Research progress on electrocatalytic CO2 reduction over carbon-based single-atom catalysts

-

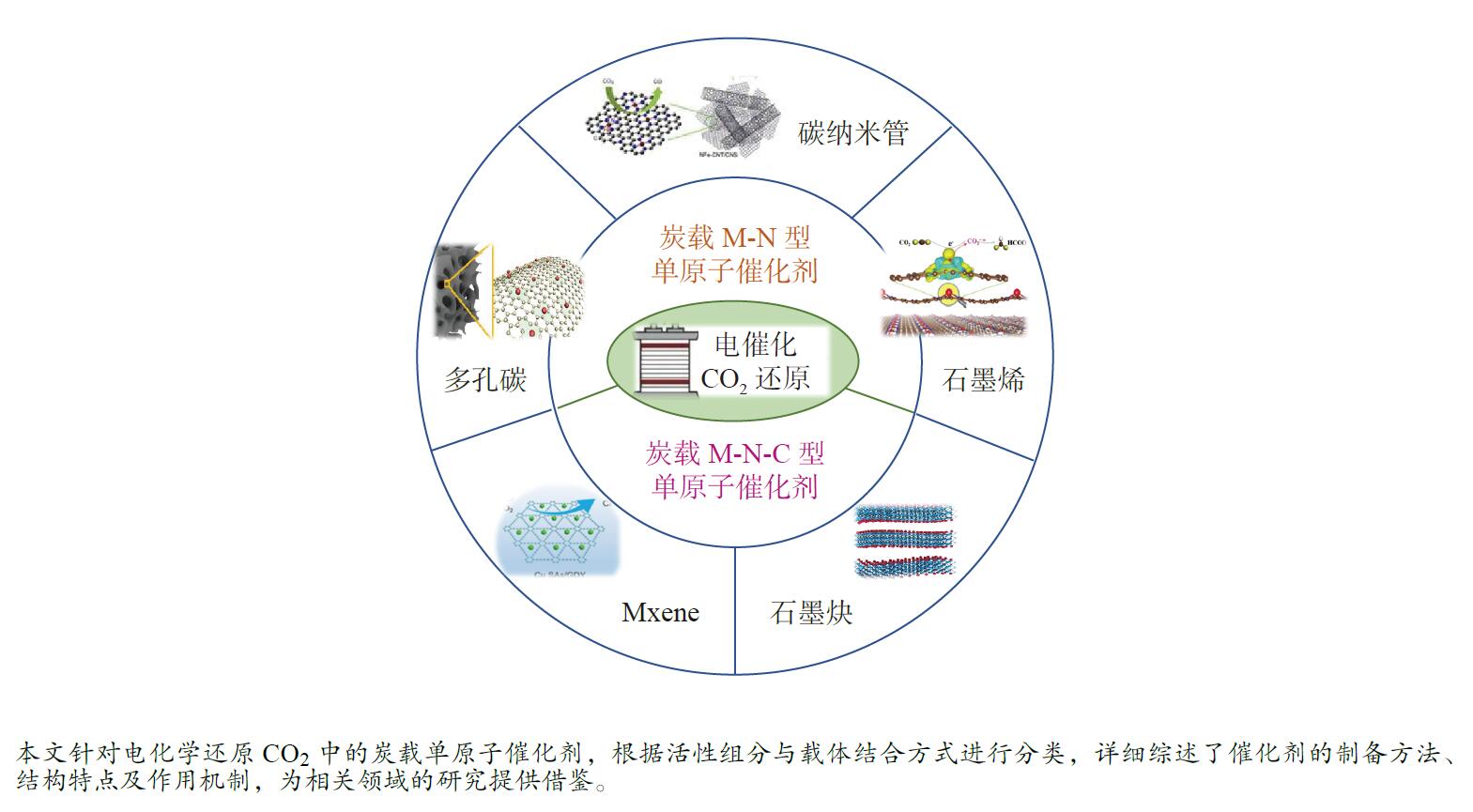

摘要: 电化学二氧化碳还原(Electrocatalytic CO2 Reduction,ECR)能够实现可再生能源的存储和利用,并将CO2转化为高值化学品,是“双碳”背景下重要的能源利用方式,经济和环境效益显著。高效催化剂是ECR过程的核心。单原子催化剂因具有理论上100%的活性组分原子利用率,是理想的ECR催化剂之一。炭材料兼具高比表面积和优异导电性等优点,是电催化的理想载体。本工作根据单原子活性中心与炭载体作用方式的不同进行分类,综述了近十年代表性炭材料负载的单原子催化剂制备、结构、性能以及在ECR反应过程中的作用机制,期望能够为相关领域的研究提供思路和借鉴。Abstract: Electrocatalytic CO2 reduction (Electrocatalytic CO2 Reduction, ECR) can realize the storage and utilization of renewable energy and convert CO2 into high-value chemicals. It is an important way of energy utilization under the background of "carbon peaking and carbon neutrality goals", with significant economic and environmental benefits. High efficiency catalyst is the core of ECR process. Single-atom catalysts are ideal for ECR because of the theoretical 100% utilization of active components. Carbon materials have the advantages of high surface area and excellent conductivity, which is quite suitable for electrocatalysis. Herein, by classifying according to the different interaction between the single atomic active center and the carbon support, we reviewed the preparation, structure, properties and action mechanism of single-atom catalysts supported on representative carbon materials in the past decade. We hope it would provide inspirations and ideas for the future investigations.

-

Key words:

- single-atom-catalyst /

- electrocatalysis /

- carbon dioxide reduction /

- carbon support

-

图 1 Ni SACs模型及结构表征[32]: (a) CO2RR模型Ni SACs的合成;(b) Ni-CNT-CC的FESEM照片(比例尺,200 nm);(c) Ni-CNT-CC的HAADF-STEM照片(比例尺,5 nm);(d) Ni K-edge XANES;插图显示了EXAFS光谱的傅里叶变换;(e) N K边X射线吸收光谱,其中峰A、B、C和D代表Ni-TAPc中吡啶氮和桥接氮的1s–π*跃迁;(f) Ni-CNT-CC和Ni-TAPc的紫外光发射光谱的第二电子截止区;插入图显示了相同光谱的更宽区域(hv=40 eV,功函数(WF)=hv (40 eV)−Ecut-off)

Figure 1 Structural characterization and the model of Ni SACs[32]: (a) Synthesis of model Ni SACs for the CO2RR, (b) FESEM image of Ni-CNT-CC (scale bar, 200 nm), (c) HAADF-STEM image of Ni-CNT-CC (scale bar, 5 nm), (d) Ni K-edge XANES; the inset displays a Fourier transform of the EXAFS spectra, (e) N K-edge X-ray absorption spectra, where peaks A, B, C, and D represent the 1s–π* transitions of pyrrolic and bridging aza nitrogen species in Ni-TAPc, (f) Second electron cut-off region of the ultraviolet photoemission spectra of Ni-CNT-CC and Ni-TAPc; the inset shows a wider region of the same spectra (hv=40 eV, work function (WF)=hv (40 eV)−Ecut-off) (with permission from Angewandte Chemie International Edition)

图 3 (a)左图为孔隙稀缺的石墨烯负载Fe-N4;右图为孔隙丰富的石墨烯负载Fe-N4[46];(b)为氮掺杂石墨烯上单原子Snδ + 的三维差分电荷密度图和CO2电还原成甲酸盐示意图(黄色和蓝色等值面分别对应电子数量的增加和耗竭区)[47];(c)为单原子FeN4和FeN5催化剂的合成路线[49]

Figure 3 (a) Schematic showing the electrocatalytic CO2 reduction behaviors on pore-deficient graphene bulk-supported Fe-N4 (the figure on the left) and pore-rich graphene-supported Fe-N4(the figure on the right)[46], (b) the figure is plots of 3D differential charge densities of the single-atom Snδ + on N-doped graphene and schematic illustration for CO2 electroreduction into formate (the yellow and blue isosurfaces correspond to the increase in the number of electrons and the depletion zone, respectively)[47], (c) synthetic route towards single-atom FeN4 and FeN5 catalysts[49] (with permission from ACS publications, Advanced Materials, and Angewandte Chemie International Edition)

图 4 (a) CO2电还原过程中N-C(橙色)、Mn-N-C(红色)、Fe-N-C(绿色)和FeMn-N-C(蓝色)催化剂的CH4法拉第选择性[55];(b) Mn-N-C和Fe-N-C上ECR的作用机理[55];(c) M-N-C电催化剂的合成方案[57];(d)从左到右依次为分别为N-C、Fe-N-C、Ni-N-C的TEM照片[59];(e) NPC和Cu-SA/NPC的LSV曲线[60];(f) Cu-SA/NPC上ECR产物的产率[60]

Figure 4 (a) CH4 faradaic selectivity of N-C (orange), Mn-N-C (red), Fe-N-C (green), and FeMn-N-C (blue) catalysts during CO2 electroreduction[55], (b) proposed mechanisms for the ECR on Mn-N-C and Fe-N-C[55], (c) protocol for the synthesis of M-N-C electrocatalysts[57], (d) from left to right are the epresentative TEM images of N-C, Fe-N-C and Ni-N-C catalysts[59], (e) LSV curves of NPC and Cu-SA/NPC[60], (f) production rate of ECR products on Cu-SA/NPC[60] (with permission from Angewandte Chemie International Edition and ACS publications)

图 5 (a) Ni SAs/N-C的Ni SAs/NS-C电催化剂中C、N、Ni、S元素的分布[61];(b) NPCA900的SEM照片(左)和NPCA900的TEM和HR-TEM照片(右)[62];(c) 用于电催化CO2还原的NiSA-Nx-C催化剂制造的主-客体合作保护策略[65];(d) In-SA/NC的制备流程示意图;(e) In-SA/NC的SEM照片;(f)In-SA/NC的TEM照片[66]

Figure 5 (a) Distribution of C, N, NI and S elements in Ni SAs/NS-C electrocatalysts of Ni SAs/N-C[61], (b)SEM images of NPCA900 (the figure of left), TEM and HR-TEM images of NPCA900 (the figure of right)[62], (c) Illustration showing the host-guest cooperative protection strategy for the fabrication of NiSA-Nx-C catalysts for electrocatalytic CO2 reduction[65], (d) Schematic illustration for the preparation of In-SAs/NC, (e) SEM, (f) TEM[66] (with permission from Angewandte Chemie International Edition)

图 6 (a)为Pt1/Ti3−xC2Ty催化苯胺N-甲酰化反应的回收试验[69];(b)第四周期过渡金属与Mo2CS2之间的能带以及和硫原子之间的键长[70];(c)、(d)、(e)为在U=0 V下,TM@Nb2NO2上ECR产生CH4的吉布斯自由能图,其中,红色路线为最有利反应途径[71];(f)为以化学式M3C2作高效催化剂在MXenes上发生ECR得到不同产物的可能机理途径,其中,红色路线为最有利反应途径[73]

Figure 6 (a) Recycling test of Pt1/Ti3–xC2Ty for the catalytic N-formylation of aniline[69], (b) Banding energy between TMs of the fourth period and Mo2CS2 and the bond length between TM and S atoms[70], (c), (d), (e) Gibbs free energy diagram for ECR on TM@Nb2NO2 to produce the final product CH4 under U = 0 V; the red pathway denotes the optimal pathway[71], (f) Proposed ECR possible mechanism pathways to different products on MXenes with the formula M3C2 as high efficiency catalysts; the red pathway denotes the optimal pathway[73] (with permission from ACS publications, Chemistry -A European Journal and Elsevier)

图 7 (a)为石墨炔负载Cu单原子ECR活性的两个影响因素[74];(b)为pyGY和TM-pyGYs的结构[76];(c)为Cu SAs/GDY的形成示意图[75]

Figure 7 (a) Two influencing factors of ECR of graphyne-supported Cu single atoms[74], (b) The structures of pyGY and TM-pyGYs[76], (c) Schematic illustration of the formation of Cu SAs/GDY[75] (with permission from Angewandte Chemie International Edition and RSC Publications)

表 1 单原子催化剂的制备方法及优缺点

Table 1 Common preparation methods advantages and disadvantages of SACs

Preparation method Description Advantages Disadvantages Mass-selected soft-landing method First, vaporizing the metal by high frequency laser evaporation source. Then the metal particle-supported catalysts with different sizes are obtained by mass spectrometer It can be used to prepare model catalyst and study reaction mechanism Its preparation conditions are harsh, high cost but low yield, difficult to scale Coprecipitation method Add precipitator to the aqueous solution of two or more metal cationic precursors to precipitate insoluble matter and then filter and roast It has simple conditions, easy operation, mature technology and is widely used There are many factors, such as the temperature and pH of precursor solution Atomic layer deposition It relates to a method for accurately and controllable coating a single atomic layer on the surface of a carrier It is convenient to study the synthesis and structure-effect relationship of supported monatomic catalysts It has poor stability, high costs and has not been commercialized High temperature pyrolysis method It uses the strong interaction between the metal and the carrier in high-temperature pyrolysis, Converting an oxide into a single atom and anchoring it It has good flexibility, wide selection of precursors and high yield The uniformity of coordination center structure and the synthesis process of nanoparticles at high temperature are difficult to control -

[1] LIU Z, DENG Z, DAVIS S, GIRON C, CIAIS P. Monitoring global carbon emissions in 2021[J]. Nat Rev Earth Environ,2022,3:217−219. [2] 胡鞍钢. 中国实现2030年前碳达峰目标及主要途径[J]. 北京工业大学学报(社会科学版),2021,21(3):1−15.HU An-gang. China's goal of achieving carbon peak by 2030 and its main approaches[J]. J Beijing Univ Technol(Soc Sci Ed),2021,21(3):1−15. [3] 邹才能, 何东博, 贾成业, 熊波, 赵群, 潘松圻. 世界能源转型内涵、路径及其对碳中和的意义[J]. 石油学报,2021,42(2):233−247.ZOU Cai-neng, HE Dong-bo, JIA Cheng-ye, XIONG Bo, ZHAO Qun, PAN Song-qi. Connotation and pathway of world energy transition and its significance for carbon neutral[J]. Acta Pet Sin,2021,42(2):233−247. [4] 周柒, 丁红蕾, 郭得通, 潘卫国, 杜威. CO2催化氢化制清洁能源的研究进展及趋势[J]. 化工学报,2020,71(8):3428−3443.ZHOU Qi, DING Hong-lei, GUO De-tong, PAN Wei-guo, DU Wei. Recent advances in catalytic methods of CO2 hydrogenation to clean energy[J]. CIESC J,2020,71(8):3428−3443. [5] ZHOU W, GUO J, SHEN S, PAN J, TANG J, CHEN L, AU C, YIN Shuang-feng. Progress in potoelectrocatalytic reduction of carbon dioxide[J]. Acta Phys-Chim Sin,2020,36(3):1906048. doi: 10.3866/PKU.WHXB201906048 [6] 任静, 谭玲, 赵宇飞, 宋宇飞. 超薄二维材料光/电催化CO2还原的最新进展[J]. 化工学报,2021,72(1):398−424.REN Jing, TAN Ling, ZHAO Yu-fei, SONG Yu-fei. Latest development of ultrathin two-dimensional materials for photocatalytic and electrocatalytic CO2 reduction[J]. CIESC J,2021,72(1):398−424. [7] YANG Y, ZHANG Y, HU J, WAN L. Progress in the mechanisms and materials for CO2 electroreduction toward C2+ products[J]. Acta Phys-Chim Sin,2020,36(1):1906085. doi: 10.3866/PKU.WHXB201906085 [8] NITOPI S, BERTHEUSSEN E, SCOTT S B, LIU X, ENGSTFELD A K, HORCH S, SEGER B, STEPHENS I E L, CHAN K, HAHN C, NØRSKOV J K, JARAMILLO T F, CHORKENDORFF I. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte[J]. Chem Rev,2019,119(12):7610−7672. doi: 10.1021/acs.chemrev.8b00705 [9] QIAO B, WANG A, YANG X, ALLARD L F, JIANG Z, CUI Y, LIU J, LI J, ZHANG T. Single-atom catalysis of CO oxidation using Pt1/FeOx[J]. Nat Chem,2011,3(8):634−641. doi: 10.1038/nchem.1095 [10] CHEN F, JIANG X, ZHANG L, LANG R, QIAO B. Single-atom catalysis: Bridging the homo-and heterogeneous catalysis[J]. Chin J Catal,2018,39:893−898. doi: 10.1016/S1872-2067(18)63047-5 [11] 崔新江, 石峰. 基于单原子催化剂的二氧化碳选择性转化[J]. 物理化学学报,2021,37(5):56−80.CUI Xin-jiang, SHI Feng. Selective conversion of CO2 by single-site catalysts[J]. Acta Phys-Chim Sin,2021,37(5):56−80. [12] LI J, ZHANG L, DOYLE DAVIS K, LI R, SUN X. Recent advances and strategies in the stabilization of single-atom catalysts for electrochemical applications[J]. Carbon Energy,2020,2(4):488−520. doi: 10.1002/cey2.74 [13] CHEN Y, JI S, CHEN C, PENG Q, WANG D, LI Y. Single-atom catalysts: Synthetic strategies and electrochemical applications[J]. Joule,2018,2(7):1242−1264. doi: 10.1016/j.joule.2018.06.019 [14] OU H, WANG D, LI Y. How to select effective electrocatalysts: Nano or single atom?[J]. Nano Sel,2021,2(3):492−511. doi: 10.1002/nano.202000239 [15] WU W, LEI W, WANG L, WANG S, ZHANG H. Preparation of single atom catalysts[J]. Prog Chem,2020,32(1):23−32. [16] ABBET S, SANCHEZ A, HEIZ U, SCHNEIDER W D, FERRARI A M, PACCHIONI G, RÖSCH N. Acetylene cyclotrimerization on supported size-selected Pdn clusters (1≤n≤30): one atom is enough![J]. J Am Chem Soc,2000,122(14):3453−3457. doi: 10.1021/ja9922476 [17] HE X, DENG Y, ZHANG Y, HE Q, XIAO D, PENG M, ZHAO Y, ZHANG H, LUO R, GAN T, JI H, MA D. Mechanochemical kilogram-scale synthesis of noble metal single-atom catalysts[J]. Cell Rep Phys Sci,2020,1(1):100004. doi: 10.1016/j.xcrp.2019.100004 [18] ZHANG M, LI X, YANG Y, LI T, LUO H, WEN L, QIN L. Multilayer self-assemblies for fabricating graphene-supported single-atomic metal via microwave-assisted emulsion micelle[J]. Small,2022,18(24):2201291. doi: 10.1002/smll.202201291 [19] HE Q, LIU D, LEE J H, LIU Y, XIE Z, HWANG S, KATTEL S, SONG L, CHEN J G. Electrochemical conversion of CO2 to syngas with controllable CO/H2 ratios over Co and Ni single-atom catalysts[J]. Angew Chem Int Ed,2020,59(8):3033−3037. doi: 10.1002/anie.201912719 [20] 竹涛, 韩一伟, 刘帅, 谢蔚, 苑博, 宋慧平, 程芳琴. 单原子位点催化剂及其电催化应用研究进展[J]. 化工进展,2022,41(2):666−681.ZHU Tao, HAN Yi-wei, LIU Shuai, XIE Wei, YUAN Bo, SONG Hui-ping, CHENG Fang-qin. Progress in electrocatalysis by single-atom site catalysts[J]. Prog Chem,2022,41(2):666−681. [21] WANG J, LI Z, WU Y, LI Y. Fabrication of single-atom catalysts with precise structure and high metal loading[J]. Adv Mater,2018,30(48):1801649. doi: 10.1002/adma.201801649 [22] 尹培群. 镍钴基电催化剂的制备及氧电极催化性能研究[D]. 合肥: 中国科学技术大学, 2017.YIN Pei-qun. Synthesis of Ni and Co-based electrocatalysts for oxygen electrodes[D]. Hefei: University of Science and Technology of China, 2017. [23] ASOKAN C, DERITA L, CHRISTOPHER P. Using probe molecule FTIR spectroscopy to identify and characterize Pt-group metal based single atom catalysts[J]. Chin J Catal,2017,38(9):1473−1480. doi: 10.1016/S1872-2067(17)62882-1 [24] YE S, LUO F, ZHANG Q, ZHANG P, XU T, WANG Q, HE D, GUO L, ZHANG Y, HE C, OUYANG X, GU M, LIU J, SUN X. Highly stable single Pt atomic sites anchored on aniline-stacked graphene for hydrogen evolution reaction[J]. Energy Environ Sci,2019,12(3):1000−1007. [25] 彭小明, 吴健群, 戴红玲, 杨展宏, 许莉, 许高平, 胡锋平. Ni-N-C单原子催化剂活化过硫酸盐降解苯酚[J]. 高等学校化学学报,2021,42(8):2581−2591.PENG Xiao-ming, WU Jian-qun, DAI Hong-ling, YANG Zhan-hong, XU Li, XU Gao-ping, HU Feng-ping. Activation of peroxymonosulfate by single atom catalysts Ni-N-C for high efficiency degradation of phenol[J]. Chem Res Chin Univ,2021,42(8):2581−2591. [26] GUO Y, MEI S, YUAN K, WANG D, LIU H, YAN C, ZHANG Y. Low-temperature CO2 methanation over CeO2-supported Ru single atoms, nanoclusters, and nanoparticles competitively tuned by strong metal-support interactions and H-spillover effect[J]. ACS Catal,2018,8(7):6203−6215. doi: 10.1021/acscatal.7b04469 [27] LI J, CHEN M, CULLEN D A, HWANG S, WANG M, LI B, LIU K, KARAKALOS S, LUCERO M, ZHANG H, LEI C, XU H, STERBINSKY G E, FENG Z, SU D, MORE K L, WANG G, WANG Z, WU G. Atomically dispersed manganese catalysts for oxygen reduction in proton-exchange membrane fuel cells[J]. Nat Catal,2018,1(12):935−945. doi: 10.1038/s41929-018-0164-8 [28] ZHANG H, HWANG S, WANG M, FENG Z, KARAKALOS S, LUO L, QIAO Z, XIE X, WANG C, SU D, SHAO Y, WU G. Single atomic iron catalysts for oxygen reduction in acidic media: particle size control and thermal activation[J]. J Am Chem Soc,2017,139(40):14143−14149. doi: 10.1021/jacs.7b06514 [29] 王成雄, 冯丰, 潘再富, 杨冬霞, 常仕英, 赵云昆. 铂族金属单原子催化剂的制备、表征技术研究进展[J]. 贵金属,2019,40(1):88−97.WANG Cheng-xiong, FENG Feng, PAN Zai-fu, YANG Dong-xia, CHANG Shi-ying, ZHAO Yun-kun. Research progress in preparation and characterization techniques of Pt-group metal based single-atom catalysts[J]. Precious Met,2019,40(1):88−97. [30] 靳永勇, 郝盼盼, 任军, 李忠. 单原子催化——概念、方法与应用[J]. 化学进展, 2015, 27(12): 1689-1704.JIN Yong-yong, HAO Pan-pan, REN Jun, LI Zhong. Single atom catalysis: Concept, method and application[J]. Prog Chem, 2015, 27(12): 1689-1704. [31] GONG L, ZHANG D, LIN C Y, ZHU Y, SHEN Y, ZHANG J, HAN X, ZHANG L, XIA Z. Catalytic mechanisms and design principles for single-atom catalysts in highly efficient CO2 conversion[J]. Adv Energy Mater,2019,9(44):1902625. doi: 10.1002/aenm.201902625 [32] LIU S, YANG H B, HUNG S F, DING J, CAI W, LIU L, GAO J, LI X, REN X, KUANG Z, HUANG Y, ZHANG T, LIU B. Elucidating the electrocatalytic CO2 reduction reaction over a model single-atom nickel catalyst[J]. Angew Chem Int Ed,2020,59(2):798−803. doi: 10.1002/anie.201911995 [33] ZHAO D, YU K, SONG P, FENG W, HU B, CHEONG W M, ZHUANG Z, LIU S, SUN K, ZHANG J, CHEN C. Atomic-level engineering Fe1N2O2 interfacial structure derived from oxygen-abundant metal–organic frameworks to promote electrochemical CO2 reduction[J]. Energy Environ Sci,2022,15(9):3795−3804. [34] ZHANG Z, ZHU Y, ASAKURA H, ZHANG B, ZHANG J, ZHOU M, HAN Y, TANAKA T, WANG A, ZHANG T, YAN N. Thermally stable single atom Pt/m-Al2O3 for selective hydrogenation and CO oxidation[J]. Nat Commun,2017,8(1):16100. doi: 10.1038/ncomms16100 [35] LI J, STEPHANOPOULOS M F, XIA Y. Introduction: Heterogeneous single-atom catalysis[J]. Chem Rev,2020,120(21):11699−11702. doi: 10.1021/acs.chemrev.0c01097 [36] 张凤翔. 碳基二维材料的电磁学及动力学性质研究[D]. 济南: 齐鲁工业大学, 2022.ZHANG Feng-xiang. Study of electro-magnetic and kinetic properties for carbon-based two-dimensional materials[D]. Jinan: Qilu University of Technology, 2022. [37] 李晓怡. 碳基铜单原子催化剂的制备及其催化性能研究[D]. 广州: 广东工业大学, 2022.Li Xiao-yi. Preparation and catalytic properties of carbon-based copper single-atom catalysts[D]. Guangzhou:Guangdong University of Technology, 2022. [38] 朱成玉, 叶幼文, 郭霞, 程菲. 不同维度碳基纳米材料的设计与合成及其在电化学储能中的应用[J]. 新型炭材料,2022,37(1):59−92. doi: 10.1016/S1872-5805(22)60579-1ZHU Cheng-yu, YE You-wen, GUO Xia, CHENG Fei. Design and synthesis of carbon-based nanomaterials for electrochemical energy storage[J]. New Res Carbon Mater,2022,37(1):59−92. doi: 10.1016/S1872-5805(22)60579-1 [39] 贺雷, 张向倩, 陆安慧. 二维炭基多孔材料的合成及应用[J]. 物理化学学报,2017,33(4):709−728. doi: 10.3866/PKU.WHXB201612201HE Lei, ZHANG Xiang-qian, LU An-hui. Two-dimensional carbon-based porous materials: Synthesis and applications[J]. Acta Phys-Chim Sin,2017,33(4):709−728. doi: 10.3866/PKU.WHXB201612201 [40] 吴诗德, 易峰, 平丹, 张逸飞, 郝健, 刘国际, 方少明. NH4Cl辅助热解制备镍-氮-碳纳米管催化剂及其电还原CO2性能[J]. 化工学报,2022,73(10):4484−4497.WU Shi-de, YI Feng, PING Dan, ZHANG Yi-Fei, HAO Jian, LIU Guo-Ji, FANG Shao-Ming. NH4Cl assisted preparation of Ni-N-CNTs catalyst and its performance for electrochemical CO2 reduction[J]. CIESC J,2022,73(10):4484−4497. [41] PAN F, ZHAO H, DENG W, FENG X, LI Y. A novel N, Fe-Decorated carbon nanotube/carbon nanosheet architecture for efficient CO2 reduction[J]. Electrochim. Acta,2018,273:154−161. doi: 10.1016/j.electacta.2018.04.047 [42] WU S, LV X, PING D, ZHANG G, WANG S, WANG H, YANG X, GUO D, FANG S. Highly exposed atomic Fe-N active sites within carbon nanorods towards electrocatalytic reduction of CO2 to CO[J]. Electrochim Acta,2020,340:135930. doi: 10.1016/j.electacta.2020.135930 [43] 赵润瑶, 纪桂鹏, 刘志敏. 吡咯氮配位单原子铜催化剂的电催化二氧化碳还原性能[J]. 高等学校化学学报, 2022, 43(7): 189−195.ZHAO Run-yao, JI Gui-peng, LIU Zhi-min. Efficient electrocatalytic CO2 reduction over pyrrole nitrogen-coordinated single-atom copper catalysts[J]. Chem Res Chin Univ, 2022, 43(7): 189−195. [44] ZHANG H, WANG H, JIA S, CHANG Q, LI N, LI Y, SHI X, LI Z, HU S. CoN4 active sites in a graphene matrix for the highly efficient electrocatalysis of CO2 reduction[J]. New Carbon Mater,2022,37(4):734−742. doi: 10.1016/S1872-5805(21)60061-6 [45] 刘灵惠. 单原子催化剂的制备、表征及电催化性能研究[D]. 重庆: 重庆大学, 2021.LIU Ling-hui. Preparation, Characterization and electro-catalytic properties of single-atom catalysts[D]. Chongqing: Chongqing University, 2021. [46] PAN F, LI B, SARNELLO E, FEI Y, FENG X, GANG Y, XIANG X, FANG L, LI T, HU Y H, WANG G, LI Y. Pore-edge tailoring of single-atom iron-nitrogen sites on graphene for enhanced CO2 reduction[J]. ACS Catal,2020,10(19):10803−10811. doi: 10.1021/acscatal.0c02499 [47] ZU X, LI X, LIU W, SUN Y, XU J, YAO T, YAN W, GAO S, WANG C, WEI S, XIE Y. Efficient and robust carbon dioxide electroreduction enabled by atomically dispersed Snδ+ sites[J]. Adv Mater,2019,31(15):1808135. doi: 10.1002/adma.201808135 [48] 杜亚东. 碳基CO2电还原催化剂的设计构筑及其性能研究[D]. 北京: 北京化工大学, 2021.DU Ya-dong. Theoretical study on modified carbon-based single atom catalysts for electrocatalytic carbon dioxide reduction[D]. Beijing: Beijing University of Chemical Technology, 2021. [49] ZHANG H, LI J, XI S, DU Y, HAI X, WANG J, XU H, WU G, ZHANG J, LU J, WANG J. A graphene-supported single-atom FeN5 catalytic site for efficient electrochemical CO2 reduction[J]. Angew Chem Int Ed,2019,131(42):15013−15018. [50] GUO C, LI Y, XU Y, XIANG Q, SUN L, ZHANG W, LI W, SI Y, LUO Z. A highly nanoporous nitrogen-doped carbon microfiber derived from bioresource as a new kind of ORR electrocatalyst[J]. Nanoscale Res Lett, 2019, 14(1). [51] 吴晓雪, 齐妍妍, 王盈懿, 王丽, 涂高美, 傅仰河, 陈德利, 朱伟东, 张富民. 钒氮共掺杂多孔碳催化剂上苄胺氧化偶联合成亚胺[J]. 无机化学学报,2022,38(6):1049−1058.WU Xiao-xue, QI Yan-yan, WANG Ying-yi, WANG Li, TU Gao-mei, FU Yang-he, CHEN De-li , ZHU Wei-dong, ZHANG Fu-min. Synthesis of amines by oxidative coupling of benzylamine over a vanadium-nitrogen Co-doped porous carbon catalyst[J]. Chin J Inorg Chem,2022,38(6):1049−1058. [52] HUANG K, ZHANG W, LI J, FAN Y, YANG B, RONG C, QI J, CHEN W, YANG J. In situ anchoring of zeolite imidazole framework-derived Co, N-doped porous carbon on multiwalled carbon nanotubes toward efficient electrocatalytic oxygen reduction[J]. ACS Sustainable Chem Eng,2020,8(1):478−485. [53] BISEN O Y, NANDAN R, YADAV A K, PAVITHRA B, KAR NANDA K. In situ self-organization of uniformly dispersed Co-N-C centers at moderate temperature without a sacrificial subsidiary metal[J]. Green Chem,2021,23(8):3115−3126. [54] HU X, DONG L, REN Y, LI W, OSCHATZ M, HAO G, LU A. Surface polarity induced simultaneous enhancement of nanopore accessibility and metal utilization in metal and nitrogen Co-doped carbon electrocatalysts for CO2 reduction[J]. ACS Appl Nano Mater, 2023, 6(11): 9495−9505. [55] VARELA A S, RANJBAR SAHRAIE N, STEINBERG J, JU W, OH H, STRASSER P. Metal-doped nitrogenated carbon as an efficient catalyst for direct CO2 electroreduction to CO and hydrocarbons[J]. Angew Chem Int Ed,2015,127(37):10908−10912. [56] 朱红林, 李文英, 黎挺挺, MICHAEL BAITINGER, JURI GRIN, 郑岳青. CO2电还原用氮掺杂碳基过渡金属单原子催化剂[J]. 化学进展,2019,31(7):939−953.ZHU Hong-lin, LI Wen-ying, LI Ting-ting, BAITINGER M, GRIN J, ZHENG Yue-qing. N-doped porous carbon supported transition metal single atomic catalysts for CO2 electroreduction reaction[J]. Prog Chem,2019,31(7):939−953. [57] HU X, HVAL H H, BJERGLUND E T, DALGAARD K J, MADSEN M R, POHL M, WELTER E, LAMAGNI P, BUHL K B, BREMHOLM M, BELLER M, PEDERSEN S U, SKRYDSTRUP T, DAASBJERG K. Selective CO2 reduction to CO in water using earth-abundant metal and nitrogen-doped carbon electrocatalysts[J]. ACS Catal,2018,8(7):6255−6264. doi: 10.1021/acscatal.8b01022 [58] YE L, YING Y, SUN D, ZHANG Z, FEI L, WEN Z, QIAO J, HUANG H. Highly efficient porous carbon electrocatalyst with controllable N-Species content for selective CO2 reduction[J]. Angew Chem Int Ed,2020,132(8):3270−3277. [59] MÖLLER T, JU W, BAGGER A, WANG X, LUO F, NGO THANH T, VARELA A S, ROSSMEISL J, STRASSER P. Efficient CO2 to CO electrolysis on solid Ni-N-C catalysts at industrial current densities[J]. Energy Environ Sci,2019,12(2):640−647. [60] ZHAO K, NIE X, WANG H, CHEN S, QUAN X, YU H, CHOI W, ZHANG G, KIM B, CHEN J G. Selective electroreduction of CO2 to acetone by single copper atoms anchored on N-doped porous carbon[J]. Nat Commun, 2020, 11(1): 2455. [61] 冯丽芳. 单原子催化位点调控及其电催化还原CO2性能研究[D]. 南昌: 南昌航空大学, 2021.FENG Li-fang. Study on the adjusting of single atom site and its electrocatalytic CO2 reduction activity[D]. Nanchang: Nanchang Hangkong University, 2021. [62] CHEN C, SUN X, YAN X, WU Y, LIU H, ZHU Q, BEDIAKO B B A, HAN B. Boosting CO2 electroreduction on N,P-Co-doped carbon aerogels[J]. Angew Chem Int Ed,2020,59(27):11123−11129. doi: 10.1002/anie.202004226 [63] 甘礼华, 李光明, 朱大章, 岳天仪, 陈龙武. 碳气凝胶的制备研究[J]. 高等学校化学学报,2000,21(6):955−957.GAN Li-hua, LI Guang-ming, ZHU Da-zhang, YUE Tian-yi, CHEN Long-wei. Studies on preparation of carbon aerogels[J]. Chem Res Chin Univ,2000,21(6):955−957. [64] LI H, EDDAOUDI M, O'KEEFFE M, YAGHI O M. Design and synthesis of an exceptionally stable and highly porous metal-organic framework[J]. Nature,1999,402(6759):276−279. doi: 10.1038/46248 [65] GONG Y N, JIAO L, QIAN Y, PAN C Y, ZHENG L, CAI X, LIU B, YU S H, JIANG H L. Regulating the coordination environment of MOF-templated single-atom nickel electrocatalysts for boosting CO2 reduction[J]. Angew Chem Int Ed,2020,132(7):2727−2731. [66] SHANG H, WANG T, PEI J, JIANG Z, ZHOU D, WANG Y, LI H, DONG J, ZHUANG Z, CHEN W, WANG D, ZHANG J, LI Y. Design of a single-atom indiumδ+-N4 interface for efficient electroreduction of CO2 to formate[J]. Angew Chem Int Ed,2020,59(50):22465−22469. doi: 10.1002/anie.202010903 [67] NAGUIB M, MOCHALIN V N, BARSOUM M W, GOGOTSI Y. 25th anniversary article: MXenes: a new family of two-dimensional materials[J]. Adv Mater,2014,26(7):992−1005. doi: 10.1002/adma.201304138 [68] ZHANG X, LEI J, WU D, ZHAO X, JING Y, ZHOU Z. A Ti-anchored Ti2 CO2 monolayer (MXene) as a single-atom catalyst for CO oxidation[J]. J Mater Chem A,2016,4(13):4871−4876. doi: 10.1039/C6TA00554C [69] ZHAO D, CHEN Z, YANG W, LIU S, ZHANG X, YU Y, CHEONG W, ZHENG L, REN F, YING G, CAO X, WANG D, PENG Q, WANG G, CHEN C. MXene (Ti3C2) vacancy-confined single-atom catalyst for efficient functionalization of CO2[J]. J Am Chem Soc,2019,141(9):4086−4093. doi: 10.1021/jacs.8b13579 [70] LI N, WANG X, LU X, ZHANG P, ONG W J. Comprehensive mechanism of CO2 electroreduction on non-noble metal single-atom catalysts of Mo2CS2‐MXene[J]. Chem-Eur J,2021,27(71):17900−17909. doi: 10.1002/chem.202103218 [71] LU S, ZHANG Y, LOU F, YU Z. Theoretical study of single transition metal atom catalysts supported on two-dimensional Nb2NO2 for efficient electrochemical CO2 reduction to CH4[J]. J CO2 Util,2022,62:102069. doi: 10.1016/j.jcou.2022.102069 [72] LI N, PENG J, SHI Z, ZHANG P, LI X. Charge transfer and orbital reconstruction of non‐noble transition metal single-atoms anchored on Ti2CTx-MXenes for highly selective CO2 electrochemical reduction[J]. Chin J Catal,2022,43:1906−1917. doi: 10.1016/S1872-2067(21)64018-4 [73] XIAO Y, ZHANG W. High throughput screening of M3C2 MXenes for efficient CO2 reduction conversion into hydrocarbon fuels[J]. Nanoscale,2020,12(14):7660−7673. doi: 10.1039/C9NR10598K [74] NI Y, MIAO L, WANG J, LIU J, YUAN M, CHEN J. Pore size effect of graphyne supports on CO2 electrocatalytic activity of Cu single atoms[J]. Phys Chem Chem Phys,2020,22(3):1181−1186. doi: 10.1039/C9CP05624F [75] SHI G, XIE Y, DU L, FU X, CHEN X, XIE W, LU T B, YUAN M, WANG M. Constructing Cu−C bonds in a graphdiyne-regulated Cu single-atom electrocatalyst for CO2 reduction to CH4[J]. Angew Chem Int Ed, 2022, 134(23). [76] WANG M, KONG L, LU X, LAWRENCE WU C. First-row transition metal embedded pyrazine-based graphynes as high-performance single atom catalysts for the CO2 reduction reaction[J]. J Mater Chem A,2022,10(16):9048−9058. doi: 10.1039/D2TA00654E -

下载:

下载: