Effect of filter media on gaseous tar reaction during low-rank coal pyrolysis

-

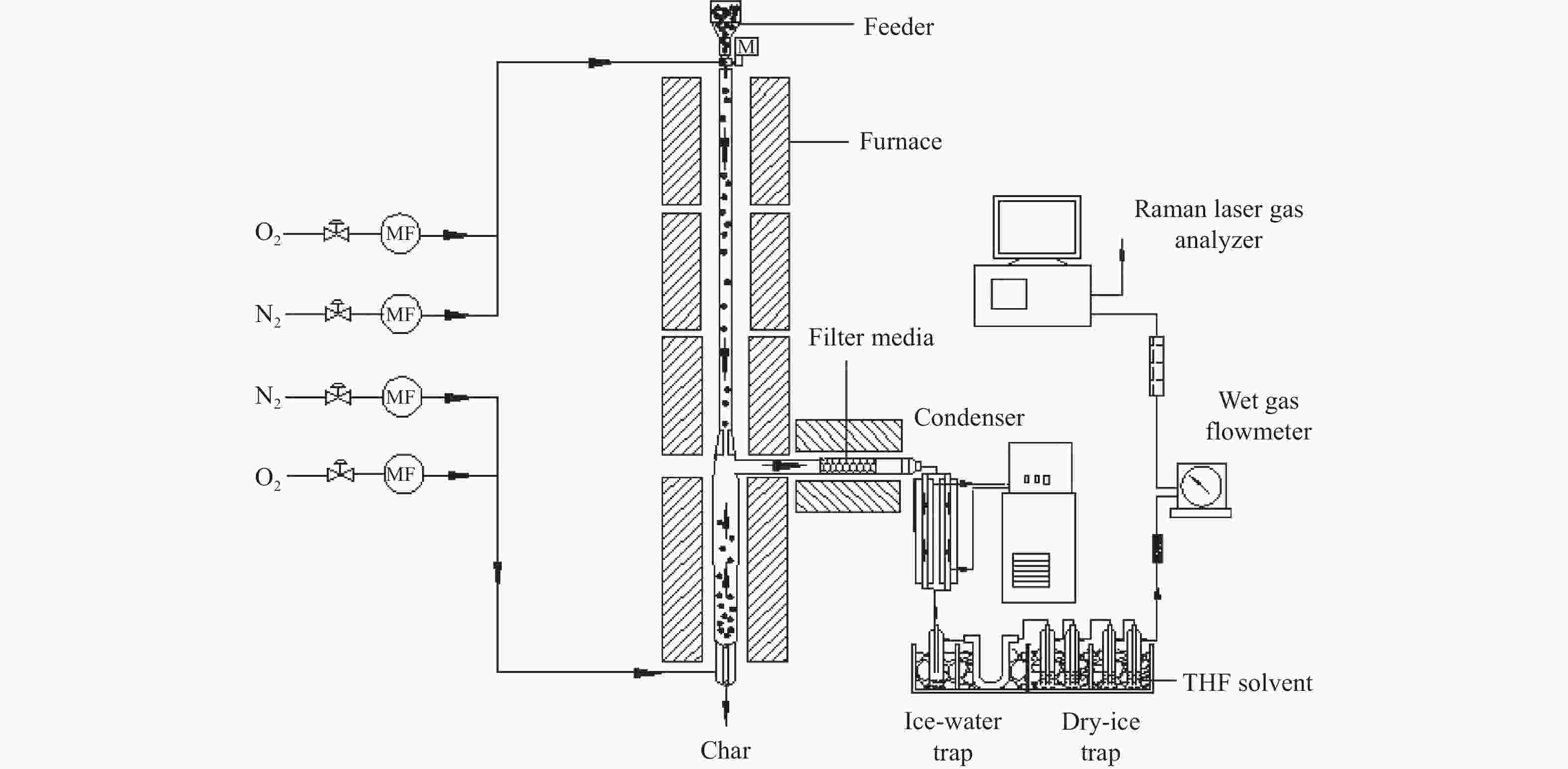

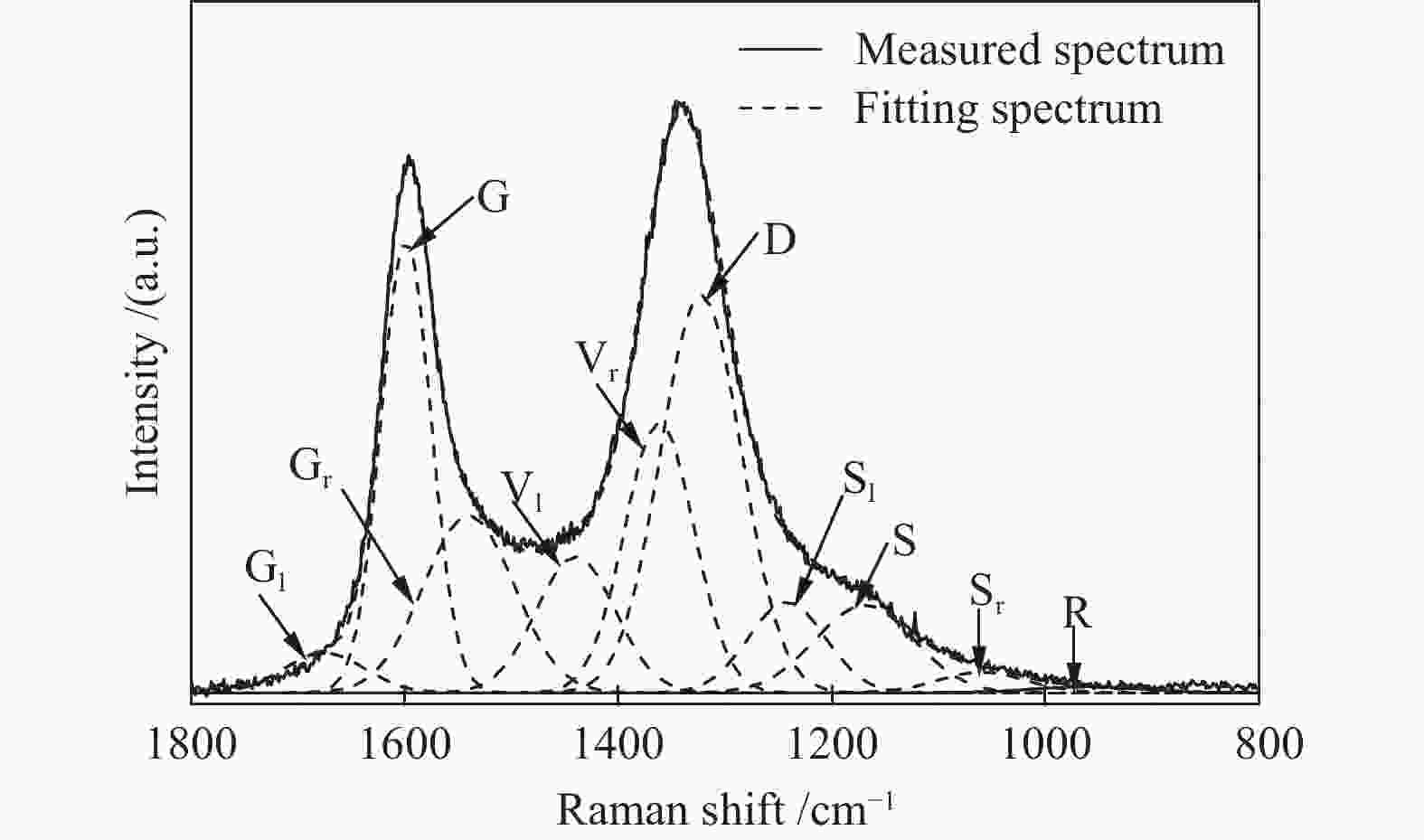

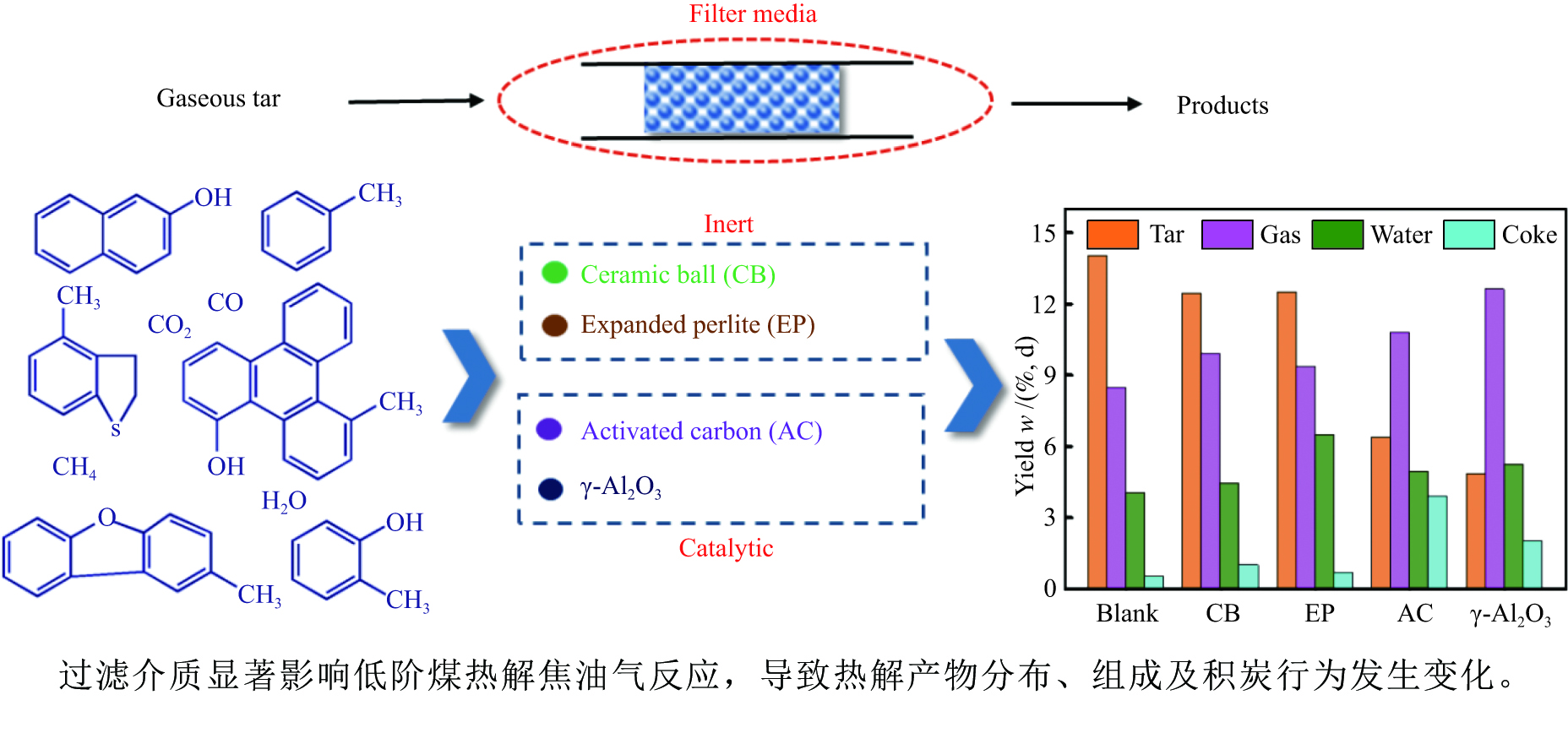

摘要: 低阶煤热解焦油气通过颗粒床过滤器除尘时,过滤介质在一定程度上会影响热解焦油气的反应行为。本研究采用下行床热解反应器考察了陶瓷球(CB)、膨胀珍珠岩(EP)、活性炭(AC)和γ-Al2O3四种颗粒床过滤介质对淖毛湖长焰煤热解焦油气反应性的影响,结果表明,热解产物的分布、组成及其积炭行为受过滤介质种类的影响显著。CB、EP相对惰性,因延长了焦油气的停留时间,加剧了裂解和缩聚反应,焦油产率减小、沥青含量升高,热解气、热解水及积炭产率增加, 但焦油积炭量和化学组成没有明显变化;AC、γ-Al2O3具有较强的催化裂解活性,可明显降低焦油沥青含量和积炭量,但会使焦油向热解气、热解水及积炭转化,导致焦油产率显著下降。同时,AC、γ-Al2O3可裂解焦油气中部分含氧化合物和含氮、硫杂环化合物,使其转化为芳香烃。Abstract: When a granular bed filter is used for the dust removal of hot gas containing tar from low-rank coal pyrolysis, the filter media will affect the reaction behavior of gaseous tar to a certain extent. Four granular bed filter media including ceramic ball (CB), expanded perlite (EP), activated carbon (AC) and γ-Al2O3, were selected to investigate their influence on the gaseous tar reaction during Naomaohu long-flame coal pyrolysis in a downer-bed pyrolysis reactor. The results indicate that the distribution and compositions of pyrolysis products and the coke deposition behavior are significantly affected by the filter media. The inert CB and EP increase the residence time of gaseous tar, which intensifies the cracking and polycondensation reactions of gaseous tar, resulting in a reduction in the tar yield and an increase in the gas, water and coke yield. In the meantime, the pitch content in tar is increased due to the polycondensation reactions of gaseous tar, while the chemical composition of tar and the amount of coke in tar have less change. The AC and γ-Al2O3, which have a strong catalytic cracking action, reduce the pitch content and the amount of coke in tar. Also, partial gaseous tar is transformed into gas, water and coke, resulting in an obvious reduction in the tar yield. Also, AC and γ-Al2O3 can crack some oxygen-containing compounds and nitrogen-containing or sulfur-containing heterocycles in the gaseous tar into aromatics.

-

Key words:

- filter media /

- low-rank coal pyrolysis /

- gaseous tar /

- reaction

-

表 1 煤样的工业分析和元素分析

Table 1 Proximate and ultimate analyses of coal sample

Proximate analysis w/% Ultimate analysis wdaf/% Mad Ad Vdaf C H N S O* 19.50 5.80 50.12 74.35 5.13 0.72 0.31 19.49 note: ad: air dry; d: dry; daf: dry and ash free; *: by difference 表 2 过滤介质的孔隙结构参数

Table 2 Pore structure parameters of different filter media

Sample SBET/(m2·g−1) Smicro/(m2·g−1) Sexter/(m2·g−1) vtotal/(mm3·g−1) vmicro/(mm3·g−1) vmeso/(mm3·g−1) d avera/nm CB 0.04 0.03 0.01 − − − 8.53 EP 0.92 0.53 0.39 2.55 0.21 2.34 11.11 AC 1221.24 469.38 751.86 577.29 192.87 384.42 2.25 γ-Al2O3 175.45 6.87 168.58 492.96 0.99 491.97 11.77 -

[1] 丁肖肖, 李洪娟, 王亚涛. 褐煤低温热解分级利用现状分析及展望[J]. 洁净煤技术,2019,25(5):1−7.DING Xiao-xiao, LI Hong-juan, WANG Ya-tao. Present situation analysis and prospect of classification and utilization of lignite pyrolysis at low temperature[J]. Clean Coal Technol,2019,25(5):1−7. [2] 白效言, 张飏, 王岩, 王之正, 周琦. 低阶煤热解关键技术问题分析及研究进展[J]. 煤炭科学技术,2018,46(1):192−198.BAI Xiao-yan, ZHANG Yang, WANG Yan, WANG Zhi-zheng, ZHOU Qi. Analysis of key issues and research progress in pyrolysis of low rank coal[J]. Coal Sci Technol,2018,46(1):192−198. [3] 颜深, 孙国刚, 孙占朋, 韩笑, 黄雷, 赵斐. 颗粒床过滤除尘技术研究进展[J]. 化工进展,2017,36(9):3152−3163.YAN Shen, SUN Guo-gang, SUN Zhan-peng, HAN Xiao, HUANG Lei, ZHAO Fei. Advances in research on granular bed filter for dust removal[J]. Chem Eng Prog,2017,36(9):3152−3163. [4] 梁鹏, 王志锋, 董众兵, 毕继诚. 炉前煤低温干馏工艺中的挥发分除尘[J]. 燃料化学学报,2006,34(1):25−29.LIANG Peng, WANG Zhi-feng, DONG Zhong-bing, BI Ji-cheng. Hot dust removal in the process of low temperature coal pyrolysis[J]. J Fuel Chem Technol,2006,34(1):25−29. [5] 张生军, 郑化安, 陈静升, 樊英杰, 李学强. 煤热解工艺中挥发分除尘技术的现状分析及建议[J]. 洁净煤技术,2014,20(3):79−82.ZHANG Sheng-jun, ZHENG Hua-an, CHEN Jing-sheng, FAN Ying-jie, LI Xue-qiang. Status analysis and improvement measures of volatile dust removal technology in coal process[J]. Clean Coal Technol,2014,20(3):79−82. [6] 王苗, 荣雷, 王毅. 基于半焦为过滤介质的颗粒床过滤器除尘性能分析[J]. 煤炭转化,2019,42(6):41−48.WANG Miao, RONG Lei, WANG Yi. Analysis of dust removal performance of granular bed filter based on semi-focal filter medium[J]. Coal Convers,2019,42(6):41−48. [7] 张健, 赵创, 王兴云. 颗粒床除尘技术在高温煤气除尘中的工程示范研究[J]. 化肥设计,2018,56(4):5−8.ZHANG Jian, ZHAO Chuang, WANG Xing-yun. Project demonstration and research of granular bed dust removal technology in high temperature gas dust removal[J]. Chem Fert Des,2018,56(4):5−8. [8] 梁鹏, 曲旋, 毕继诚. 炉前煤低温干馏的工艺研究[J]. 燃料化学学报,2008,36(4):401−405.LIANG Peng, QU Xuan, BI Ji-cheng. Low temperature coal pyrolysis by solid heat carrier in a moving bed yrolyzer[J]. J Fuel Chem Technol,2008,36(4):401−405. [9] 曲旋, 张荣, 毕继诚, 巩秀魁, 王乃荣. CFB燃烧/煤热解多联供技术的中试初探[J]. 化工进展,2008,27(S):386−390.QU Xuan, ZHANG Rong, BI Ji-cheng, GONG Xiu-kui, WANG Nai-long. Pilot test of CFB combustion/coal pyrolysis multi-supply technology[J]. Chem Eng Prog,2008,27(S):386−390. [10] 宋文立, 姚建忠, 郝丽芳. 一种颗粒除尘过滤器及除尘过滤方法: 中国, 102716628A [P]. 2012-06-04.SONG Wen-li, YAO Jian-zhong, HAO Li-fang. A granular bed filter for dust removal and its filter method: CN, 102716628A [P]. 2012-06-04. [11] 王苗, 杜鑫, 王毅. 旋风-颗粒床过滤器两级除尘的分析与优化[J]. 化学工程,2020,48(4):55−59.WANG Miao, DU Xin, WANG Yi. Analysis and optimization on two-stage dust removal of cyclone separator-granlllar bed filter[J]. Chem Eng,2020,48(4):55−59. [12] LIU Z Y, GUO X J, SHI L, HE W J, WU J F, LIU Q Y, LIU J H. Reaction of volatiles-a crucial step in pyrolysis of coals[J]. Fuel,2015,154:361−369. doi: 10.1016/j.fuel.2015.04.006 [13] DONG L, HAN S, YU W H, LEI Z P, KANG S G, ZHANG K, YAN J C, LI Z K. Effect of volatile reactions on the yield and quality of tar from pyrolysis of Shenhua bituminous coal[J]. J Anal Appl Pyrolysis,2019,140:321−330. doi: 10.1016/j.jaap.2019.04.009 [14] ZHOU Q Q, LIU Q Y, SHI L, YAN Y X, WU J F, XIANG C, WANG T, LIU Z Y. Effect of volatiles’ reaction on composition of tars derived from pyrolysis of a lignite and a bituminous coal[J]. Fuel,2019,242:140−148. doi: 10.1016/j.fuel.2019.01.005 [15] JIN L J, BAI X Y, LI Y, DONG C, LI X. In-situ catalytic upgrading of coal pyrolysis tar on carbon-based catalyst in a fixed-bed reactor[J]. Fuel Process Technol,2016,147:41−46. doi: 10.1016/j.fuproc.2015.12.028 [16] 孙鸣, 刘永琦, 张丹, 马明明, 么秋香, 贾强, 马晓迅. 基于Py-GC/MS的中低温煤焦油催化裂解研究[J]. 中国矿业大学学报,2019,48(3):647−654.SUN Ming, LIU Yong-qi, ZHANG Dan, MA Ming-ming, YAO Qiu-xiang, JIA Qiang, MA Xiao-xun. Catalytic cracking of low temperature coal tar by Py-GC/MS[J]. J China Univ Min Technol,2019,48(3):647−654. [17] ZHANG S, CHEN Z D, ZHANG H Y, WANG Y G, XU X Q, CHENG L, ZHANG Y M. The catalytic reforming of tar from pyrolysis and gasification of brown coal: Effects of parental carbon materials on the performance of char catalysts[J]. Fuel Process Technol,2018,174:142−148. doi: 10.1016/j.fuproc.2018.02.022 [18] 包建国, 龚建议, 杨运泉, 陈卓, 蒋新民. CoMo/γ-Al2O3 催化剂的制备及其加氢脱氧性能[J]. 石油化工,2010,39(1):42−46.BAO Jian-guo, GONG Jian-yi, YANG Yun-quan, CHEN Zhuo, JIANG Xin-min. Preparation and hydrodeoxygenation performances of CoMo/γ-Al2O3 catalyst[J]. Petrochem Technol,2010,39(1):42−46. [19] 敦启孟, 陈兆辉, 皇甫林, 周杨, 余剑, 高士秋, 刘鸿雁. 温度和停留时间对煤热解挥发分二次反应的影响[J]. 过程工程学报,2018,18(1):140−147.DUN Qi-meng, CHEN Zhao-hui, HUANG Fu-lin, ZHOU Yang, YU Jian, GAO Shi-qiu, LIU Hong-yan. Influences of temperature and residence time on secondary reactions of volatiles from coal pyrolysis[J]. Chin J Process Eng,2018,18(1):140−147. [20] BALASUNDRAM V, IBRAHIM N, KASMANI R M, ISHA R, HAMID M K A, HASBULLAH H, ALI R R. Catalytic upgrading of sugarcane bagasse pyrolysis vapours over rare earth metal (Ce) loaded HZSM-5: Effect of catalyst to biomass ratio on the organic compounds in pyrolysis oil[J]. Appl Energy,2018,220:787−799. doi: 10.1016/j.apenergy.2018.03.141 [21] WU J F, LIU QY, WANG R X, HE W J, SHI L, GUO X J, CHEN Z Z, JI L M. Coke formation during during thermal reaction of tar from pyrolysis of a subbituminous coal[J]. Fuel Process Technol,2017,155:68−73. doi: 10.1016/j.fuproc.2016.03.022 [22] LI S L, ZHANG S P, FENG Z Y, YAN Y J. Coke formation in the catalytic cracking of bio-oil model compounds[J]. Environ Prog Sustai,2015,34(1):1−8. doi: 10.1002/ep.12077 [23] LIU L L, KUMAR S, WANG Z H, HE Y, CEN K F. Catalytic effect of metal chlorides on coal pyrolysis and gasification part I. Combined TG-FTIR study for coal pyrolysis[J]. Thermochim Acta,2017,655:331−336. doi: 10.1016/j.tca.2017.07.007 [24] XU W C, TOMITA A. Effect of temperature on the flash pyrolysis of various coals[J]. Fuel,1987,66(5):632−636. doi: 10.1016/0016-2361(87)90271-7 [25] JIA Y B, HUANG J J, WANG Y. Effects of calcium oxide on the cracking of coal tar in the freeboard of a fluidized bed[J]. Energy Fuels,2004,18(6):1625−1632. doi: 10.1021/ef034077v [26] HAN J Z, WANG X D, YUE J R, GAO S Q, XU G W. Catalytic upgrading of coal pyrolysis tar over char-based catalysts[J]. Fuel Process Technol,2014,122:98−106. doi: 10.1016/j.fuproc.2014.01.033 -

下载:

下载: