Research progress in the growth mechanism of carbon nanotubes prepared by catalytic pyrolysis of waste plastics

-

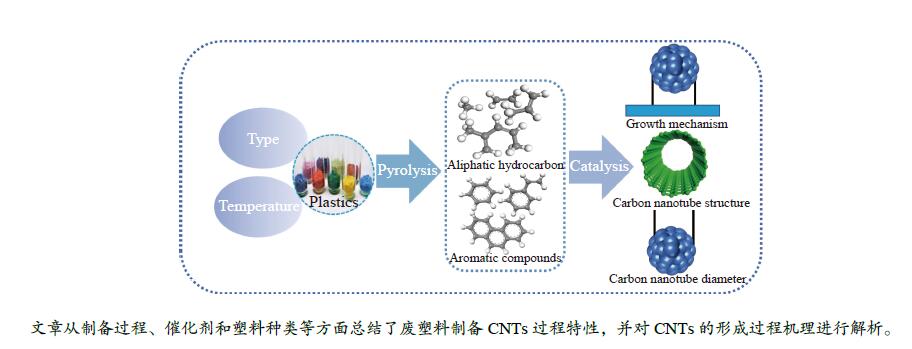

摘要: 催化热解技术可将废塑料转化为高品质的碳纳米管(CNTs),实现废塑料的回收和高价值利用。然而,塑料催化热解过程复杂,影响因素繁多,且碳纳米管的生长机制不清,因此,本综述从塑料种类、温度、催化剂等角度阐述了塑料结构以及热解过程对碳纳米管生长过程以及结构特性的影响,并解析了碳纳米管的成核和成长过程机理。发现挥发分种类和温度会对CNTs结构产生影响,而催化剂的性能将影响碳纳米管的直径和生长方式;催化剂与CNTs之间的作用力大小取决于催化剂的种类,CNTs边界的碳扩散强度又受反应条件、催化剂和碳源种类的影响,两者之间的相对大小决定CNTs成核和生长具体过程。该综述为废塑料热解制备碳纳米管过程的理解以及废塑料资源化利用技术的开发提供理论参考。Abstract: Catalytic pyrolysis technology can convert waste plastics into high-quality carbon nanotubes (CNTs), achieving the recycling and high-value utilization of waste plastics. However, the process of plastic catalytic pyrolysis is complex, with numerous influencing factors, and the growth mechanism of carbon nanotubes is unclear. Therefore, this article elaborates on the influence of plastic structure and pyrolysis process on the growth process and structural characteristics of carbon nanotubes from the perspectives of plastic type, temperature, catalyst, etc., and analyzes the nucleation and growth mechanism of carbon nanotubes. It is found that the type and temperature of volatile matter will affect the structure of CNTs, while the performance of the catalyst will affect the diameter and growth mode of carbon nanotubes. The force between the catalyst and CNTs depends on the type of catalyst, and the carbon diffusion intensity at the boundary of CNTs is influenced by reaction conditions, catalyst and carbon source types. The relative size between the two determines the specific process of CNTs nucleation and growth.This review provides theoretical reference for the understanding of the process of preparing carbon nanotubes from waste plastic pyrolysis and the development of waste plastic resource utilization technologies.

-

Key words:

- plastic /

- catalytic pyrolysis /

- carbon nanotubes /

- growth mechanism

-

图 1 不同类型废塑料催化热解的TEM照片

Figure 1 TEM images of catalytic pyrolysis of different types of waste plastics[6] (a): PP; (b): HDPE; (c): LDPE; (d): HIPS; (e): GPPS (with permission from Elsevier)

表 1 不同塑料制备CNTs特性

Table 1 Summary of CNTs prepared by different plastics

Material Catalyzer Reactor t/℃ CNTs/% Diameter/nm Ref. PP NiMo single-stage fixed-bed quartz reactor 700 18.4 25.08±7.538a

0.335b[10] PP NiMo/CaTiO3 40 24.01±4.890a

0.340bPE ferrocene two-stage fixed-bed quartz reactor 450c−800d – (22–36)a [11] PVCe – (22–37)a HDPEf Ni-Mn-Al two-stage fixed-bed quartz reactor 500c−800d 32.6 – [12] HDPE/PVC 25.1 – PP iron nanoparticles single-stage fixed-bed quartz reactor 700 – 16.5–40a [13] PS – 7.5–25a PP Fe/ Al2O3 two-stage fixed-bed quartz reactor 500c−800d 30.2i – [6] LDPEg 35.9h – HIPSi 49.4h – PP NiMo/MgOj single-stage fixed-bed quartz reactor 700 – (10–30)a [14] PP NiMo/MgOk – (10–22)a PP Fe\Ni\Mg/ Mg2Al4Si5O18 two-stage stainless steel reactor 500c−750d – (10–30)a

5b[15] LDPE NiMo/Al2O3 two-stage fixed-bed quartz reactor (500−800)c−(600–800)d 14.7–28.1 (11–49)a [16] HDPE Ni/Mo/MgO multinuclear reactor (450–700)c−800d 0.76–20.1 (20–50)a

10l[17] a:CNTs external diameter; b:CNTs internal diameter; c:Pyrolysis temperature; d: Catalytic temperature; e: Polyvinyl chloride; f: High density polyethylene; g: Low density polyethylene; h: Containing amorphous carbon; i: High impact polystyrene; j: Sol gel method; k: Incipient wet impregnation methods; l: Average wall thickness -

[1] LANDRIGAN P J, RAPS H, CROPPER M, BALD C, BRUNNER M, CANONIZADO E M, CHARLES D, CHILES T C, DONOHUE M J, ENCK J, FENICHEL P, FLEMING L E, FERRIER-PAGES C, FORDHAM R, GOZT A, GRIFFIN C, HAHN M E, HARYANTO B, HIXSON R, IANELLI H, JAMES B D, KUMAR P, LABORDE A, LAW K L, MARTIN K, MU J, MULDERS Y, MUSTAPHA A, NIU J, PAHL S, PARK Y, PEDROTTI M-L, PITT J A, RUCHIRAWAT M, SEEWOO B J, SPRING M, STEGEMAN J J, SUK W, SYMEONIDES C, TAKADA H, THOMPSON R C, VICINI A, WANG Z, WHITMAN E, WIRTH D, WOLFF M, YOUSUF A K, DUNLOP S. The minderoo-monaco commission on plastics and human health[J]. Ann Glob Health,2023,89(1):1−215. doi: 10.5334/aogh.3890 [2] PRATA J C, SILVA A L P, WALKER T R, DUARTE A C, ROCHA-SANTOS T. Covid-19 pandemic repercussions on the use and management of plastics[J]. Environ Sci Technol,2020,54(13):7760−7765. doi: 10.1021/acs.est.0c02178 [3] ADYEL T M. Accumulation of plastic waste during covid-19[J]. Science,2020,369(6509):1314−1315. doi: 10.1126/science.abd9925 [4] DONG J P, ZHANG H N, WEI C, YANG L, CAO C F, YANG S H, ZHANG Z T. Feasibility evaluation of the terminated waste energy in situ conversion strategy toward carbon neutralization in metallurgical processes[J]. ACS Sustainable Chem Eng,2021,9(42):14079−14089. doi: 10.1021/acssuschemeng.1c03731 [5] YAO D D, LI H, DAI Y J, WANG C H. Impact of temperature on the activity of Fe-Ni catalysts for pyrolysis and decomposition processing of plastic waste[J]. Chem Eng J,2021,408(1):127268. [6] CAI N, LI X Q, XIA S W, SUN L, HU J H, BARTOCCI P, FANTOZZI F, WILLIAMS P T, YANG H P, CHEN H P. Pyrolysis-catalysis of different waste plastics over Fe/Al2O3 catalyst: High-value hydrogen, liquid fuels, carbon nanotubes and possible reaction mechanisms[J]. Energy Convers Manage,2021,229(1):113794. [7] ACOMB J C, WU C F, WILLIAMS P T. The use of different metal catalysts for the simultaneous production of carbon nanotubes and hydrogen from pyrolysis of plastic feedstocks[J]. Appl Catal B: Environ,2016,180(894):497−510. [8] LUO J Z, YU Z L, NG C F, AU C T. CO2/CH4 reforming over Ni-La2O3/5A: An investigation on carbon deposition and reaction steps[J]. J Catal,2000,194(2):198−210. doi: 10.1006/jcat.2000.2941 [9] AZARA A, BENYOUSSEF E H, MOHELLEBI F, CHAMOUMI M, GITZHOFER F, ABATZOGLOU N. Catalytic dry reforming and cracking of ethylene for carbon nanofilaments and hydrogen production using a catalyst derived from a mining residue[J]. Catalysts,2019,9(12):1069. doi: 10.3390/catal9121069 [10] MODEKWE H U, MAMO M A, MOOTHI K, DARAMOLA M O. Effect of different catalyst supports on the quality, yield and morphology of carbon nanotubes produced from waste polypropylene plastics[J]. Catalysts,2021,11(6):692. doi: 10.3390/catal11060692 [11] YANG Z, ZHANG Q, LUO G H, HUANG J Q, ZHAO M Q, WEI F. Coupled process of plastics pyrolysis and chemical vapor deposition for controllable synthesis of vertically aligned carbon nanotube arrays[J]. Appl Phys A-Mater,2010,100(2):533−540. doi: 10.1007/s00339-010-5868-9 [12] WU C F, NAHIL M A, MISKOLCZI N, HUANG J, WILLIAMS P T. Processing real-world waste plastics by pyrolysis-reforming for hydrogen and high-value carbon nanotubes[J]. Environ Sci Technol,2014,48(1):819−826. doi: 10.1021/es402488b [13] CHUNG Y H, JOU S. Carbon nanotubes from catalytic pyrolysis of polypropylene[J]. Mater Chem Phys,2005,92(1):256−259. doi: 10.1016/j.matchemphys.2005.01.023 [14] MODEKWE H U, MAMO M, MOOTHI K, DARAMOLA M O. Synthesis of bimetallic NiMo/MgO catalyst for catalytic conversion of waste plastics (polypropylene) to carbon nanotubes (CNTs) via chemical vapour deposition method[Z]. Mater Today: Proc. 2021, 38 (1): 549−552 [15] WANG J Q, SHEN B X, LAN M C, KANG D R, WU C F. Carbon nanotubes (CNTs) production from catalytic pyrolysis of waste plastics: The influence of catalyst and reaction pressure[J]. Catal Today,2020,351(1):50−57. [16] ABOUL-ENEIN A A, ADEL-RAHMAN H, HAGGAR A M, AWADALLAH A E. Simple method for synthesis of carbon nanotubes over Ni-Mo/Al2O3 catalyst via pyrolysis of polyethylene waste using a two-stage process[J]. Fullerenes, Nanotubes, Carbon Nanostruct,2017,25(4):211−222. doi: 10.1080/1536383X.2016.1277422 [17] BAJAD G S, VIJAYAKUMAR R P, GUPTA A G, JAGTAP V, SINGH Y P. Production of liquid hydrocarbons, carbon nanotubes and hydrogen rich gases from waste plastic in a multi-core reactor[J]. J Anal Appl Pyrolysis,2017,125(1):83−90. [18] BAROULAKI I, KARAKASI O, PAPPA G, TARANTILI P A, ECONOMIDES D, MAGOULAS K. Preparation and study of plastic compounds containing polyolefins and post used newspaper fibers[J]. Compos Part A-Appl S,2006,37(10):1613−1625. doi: 10.1016/j.compositesa.2005.10.012 [19] SALEEM J, RIAZ M A, MCKAY G. Oil sorbents from plastic wastes and polymers: A review[J]. J Hazard Mater,2018,341(1):424−437. [20] WU C F, WILLIAMS P T. Pyrolysis-gasification of plastics, mixed plastics and real-world plastic waste with and without Ni-Mg-Al catalyst[J]. Fuel,2010,89(10):3022−3032. doi: 10.1016/j.fuel.2010.05.032 [21] ZHU Y, MIAO J, ZHANG Y R, LI C C, WANG Y Y, CHENG Y, LONG M C, WANG J W, WU C F. Carbon nanotubes production from real-world waste plastics and the pyrolysis behaviour[J]. Waste Manage,2023,166(1):141−151. [22] RATNASARI D K, NAHIL M A, WILLIAMS P T. Catalytic pyrolysis of waste plastics using staged catalysis for production of gasoline range hydrocarbon oils[J]. J Anal Appl Pyrolysis,2017,124(1):631−637. [23] XIAO H Y, HARDING J, LEI S S, CHEN W, XIA S W, CAI N, CHEN X, HU J H, CHEN Y Q, WANG X H, TU X, YANG H P, CHEN H P. Hydrogen and aromatics recovery through plasma-catalytic pyrolysis of waste polypropylene[J]. J Clean Pr,2022,350(1):131467. [24] LI Q W, YAN H, ZHANG J, LIU Z F. Effect of hydrocarbons precursors on the formation of carbon nanotubes in chemical vapor deposition[J]. Carbon,2004,42(4):829−835. doi: 10.1016/j.carbon.2004.01.070 [25] SHAH K A, TALI B A. Synthesis of carbon nanotubes by catalytic chemical vapour deposition: A review on carbon sources, catalysts and substrates[J]. Mater Sci Semicond Process,2016,41(1):67−82. [26] LAI H J, LIN M C C, YANG M H, LI A K. Synthesis of carbon nanotubes using polycyclic aromatic hydrocarbons as carbon sources in an arc discharge[J]. Mater Sci Eng, C,2001,16(1/2):23−26. doi: 10.1016/S0928-4931(01)00303-4 [27] PARKER J, BEASLEY C, LIN A, CHEN H Y, WONG H S P. Increasing the semiconducting fraction in ensembles of single-walled carbon nanotubes[J]. Carbon,2012,50(14):5093−5098. doi: 10.1016/j.carbon.2012.06.049 [28] GONG J, LIU J, WAN D, CHEN X C, WEN X, MIJOWSKA E, JIANG Z W, WANG Y H, TANG T. Catalytic carbonization of polypropylene by the combined catalysis of activated carbon with Ni2O3 into carbon nanotubes and its mechanism[J]. Appl Catal A: Gen,2012,449(1):112−120. [29] GONG J, LIU J, JIANG Z W, WEN X, CHEN X C, MIJOWSKA E, WANG Y H, TANG T. Effect of the added amount of organically-modified montmorillonite on the catalytic carbonization of polypropylene into cup-stacked carbon nanotubes[J]. Chem Eng J,2013,225(1):798−808. [30] VEKSHA A, CHEN W Q, LIANG L L, LISAK G. Converting polyolefin plastics into few-walled carbon nanotubes via a tandem catalytic process: Importance of gas composition and system configuration[J]. J Hazard Mater,2022,435(1):128949. [31] ZHANG Q, YU H, HUANG J Q, HU L, QIAN W Z, WANG D Z, WEI F. Carbon nanofiber microspheres obtained from ethylene using FeCl3 as the catalyst precursor[J]. Mater Lett,2008,62(17/18):3149−3151. doi: 10.1016/j.matlet.2008.02.007 [32] LV R T, KANG F Y, ZHU D, ZHU Y Q, GUI X C, WEI J Q, GU J L, LI D J, WANG K L, WU D H. Enhanced field emission of open-ended, thin-walled carbon nanotubes filled with ferromagnetic nanowires[J]. Carbon,2009,47(11):2709−2715. doi: 10.1016/j.carbon.2009.05.027 [33] LV R T, TSUGE S, GUI X C, TAKAI K, KANG F Y, ENOKI T, WEI J Q, GU J L, WANG K L, WU D H. In situ synthesis and magnetic anisotropy of ferromagnetic buckypaper[J]. Carbon,2009,47(4):1141−1145. doi: 10.1016/j.carbon.2008.12.048 [34] 祝玉婷. 聚氯乙烯有氧脱氯及催化热解制备碳纳米管实验研究[D]. 武汉: 华中科技大学, 2021.ZHU Yu-ting Experimental study on the production of carbon nanotubes from catalytic pyrolysis of polyvinyl chloride dechlorinated under acrobic condition[D]. Wuhan: Huazhong University of Science and Technology, 2021. [35] ARTETXE M, LOPEZ G, AMUTIO M, ELORDI G, BILBAO J, OLAZAR M. Light olefins from hdpe cracking in a two-step thermal and catalytic process[J]. Chem Eng J,2012,207(1):27−34. [36] 贺兴处, 陈德珍. 典型聚乙烯、聚丙烯、聚苯乙烯废塑料共热解初期反应特性的reaxff分子模拟研究[J]. 燃料化学学报,2022,50(3):346−356.HE Xing-chu, CHEN De-zhen. ReaxFF MD study on the early stage co-pyrolysis of mixed PE/PP/PS plastic waste[J]. J Fuel Chem Technol,2022,50(3):346−356. [37] YANG R X, WU S L, CHUANG K H, WEY M Y. Co-production of carbon nanotubes and hydrogen from waste plastic gasification in a two-stage fluidized catalytic bed[J]. Renewable Energy,2020,159(1):10−22. [38] WESTERHOUT R W J, KUIPERS J A M, VAN SWAAIJ W P M. Experimental determination of the yield of pyrolysis products of polyethene and polypropene. Influence of reaction conditions[J]. Ind Eng Chem Res,1998,37(3):841−847. doi: 10.1021/ie970384a [39] LIU J, JIANG Z W, YU H O, TANG T. Catalytic pyrolysis of polypropylene to synthesize carbon nanotubes and hydrogen through a two-stage process[J]. Polym Degrad Stab,2011,96(10):1711−1719. doi: 10.1016/j.polymdegradstab.2011.08.008 [40] WILLIAMS P T. Hydrogen and carbon nanotubes from pyrolysis-catalysis of waste plastics: A review[J]. Top Curr Chem,2021,12(1):1−28. [41] ZHANG Y H, NAHIL M A, WU C F, WILLIAMS P T. Pyrolysis-catalysis of waste plastic using a nickel-stainless-steel mesh catalyst for high-value carbon products[J]. Environ Technol,2017,38(22):2889−2897. doi: 10.1080/09593330.2017.1281351 [42] CAI N, XIA S, XIAO H, CHEN Y, CHEN W, YANG H, WU C, CHEN H. Distinguishing the impact of temperature on iron catalyst during the catalytic-pyrolysis of waste polypropylene[J]. Proc Combust Inst,2022,39(1):835−845. [43] ACOMB J C, WU C F, WILLIAMS P T. Effect of growth temperature and feedstock: Catalyst ratio on the production of carbon nanotubes and hydrogen from the pyrolysis of waste plastics[J]. J Anal Appl Pyrolysis,2015,113(1):231−238. [44] LEE C J, PARK J, HUH Y, LEE J Y. Temperature effect on the growth of carbon nanotubes using thermal chemical vapor deposition[J]. Chem Phys Lett,2001,343(1/2):33−38. doi: 10.1016/S0009-2614(01)00680-7 [45] MISHRA N, DAS G, ANSALDO A, GENOVESE A, MALERBA M, POVIA M, RICCI D, DI FABRIZIO E, DI ZITTI E, SHARON M, SHARON M. Pyrolysis of waste polypropylene for the synthesis of carbon nanotubes[J]. J Anal Appl Pyrolysis,2012,94(1):91−98. [46] DUCATI C, ALEXANDROU I, CHHOWALLA M, AMARATUNGA G A J, ROBERTSON J. Temperature selective growth of carbon nanotubes by chemical vapor deposition[J]. J Appl Phys,2002,92(6):3299−3303. doi: 10.1063/1.1499746 [47] SHUDIN N H, MUKRI M A R, AZIZ M, OTHMAN M H D, TANEMURA M, YUSOP M Z M. The role of solid, liquid and gaseous hydrocarbon precursors on chemical vapor deposition grown carbon nanomaterials' growth temperature[J]. Synthetic Met,2021,274(1):116735. [48] DAI L L, KARAKAS O, CHENG Y L, COBB K, CHEN P, RUAN R. A review on carbon materials production from plastic wastes[J]. Chem Eng J,2023,453(1):139725. [49] 姚丁丁. 废塑料催化热解制备富氢气体和碳纳米管的实验研究[D]. 武汉: 华中科技大学, 2018.YAO Ding-ding Hydrogen rich syngas and carbon nanotubes production from pyrolysis catalysis of waste plastics[D]. Wuhan: Huazhong University of Science and Technology, 2018. [50] 肖皓宇, 杨海平, 张雄, 陈应泉, 王贤华, 陈汉平. 塑料催化热解制备高附加值产品的研究进展[J]. 化工学报,2022,73(8):3461−3471.XIAO Hao-yu, YANG Hai-ping, ZHANG Xiong, CHEN Ying-quan, WANG Xian-hua, CHEN Han-ping. Recent progress of catalytic pyrolysis of plastics to produce high value-added products[J]. CIESC J,2022,73(8):3461−3471. [51] 冯时宇, 李洋, 李凯, 胡斌, 刘吉, 陆强. 塑料废弃物热催化制备碳纳米管的研究进展[J]. 环境工程,2021,39(4):107−114.FENG Shi-yu, LI Yang, LI Kai, HU Bin, LIU Ji, LU Qiang. Progress in preparation of carbon nanotubes by thermal catalysis of waste plastics[J]. Environ Eng,2021,39(4):107−114. [52] LIU X T, ZHANG Y S, NAHIL M A, WILLIAMS P T, WU C F. Development of Ni- and Fe- based catalysts with different metal particle sizes for the production of carbon nanotubes and hydrogen from thermo-chemical conversion of waste plastics[J]. J Anal Appl Pyrolysis,2017,125(1):32−39. [53] ZHAO N, WU Q R, ZHANG X Y, YANG T, LI D, ZHANG X T, MA C, LIU R L, XIN L T, HE M S. Chemical vapor deposition growth of single-walled carbon nanotubes from plastic polymers[J]. Carbon,2022,187(1):29−34. [54] LIN Y C, LIN J H. Purity-controllable growth of bamboo-like multi-walled carbon nanotubes over copper-based catalysts[J]. Catal Commun,2013,34(1):41−44. [55] SHEN Y F, ZHAO P T, SHAO Q F, TAKAHASHI F, YOSHIKAWA K. In situ catalytic conversion of tar using rice husk char/ash supported nickel-iron catalysts for biomass pyrolytic gasification combined with the mixing-simulation in fluidized-bed gasifier[J]. Appl Energy,2015,160(1):808−819. [56] FLAHAUT E, GOVINDARAJ A, PEIGNEY A, LAURENT C, ROUSSET A, RAO C N R. Synthesis of single-walled carbon nanotubes using binary (Fe, Co, Ni) alloy nanoparticles prepared in situ by the reduction of oxide solid solutions[J]. Chem Phys Lett,1999,300(1/2):236−242. doi: 10.1016/S0009-2614(98)01304-9 [57] NAHIL M A, WU C F, WILLIAMS P T. Influence of metal addition to Ni-based catalysts for the co-production of carbon nanotubes and hydrogen from the thermal processing of waste polypropylene[J]. Fuel Process Technol,2015,130(1):46−53. [58] YAO D D, ZHANG Y S, WILLIAMS P T, YANG H P, CHEN H P. Co-production of hydrogen and carbon nanotubes from real-world waste plastics: Influence of catalyst composition and operational parameters[J]. Appl Catal B: Environ,2018,221(1):584−597. [59] YAO D D, WU C F, YANG H P, ZHANG Y S, NAHIL M A, CHEN Y Q, WILLIAMS P T, CHEN H P. Co-production of hydrogen and carbon nanotubes from catalytic pyrolysis of waste plastics on Ni-Fe bimetallic catalyst[J]. Energy Convers Manage,2017,148(1):692−700. [60] SHEN W, WANG Y, SHI X, SHAH N, HUGGINS F, BOLLINENI S, SEEHRA M, HUFFMAN G. Catalytic nonoxidative dehydrogenation of ethane over Fe-Ni and Ni catalysts supported on Mg(Al)O to produce hydrogen and easily purified carbon nanotubes[J]. Energy Fuels,2007,21(6):3520−3529. doi: 10.1021/ef7004018 [61] LIU B L, TANG D M, SUN C H, LIU C, REN W C, LI F, YU W J, YIN L C, ZHANG L L, JIANG C B, CHENG H M. Importance of oxygen in the metal-free catalytic growth of single-walled carbon nanotubes from siox by a vapor-solid-solid mechanism[J]. JACS,2011,133(2):197−199. doi: 10.1021/ja107855q [62] TAKAGI D, KOBAYASHI Y, HOMMAM Y. Carbon nanotube growth from diamond[J]. JACS,2009,131(20):6922−6923. doi: 10.1021/ja901295j [63] ABOUL-ENEIN A A, AWADALLAH A E, ABDEL-RAHMAN A A H, HAGGAR A M. Synthesis of multi-walled carbon nanotubes via pyrolysis of plastic waste using a two-stage process[J]. Fullerenes, Nanotubes, Carbon Nanostruct,2018,26(7):443−450. doi: 10.1080/1536383X.2018.1447929 [64] AWADALLAH A E, ABOUL-ENEIN A A, YONIS M M, ABOUL-GHEIT A K. Effect of structural promoters on the catalytic performance of cobalt-based catalysts during natural gas decomposition to hydrogen and carbon nanotubes[J]. Fullerenes, Nanotubes, Carbon Nanostruct,2016,24(3):181−189. doi: 10.1080/1536383X.2015.1132206 [65] CAI N, XIA S W, LI X Q, XIAO H Y, CHEN X, CHEN Y Q, BARTOCCI P, CHEN H P, WILLIAMS P T, YANG H P. High-value products from ex-situ catalytic pyrolysis of polypropylene waste using iron-based catalysts: The influence of support materials[J]. Waste Manage,2021,136(1):47−56. [66] TAKENAKA S, SERIZAWA M, OTSUKA K. Formation of filamentous carbons over supported fe catalysts through methane decomposition[J]. J Catal,2004,222(2):520−531. doi: 10.1016/j.jcat.2003.11.017 [67] WEI J Q, ZHU H W, JIA Y, SHU Q K, LI C G, WANG K L, WEI B Q, ZHU Y Q, WANG Z C, LUO J B, LIU W J, WU D H. The effect of sulfur on the number of layers in a carbon nanotube[J]. Carbon,2007,45(11):2152−2158. doi: 10.1016/j.carbon.2007.07.001 [68] CI L J, ZHOU Z P, TANG D S, YAN X Q, LIANG Y X, LIU D F, YUAN H J, ZHOU W Y, WANG G, XIE S S. Double wall carbon nanotubes with an inner diameter of 0.4 nm[J]. Chem Vap Dep,2003,9(3):119−121. doi: 10.1002/cvde.200304142 [69] YANG R X, CHUANG K H, WEY M Y. Effects of nickel species on Ni/Al2O3 catalysts in carbon nanotube and hydrogen production by waste plastic gasification: Bench- and pilot-scale tests[J]. Energy Fuels,2015,29(12):8178−8187. [70] LOUCHEV O A, SATO Y, KANDA H. Mechanism of thermokinetical selection between carbon nanotube and fullerene-like nanoparticle formation[J]. J Appl Phys,2002,91(12):10074−10080. doi: 10.1063/1.1479469 [71] GAVILLET J, LOISEAU A, JOURNET C, WILLAIME F, DUCASTELLE F, CHARLIER J C. Root-growth mechanism for single-wall carbon nanotubes[J]. Phys Rev Lett,2001,87(27):275504. doi: 10.1103/PhysRevLett.87.275504 [72] PAGE A J, YAMANE H, OHTA Y, IRLE S, MOROKUMA K. QM/MD simulation of SWNT nucleation on transition-metal carbide nanoparticles[J]. JACS,2010,132(44):15699−15707. doi: 10.1021/ja106264q [73] CAI N, XIA S W, LI X Q, SUN L, BARTOCCI P, FANTOZZI F, ZHANG H Z, CHEN H P, WILLIAMS P T, YANG H P. Influence of the ratio of Fe/Al2O3 on waste polypropylene pyrolysis for high value-added products[J]. J Clean Pr,2021,315(1):128240. [74] EDGAR K, SPENCER J L. The synthesis of carbon nanotubes from muller clusters[J]. Curr Appl Phys,2006,6(3):419−421. doi: 10.1016/j.cap.2005.11.032 [75] AMARA H, BICHARA C, DUCASTELLE F. Understanding the nucleation mechanisms of carbon nanotubes in catalytic chemical vapor deposition[J]. Phys Rev Lett,2008,100(5):056105. doi: 10.1103/PhysRevLett.100.056105 [76] DING F, ROSEN A, CURTAROLO S, BOLTON K. Modeling the melting of supported clusters[J]. Appl Phys Lett,2006,88(13):133110. doi: 10.1063/1.2187950 [77] ABILD-PEDERSEN F, NORSKOV J K, ROSTRUP-NIELSEN J R, SEHESTED J, HELVEG S. Mechanisms for catalytic carbon nanofiber growth studied by ab initio density functional theory calculations[J]. Phys Rev B,2006,73(11):115419. doi: 10.1103/PhysRevB.73.115419 [78] OHTA Y, OKAMOTO Y, IRLE S, MOROKUMA K. Temperature dependence of iron-catalyzed continued single-walled carbon nanotube growth rates: Density functional tight-binding molecular dynamics simulations[J]. J Phys Chem C,2009,113(1):159−169. doi: 10.1021/jp808493f [79] RATY J Y, GYGI F, GALLI G. Growth of carbon nanotubes on metal nanoparticles: A microscopic mechanism from ab initio molecular dynamics simulations[J]. Phys Rev Lett,2005,95(9):096103. doi: 10.1103/PhysRevLett.95.096103 [80] LOUCHEV O A, SATO Y, KANDA H. Morphological stabilization, destabilization, and open-end closure during carbon nanotube growth mediated by surface diffusion[J]. Phys Rev E,2002,66(1):011601. doi: 10.1103/PhysRevE.66.011601 [81] DING F, ROSEN A, BOLTON K. Molecular dynamics study of the catalyst particle size dependence on carbon nanotube growth[J]. J Chem Phys,2004,121(6):2775−2779. doi: 10.1063/1.1770424 [82] DING F, LARSSON P, LARSSON J A, AHUJA R, DUAN H M, ROSEN A, BOLTON K. The importance of strong carbon-metal adhesion for catalytic nucleation of single-walled carbon nanotubes[J]. Nano Lett,2008,8(2):463−468. doi: 10.1021/nl072431m [83] AMARA H, BICHARA C. Modeling the growth of single-wall carbon nanotubes[J]. Top Curr Chem,2017,375(3):55. doi: 10.1007/s41061-017-0141-8 [84] JOURDAIN V, BICHARA C. Current understanding of the growth of carbon nanotubes in catalytic chemical vapour deposition[J]. Carbon,2013,58:2−39. doi: 10.1016/j.carbon.2013.02.046 [85] SHIBUTA Y, MARUYAMA S. A molecular dynamics study of the effect of a substrate on catalytic metal clusters in nucleation process of single-walled carbon nanotubes[J]. Chem Phys Lett,2007,437(4/6):218−223. doi: 10.1016/j.cplett.2007.02.019 [86] RIBAS M A, DING F, BALBUENA P B, YAKOBSON B I. Nanotube nucleation versus carbon-catalyst adhesion-probed by molecular dynamics simulations[J]. J Chem Phys,2009,131(22):224501. doi: 10.1063/1.3266947 [87] DING F, ROSEN A, BOLTON K. Dependence of swnt growth mechanism on temperature and catalyst particle size: Bulk versus surface diffusion[J]. Carbon,2005,43(10):2215−2217. doi: 10.1016/j.carbon.2005.03.021 [88] DING F, BOLTON K, ROSEN A. Nucleation and growth of single-walled carbon nanotubes: A molecular dynamics study[J]. J Phys Chem B,2004,108(45):17369−17377. doi: 10.1021/jp046645t [89] BRENNER D W, SHENDEROVA O A, HARRISON J A, STUART S J, NI B, SINNOTT S B. A second-generation reactive empirical bond order (rebo) potential energy expression for hydrocarbons[J]. J Phys-Condens Mater,2002,14(4):783−802. doi: 10.1088/0953-8984/14/4/312 [90] BRENNER D W. Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films[J]. Phys Rev B: Condens Matter,1990,42(15):9458−9471. doi: 10.1103/PhysRevB.42.9458 [91] TESSONNIER J P, SU D S. Recent progress on the growth mechanism of carbon nanotubes: A review[J]. ChemSusChem,2011,4(7):824−847. doi: 10.1002/cssc.201100175 [92] HELVEG S, LOPEZ-CARTES C, SEHESTED J, HANSEN P L, CLAUSEN B S, ROSTRUP-NIELSEN J R, ABILD-PEDERSEN F, NORSKOV J K. Atomic-scale imaging of carbon nanofibre growth[J]. Nature,2004,427(6973):426−429. doi: 10.1038/nature02278 [93] YOSHIDA H, TAKEDA S, UCHIYAMA T, KOHNO H, HOMMA Y. Atomic-scale in-situ observation of carbon nanotube growth from solid state iron carbide nanoparticles[J]. Nano Lett,2008,8(7):2082−2086. doi: 10.1021/nl080452q [94] ZHANG Y S, ZHU H L, YAO D D, WILLIAMS P T, WU C F, XU D, HU Q, MANOS G, YU L, ZHAO M, SHEARING P R, BRETT D J L. Thermo-chemical conversion of carbonaceous wastes for CNT and hydrogen production: A review[J]. Sustainable Energy Fuels,2021,5(17):4173−4208. doi: 10.1039/D1SE00619C [95] MA L N, DONG X F, CHEN M L, ZHU L, WANG C X, YANG F L, DONG Y C. Fabrication and water treatment application of carbon nanotubes (CNTs)-based composite membranes: A review[J]. Membranes,2017,7(1):16. doi: 10.3390/membranes7010016 [96] LIU W-W, AZIZ A, CHAI S-P, MOHAMED A R, TYE C-T. The effect of carbon precursors (methane, benzene and camphor) on the quality of carbon nanotubes synthesised by the chemical vapour decomposition[J]. Physica E,2011,43(8):1535−1542. doi: 10.1016/j.physe.2011.05.012 [97] AGO H, ISHIGAMI N, YOSHIHARA N, IMAMOTO K, AKITA S, IKEDA K, TSUJI M, IKUTA T, TAKAHASHI K. Visualization of horizontally-aligned single-walled carbon nanotube growth with 13C/12C isotopes[J]. J Phys Chem C,2008,112(6):1735−1738. doi: 10.1021/jp709737q [98] HUANG S M, WOODSON M, SMALLEY R, LIU J. Growth mechanism of oriented long single walled carbon nanotubes using "fast-heating" chemical vapor deposition process[J]. Nano Lett,2004,4(6):1025−1028. doi: 10.1021/nl049691d -

下载:

下载: