Effects of oxidative torrefaction on biomass gasification and alkali metal release and transformation characteristics

-

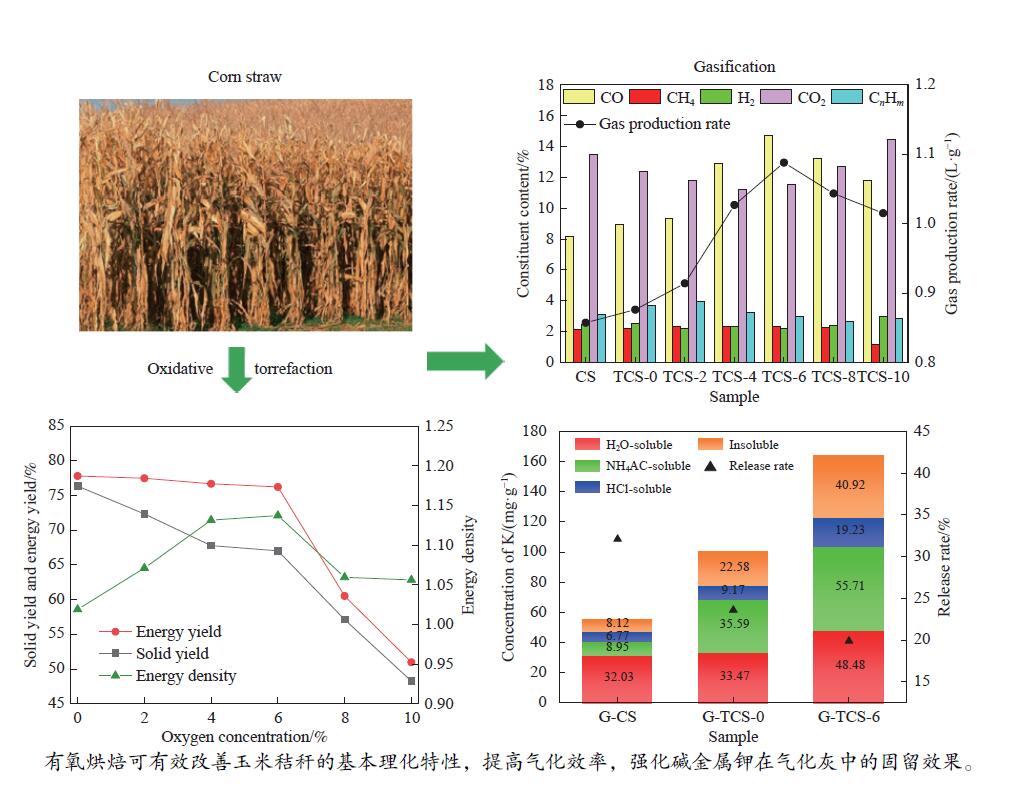

摘要: 本工作研究了有氧烘焙对玉米秸秆组成成分、烘焙产率、化学结构及微观结构等理化特性及气化特性的影响,同时考察了玉米秸秆烘焙及气化过程中碱金属的迁移转化规律。结果表明,烘焙可有效提高玉米秸秆中固定碳含量,降低H/C、O/C。相较于惰性烘焙,有氧烘焙具有更好的提质效果,结合H/C、O/C、质量产率和能量产率发现,氧气体积分数为6%时较合适。烘焙玉米秸秆气化气中CO含量、气体产率及热值随烘焙气氛中氧气含量的增加呈先上升后下降的趋势,在氧气体积分数为6%时气化品质相对较好,此时气体组分中CO体积分数为14.73%、气体产率达到1.09 L/g、气体热值达到4.93 MJ/m3。烘焙过程中碱金属在玉米秸秆中富集,并促进部分水溶态钾向醋酸铵溶态钾转化,有助于气化过程中生成更多不溶态钾,且有氧烘焙促进作用更明显。研究结果可为生物质有氧烘焙提质及气化产气的技术推广提供基础数据及技术支持。Abstract: The effects of oxidative torrefaction on the basic physicochemical, such as composition, torrefaction yield, chemical structure, and microstructure, and gasification properties of corn straw, were studied. The release and transformation of alkali metals during torrefaction and gasification of corn straw were also investigated. The results show that torrefaction can increase the fixed carbon content in corn straw effectively and decrease the values of H/C and O/C. Compared with inert atmosphere torrefaction, oxidative torrefaction has better quality improvement effects, and the best roasting atmosphere is 6% oxygen concentration. Combining H/C, O/C, mass yield and energy yield, it is found that the oxygen concentration of 6% during torrefaction is suitable. The concentration of CO, gas production rate, and gas calorific value of torrefied corn straw increased first and then decreased with the increase of oxygen concentration in the torrefaction atmosphere during gasification. The gasification characteristics were optimal at 6% oxygen concentration, with CO content of 14.73%, gas production rate of 1.09 L/g, and gas calorific value of 4.93 MJ/m3. The alkali metals were enriched in the corn straw during the torrefaction process. The conversion from water-soluble K to ion-exchanged K was also promoted, which helped produce more insoluble K in the gasification process. The oxidative torrefaction promoted the effect more pronounced. The results of the study can provide essential data and technical support for the technological promotion of oxidative torrefaction and gasification of biomass.

-

Key words:

- biomass /

- oxidative torrefaction /

- gasification /

- alkali metals

-

表 1 玉米秸秆的物性参数

Table 1 Physical parameters of corn straw

Sample Proximate analysis wad/% Ultimate analysis w/% QHHV/(MJ·kg−1) Va Aa FCa Ma C H N O* CS 79.19 2.92 8.35 9.54 47.99 6.67 0.98 44.36 17.30 TCS-0 75.99 3.89 16.62 3.50 51.32 5.65 0.99 42.04 19.90 TCS-2 73.68 4.03 18.23 4.06 53.16 5.80 0.79 40.25 19.94 TCS-4 65.88 4.43 25.49 4.20 54.77 5.40 1.29 38.54 21.26 TCS-6 67.51 4.65 24.23 3.61 55.82 5.24 1.59 37.36 22.15 TCS-8 73.41 5.17 17.84 3.58 52.38 5.14 0.89 41.59 21.40 TCS-10 75.43 5.49 15.71 3.37 51.37 4.72 0.32 43.58 20.16 O*: calculated by difference. 表 2 玉米秸秆组成成分

Table 2 Composition content of corn straw

Sample Content/% hemicelluloses cellulose lignin CS 23.95 35.88 25.35 TCS-0 18.01 33.66 25.10 TCS-2 16.12 32.71 23.98 TCS-4 14.46 31.52 24.33 TCS-6 13.07 31.95 24.78 TCS-8 11.33 29.4 25.04 TCS-10 10.92 28.27 24.69 -

[1] 黄晟, 王静宇, 郭沛, 等. 碳中和目标下能源结构优化的近期策略与远期展望[J]. 化工进展,2022,41(11):5695−5708.HUANG Sheng, WANG Jingyu, GUO Pei, et al. Short-term strategy and long-term prospect of energy structure optimization under carbon neutrality target[J]. Chem Ind Eng Prog,2022,41(11):5695−5708. [2] FAIZAN M, SONG H. Critical review on catalytic biomass gasification: State-of-art progress, technical challenges, and perspectives in future development[J]. J Cleaner Production,2023,408:137224. [3] 王卓智, 张雷, 熊立夫, 等. 烘焙预处理对稻壳燃料品质及热解特性的调控机制研究[J]. 燃料化学学报(中英文),2023,51(3):320−329.WANG Zhuozhi, ZHANG Lei, XIONG Lifu, et al. Study on the regulation mechanism of torrefaction pretreatment on fuel quality and pyrolysis characteristics of rice husk[J]. J Fuel Chem Technol,2023,51(3):320−329. [4] 高攀, 赵泽衡, 刘禹彤, 等. 气体加压烘焙对玉米秸秆提质及热解特性的影响[J]. 燃料化学学报,2022,50(6):735−746. doi: 10.1016/S1872-5813(21)60190-1GAO Pan, ZHAO Zeheng, LIU Yutong, et al. Effect of gas-pressurized torrefaction on the upgrading and pyrolysis characteristics of corn stalk[J]. J Fuel Chem Technol,2022,50(6):735−746. doi: 10.1016/S1872-5813(21)60190-1 [5] 谢腾, 丛宏斌, 赵立欣, 等. 烘焙对生物质理化特性影响综述与秸秆烘焙研究前景分析[J]. 应用化工,2020,49(1):2841−2846.XIE Teng, CONG Hongbin, ZHAO Lixin, et al. A review of the effects of torrefaction on biomass physicochemical properties and analysis of research prospects for straw torrefaction[J]. Appl Chem Ind (Xi'an, China),2020,49(1):2841−2846. [6] KONG G, WANG K J, ZHANG X, et al. Torrefaction/carbonization-enhanced gasification-steam reforming of biomass for promoting hydrogen-enriched syngas production and tar elimination over gasification biochar[J]. Bioresour Technol.,2022,363:127960. doi: 10.1016/j.biortech.2022.127960 [7] COUHERT C, SALVADOR S, COMMANDRÉ J-M. Impact of torrefaction on syngas production from wood[J]. Fuel,2009,88(11):2286−2290. doi: 10.1016/j.fuel.2009.05.003 [8] KUO P C, WU W. Thermodynamic analysis of a combined heat and power system with CO2 utilization based on co-gasification of biomass and coal[J]. Chem Eng Sci,2016,142:201−214. doi: 10.1016/j.ces.2015.11.030 [9] UEMURA Y, SELLAPPAH V, TRINH T H, et al. Torrefaction of empty fruit bunches under biomass combustion gas atmosphere[J]. Bioresour Technol,2017,243:107−117. doi: 10.1016/j.biortech.2017.06.057 [10] ONSREE T, TIPPAYAWONG N. Analysis of reaction kinetics for torrefaction of pelletized agricultural biomass with dry flue gas[J]. Energy Reports,2020,6(S9):61−65. [11] WANG Z Z, XIE K, ZHU W K, et al. Effects of oxygen deficient and flue gas torrefaction on the surface property and structural feature of typical agriculture waste: Rice husk[J]. Fuel,2022,327:125211. doi: 10.1016/j.fuel.2022.125211 [12] RIAZ S, OLUWOYE I, AL-ABDELI Y M. Oxidative torrefaction of densified woody biomass: Performance, combustion kinetics and thermodynamics[J]. Renewable Energy,2022,199:908−918. doi: 10.1016/j.renene.2022.09.023 [13] ZHANG C, HO S H, CHEN W H, et al. Oxidative torrefaction of biomass nutshells: Evaluations of energy efficiency as well as biochar transportation and storage[J]. Appl Energy,2019,235(FEB.1):428−441. [14] PINTO F, GOMINHO J, ANDRÉ R N, et al. Improvement of gasification performance of Eucalyptus globulus stumps with torrefaction and densification pre-treatments[J]. Fuel,2017,206:289−299. doi: 10.1016/j.fuel.2017.06.008 [15] SHOULAIFAR T K, DEMARTINI N, KARLSTRÖM O, et al. Impact of organically bonded potassium on torrefaction: Part 1. Experimental[J]. Fuel,2016,165:544−552. doi: 10.1016/j.fuel.2015.06.024 [16] SAFAR M, LIN B J, CHEN W H, et al. Catalytic effects of potassium on biomass pyrolysis, combustion and torrefaction[J]. Appl Energy,2019,235(Feb.1):346−355. [17] 余作伟, 刘倩, 钟文琪, 等. 烘焙生物质燃烧过程中钾的赋存形态及析出迁移特性[J]. 化工学报,2021,72(4):2258−2266.YU Zuowei, LIU Qian, ZHONG Wenqi, et al. Occurrence form and release and migration characteristics of potassium during combustion of torrefied biomass[J]. CIESC J,2021,72(4):2258−2266. [18] 陈汉鼎. 稻草烘焙过程和后续热解过程中氯和钾的迁移机制[D]. 上海: 华东理工大学, 2017.CHEN Handing. Migration mechanisms of chlorine and potassium during torrefaction and subsequent pyrolysis of rice straw[D]. Shanghai: East China University of Science and Technology, 2017. [19] ZHANG Y, GENG P, LIU R. Synergistic combination of biomass torrefaction and co-gasification: Reactivity studies[J]. Bioresour. Technol. , 2017, 245(Pt A): 225−233. [20] 洪千惠, 刘霞, 唐龙飞, 等. 农林废弃生物质与煤共气化灰渣的理化特性研究进展[J]. 燃料化学学报,2022,50(6):641−651. doi: 10.1016/S1872-5813(21)60197-4HONG Qianhui, LIU Xia, TANG Longfei, et al. Progress in physicochemical properties of ash/slag from co-gasification of agroforestry waste biomass and coal[J]. J Fuel Chem Technol,2022,50(6):641−651. doi: 10.1016/S1872-5813(21)60197-4 [21] HUANG Y Q, LIU H C, YUAN H Y, et al. Release and transformation pathways of various K species during thermal conversion of agricultural straw. Part 1: Devolatilization stage[J]. Energy Fuels,2018,32(9):9605−9613. doi: 10.1021/acs.energyfuels.8b02191 [22] 蒋好, 朱有健, 刘恒, 等. 秸秆烘焙过程氯, 硫释放及AAEMs迁徙转化特性研究[J]. 化工学报,2020,71(12):5785−5792.JAING Hao, ZHU Youjian, LIU Heng, et al. Release and transformation characteristics of chlorine, sulfur and AAEMs during cornstalk torrefaction[J]. CIESC J,2020,71(12):5785−5792. [23] ACHARYA B, DUTTA A, MINARET J. Review on comparative study of dry and wet torrefaction[J]. Sustainable Energy Technolo Assess,2015,12:26−37. doi: 10.1016/j.seta.2015.08.003 [24] MEI Y Y, CHE Q F, YANG Q, et al. Torrefaction of different parts from a corn stalk and its effect on the characterization of products[J]. Ind Crops Prod,2016,92:26−33. doi: 10.1016/j.indcrop.2016.07.021 [25] SASIKUMAR C, SUNDARESAN R, KANNAN R, et al. Investigation on biomass gasification process[J]. Mater Today: Proc,2022,64(P5):1844−1848. [26] ZHANG L, WANG Z Z, MA J, KONG W W, et al. Analysis of functionality distribution and microstructural characteristics of upgraded rice husk after undergoing non-oxidative and oxidative torrefaction[J]. Fuel,2022,310(PC):122477. [27] MARCELLO M D, TSALIDIS G A, SPINELLI G, et al. Pilot scale steam-oxygen CFB gasification of commercial torrefied wood pellets. The effect of torrefaction on the gasification performance[J]. Biomass Bioenergy,2017,105:411−420. doi: 10.1016/j.biombioe.2017.08.005 [28] XIE D, ZHONG Y, HUANG J C, et al. Steam gasification of the raw and torrefied mixed typical food wastes: Effect of interactions on syngas production[J]. Fuel,2022,323:124354. doi: 10.1016/j.fuel.2022.124354 [29] ZHAO H B, SONG Q, WU X Y, et al. Study on the transformation of inherent potassium during the fast-pyrolysis process of rice straw[J]. Energy Fuels,2015,29(10):6404−6411. doi: 10.1021/acs.energyfuels.5b00851 [30] ZHANG Z H, SONG Q, ALWAHABI Z T, et al. Temporal release of potassium from pinewood particles during combustion[J]. Combust Flame,2015,162(2):496−505. doi: 10.1016/j.combustflame.2014.07.030 [31] JORDAN C A, AKAY G. Speciation and distribution of alkali, alkali earth metals and major ash forming elements during gasification of fuel cane bagasse[J]. Fuel,2012,91(1):253−263. doi: 10.1016/j.fuel.2011.05.031 -

下载:

下载: