2CO3 120 0.5 5.8 42.7 [29] 7 K2CO3 150 2.6 16.2 38.7 [30] notes: Entry 1–5: DMC was synthesized with the participation of CH3I and different alkali metal carbonates, reaction conditions: methanol 198 mmol, CH3I 24 mmol, catalyst 3 mmol, and reaction time of 4 h 表 6 过渡金属氧化物催化剂上CO2和CH3OH合成DMC的催化性能

Table 6 Catalytic performance of transition metal oxide catalysts for the synthesis of DMC from CO2 and CH3OH

Catalyst t /℃ p / × 106 Pa x /% s /% Ref. H3PO4/V2O5 140 1.0 1.80 92.1 [31] ZrO2 170 5.0 0.34 100 [32] CeO2 130 1.2 0.25 100 [34] Ga2O3/Ce0.6Zr0.4O2 170 6.0 0.50 100 [36] Ce0.5Zr0.5O2 140 7.5 4.93 100 [37] Ce0.5Zr0.5O2 120 15.0 0.77 100 [38] Fe0.3Zr0.7Oy 110 5.0 0.66 100 [39] CeO2 120 15.0 0.66 100 [40] CeO2 140 6.5 0.51 100 [41] Ti0.04Ce0.96O2 120 0.8 5.38 83.1 [42] Ti0.10Ce0.90O2/Hcc 140 2.4 24.3 79.0 [46] Ce0.90Mg0.10O2/Hcc 140 2.4 25.42 79.8 [47] Zn0.10Ce0.90O2/Hcc 160 2.4 20.5 82.3 [48] Bi0.12Ce0.88Oδ/Hcc 140 2.4 20.8 83.5 [49] notes: Hcc means honeycomb cordierite 表 7 MO/ Ce0.6Zr0.4O2催化剂上DMC生成量、比表面积、酸度、碱度[36]

Table 7 Amount of DMC generated, related to the surface area, acidity and basicity of the MO/Ce0.6Zr0.4O2 catalyst for the synthesis of DMC from CO2 and CH3OH[36]

Catalyst DMC amount

/(mmol·g−1)Surface area

/(m2·g−1)aAcidity

/(mol·g−1)bBasicity

/(mol·g−1)cCe0.6Zr0.4O2 0.75 53.8 85.7 17.0 Ga2O3/Ce0.6Zr0.4O2 2.4 50.0 226.3 121.8 La2O3/Ce0.6Zr0.4O2 2.1 52.2 210.4 110.8 Ni2O3/Ce0.6Zr0.4O2 1.85 42.8 188.6 94.2 Fe2O3/Ce0.6Zr0.4O2 1.83 48.1 180.1 88.0 Y2O3/Ce0.6Zr0.4O2 1.8 45.8 164.5 84.6 Co3O4/Ce0.6Zr0.4O2 1.7 43.4 146.5 78.3 Al2O3/Ce0.6Zr0.4O2 1.5 41.9 132.6 68.2 notes: a: the surface area was calculated by the BET (Brunauer-Emmett-Teller) equation, b: acidity was determined by NH3-TPD measurement, c: the basicity the CO2-TPD measurement 表 8 基于Eley-Rideal和Langmuir-Hinshelwood的反应机制[33,37]

Table 8 Reaction mechanisms for the synthesis of DMC from CO2 and CH3OH, based on the Eley-Rideal and Langmuir-Hinshelwood mechanisms[33,37]

Elementary

reactionEley-Rideal mechanism Langmuir-Hinshelwood mechanism S1 MeOH + * ↔ MeOH* CO2 + * ↔ CO2* S2 MeOH* + CO2 ↔ MC* MeOH + * ↔ MeOH* S3 MC* + MeOH* ↔ DMC + H2O + * 2MeOH* + CO2* ↔ DMC* + H2O* + * S4 DMC* ↔ DMC + * S5 H2O* ↔ H2O + * Controlling step S2 S3 or S1 Apparent rate law R = k[CO2][MeOH][*] R = k[CO2][MeOH]2[*]

or R = k[CO2][*]3*: Active sites; MC: methyl carbonate 表 9 Cu-Ni合金催化剂上CO2和CH3OH合成DMC催化性能

Table 9 Catalytic performance of the Cu-Ni alloy for the synthesis of DMC from CO2 and CH3OH

Catalyst t /℃ p / × 106 Pa x /% s /% Ref. Cu-Ni/VSO 140 0.9 2.4 87.2 [49] Cu-Ni/MWCNT 120 1.2 4.44 91 [50] Cu-Ni/HNTs 130 1.2 7.85 89 [53] Cu-Ni/GO 105 1.2 9.0 88.0 [54] Cu-Ni/MS 120 1.1 5.0 86.0 [55] Cu-Ni/VAC 110 1.2 7.76 89.9 [56] Cu-Ni/VSiO 140 1.2 4.2 93.1 [57] MWCNT: multi-walled carbon nanotubes; HNTs: halloysite nanotubes; GO: graphite oxide; VAC: vanadium doped with activated carbon 表 10 杂多酸催化剂上CO2和CH3OH合成DMC催化性能

Table 10 Performance of the heteropolyacid catalysts for the synthesis of DMC from CO2 and CH3OH

表 11 不同催化-脱水体系中CO2和CH3OH合成DMC性能

Table 11 Performance of various catalytic-dehydration systems for the synthesis of DMC from CO2 and CH3OH

Catalysts-dehydrants agent t /℃ p / × 106 Pa x /% s /% Ref. CeO2-2–CP 120 20 95 99 [71] CeO2-2–CP 120 5.0 97 99 [72] CeO2-2–CP 120 3.0 88 100 [77] Ce0.5Zr0.5O2-TMM 100 12.0 10.4 100 [78] NiL2-DCC 80 1.0 61 100 [80] Cu-Ni/diatomite-3A MS 120 1.2 6.5 91.2 [82] Bu2SnO- CaC2 180 15.0 11.3 100 [83] KCl-DBC 140 1.5 40 100 [84] CuCeO2-MTCL 140 5.0 14 80 [85] MS: molecular sieves -

[1] ALPER E, ORHAN O Y. CO2 utilization: Developments in conversion processes[J]. Petroleum,2017,3(1):109−126. doi: 10.1016/j.petlm.2016.11.003 [2] ALI K A, ABDULLAH A Z, MOHAMED A R. Visible light responsive TiO2 nanoparticles modified using Ce and La for photocatalytic reduction of CO2: Effect of Ce dopant content[J]. Appl Catal A: Gen,2017,537:111−120. doi: 10.1016/j.apcata.2017.03.022 [3] CHEN Y, YANG Y, TIAN S, YE Z, TANG Q, YE L, LI G. Highly effective synthesis of dimethyl carbonate over Cu-Ni alloy nanoparticles@porous organic polymers composite[J]. Appl Catal A: Gen,2019,587:117275. doi: 10.1016/j.apcata.2019.117275 [4] 左怀纪, 冯园园, 朱国伟. 碳酸二甲酯生产技术进展[J]. 河南化工,2013,5:24−27. doi: 10.14173/j.cnki.hnhg.2013.05.010ZUO Huai-ji, FENG Yuan-yuan, ZHU Guo-wei. Technology development of the production of dimethyl carbonate[J]. Henan Chem Ind,2013,5:24−27. doi: 10.14173/j.cnki.hnhg.2013.05.010 [5] YANG T, ZHOU R, WANG D W, JIANG S P, YAMAUCHI Y, QIAO S Z, MONTEIRO M J, LIU J. Hierarchical mesoporous yolk-shell structured carbonaceous nanospheres for high performance electrochemical capacitive energy storage[J]. Chem Commun,2015,51(13):2518−2521. doi: 10.1039/C4CC09366F [6] 米多, 孔庆国. 2020年碳酸二甲酯技术与市场[J]. 化学工业,2021,39(3):76−80.MI Duo, KONG Qing-guo. Technology and market of dimethyl carbonate in 2020[J]. Chem Ind,2021,39(3):76−80. [7] 朱建良, 张珂, 李乐易, 赵晶. 甲醇氧化羰基化合成碳酸二甲酯铜系催化剂研究进展[J]. 南京工业大学学报 (自然科学版),2021,43(4):420−424 + 479. doi: 10.3969/j.issn.1671–7627.2021.04.002ZHU Jian-liang, ZHANG Ke, LI Yue-yi, ZHAO Jing. Research progress of copper-based catalysts for oxidative carbonylation of methanol to dimethyl carbonate[J]. J Nanjing Tech Univ Nat Sci Ed,2021,43(4):420−424 + 479. doi: 10.3969/j.issn.1671–7627.2021.04.002 [8] 王红星, 窦雅利, 刘伯潭, 盖晓龙. 精馏与结晶耦合制备电子级碳酸二甲酯的方法: 中国, 501096A[P]. 2017-12-22.WANG Hong-xing, DOU Ya-li, LIU Bo-tan, GAI Xiao-long. Method for preparing electronic-grade dimethyl carbonate by coupling distillation and crystallization: CN, 107501096A[P]. 2017-12-22. [9] TAN H Z, WANG Z Q, XU Z N, SUN J, XU Y P, CHEN Q S, CHEN Y, GUO G C. Review on the synthesis of dimethyl carbonate[J]. Catal Today,2018,316:2−12. doi: 10.1016/j.cattod.2018.02.021 [10] TUNDO P, SELVA M. The chemistry of dimethyl carbonate[J]. Acc Chem Res,2002,35(9):706−716. doi: 10.1021/ar010076f [11] 史建公, 刘志坚, 刘春生. 二氧化碳为原料合成碳酸二甲酯研究进展[J]. 中外能源,2019,24(10):49−71.SHI Jian-gong, LIU Zhi-jian, LIU Chun-sheng. Research progress in synthesis of dimethyl carbonate from carbon dioxide[J]. Sino-Global Energy,2019,24(10):49−71. [12] ZHANG M, XU Y, WILLIAMS B L, XIAO M, WANG S, HAN D, SUN L, MENG Y. Catalytic materials for direct synthesis of dimethyl carbonate (DMC) from CO2[J]. J Cleaner Prod,2021,279:123344. doi: 10.1016/j.jclepro.2020.123344 [13] SANTOS B A V, SILVA V, LOUREIRO J M, BARBOSA D, RODRIGUES A E. Modeling of physical and chemical equilibrium for the direct synthesis of dimethyl carbonate at high pressure conditions[J]. Fluid Phase Equilib,2012,336:41−51. doi: 10.1016/j.fluid.2012.08.022 [14] KUMAR P, WITH P, SRIVASTAVA V C, GLÄSER R, MISHRA I M. Efficient ceria-zirconium oxide catalyst for carbon dioxide conversions: characterization, catalytic activity and thermodynamic study[J]. J Alloys Compd,2017,696:718−726. doi: 10.1016/j.jallcom.2016.10.293 [15] ZHANG Z, WU C, MA J, SONG J, FAN H, LIU J, ZHU Q, HAN B. A strategy to overcome the thermodynamic limitation in CO2 conversion using ionic liquids and urea[J]. Green Chem,2015,17(3):1633−1639. doi: 10.1039/C4GC02199A [16] KABRA S K, TURPEINEN E, KEISKI R L, YADAV G D. Direct synthesis of dimethyl carbonate from methanol and carbon dioxide: A thermodynamic and experimental study[J]. J Supercrit Fluids,2016,117:98−107. doi: 10.1016/j.supflu.2016.05.039 [17] PANDEY S, SRIVASTAVA V C, KUMAR V. Comparative thermodynamic analysis of CO2 based dimethyl carbonate synthesis routes[J]. Can J Chem Eng,2021,99(2):467−478. doi: 10.1002/cjce.23893 [18] ETA V, MAKI-ARVELA P, LEINO A R, KORDÁS K, SAMLI T, MURZIN D Y, MIKKOLA J P. Synthesis of dimethyl carbonate from methanol and carbon dioxide: Circumventing thermodynamic limitations[J]. Ind Eng Chem Res,2010,49(20):9609−9617. doi: 10.1021/ie1012147 [19] LI W, GUAN T, CAO Y, ZHANG Y, ZHANG T. Isobaric vapor-liquid equilibrium for toluene-methanol system including three ionic liquids with acetate anion at 101.3 kPa[J]. Fluid Phase Equilib,2020,506:112412. doi: 10.1016/j.fluid.2019.112412 [20] PENG B, DOU H R, SHI H, EMBER E E, LERCHER J A. Overcoming thermodynamic limitations in dimethyl carbonate synthesis from methanol and CO2[J]. Catal Lett,2018,148:1914−1919. doi: 10.1007/s10562-018-2402-8 [21] SUN J, LU B, WANG X, LI X, ZHAO J, CAI Q. A functionalized basic ionic liquid for synthesis of dimethyl carbonate from methanol and CO2[J]. Fuel Process Technol,2013,115:233−237. doi: 10.1016/j.fuproc.2013.06.009 [22] ZHAO T, HU X, WU D, LI R, YANG G, WU Y. Direct synthesis of dimethyl carbonate from carbon dioxide and methanol at room temperature using imidazolium hydrogen carbonate ionic liquid as a recyclable catalyst and dehydrant[J]. ChemSusChem,2017,10(9):2046−2052. doi: 10.1002/cssc.201700128 [23] BUSS F, MEHLMANN P, MÜCK-LICHTENFELD C, BERGANDER K, DIELMANN F. Reversible carbon dioxide binding by simple Lewis base adducts with electron-rich phosphines[J]. J Am Chem Soc,2016,138(6):1840−1843. doi: 10.1021/jacs.5b13116 [24] FIORANI G, GUO W, KLEIJ A W. Sustainable conversion of carbon dioxide: the advent of organocatalysis[J]. Green Chem,2015,17(3):1375−1389. doi: 10.1039/C4GC01959H [25] VILLIERS C, DOGNON J P, POLLET R, THUÉRY P, EPHRITIKHINE M. An isolated CO2 adduct of a nitrogen base: Crystal and electronic structures[J]. Angew Chem,2010,122(20):3543−3546. doi: 10.1002/ange.201001035 [26] WÜNSCHE M A, MEHLMANN P, WITTELER T, BUß F, RATHMANN P, DIELMANN F. Imidazolin-2-ylidenaminophosphines as highly electron-rich ligands for transition-metal catalysts[J]. Angew Chem Int Ed,2015,54(40):11857−11860. doi: 10.1002/anie.201504993 [27] 师艳宁, 高伟, 王淑莉, 金洗郎, 李剑利, 史真. 甲醇和二氧化碳合成碳酸二甲酯催化剂的研究进展[J]. 化学试剂,2012,34(4):319−326. doi: 10.13822/j.cnki.hxsj.2012.04.016SHI Yan-ning, GAO Wei, WANG Shu-li, JIN Xi-lang, LI Jian-li, SHI Zhen. Progress of catalysts in synthesis of dimethyl carbonate from methanol and carbon dioxide[J]. Chem Reagents,2012,34(4):319−326. doi: 10.13822/j.cnki.hxsj.2012.04.016 [28] FUJITA S, BHANAGE B M, IKUSHIMA Y, ARAI M. Synthesis of dimethyl carbonate from carbon dioxide and methanol in the presence of methyl iodide and base catalysts under mild conditions: Effect of reaction conditions and reaction mechanism[J]. Green Chem,2001,3(2):87−91. doi: 10.1039/b100363l [29] LIU C, ZHANG S, CAI B, JIN Z. Low pressure one-pot synthesis of dimethyl carbonate catalyzed by an alkali carbonate[J]. Chin J Catal,2015,36(7):1136−1141. doi: 10.1016/S1872-2067(14)60309-0 [30] YANG Q, WANG H, DING X, YANG X, WANG Y. One-pot synthesis of dimethyl carbonate from carbon dioxide, cyclohexene oxide, and methanol[J]. Res Chem Intermed,2015,41:4101−4111. doi: 10.1007/s11164-013-1514-4 [31] WU X L, XIAO M, MENG Y Z, LI Y X. Direct synthesis of dimethyl carbonate on HgPO4 modified V2O5[J]. J Mol Catal A: Chem,2005,238(1/2):158−162. [32] TOMISHIGE K, IKEDA Y, SAKAIHORI T, FUJIMOTO K. Catalytic properties and structure of zirconia catalysts for direct synthesis of dimethyl carbonate from methanol and carbon dioxide[J]. J Catal,2000,192(2):355−362. doi: 10.1006/jcat.2000.2854 [33] JUNG K T, BELL A T. An in situ infrared study of dimethyl carbonate synthesis from carbon dioxide and methanol over zirconia[J]. J Catal,2001,204(2):339−347. doi: 10.1006/jcat.2001.3411 [34] YOSHIDA Y, ARAI Y, KADO S, KUNIMORI K, TOMISHIGE K. Direct synthesis of organic carbonates from the reaction of CO2 with methanol and ethanol over CeO2 catalysts[J]. Catal Today,2006,115(1/4):95−101. [35] 卢惠, 张新堂. CeO2催化剂的制备条件对甲醇和二氧化碳合成碳酸二甲酯的影响[J]. 现代化工,2020,40(2):177−180 + 186. doi: 10.16606/j.cnki.issn0253–4320.2020.02.037LU-Hui, ZHANG Xin-tang. Effect of preparation conditions of CeO2 catalyst on its catalytic performance in synthesis of dimethyl carbonate from methanol and carbon dioxide[J]. Mod Chem Ind,2020,40(2):177−180 + 186. doi: 10.16606/j.cnki.issn0253–4320.2020.02.037 [36] LEE H J, JOE W, SONG I K. Direct synthesis of dimethyl carbonate from methanol and carbon dioxide over transition metal oxide/Ce0.6Zr0.4O2 catalysts: Effect of acidity and basicity of the catalysts[J]. Korean J Chem Eng,2012,29:317−322. doi: 10.1007/s11814-011-0185-3 [37] TAMBOLI A H, CHAUGULE A A, GOSAVI S W, GOSAVI S W, KIM H. CexZr1-xO2 solid solutions for catalytic synthesis of dimethyl carbonate from CO2: Reaction mechanism and the effect of catalyst morphology on catalytic activity[J]. Fuel,2018,216:245−254. doi: 10.1016/j.fuel.2017.12.008 [38] KUMAR P, SRIVASTAVA V C, SHUKLA K, SHUKLA K, GLÄSER R, MISHRA I M. Dimethyl carbonate synthesis from carbon dioxide using ceria-zirconia catalysts prepared using a templating method: characterization, parametric optimization and chemical equilibrium modeling[J]. RSC Adv,2016,6(111):110235−110246. doi: 10.1039/C6RA22643D [39] LI A, PU Y, LI F, LUO J, ZHAO N, XIAO F. Synthesis of dimethyl carbonate from methanol and CO2 over Fe-Zr mixed oxides[J]. J CO2 Util,2017,19:33−39. doi: 10.1016/j.jcou.2017.02.016 [40] KUMAR P, WITH P, SRIVASTAVA V C, GLÄSER R, MISHRA I M. Conversion of carbon dioxide along with methanol to dimethyl carbonate over ceria catalyst[J]. J Environ Chem Eng,2015,3(4):2943−2947. doi: 10.1016/j.jece.2015.10.016 [41] CUI Z, FAN J, DUAN H, ZHANG J, XUE Y, TAN Y. Effect of calcination atmospheres on the catalytic performance of nano-CeO2 in direct synthesis of DMC from methanol and CO2[J]. Korean J Chem Eng,2017,34:29−36. doi: 10.1007/s11814-016-0212-5 [42] FU Z, ZHONG Y, YU Y, LONG L, XIAO M, HAN D, WANG S, MENG Y. TiO2-doped CeO2 nanorod catalyst for direct conversion of CO2 and CH3OH to dimethyl carbonate: Catalytic performance and kinetic study[J]. ACS Omega,2018,3(1):198−207. doi: 10.1021/acsomega.7b01475 [43] SANTOS B A V, PEREIRA C S M, SILVA V, LOUREIRO J M, RODRIGUES A E. Kinetic study for the direct synthesis of dimethyl carbonate from methanol and CO2 over CeO2 at high pressure conditions[J]. Appl Catal A: Gen,2013,455:219−226. doi: 10.1016/j.apcata.2013.02.003 [44] MARIN C M, LI L, BHALKIKAR A, DOYLE J E, ZENG X C, CHEUNG C L. Kinetic and mechanistic investigations of the direct synthesis of dimethyl carbonate from carbon dioxide over ceria nanorod catalysts[J]. J Catal,2016,340:295−301. doi: 10.1016/j.jcat.2016.06.003 [45] CHEN Y, WANG H, QIN Z, TIAN S, YE Z, YE L, ABROSHAN H, LI G. TixCe1−xO2 nanocomposites: A monolithic catalyst for the direct conversion of carbon dioxide and methanol to dimethyl carbonate[J]. Green Chem,2019,21(17):4642−4649. doi: 10.1039/C9GC00811J [46] 严栎颖, 李月, 邓杰, 赵翕, 塔娜, 陈永东. 镁掺杂氧化铈整体式催化剂催化CO2和CH3OH直接合成碳酸二甲酯[J]. 无机化学学报,2022,38(7):1402−1410. doi: 10.11862/CJIC.2022.139YAN Li-ying, LI Yue, DENG Jie, ZHAO Xi, TA Na, CHEN Yong-dong. Direct synthesis of dimethyl carbonate from CO2 and methanol by Mg-doped ceria monolithic catalyst[J]. Chin J Inorg Chem,2022,38(7):1402−1410. doi: 10.11862/CJIC.2022.139 [47] CHEN Y, TANG Q, YE Z, LI Y, YANG Y, PU H, LI G. Monolithic ZnxCe1−xO2 catalysts for catalytic synthesis of dimethyl carbonate from CO2 and methanol[J]. New J Chem,2020,44(29):12522−12530. doi: 10.1039/D0NJ02650F [48] CHEN Y, LI Y, CHEN W, XU W W, HAN Z, WAHEED A, YE Z, LI G. Continuous dimethyl carbonate synthesis from CO2 and methanol over BixCe1−xOδ monoliths: Effect of bismuth doping on population of oxygen vacancies, activity, and reaction pathway[J]. Nano Res,2022,15:1366−1374. doi: 10.1007/s12274-021-3669-4 [49] WU X L, MENG Y Z, XIAO M, LU Y X. Direct synthesis of dimethyl carbonate (DMC) using Cu-Ni/VSO as catalyst[J]. J Mol Catal A: Chem, 2006, 249(1/2): 93–97. [50] BIAN J, XIAO M, WANG S J, LU Y X, MENG Y Z. Carbon nanotubes supported Cu-Ni bimetallic catalysts and their properties for the direct synthesis of dimethyl carbonate from methanol and carbon dioxide[J]. Appl Surf Sci,2009,255(16):7188−7196. doi: 10.1016/j.apsusc.2009.03.057 [51] RONG T J, XIAO J. The catalytic cracking activity of the kaolin-group minerals[J]. Mater Lett,2002,57(2):297−301. doi: 10.1016/S0167-577X(02)00781-4 [52] ZANG J, KONDURI S, NAIR S, SHOLL D S. Self-diffusion of water and simple alcohols in single-walled aluminosilicate nanotubes[J]. ACS Nano,2009,3(6):1548−1556. doi: 10.1021/nn9001837 [53] ZHOU Y, WANG S, XIAO M, HAN D, LU Y, MENG Y. Formation of dimethyl carbonate on nature clay supported bimetallic copper-nickel catalysts[J]. J Cleaner Prod,2015,103:925−933. doi: 10.1016/j.jclepro.2014.08.075 [54] BIAN J, XIAO M, WANG S, WANG X, LU Y, MENG Y. Highly effective synthesis of dimethyl carbonate from methanol and carbon dioxide using a novel copper-nickel/graphite bimetallic nanocomposite catalyst[J]. Chen Eng J, 2009, 147(2/3): 287–296. [55] CHEN H, WANG S, XIAO M, HAN D, LU Y, MENG Y. Direct synthesis of dimethyl carbonate from CO2 and CH3OH using 0.4 nm molecular sieve supported Cu-Ni bimetal catalyst[J]. Chin J Chem Eng,2012,20(5):906−913. doi: 10.1016/S1004-9541(12)60417-0 [56] BIAN J, XIAO M, WANG S, LU Y, MENG Y. Direct synthesis of DMC from CH3OH and CO2 over V-doped Cu-Ni/AC catalysts[J]. Catal Commun,2009,10(8):1142−1145. doi: 10.1016/j.catcom.2008.12.008 [57] ZHANG M, ALFEROV K A, XIAO M, HAN D, WANG S, MENG Y. Continuous dimethyl carbonate synthesis from CO2 and methanol using Cu-Ni@VSiO as catalyst synthesized by a novel sulfuration method[J]. Catalysts,2018,8(4):142. doi: 10.3390/catal8040142 [58] VERMA S, BAIG R B, NADAGOUDA M N, VARMA R S. Fixation of carbon dioxide into dimethyl carbonate over titanium-based zeolitic thiophene-benzimidazolate framework[J]. Sci Rep,2017,7(1):1−5. doi: 10.1038/s41598-016-0028-x [59] POUNGSOMBATE A, IMYEN T, DITTANET P, EMBLEY B, KONGKACHUICHAY P. Direct synthesis of dimethyl carbonate from CO2 and methanol by supported bimetallic Cu-Ni/ZIF-8 MOF catalysts[J]. J Taiwan Inst Chem Eng,2017,80:16−24. doi: 10.1016/j.jtice.2017.07.019 [60] XUAN K, PU Y, LI F, LI A, LUO J, LI L, WANG F, ZHAO N, XIAO F. Direct synthesis of dimethyl carbonate from CO2 and methanol over trifluoroacetic acid modulated UiO-66[J]. J CO2 Util,2018,27:272−282. doi: 10.1016/j.jcou.2018.08.002 [61] XUAN K, PU Y, LI F, LUO J, ZHAO N, XIAO F. Metal-organic frameworks MOF-808-X as highly efficient catalysts for direct synthesis of dimethyl carbonate from CO2 and methanol[J]. Chin J Catal,2019,40(4):553−566. doi: 10.1016/S1872-2067(19)63291-2 [62] LEE H J, PARK S, JUNG J C, SONG I K. Direct synthesis of dimethyl carbonate from methanol and carbon dioxide over H3PW12O40/CexZr1−xO2 catalysts: Effect of acidity of the catalysts[J]. Korean J Chem Eng,2011,28:1518−1522. doi: 10.1007/s11814-011-0020-x [63] IKEDA Y, ASADULLAH M, FUJIMOTO K, TOMISHIGE K. Structure of the active sites on H3PO4/ZrO2 catalysts for dimethyl carbonate synthesis from methanol and carbon dioxide[J]. J Phys Chem B,2001,105(43):10653−10658. doi: 10.1021/jp0121522 [64] KUMAR S, GAWANDE M B, MEDŘÍK I, PETR M, TOMANEC O, KUPKA V, VARMA R S, ZBOŘIL R. Mechanochemical synthesis of Cu2S bonded 2D-sulfonated organic polymers: continuous production of dimethyl carbonate (DMC) via preheating of reactants[J]. Green Chem,2020,22(17):5619−5627. doi: 10.1039/D0GC01030H [65] JIANG Z, ZHAO S, YANG Y, TAN M, YANG G, TAN Y. Direct synthesis of dimethyl carbonate from carbon dioxide and methanol over Ce-BTC-derived CeO2[J]. Chem Eng Sci, 2023: 118760. [66] AOUISSI A, AL-OTHMAN Z A, AL-AMRO A. Gas-phase synthesis of dimethyl carbonate from methanol and carbon dioxide over Co1.5PW12O40 keggin-type heteropolyanion[J]. Int J Mol Sci,2010,11(4):1343−1351. doi: 10.3390/ijms11041343 [67] AOUISSI A, AL-DEYAB S S, AL-OWAIS A, AL-AMRO A. Reactivity of heteropolytungstate and heteropolymolybdate metal transition salts in the synthesis of dimethyl carbonate from methanol and CO2[J]. Int J Mol Sci,2010,11(7):2770−2779. doi: 10.3390/ijms11072770 [68] JIANG C, GUO Y, WANG C, HU C, WU Y, WANG E. Synthesis of dimethyl carbonate from methanol and carbon dioxide in the presence of polyoxometalates under mild conditions[J]. Appl Catal A: Gen, 2003, 256(1/2): 203–212. [69] CHIANG C L, LIN K S, YU S H. Preparation and characterization of H3PW12O40/ZrO2 catalyst for carbonation of methanol into dimethyl carbonate[J]. Res Chem Intermed,2018,44:3797−3811. doi: 10.1007/s11164-018-3383-3 [70] CHIANG C L, LIN K S, YU S H, LIN Y G. Synthesis and characterization of H3PW12O40/Ce0.1Ti0.9O2 for dimethyl carbonate formation via methanol carbonation[J]. Int J Hydrogen Energy,2017,42(34):22108−22122. doi: 10.1016/j.ijhydene.2017.03.120 [71] BANSODE A, URAKAWA A. Continuous DMC synthesis from CO2 and methanol over a CeO2 catalyst in a fixed bed reactor in the presence of a dehydrating agent[J]. ACS Catal,2014,4(11):3877−3880. doi: 10.1021/cs501221q [72] HONDA M, TAMURA M, NAKAGAWA Y, NAKAO K, SUZUKI K, TOMISHIGE K. Organic carbonate synthesis from CO2 and alcohol over CeO2 with 2-cyanopyridine: Scope and mechanistic studies[J]. J Catal,2014,318:95−107. doi: 10.1016/j.jcat.2014.07.022 [73] TAMURA M, WAKASUGI H, SHIMIZU K, SATSUMA A. Efficient and substrate-specific hydration of nitriles to amides in water by using a CeO2 catalyst[J]. Chem Eur J,2011,17(41):11428−11431. doi: 10.1002/chem.201101576 [74] HONDA M, TAMURA M, NAKAGAWA Y, SONEHARA S, SUZUKI K, FUJIMOTO K, TOMISHIGE K. Ceria-catalyzed conversion of carbon dioxide into dimethyl carbonate with 2-cyanopyridine[J]. ChemSusChem,2013,6(8):1341−1344. doi: 10.1002/cssc.201300229 [75] HONDA M, TAMURA M, NAKAGAWA Y, TOMISHIGE K. Catalytic CO2 conversion to organic carbonates with alcohols in combination with dehydration system[J]. Catal Sci Technol,2014,4(9):2830−2845. doi: 10.1039/C4CY00557K [76] MARLIN D S, OLMSTEAD M M, MASCHARAK P K. Extended structures controlled by intramolecular and intermolecular hydrogen bonding: A case study with pyridine-2, 6-dicarboxamide, 1, 3-benzenedicarboxamide and N, N′-dimethyl-2, 6-pyridinedicarboxamide[J]. J Mol Struct, 2000, 554(2/3): 211–223. [77] STOIAN D, MEDINA F, URAKAWA A. Improving the stability of CeO2 catalyst by rare earth metal promotion and molecular insights in the dimethyl carbonate synthesis from CO2 and methanol with 2-cyanopyridine[J]. ACS Catal,2018,8(4):3181−3193. doi: 10.1021/acscatal.7b04198 [78] ZHANG Z F, LIU Z W, LU J, LIU Z T. Synthesis of dimethyl carbonate from carbon dioxide and methanol over CexZr1−xO2 and Br/Ce0.5Zr0.5O2[J]. Ind Eng Chem Res,2011,50(4):1981−1988. doi: 10.1021/ie102017j [79] ARESTA M, DIBENEDETTO A, FRACCHIOLLA E, GIANNOCCARO P, PASTORE C, PÁPAI I, SCHUBERT G. Mechanism of formation of organic carbonates from aliphatic alcohols and carbon dioxide under mild conditions promoted by carbodiimides. DFT calculation and experimental study[J]. J Org Chem,2005,70(16):6177−6186. doi: 10.1021/jo050392y [80] SHI Y, JIN X, HU Y, WANG S, LI J, SHI Z. Synthesis and characterization of bis[2-(1H-benzimidazol-2-yl) benzoato] nickel(II), and its use for preparation of dimethyl carbonate from methanol and CO2[J]. Res Chem Intermed,2014,40:1179−1186. doi: 10.1007/s11164-013-1030-6 [81] WANG S, ZHOU J, ZHAO S, ZHAO Y, MA X. Enhancement of dimethyl carbonate synthesis with in situ hydrolysis of 2, 2-dimethoxy propane[J]. Chem Eng Technol,2016,39(4):723−729. doi: 10.1002/ceat.201400603 [82] HAN D, CHEN Y, WANG S, XIAO M, LU Y, MENG Y. Effect of in-situ dehydration on activity and stability of Cu-Ni-K2O/diatomite as catalyst for direct synthesis of dimethyl carbonate[J]. Catalysts,2018,8(9):343. doi: 10.3390/catal8090343 [83] ZHANG Z, LIU S, ZHANG L, YIN S, YANG G, HAN B. Driving dimethyl carbonate synthesis from CO2 and methanol and production of acetylene simultaneously using CaC2[J]. Chem Commun,2018,54(35):4410−4412. doi: 10.1039/C8CC01005F [84] LI L, SHI S, SONG L, GUO L, WANG Y, MA H, HOU J, WANG H. One-step synthesis of dimethyl carbonate from carbon dioxide, propylene oxide and methanol over alkali halides promoted by crown ethers[J]. J Organomet Chem,2015,794:231−236. doi: 10.1016/j.jorganchem.2015.07.010 [85] MARCINIAK A A, ALVES O C, APPEL L G, MOTA C J A. Synthesis of dimethyl carbonate from CO2 and methanol over CeO2: Role of copper as dopant and the use of methyl trichloro acetate as dehydrating agent[J]. J Catal,2019,371:88−95. doi: 10.1016/j.jcat.2019.01.035 [86] INUI K, KURABAYASHI T, SATO S, ICHIKAWA N. Effective formation of ethyl acetate from ethanol over Cu-Zn-Zr-Al-O catalyst[J]. J Mol Catal A: Chem,2004,216(1):147−156. doi: 10.1016/j.molcata.2004.02.017 [87] LIU H, GUO L, ZOU L, CAO M, ZHOU J, OUYANG S. Theoretical and experimental study on solid chemical reaction between BaCO3 and TiO2 in microwave field[J]. Mater Sci Eng B,2004,113(2):161−165. doi: 10.1016/S0921-5107(04)00398-8 [88] 张福灿, 刘平, 张侃, 吉可明, 张建利, 赵亮, 宋清文. 磺胺嘧啶银/超强碱协同催化 CO2/醇耦合反应选择性制碳酸二甲酯[J]. 燃料化学学报,2023,51(3):304−313. doi: 10.1016/S1872–5813(22)60053–7ZHANG Fu-can, LIU Ping, ZHANG Kan, JI Ke-ming, ZHANG Jian-li, SONG Qing-wen. Synergistic silver sulfadiazine/superbase-catalyzed selective synthesis of dimethyl carbonate via the coupling reaction of CO2 and alcohols[J]. J Fuel Chem Technol,2023,51(3):304−313. doi: 10.1016/S1872–5813(22)60053–7 [89] LI C F, ZHONG S H. Study on application of membrane reactor in direct synthesis DMC from CO2 and CH3OH over Cu-KF/MgSiO catalyst[J]. Catal Today, 2003, 82(1/4): 83–90. [90] WANG N, LIU Y, HUANG A, CARO J. Hydrophilic SOD and LTA membranes for membrane-supported methanol, dimethyl ether and dimethyl carbonate synthesis[J]. Microporous Mesoporous Mater,2015,207:33−38. doi: 10.1016/j.micromeso.2014.12.028 [91] HU X, CHENG H, KANG X, CHEN L, YUAN X, QI Z. Analysis of direct synthesis of dimethyl carbonate from methanol and CO2 intensified by in-situ hydration-assisted reactive distillation with side reactor[J]. Chem Eng Process,2018,129:109−117. doi: 10.1016/j.cep.2018.05.007 [92] WU T W, CHIEN I L. CO2 utilization feasibility study: Dimethyl carbonate direct synthesis process with dehydration reactive distillation[J]. Ind Eng Chem Res,2019,59(3):1234−1248. [93] ZHOU J, ZHOU C, XU K, CARO J, HUANG A. Seeding-free synthesis of large tubular zeolite FAU membranes for dewatering of dimethyl carbonate by pervaporation[J]. Microporous Mesoporous Mater,2020,292:109713. doi: 10.1016/j.micromeso.2019.109713 [94] 周俊杰. 分子筛膜催化反应器在碳酸二甲酯制备方面的应用[D]. 宁波: 中国科学院宁波材料技术与工程研究所, 2021.ZHOU Jun-jie. Application of zeolite membrane reactor in the preparation of dimethyl carbonate[D]. Ningbo: Ningbo Institute of Materials Technology and Engineering Chinese Academy of Sciences, 2021. -

下载:

下载: