K-modified NiMoS/ZnAl oxide catalysts for higher alcohols synthesis from syngas

-

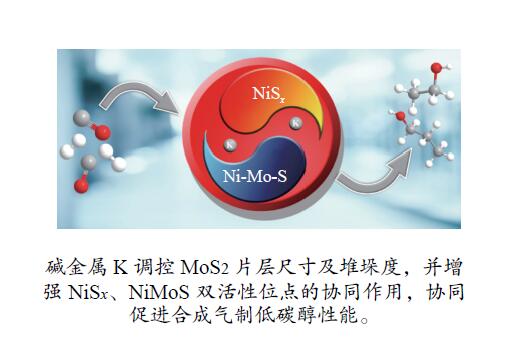

摘要: 采用共沉淀法和浸渍法,以ZnAl混合金属氧化物为载体,制备了系列不同K/Mo物质的量比的高分散K改性NiMoS/ZnAl催化剂,并对其合成气转化制低碳醇性能进行了研究。结果表明,K的引入可以调变MoS2片层的堆积程度和尺寸,提高NiSx和NiMoS之间的协同作用,促进低碳醇合成(HAS)过程中CHx的插入和非解离CO的插入能力,有效抑制烃类和CO2的生成。其中,K/Mo物质的量比为0.6的KNiMoS/ZnAl催化剂具有最多的双层MoS2结构(33.7%)和适宜的NiSx与NiMoS协同作用,产物中总醇选择性达到69.8%,低碳醇空时产率为78.6 mg/(g·h)。

-

关键词:

- NiMoS/ZnAl催化剂 /

- K改性 /

- 合成气 /

- 低碳醇 /

- 协同效应

Abstract: Improving the C2+ alcohols yield is highly desirable for the direct synthesis of higher alcohols from syngas. In this work, a series of highly dispersed K-modified NiMoS catalysts with different K contents on ZnAl-mixed oxide support were prepared by the combination of co-precipitation and impregnation method. And their performance in higher alcohols synthesis (HAS) from syngas was investigated. The results show that the introduction of K can modulate the stacking degree of MoS2 slabs, and improve the interaction between NiSx and NiMoS phases. The as-prepared catalyst is conducive to promote the insertion of CHx and non-dissociative CO in HAS, and effectively suppress the generation of hydrocarbons and CO2. The 0.6KNiMoS/ZnAl catalyst exhibits the most double-layer MoS2 slabs (33.7%) and highly synergetic effects between NiSx and NiMoS to achieve the total alcohols selectivity (69.8%) and space-time yield (78.6 mg/(g·h)) of C2+ alcohols.-

Key words:

- NiMoS/ZnAl catalysts /

- K modification /

- synthesis gas /

- higher alcohols /

- synergetic effect

-

图 3 xKNiMoS/ZnAl催化剂(x=(a)0,(b)0.3,(c)0.6,(d)1.0)的TEM照片、MoS2的(e)晶粒堆积层数和(f)长度分布、xKNiMoS/ZnAl催化剂(x=(g)0.3,(h)1.0)的HAADF-STEM图片和元素分布

Figure 3 TEM images of xKNiMoS/ZnAl catalysts (x=(a) 0, (b) 0.3, (c) 0.6, (d) 1.0), (e) MoS2 stacking degree and (f) MoS2 slab length, HAADF-STEM images and element mapping of xKNiMoS/ZnAl catalysts (x=(g) 0.3, (h) 1.0)

表 1 xKNiMoS/ZnAl催化剂的ICP-OES元素分析

Table 1 ICP-OES results of xKNiMoS/ZnAl catalysts

Sample UItimate analysis w/% K/Mo K Ni Mo Zn Al KNiMoS/ZnAl 0 7.49 12.12 29.20 6.86 0 0.3KNiMoS/ZnAl 1.44 7.27 12.30 28.24 6.60 0.29 0.6KNiMoS/ZnAl 2.98 7.54 12.40 28.16 6.53 0.59 1.0KNiMoS/ZnAl 4.89 7.33 12.29 29.95 6.67 0.98 表 2 xKNiMoS/ZnAl催化剂的XPS表征

Table 2 XPS characterization of xKNiMoS/ZnAl catalysts

Catalyst Binding energies for

Mo 3d5/2/eVSulfidation degree/% Mo4+ Mo5+ Mo6+ NiMoS/ZnAl 229.0 230.2 232.5 65.6 0.3KNiMoS/ZnAl 229.0 230.2 232.4 53.8 0.6KNiMoS/ZnAl 229.0 230.1 232.3 48.6 1.0KNiMoS/ZnAl 228.9 230.2 232.0 41.8 表 3 xKNiMoS/ZnAl催化剂HRTEM表征

Table 3 HRTEM characterization of xKNiMoS/ZnAl catalysts

Catalyst Laverage/nm Naverage ƒMo/% NiMoS/ZnAl 5.80 2.44 16.7 0.3KNiMoS/ZnAl 5.98 2.64 15.9 0.6KNiMoS/ZnAl 5.96 2.96 16.2 1.0KNiMoS/ZnAl 6.37 3.01 9.2 表 4 KNiMoS/ZnAl催化剂的HAS性能

Table 4 Catalytic performance of carbon monoxide hydrogenation on KNiMoS/ZnAl catalysts

Catalyst xCO/% Selection s/% C2+OH STY/(mg·gcat−1·h−1) alcohols hydrocarbons CO2 NiMoS/ZnAl 12.5 48.3 28.5 23.2 62.4 0.3KNiMoS/ZnAl 12.0 60.4 19.2 20.4 69.1 0.6KNiMoS/ZnAl 11.6 69.8 11.7 18.5 78.6 1.0KNiMoS/ZnAl 10.7 64.9 15.5 19.6 63.9 KNiMoS/ZnAl-60 9.0 63.6 19.2 17.1 53.9 KNiMoS/ZnAl-120 10.7 64.9 15.5 19.6 63.9 KNiMoS/ZnAl-180 8.8 59.0 22.7 18.3 48.8 Reaction conditions: p=5 MPa,t=350 ℃,GHSV=3000 mL/(g·h). -

[1] SPIVEY J J, EGBEBI A. Heterogeneous catalytic synthesis of ethanol from biomass-derived syngas[J]. Chem Soc Rev,2007,36:1514−1528. doi: 10.1039/b414039g [2] FANG K, LI D, LIN M, et al. A short review of heterogeneous catalytic process for mixed alcohols synthesis via syngas[J]. Catal Today,2009,147(2):133−138. doi: 10.1016/j.cattod.2009.01.038 [3] DEVARAPALLI M, ATIYEH H K. A review of conversion processes for bioethanol production with a focus on syngas fermentation[J]. Biofuel Res J,2015,2(3):268−280. doi: 10.18331/BRJ2015.2.3.5 [4] LAN E I, LIAO J C. Microbial synthesis of n-butanol, isobutanol, and other higher alcohols from diverse resources[J]. Bioresour Technol,2013,135:339−349. doi: 10.1016/j.biortech.2012.09.104 [5] ROSS J R H, KEULEN A N J V, HEGARTY M E S, et al. The catalytic conversion of natural gas to useful products[J]. Catal Today,1996,30:193−199. doi: 10.1016/0920-5861(96)00035-1 [6] WILHELM D J, SIMBECK D R, KARP A D, et al. Syngas production for gas-to-liquids applications: technologies, issues and outlook[J]. Fuel Processing Technol,2001,71:139−148. doi: 10.1016/S0378-3820(01)00140-0 [7] XIE W, ZHOU J, JI L, et al. Targeted design and synthesis of a highly selective Mo-based catalyst for the synthesis of higher alcohols[J]. RSC Adv,2016,6(45):38741−38745. doi: 10.1039/C6RA05332G [8] LUAN X, YONG J, DAI X, et al. Tungsten-doped molybdenum sulfide with dominant double-layer structure on mixed MgAl oxide for higher alcohol synthesis in CO hydrogenation[J]. Ind Eng Chem Res,2018,57(31):10170−10179. [9] LUK H T, MONDELLI C, FERRE D C, et al. Status and prospects in higher alcohols synthesis from syngas[J]. Chem Soc Rev,2017,46(5):1358−1426. doi: 10.1039/C6CS00324A [10] YONG J, LUAN X, DAI X, et al. Tuning the metal-support interaction in supported K-promoted NiMo catalysts for enhanced selectivity and productivity towards higher alcohols in CO hydrogenation[J]. Catal Sci Technol,2017,7(18):4206−4215. doi: 10.1039/C7CY01295K [11] XIAO K, BAO Z, QI X, et al. Advances in bifunctional catalysis for higher alcohol synthesis from syngas[J]. Chin J Catal,2013,34(1):116−129. doi: 10.1016/S1872-2067(11)60496-8 [12] ZAMAN S, SMITH K J. A review of molybdenum catalysts for synthesis gas conversion to alcohols: catalysts, mechanisms and kinetics[J]. Catal Rev,2012,54(1):41−132. doi: 10.1080/01614940.2012.627224 [13] HUANG X, XU X, LUAN X, et al. CoP nanowires coupled with CoMoP nanosheets as a highly efficient cooperative catalyst for hydrogen evolution reaction[J]. Nano Energy,2020,68:104332. doi: 10.1016/j.nanoen.2019.104332 [14] LIAKAKOU E T, HERACLEOUS E, TRIANTAFYLLIDIS K S, et al. K-promoted NiMo catalysts supported on activated carbon for the hydrogenation reaction of CO to higher alcohols: effect of support and active metal[J]. Appl Catal B: Environ,2015,165:296−305. doi: 10.1016/j.apcatb.2014.10.027 [15] WANG J, XIE J, HUANG Y, et al. An efficient Ni-Mo-K sulfide catalyst doped with CNTs for conversion of syngas to ethanol and higher alcohols[J]. Appl Catal A: Gen,2013,468:44−51. doi: 10.1016/j.apcata.2013.08.026 [16] MORRILL M R, THAO N T, SHOU H, et al. Origins of unusual alcohol selectivities over mixed MgAl oxide-supported K/MoS2 catalysts for higher alcohol synthesis from syngas[J]. ACS Catal,2013,3(7):1665−1675. doi: 10.1021/cs400147d [17] TAVASOLI A, KARIMI S, DAVARI M, et al. Enhancement of MoO3-K2O/CNTs nanocatalyst activity and selectivity in higher alcohols synthesis using microemulsion technique[J]. J Ind Eng Chem,2014,20(2):674−681. doi: 10.1016/j.jiec.2013.05.032 [18] MORRILL M R, THAO N T, AGRAWAL P K, et al. Mixed MgAl oxide supported potassium promoted molybdenum sulfide as a selective catalyst for higher alcohol synthesis from syngas[J]. Catal Let,2012,142(7):875−881. doi: 10.1007/s10562-012-0827-z [19] TOULHOAT H. A perspective on the catalytic hydrogenation of aromatics by Co(Ni)MoS phases[J]. J Catal,2021,403:121−130. doi: 10.1016/j.jcat.2021.01.020 [20] JARAMILLO T F, JØRGENSEN K P, BONDE J, et al. Identification of active edge sites for electrochemical H2 evolution from MoS2 nanocatalysts[J]. Science,2007,317(5834):100−102. doi: 10.1126/science.1141483 [21] TABORGA CLAURE M, CHAI S-H, DAI S, et al. Tuning of higher alcohol selectivity and productivity in CO hydrogenation reactions over K/MoS2 domains supported on mesoporous activated carbon and mixed MgAl oxide[J]. J Catal,2015,324:88−97. doi: 10.1016/j.jcat.2015.01.015 [22] ZHANG X, LUAN X, DAI X, et al. Enhanced higher alcohol synthesis from CO hydrogenation on Zn-modified MgAl-mixed oxide supported KNiMoS-based catalysts[J]. Ind Eng Chem Res,2020,59(4):1413−1421. doi: 10.1021/acs.iecr.9b04047 [23] HEDRICK S A, CHUANG S S C, PANT A, et al. Activity and selectivity of Group VIII, alkali-promoted Mn-Ni, and Mo-based catalysts for C2+ oxygenate synthesis from the CO hydrogenation and CO/H2/C2H4 reactions.[J]. Catal Today,2000,55:247−257. doi: 10.1016/S0920-5861(99)00245-X [24] LI D, ZHAO N, QI H, et al. Ultrasonic preparation of Ni modified K2CO3/MoS2 catalyst for higher alcohols synthesis[J]. Catal Commun,2005,6(10):674−678. doi: 10.1016/j.catcom.2005.06.007 [25] DING M, TU J, QIU M, et al. Impact of potassium promoter on Cu-Fe based mixed alcohols synthesis catalyst[J]. Appl Energy,2015,138:584−589. doi: 10.1016/j.apenergy.2014.01.010 [26] AQUINO A D D, COBO A J G. Synthesis of higher alcohols with cobalt and copper based model catalysts: effect of the alkaline metals[J]. Catal Today,2001,65:209−216. doi: 10.1016/S0920-5861(00)00575-7 [27] MASIH D, ROHANI S, KONDO J N, et al. Low-temperature methanol dehydration to dimethyl ether over various small-pore zeolites[J]. Appl Catal B: Environ,2017,217:247−255. doi: 10.1016/j.apcatb.2017.05.089 [28] CHOUDARY B M, LAKSHMI KANTAM M, NEERAJA V, et al. Layered double hydroxide fluoride: a novel solid base catalyst for C-C bond formation[J]. Green Chem,2001,3(5):257−260. doi: 10.1039/b107124f [29] SANTOS V P, VAN DER LINDEN B, CHOJECKI A, et al. Mechanistic insight into the synthesis of higher alcohols from syngas: The role of K promotion on MoS2 catalysts[J]. ACS Catal,2013,3(7):1634−1637. doi: 10.1021/cs4003518 [30] SUBRAMANI V, GANGWAL S K. A review of recent literature to search for an efficient catalytic process for the conversion of syngas to ethanol[J]. Energy Fuels,2008,22:814−839. [31] TIENTHAO N, HASSANZAHEDINIAKI M, ALAMDARI H, et al. Effect of alkali additives over nanocrystalline Co-Cu-based perovskites as catalysts for higher-alcohol synthesis[J]. J Catal,2007,245(2):348−357. doi: 10.1016/j.jcat.2006.10.026 [32] SUáREZ PARíS R, MONTES V, BOUTONNET M, et al. Higher alcohol synthesis over nickel-modified alkali-doped molybdenum sulfide catalysts prepared by conventional coprecipitation and coprecipitation in microemulsions[J]. Catal Today,2015,258:294−303. doi: 10.1016/j.cattod.2014.12.003 [33] ZENG F, XI X, CAO H, et al. Synthesis of mixed alcohols with enhanced C3+ alcohol production by CO hydrogenation over potassium promoted molybdenum sulfide[J]. Appl Catal B: Environ,2019,246:232−241. doi: 10.1016/j.apcatb.2019.01.063 [34] CHOW W L, LUO X, QUEK S Q, et al. Evolution of Raman scattering and electronic structure of ultrathin molybdenum disulfide by oxygen chemisorption[J]. Adv Electron Mater,2015,1(1/2):1400037. doi: 10.1002/aelm.201400037 [35] LI H, ZHANG Q, YAP C C R, et al. From bulk to monolayer MoS2: evolution of Raman scattering[J]. Adv Funct Mater,2012,22(7):1385−1390. doi: 10.1002/adfm.201102111 [36] BENOIST L, GONBEAU D, PFISTER-GUILLOUZO G, et al. X-ray photoelectron spectroscopy characterization of amorphous molybdenum oxysulfide thin films[J]. Thin Solid Films,1995,258:110−114. [37] LIU C, VIRGINIE M, GRIBOVAL-CONSTANT A, et al. Potassium promotion effects in carbon nanotube supported molybdenum sulfide catalysts for carbon monoxide hydrogenation[J]. Catal Today,2016,261:137−145. doi: 10.1016/j.cattod.2015.07.003 [38] QIU L, XU G. Peak overlaps and corresponding solutions in the X-ray photoelectron spectroscopic study of hydrodesulfurization catalysts[J]. Appl Surf Sci,2010,256(11):3413−3417. doi: 10.1016/j.apsusc.2009.12.043 [39] FAN Y, XIAO H, SHI G, et al. Citric acid-assisted hydrothermal method for preparing NiW/USY-Al2O3 ultradeep hydrodesulfurization catalysts[J]. J Catal,2011,279(1):27−35. doi: 10.1016/j.jcat.2010.12.014 [40] HARRIS S, CHIANELLI R R. Catalysis by transition metal sulfides: a theoretical and experimental study of the relation between the synergic systems and the binary transition metal sulfides[J]. J Catal,1986,98:17−31. doi: 10.1016/0021-9517(86)90292-7 [41] GANDUBERT A D, KREBS E, LEGENS C, et al. Optimal promoter edge decoration of CoMoS catalysts: a combined theoretical and experimental study[J]. Catal Today,2008,130(1):149−159. doi: 10.1016/j.cattod.2007.06.041 [42] HAN W, YUAN P, FAN Y, et al. Preparation of supported hydrodesulfurization catalysts with enhanced performance using Mo-based inorganic-organic hybrid nanocrystals as a superior precursor[J]. J Mater Chem,2012,22:25340−25353. doi: 10.1039/c2jm34979e [43] NIKULSHIN P A, ISHUTENKO D I, MOZHAEV A A, et al. Effects of composition and morphology of active phase of CoMo/Al2O3 catalysts prepared using Co2Mo10-heteropolyacid and chelating agents on their catalytic properties in HDS and HYD reactions[J]. J Catal,2014,312:152−169. doi: 10.1016/j.jcat.2014.01.014 [44] LI D, YANG C, LI W, et al. Ni/ADM: A high activity and selectivity to C2+OH catalyst for catalytic conversion of synthesis gas to C1-C5 mixed alcohols[J]. Top Catal,2005,32:233−239. doi: 10.1007/s11244-005-2901-x [45] ANDERSSON R, BOUTONNET M, JÄRÅS S. On-line gas chromatographic analysis of higher alcohol synthesis products from syngas[J]. J Chromatogr A,2012,1247:134−145. doi: 10.1016/j.chroma.2012.05.060 [46] DAAGE M, CHIANELLI R R. Structure-function relations in molybdenum sulfide catalysts: The "Rim-Edge" model[J]. J Catal,1994,149:414−427. doi: 10.1006/jcat.1994.1308 -

下载:

下载: