Influence mechanism of Ca-Fe flux on fusibility and crystallization behavior of coal fly ash

-

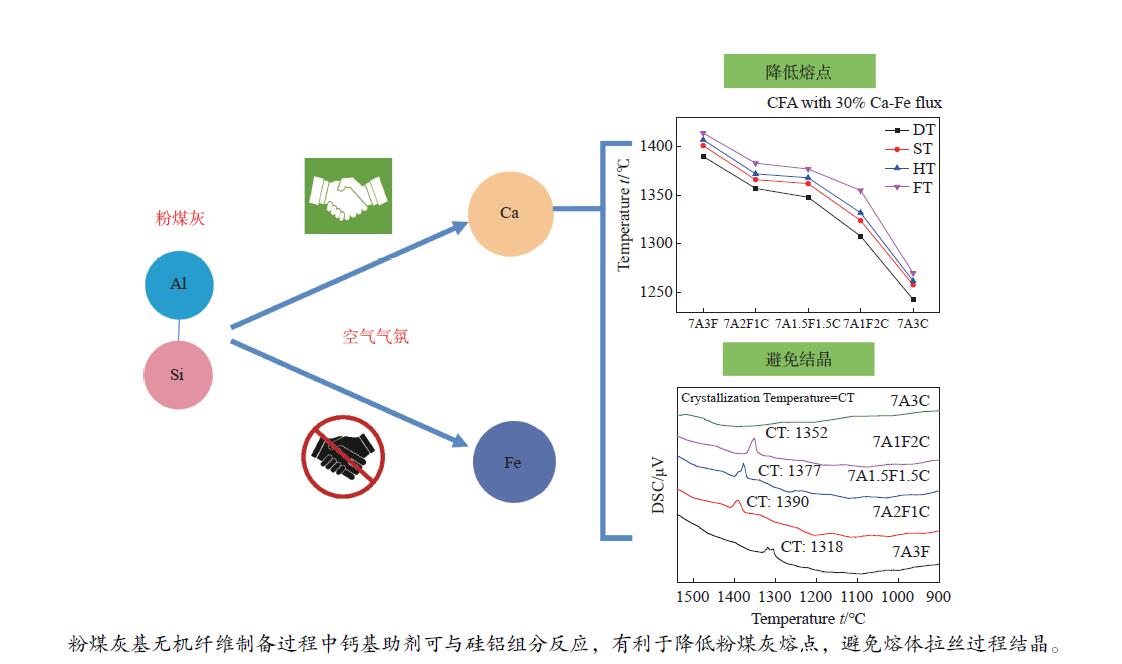

摘要: 利用粉煤灰制备高强度无机纤维是实现其高值化利用的重要路径,由于粉煤灰硅铝含量较高,可通过添加钙铁助剂降低均质化过程中原料熔融温度,避免降温拉丝过程中结晶行为。本工作研究了空气气氛下不同含量及比例钙铁助剂对煤灰熔融性及结晶行为的影响机理。结果表明,空气气氛下氧化钙(CaO)与氧化铁(Fe2O3)不存在协同助熔效果,CaO的助熔效果优于Fe2O3。高温下Fe2O3未与硅铝组分生成低熔点矿物,而添加CaO有利于将难熔的莫来石转化为钙长石,使得粉煤灰熔点大幅度降低;然而,当CaO添加量超过30%时,生成了大量的钙黄长石,使得粉煤灰熔点迅速升高。降温过程中,铁元素以赤铁矿形式析出,析晶温度相对较低;而钙元素以钙长石形式析出,析晶温度相对较高,不利于无机纤维制备过程中纺丝操作。当CaO含量为32.46%时,粉煤灰熔点最低,且降温过程中无晶体析出,因此,在粉煤灰基无机纤维制备过程中应选择钙基助剂调控熔融性和结晶行为。Abstract: The preparation of high-strength inorganic fibers by coal fly ash is an important method to achieve its high-value utilization. Due to high content of SiO2 and Al2O3 in coal fly ash, it is necessary that Ca-Fe flux should be added to decrease melting temperature of coal fly ash during homogenization of slag and avoid crystallization behavior during preparation of fibers. In this paper, the influence mechanism of Ca-Fe flux on the fusibility and crystallization behavior of coal fly ash under air atmosphere was investigated. The results show that calcium oxide (CaO) and iron oxide (Fe2O3) does not show synergistic fluxing effect on fusibility of coal fly ash under air atmosphere, moreover, the fluxing effect of CaO on fusibility is more obvious than that of Fe2O3. At high temperature, Fe2O3 cannot react with silicon-aluminum components to form low melting point minerals, while CaO is beneficial to transform refractory mullite into anorthite, which greatly reduces the melting point of fly ash. However, excess CaO (>30%) leads to formation of calcium feldspar, which increases melting point of fly ash obviously. During the cooling process, iron precipitates in the form of hematite while calcium precipitates in the form of anorthite, and the crystallization temperature of hematite is lower than that of anorthite. When content of CaO is 32.46%, the melting point of coal fly ash is the lowest, and there is no crystallization during the cooling process. Therefore, CaO is suitable to adjust fusibility and crystallization behavior of coal fly ash during preparation of inorganic fiber.

-

Key words:

- coal fly ash /

- inorganic fiber /

- Ca-Fe flux /

- ash fusion temperature /

- crystallization

-

表 1 粉煤灰化学组成

Table 1 Chemical composition of coal fly ash

Sample Chemical composition w/% SiO2 Al2O3 Fe2O3 CaO TiO2 K2O SO3 MgO Na2O P2O5 CFA 50.10 39.00 3.62 2.46 1.35 0.87 0.63 0.53 0.31 0.29 -

[1] 刘梦茹, 杨亚东, 杨素洁, 等. 粉煤灰资源综合利用现状研究[J]. 化工矿物与加工,2021,50(4):45−48. doi: 10.16283/j.cnki.hgkwyjg.2021.04.010LIU Mengru, YANG Yadong, YANG Sujie, et al. Study on status of comprehensive utilization of fly ash[J]. Ind Min Process,2021,50(4):45−48. doi: 10.16283/j.cnki.hgkwyjg.2021.04.010 [2] 关于“十四五”大宗固体废弃物综合利用的指导意见[J]. 再生资源与循环经济, 2021, 14(4): 1−3.Guiding Opinions on the Comprehensive Utilization of Bulk Solid Waste during the 14th Five Year Plan[J]. Recycl Res, 2021, 14(4): 1−3. [3] BLISSETT RS, ROWSON NA. A review of the multi-component utilisation of coal fly ash[J]. Fuel,2012,97:1−23. doi: 10.1016/j.fuel.2012.03.024 [4] YAO Z, JI X, SARKER PK, et al. A comprehensive review on the applications of coal fly ash[J]. Earth-Sci Rev,2015,141:105−121. doi: 10.1016/j.earscirev.2014.11.016 [5] ZHANG J, WEN X, CHENG F. Preparation, thermal stability and mechanical properties of inorganic continuous fibers produced from fly ash and magnesium slag[J]. Waste Manag,2021,120:156−163. doi: 10.1016/j.wasman.2020.11.021 [6] MA Z, TIAN X, LIAO H, et al. Improvement of fly ash fusion characteristics by adding metallurgical slag at high temperature for production of continuous fiber[J]. J Clean Prod,2018,171:464−481. doi: 10.1016/j.jclepro.2017.10.031 [7] 张金才, 王志英, 程芳琴. 固废基无机纤维的研究进展[J]. 材料导报,2021,35(7):7019−7026. doi: 10.11896/cldb.20060263ZHANG Jincai, WANG Zhiying, CHENG Fangqin. Progress on the study of solid waste based inorganic fibers[J]. Mater Rep,2021,35(7):7019−7026. doi: 10.11896/cldb.20060263 [8] WANG S, ZHANG C, CHEN J. Utilization of coal fly ash for the production of glass-ceramics with unique performances: A brief review[J]. J Mater Sci Technol,2014,30(12):1208−1212. doi: 10.1016/j.jmst.2014.10.005 [9] 宋平, 高欢, 汪灵, 等. 玄武岩纤维基本特征及应用前景分析[J]. 矿产保护与利用,2022,42(4):173−178. doi: 10.13779/j.cnki.issn1001-0076.2022.01.041SONG Ping, GAO Huan, WANG Ling, et al. Basic characteristics and application prospect analysis of basalt fiber[J]. Conserv Utili Min Res,2022,42(4):173−178. doi: 10.13779/j.cnki.issn1001-0076.2022.01.041 [10] KONG L, BAI J, LI W. Viscosity-temperature property of coal ash slag at the condition of entrained flow gasification: A review[J]. Fuel Process Technol,2021,215:106751. doi: 10.1016/j.fuproc.2021.106751 [11] SHI W, BAI J, KONG L, et al. An overview of the coal ash transition process from solid to slag[J]. Fuel,2021,287:119537. doi: 10.1016/j.fuel.2020.119537 [12] KRISHNAMOORTHY V, PISUPATI S. A critical review of mineral matter related issues during gasification of coal in fixed, fluidized, and entrained flow gasifiers[J]. Energies,2015,8(9):10430−10463. doi: 10.3390/en80910430 [13] 胡晓飞, 郭庆华, 刘霞, 等. 高钙高铁煤灰熔融及黏温特性研究[J]. 燃料化学学报,2016,44(7):769−776.HU Xiaofei, GUO Qinghua, LIU Xia, et al. Ash fusion and viscosity behavior of coal ash with high content of Fe and Ca[J]. J Fuel Chem Technol,2016,44(7):769−776. [14] SHI W, KONG L, BAI J, et al. Effect of CaO/Fe2O3 on fusion behaviors of coal ash at high temperatures[J]. Fuel Process Technol,2018,181:18−24. doi: 10.1016/j.fuproc.2018.09.007 [15] WANG Q, DING Y, RANDL N. Investigation on the alkali resistance of basalt fiber and its textile in different alkaline environments[J]. Constr Build Mater,2021,272:121670. doi: 10.1016/j.conbuildmat.2020.121670 [16] 许洁, 刘霞, 李德侠, 等. 煤灰流动温度预测模型的研究[J]. 燃料化学学报,2012,40(12):1415−1421.XU Jie, LIU Xia, LI Dexia, et al. Prediction model for flow temperature of coal ash[J]. J Fuel Chem Technol,2012,40(12):1415−1421. [17] 石文举, 白进, 孔令学, 等. 不同气氛下Ca-Fe二元助剂改变高硅铝煤灰熔融温度的规律和机制[J]. 化工学报,2022,73(10):4638−4647.SHI Wenju, BAI Jin, KONG Lingxue, et al. The variety regulation and mechanism of high silica and alumina coal ash fusion temperature caused by Ca-Fe binary flux under different atmosphere[J]. CIESC J,2022,73(10):4638−4647. [18] SHI W, DAI X, BAI J, et al. A new method of estimating the liquidus temperature of coal ash slag using ash composition[J]. Chem Eng Sci,2018,175:278−285. doi: 10.1016/j.ces.2017.10.002 [19] SONG W, TANG L, ZHU X, et al. Effect of coal ash composition on ash fusion temperatures[J]. Energy Fuels,2010,24(1):182−189. doi: 10.1021/ef900537m [20] HE C, BAI J, LI W, et al. Iron transformation behavior in coal ash slag in the entrained flow gasifier and the application for Yanzhou coal[J]. Fuel,2019,237:851−859. doi: 10.1016/j.fuel.2018.09.134 [21] ZHANG J, XU X, CHENG F, et al. Study progress on inorganic fibers from industry solid wastes and the key factors determining their characteristics[J]. Materials,2022,15(20):7256. doi: 10.3390/ma15207256 -

下载:

下载: