Recent advances in the preparation of high-value-added chemicals by catalytic hydrogenolysis of lignin

-

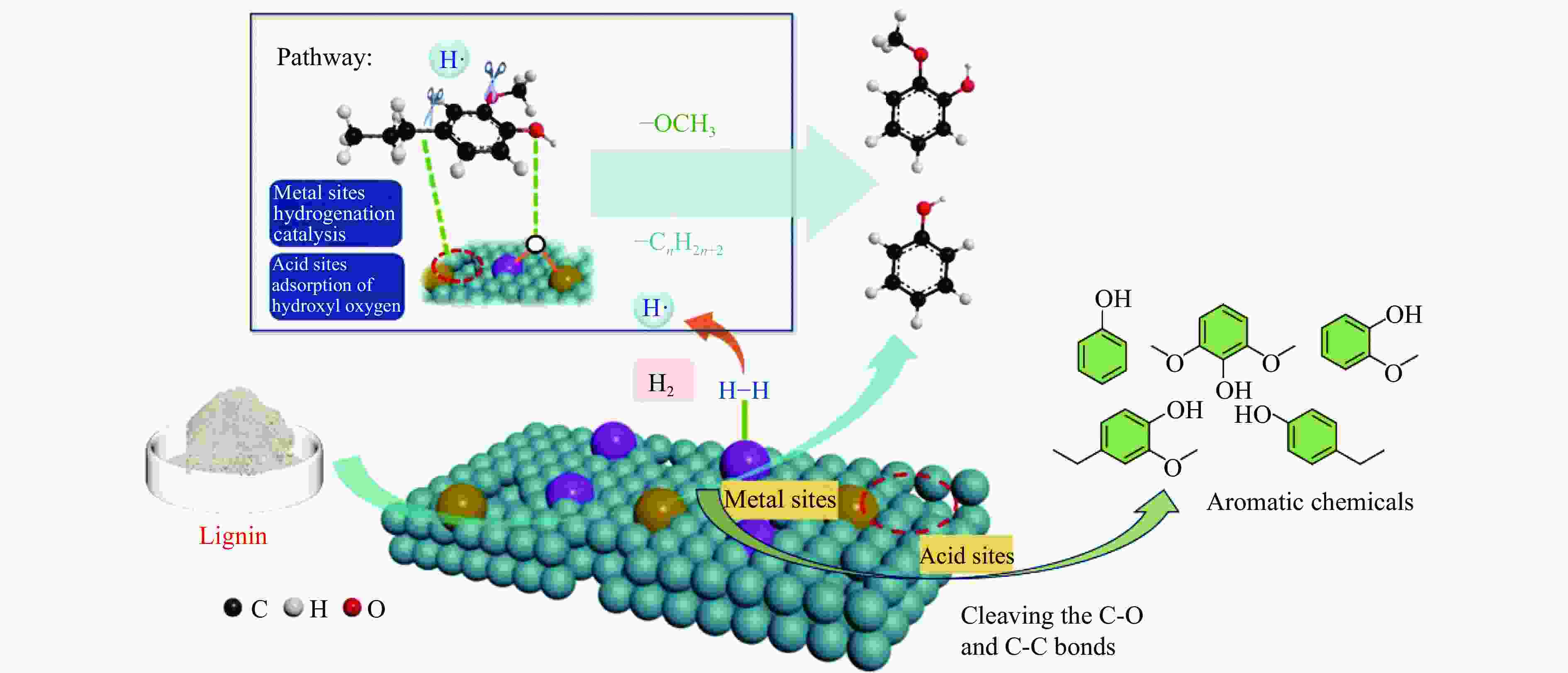

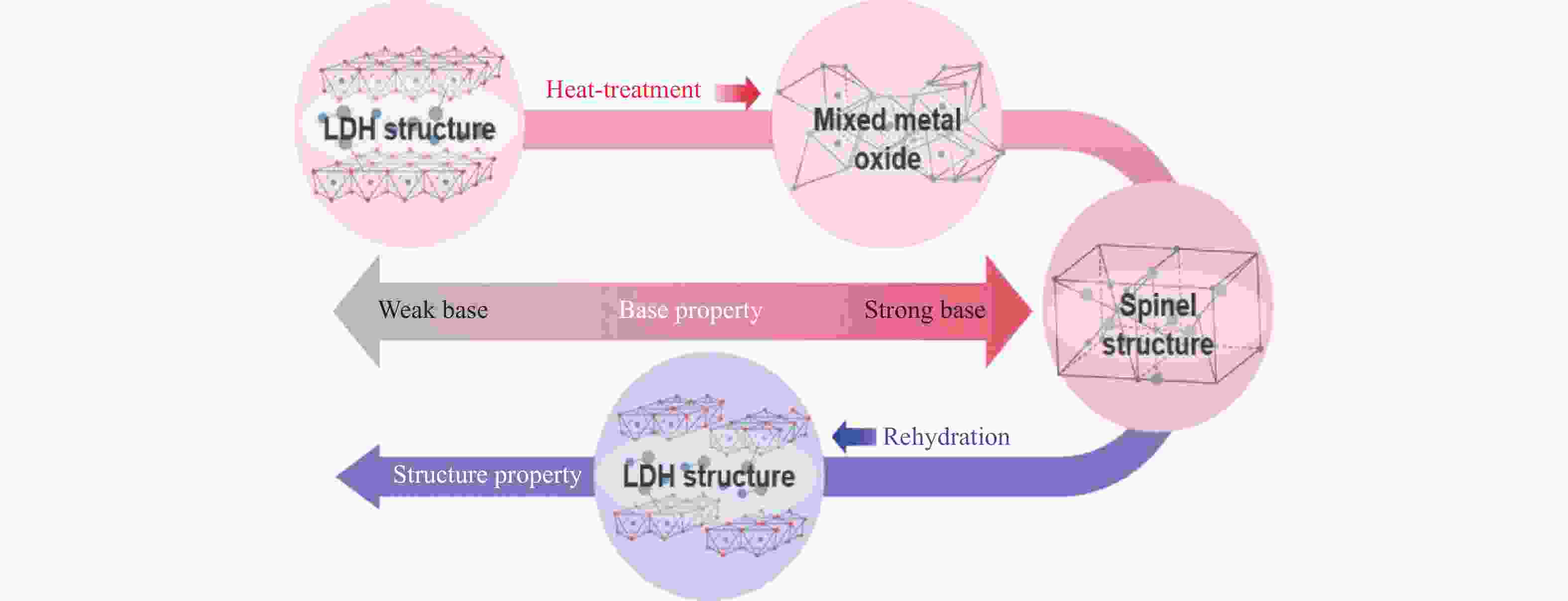

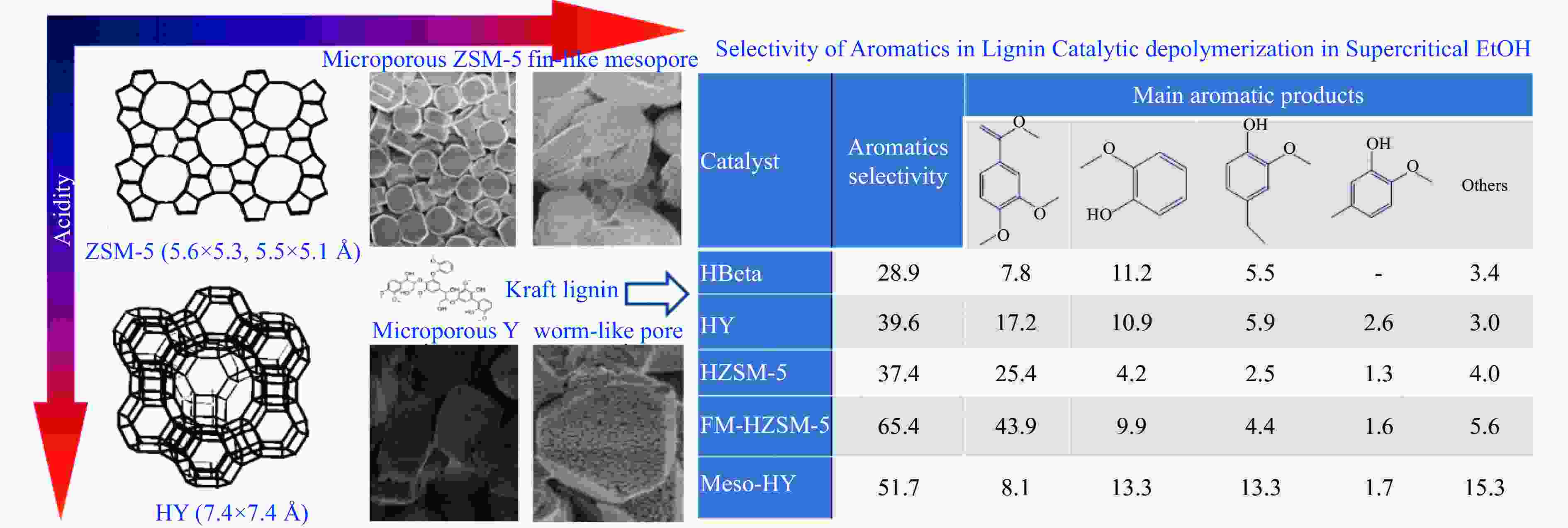

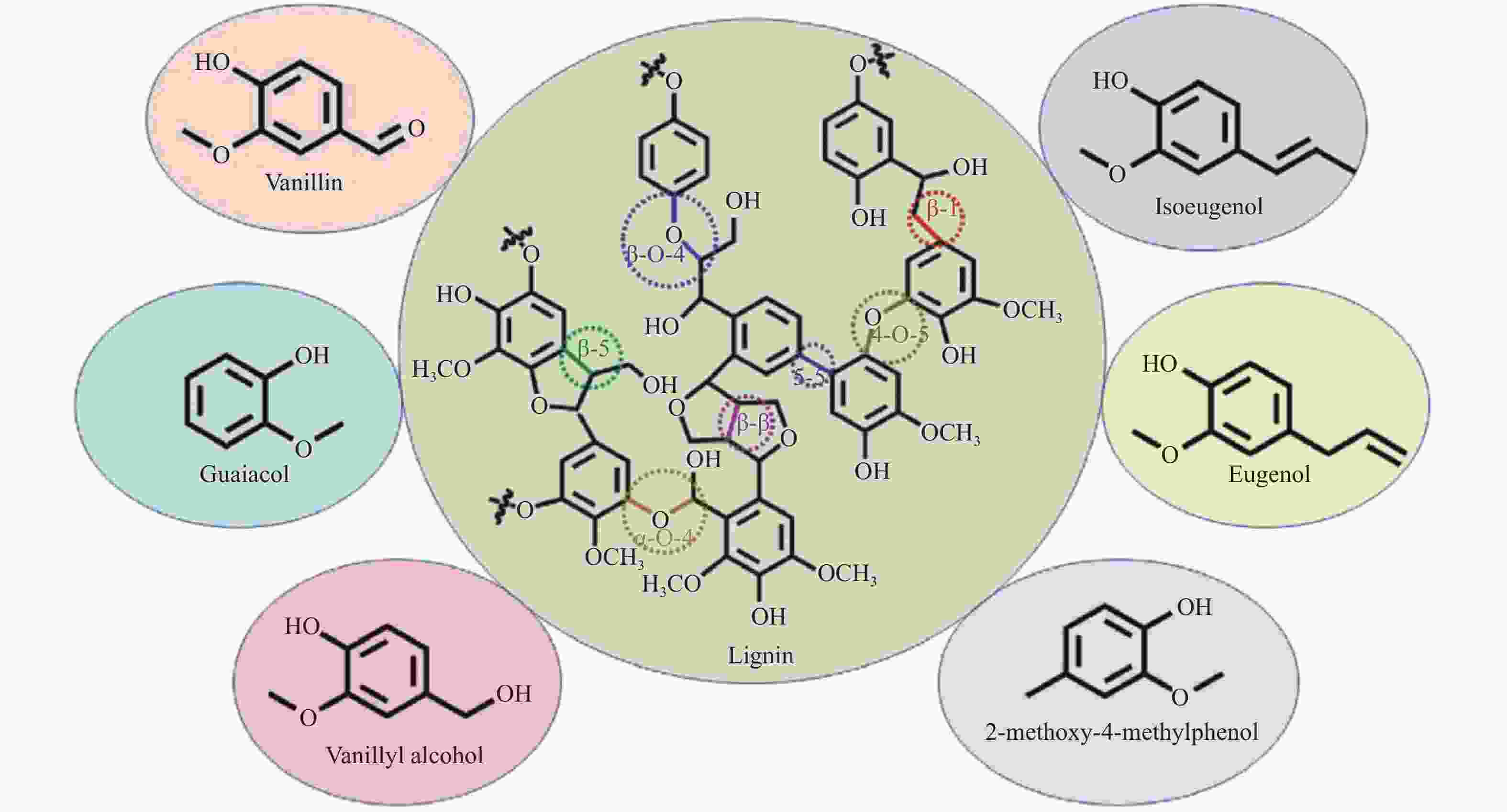

摘要: 开发和利用可再生生物质资源是实现二氧化碳减排的有效途径。而生物质结构复杂,整体反应性和利用率较低。木质素是自然界中唯一具有高能量密度的可再生芳香族聚合物,其转化和利用在全球范围内引起了广泛关注。然而,木质素结构的复杂性、连接方式的不确定性、侧链连接的稳定性以及反应片段不可避免的再缩合,使得将木质素解聚成生物燃料或芳香化学品成为一项艰巨的挑战。催化氢解技术可将木质素转化为高选择性、高收率的酚类单体。但是木质素催化解聚过程中化学键的定向剪切,产物与结构之间的转化机理仍不清晰。本工作针对木质素的催化氢解生产高值化学品的最新研究进展,重点总结了木质素的催化氢解过程中催化剂及其高值化学品产物间的耦合关联,着重讨论了不同催化剂体系对木质素解聚产物过程机理的影响,尤其对于金属基催化剂,综述了贵金属基催化剂、过渡基金属催化剂、水滑石催化剂和金属有机框架催化剂对于产物分布影响的最新进展,并进一步总结了不同催化剂存在的问题和转化机制;同时木质素加氢催化裂解过程中溶剂是促进木质素溶解、加速传热传质、促进反应物和催化剂在反应器中均匀分散的关键。本工作并对木质素液化的主要溶剂,例如水、醇类和新型溶剂体系对木质素的解聚效应进行综述。最后,就领域所面临的机遇和挑战进行了总结和展望,为木质素高效定向转化与高值化利用提供了理论参考。Abstract: The development and utilization of renewable biomass resources is an effective way to achieve CO2 reduction. Biomass, on the other hand, has a complex structure with low overall reactivity and utilization. Lignin is the only renewable aromatic polymer with high energy density in nature, and its conversion and utilization have attracted much attention worldwide. However, the complexity of the lignin structure, the uncertainty of the linkages, the stability of the side-chain connections, and the inevitable recondensation of the reactive fragments make the depolymerization of lignin into biofuels or aromatic chemicals a formidable challenge. Catalytic hydrogenolysis technology converts lignin into highly selective, high-yield phenolic monomers with high heating value, low oxygen content, and high carbon utilization of the product. However, the mechanism of the conversion between products and structures remains unclear with respect to the directed bond shearing during the catalytic depolymerization of lignin. In this paper, in view of the latest research progress on the catalytic hydrogenolysis of lignin for the production of high-value chemicals. We focus on the catalytic hydrogenolysis of lignin to summarize the coupling correlation between the catalysts and their products of high-value chemicals and focus on the influence of different catalyst systems on the process mechanism of lignin depolymerization products. For metal-based catalysts in particular, a detailed review of recent advances in the effects of noble metal-based catalysts, transition metal-based catalysts, hydrotalcite catalysts, and metal-organic framework catalysts on product distribution is presented. And further summarized the problems and conversion mechanisms of different catalysts. Meanwhile, the solvent in the lignin catalytic hydrogenolysis cracking process is the key to promote lignin dissolution, accelerating the heat and mass transfer, and promoting the homogeneous dispersion of reactants and catalysts in the reactor. In this paper, the main solvents for lignin liquefaction, such as water, alcohol, and new solvent systems, are reviewed for their depolymerization impact on lignin. And further, outline the effect of the solvent system on the properties of lignin conversion products. Nevertheless, there are still many difficulties in the catalytic hydrogenolysis of lignin for the preparation of high-value chemicals. The complexity of the macromolecular structure of lignin, the directed depolymerization of the C−O and C−C structures is still difficult, and the preparation of efficient catalysts as well as the mechanism of directional regulation of the products are still to be further investigated. Due to the insolubility of lignin, no solvent system that can completely dissolve lignin has been found yet; secondly, the research on the solvent effect is still only in the preliminary exploration stage. Novel technology for favorable conversion of lignin is still only at the stage of laboratory research. And the efficient conversion of renewable lignin into valuable chemicals and fuels is of great significance in solving the energy crisis and slowing down global warming, and at the same time, it will help our country to realize the energy-dependence transition from oil to renewable biomass. So finally, the opportunities and challenges facing the field are summarized and outlooked, providing a theoretical reference for efficient targeted conversion and high-value utilization of lignin.

-

Key words:

- lignin /

- catalytic /

- hydrogenolysis /

- chemicals

1) #: 共同第一作者 -

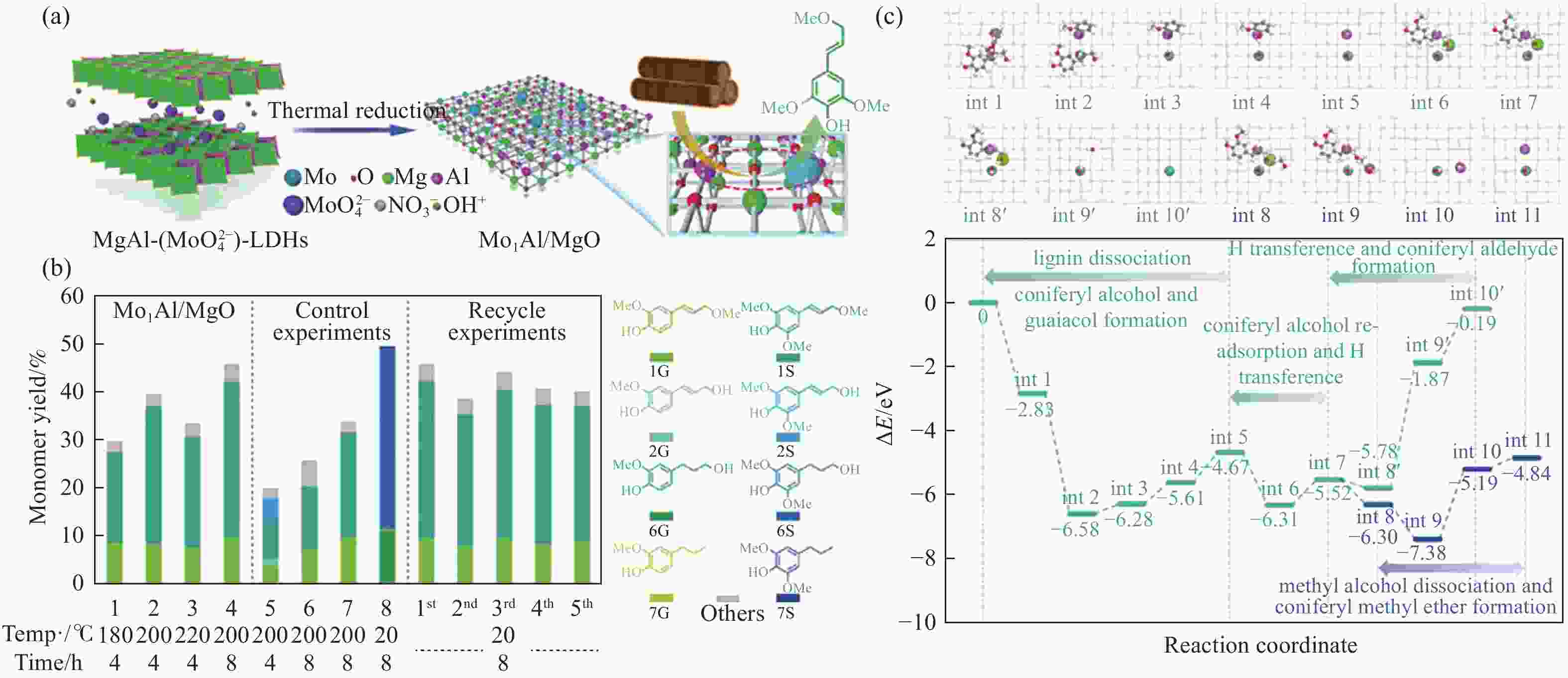

图 4 (a) Mo1Al/MgO催化氢解木质素转化示意图;(b)不同条件下木质素解聚性能;(c) DFT计算的能量面[16,42]

Figure 4 (a) Schematic diagram of Mo1Al/MgO-catalyzed hydrolytic lignin conversion; (b) Lignin depolymerization performance under different conditions; (c) Energy surfaces calculated by DFT[16,42] (with permission from Wiley and ACS Publications)

表 1 生物质提取木质素典型连接键含量

Table 1 Lignin linkage bond content of different biomass extracts

Linkage bond/% β-O-4 5-5 α-O-4 4-O-5 β-5 β-1 β-β Softwood 43−50 9.5−11 6−8 3.5−4 9−12 7 2 Hardwood 50−65 4.5 6−8 6.5 6 7 3 Herbaceous plant 40 – – – 4 1 6 表 2 木质素在不同反应条件下产物分布

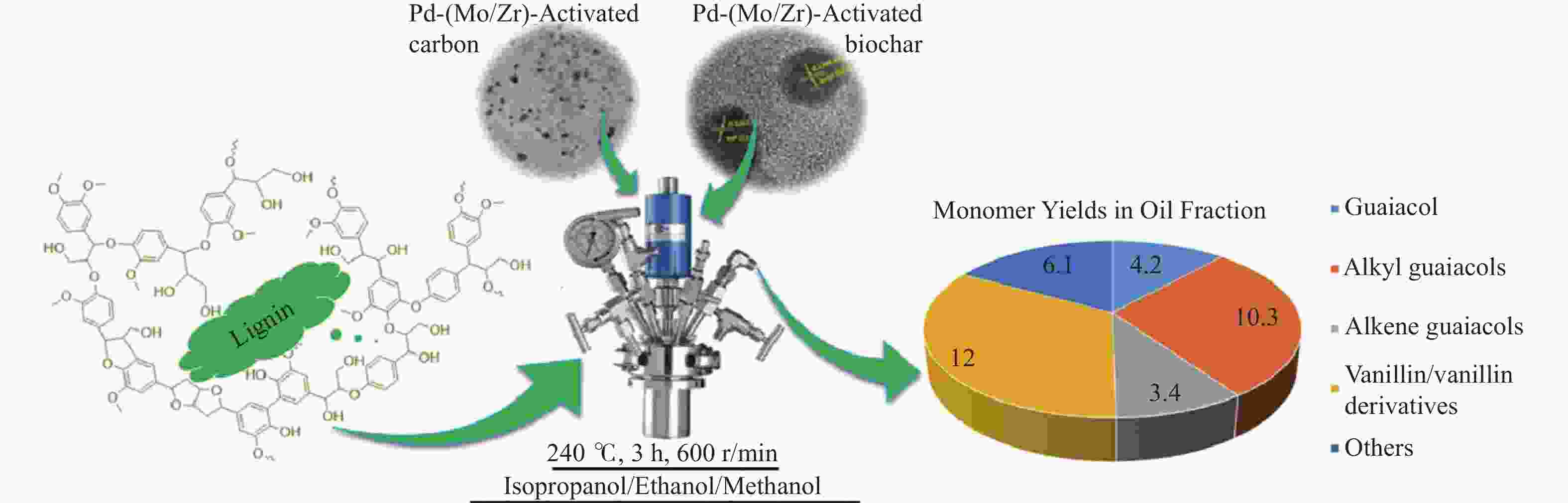

Table 2 Product distribution of lignin under different reaction conditions

Raw Reaction condition Catalyst Solvent Major product/% Reference Alkali lignin 400 ℃ ,4 h Lewis acid Water, methanol Aromatic compounds 0.1–0.5;

monophenol 0.9–5.5, catechol 0.5–3.5[85] Alkali lignin 350 ℃ ,28 h NiMoS/Al2O3 Tetrahydronaphthalene Monomeric phenols and long-chain

alkanes 25[86] Alkali lignin,

Organosolv lignin250 ℃, 20 h Ru/Nb2O5 Water Aromatic hydrocarbon 20.4

cycloalkane 8.6[87] hydrolysed lignin 250 ℃, 15 min MgO Tetrahydrofuran Monophenol 13.2 [88] Alkali lignin 300 ℃, 8 h CuMgAlOx Ethanol Monophenol 23 [39] Sulfated lignin 350 ℃,4 h ZrO2/K2CO3 Water/phenol Monophenol 27 [89] Sulfated lignin 350 ℃, 4 h NiMo, ZrO2 Dimethyl sulfide Monophenol 26.4 [90] Organosolv lignin 160 ℃, 24 h CuZnAl Propylene glycol Monophenol 56.1 [91] -

[1] WANG S, RU B, LIN H, et al. Pyrolysis behaviors of four lignin polymers isolated from the same pine wood[J]. Bioresour Technol,2015,182:120−127. doi: 10.1016/j.biortech.2015.01.127 [2] SHEN D, JIN W, HU J, et al. An overview on fast pyrolysis of the main constituents in lignocellulosic biomass to valued-added chemicals: Structures, pathways and interactions[J]. Renew Sustain Energy Rev,2015,51:761−774. doi: 10.1016/j.rser.2015.06.054 [3] SHEN D, LIU G, ZHAO J, et al. Thermo-chemical conversion of lignin to aromatic compounds: Effect of lignin source and reaction temperature[J]. J Anal Appl Pyrol,2015,112:56−65. doi: 10.1016/j.jaap.2015.02.022 [4] ZEVALLOS TORRES L A, LORENCI WOICIECHOWSKI A, DE ANDRADE TANOBE V O, et al. Lignin as a potential source of high-added value compounds: A review[J]. J Clean Prod,2020,263:1−18. [5] SETHUPATHY S, MURILLO MORALES G, GAO L, et al. Lignin valorization: Status, challenges and opportunities[J]. Bioresour Technol,2022,347:1−16. [6] DONG Z, LIU Z, ZHANG X, et al. Pyrolytic characteristics of hemicellulose, cellulose and lignin under CO2 atmosphere[J]. Fuel,2019,256:1−9. [7] LIU X, BOUXIN F P, FAN J, et al. Recent advances in the catalytic depolymerization of lignin towards phenolic chemicals: A Review[J]. Chem,2020,13(17):4296−4317. [8] LIAO Y, KOELEWIJN S-F, VAN DEN BOSSCHE G, et al. A sustainable wood biorefinery for low-carbon footprint chemicals production[J]. Sci,2020,367(6484):1385−1390. doi: 10.1126/science.aau1567 [9] JIA Z, JI N, DIAO X, et al. Highly selective hydrodeoxygenation of lignin to naphthenes over three-dimensional flower-like Ni2P derived from hydrotalcite[J]. ACS Catal,2022,12(2):1338−1356. doi: 10.1021/acscatal.1c05495 [10] WANG M, LIU M, LI H, et al. Dealkylation of lignin to phenol via oxidation–hydrogenation strategy[J]. ACS Catal,2018,8(8):6837−6843. doi: 10.1021/acscatal.8b00886 [11] ZHAO M, ZHAO L, ZHAO X-Y, et al. Pd-based nano-catalysts promote biomass lignin conversion into value-added chemicals[J]. Mater,2023,16(14):1−13. [12] LUO Z, LIU C, RADU A, et al. Carbon–carbon bond cleavage for a lignin refinery[J]. Nat Chem Eng,2024,1(1):61−72. doi: 10.1038/s44286-023-00006-0 [13] XU Q, WANG Q, XIAO L P, et al. Metal-organic framework-derived CuO catalysts for the efficient hydrogenolysis of hardwood lignin into phenolic monomers[J]. J Mater Chem A,2023,11(44):23809−23820. doi: 10.1039/D3TA04927B [14] SHEN Z S, WANG W, PAN L, et al. Ni5Fe5/Al2O3 catalytic hydrogenolysis of lignin: mechanism investigation and selectivity regulation[J]. Green Chem,2023,25(19):7782−7793. doi: 10.1039/D3GC01988H [15] WU Y, DANG Q, WU T, et al. Efficient lignin depolymerization process for phenolic products with lignin-based catalysts and mixed solvents[J]. Energy Fuels,2023,37(7):5206−5219. doi: 10.1021/acs.energyfuels.3c00063 [16] SHEN Z S, SHI C X, LIU F, et al. Advances in heterogeneous catalysts for lignin hydrogenolysis[J]. Adv Sci,2023,11:1−24. [17] WANG Y, WEI L, HOU Q, et al. A Review on catalytic depolymerization of lignin towards high-value chemicals: solvent and catalyst[J]. Fermen Basel,2023,9(4):1−21. [18] GALE M, CAI C M, GILLIARD-ABDUL-AZIZ K L. Heterogeneous catalyst design principles for the conversion of lignin into high-value commodity fuels and chemicals[J]. Chem,2020,13(8):1947−66. [19] 王则祥, 李航, 谢文銮, 等. 木质素基本结构、热解机理及特性研究进展[J]. 新能源进展,2020,8(1):6−14. doi: 10.3969/j.issn.2095-560X.2020.01.002Wang Zexiang, Li Hang, Xie Wenluan, et al. Progress in the study of the basic structure, pyrolysis mechanism and properties of lignin[J]. New energy progress,2020,8(1):6−14. doi: 10.3969/j.issn.2095-560X.2020.01.002 [20] DENG J, ZHOU C, YANG Y, et al. Visible-light-driven selective cleavage of C−C bonds in lignin model substrates using carbon nitride-supported ruthenium single-atom catalyst[J]. Chem Eng J,2023,462:1−10. [21] GE Y, LI Z. Application of lignin and its derivatives in adsorption of heavy metal ions in water: A Review[J]. ACS Sustain Chem Eng,2018,6(5):7181−7192. doi: 10.1021/acssuschemeng.8b01345 [22] CHENG C, SHEN D, GU S, et al. State-of-the-art catalytic hydrogenolysis of lignin for the production of aromatic chemicals[J]. Catal Sci & Technol,2018,8(24):6275−6296. [23] WANG S, ZHANG K, LI H, et al. Selective hydrogenolysis of catechyl lignin into propenylcatechol over an atomically dispersed ruthenium catalyst[J]. Nat Commun,2021,12(1):1−9. doi: 10.1038/s41467-020-20314-w [24] GóMEZ-MONEDERO B, PILAR RUIZ M, BIMBELA F, et al. Selective depolymerization of industrial lignin-containing stillage obtained from cellulosic bioethanol processing[J]. Fuel Process Technol,2018,173:165−172. doi: 10.1016/j.fuproc.2018.01.021 [25] KARNITSKI A, CHOI J W, SUH D J, et al. Roles of metal and acid sites in the reductive depolymerization of concentrated lignin over supported Pd catalysts[J]. Catal Today,2023,411:1−9. [26] CHEN L, PAN L, VAN MUYDEN A P, et al. Anchoring single platinum atoms onto nickel nanoparticles affords highly selective catalysts for lignin conversion[J]. Cell Rep Phys Sci,2021,2(9):1−10. [27] CHEN L, XIN J Y, NI L L, et al. Conversion of lignin model compounds under mild conditions in pseudo-homogeneous systems[J]. Green Chem,2016,18(8):2341−2352. doi: 10.1039/C5GC03121D [28] DONG L, LIN L, HAN X, et al. Breaking the limit of lignin monomer production via cleavage of interunit carbon-carbon linkages[J]. Chem,2019,5(6):1521−1536. doi: 10.1016/j.chempr.2019.03.007 [29] ZHANG J, SU Z, WU Z, et al. Basic carrier promoted Pt-catalyzed hydrogenolysis of alkaline lignin[J]. Catal today,2021,365:193−198. doi: 10.1016/j.cattod.2020.06.027 [30] JIANG M, CHEN X, WANG L, et al. Anchoring single Ni atoms on CeO2 nanospheres as an efficient catalyst for the hydrogenolysis of lignin to aromatic monomers[J]. Fuel,2022,324:1−11. [31] QI Y, ZENG X Z, XIONG L Y Z, et al. Efficient conversion of lignin to alkylphenols over highly stable inverse spinel MnFe2O4 catalysts[J]. Fro Chem Sci Eng,2023,17(8):1085−1095. doi: 10.1007/s11705-022-2236-1 [32] ZHANG J, TEO J, XI C, et al. A series of NiM (M = Ru, Rh, and Pd) bimetallic catalysts for effective lignin hydrogenolysis in water[J]. ACS catal,2014,4(5):1574−1583. doi: 10.1021/cs401199f [33] MA D, LU S, LIU X, et al. Depolymerization and hydrodeoxygenation of lignin to aromatic hydrocarbons with a Ru catalyst on a variety of Nb-based supports[J]. J catal,2019,40(4):609−617. [34] CHENG C, LI P, YU W, et al. Nonprecious metal/bimetallic catalytic hydrogenolysis of lignin in a mixed-solvent system[J]. ACS Sustain Chem Eng,2020,8(43):16217−16228. doi: 10.1021/acssuschemeng.0c05362 [35] ZHU J, CHEN F, ZHANG Z, et al. M-gallate (M = Ni, Co) metal-organic framework-derived Ni/C and bimetallic Ni-Co/C catalysts for lignin conversion into monophenols[J]. ACS Sustain Chem Eng,2019,7(15):12955−12963. doi: 10.1021/acssuschemeng.9b02005 [36] YAN B, LIN X, CHEN Z, et al. Selective production of phenolic monomers via high efficient lignin depolymerization with a carbon based nickel-iron-molybdenum carbide catalyst under mild conditions[J]. Bioresour Technol,2021,321:1−8. [37] LONG J X, SHU R Y, YUAN Z Q, et al. Efficient valorization of lignin depolymerization products in the present of NixMg1-xO[J]. Appl Energy,2015,157:540−545. doi: 10.1016/j.apenergy.2015.04.011 [38] KORANYI T I, HUANG X, COUMANS A E, et al. Synergy in lignin upgrading by a combination of Cu-based mixed oxide and Ni-phosphide catalysts in supercritical ethanol[J]. ACS Sustain Chem Eng,2017,5(4):3535−3543. doi: 10.1021/acssuschemeng.7b00239 [39] GALEBACH P H, SOEHERMAN J K, GILCHER E, et al. Production of renewable alcohols from maple wood using supercritical methanol hydrodeoxygenation in a semi-continuous flowthrough reactor[J]. Green Chem,2020,22(23):8462−8477. doi: 10.1039/D0GC03218B [40] MCCLELLAND D J, GALEBACH P H, MOTAGAMWALA A H, et al. Supercritical methanol depolymerization and hydrodeoxygenation of lignin and biomass over reduced copper porous metal oxides[J]. Green Chem,2019,21(11):2988−3005. doi: 10.1039/C9GC00589G [41] 汪文静, 刘红缨, 车琳, 等. Ni/镁铝水滑石催化剂解聚木质素[J]. 化学工程,2022,50(12):6−10+16.WANG Wenjing, LIU Hongying, CHE Lin, et al. Depolymerisation of lignin by Ni/magnesium-aluminium hydrotalcite catalyst[J]. Chem Eng,2022,50(12):6−10+16. [42] MENG G, LAN W, ZHANG L, et al. Synergy of single atoms and lewis acid sites for efficient and selective lignin disassembly into monolignol derivatives[J]. J Am Chem Soc,2023,145(23):12884−12893. doi: 10.1021/jacs.3c04028 [43] KIM H U, LIMARTA S O, JAE J. Depolymerization of kraft lignin over a Ru-Mg-Al-oxide catalyst[J]. Clean Technol,2021,27(2):190−197. [44] TOTONG S, LAOSIRIPOJANA W, LAOSIRIPOJANA N, et al. Nickel and rhenium mixed oxides-doped graphene oxide (MOs/GO) catalyst for the oxidative depolymerization of fractionated bagasse lignin[J]. Ind Eng Chem Res,2022,61(1):215−223. doi: 10.1021/acs.iecr.1c03848 [45] ZHOU M, TANG C, XIA H, et al. Ni-based MOFs catalytic oxidative cleavage of lignin models and lignosulfonate under oxygen atmosphere[J]. Fuel,2022,320:1−9. [46] CHEN C, LIU P, XIA H, et al. Catalytic conversion of lignin to liquid fuels with an improved H/C-eff value over bimetallic NiMo-MOF-derived catalysts[J]. ACS Sustain chem eng,2021,9(41):13937−13952. doi: 10.1021/acssuschemeng.1c05273 [47] GUO G, CHEN D, AHMED T, et al. Catalytic depolymerization of Kraft lignin towards liquid fuels over bifunctional molybdenum oxide based supported catalyst[J]. Fuel,2021,306:1−12. [48] GUO G, LI W, AHMED T, et al. Production of liquid fuels from Kraft lignin over bimetallic Ni-Mo supported on ZIF-derived porous carbon catalyst[J]. RSC Adv,2021,11(60):37932−37941. doi: 10.1039/D1RA05354J [49] KONG L, LIU C, GAO J, et al. Efficient and controllable alcoholysis of Kraft lignin catalyzed by porous zeolite-supported nickel-copper catalyst[J]. Bioresour Telchnol,2019,276:310−317. doi: 10.1016/j.biortech.2019.01.015 [50] WANG Y, SONG J, BAXTER N C, et al. Synthesis of hierarchical ZSM-5 zeolites by solid-state crystallization and their catalytic properties[J]. J Catal,2017,349:53−65. doi: 10.1016/j.jcat.2017.03.005 [51] KIM J-Y, PARK S Y, CHOI I-G, et al. Evaluation of RuxNi1-x/SBA-15 catalysts for depolymerization features of lignin macromolecule into monomeric phenols[J]. Chem Eng J,2018,336:640−648. doi: 10.1016/j.cej.2017.11.118 [52] MENG Q, YAN J, WU R, et al. Sustainable production of benzene from lignin[J]. Nat Commun,2021,12(1):1−12. doi: 10.1038/s41467-020-20314-w [53] YAN J, MENG Q, SHEN X, et al. Selective valorization of lignin to phenol by direct transformation of Csp2-Csp3 and C−O bonds[J]. Sci Adv,2020,6(45):1−10. [54] ZHANG B, LI W, ZHANG T, et al. Study on the removal and depolymerization of lignin from corn stover through the synergistic effect of Brønsted acid, Lewis acid and hydrogenation sites[J]. Fuel,2021,305:1−9. [55] ZENG Z, XIE J, GUO Y, et al. Hydrogenolysis of lignin to produce aromatic monomers over FePd bimetallic catalyst supported on HZSM-5[J]. Fuel Process Technol,2021,213:1−10. [56] LI L, CUI M, WANG X, et al. Critical Techniques for Overcoming the Diffusion Limitations in Heterogeneously Catalytic Depolymerization of Lignin[J]. Chem,2023,16:1−13. [57] BAXTER N C, WANG Y X, HUANG H J, et al. Kraft lignin ethanolysis over zeolites with different acidity and pore structures for aromatics production[J]. Catal,2021,11(2):1−15. [58] HU Y, JIANG G, XU G, et al. Hydrogenolysis of lignin model compounds into aromatics withbimetallic Ru-Ni supported onto nitrogen-doped activated carbon catalyst[J]. Mol Catal,2017,445:316−26. [59] MA R, HAO W, MA X, et al. Catalytic ethanolysis of Kraft lignin into high-value small-molecular chemicals over a nanostructured -molybdenum carbide catalyst[J]. Angew Chem Int Ed,2014,53:7310−7315. doi: 10.1002/anie.201402752 [60] LIU Z, LI H, GAO X, et al. Rational highly dispersed ruthenium for reductive catalytic fractionation of lignocellulose[J]. Nat Commun,2022,13(1):1−11. doi: 10.1038/s41467-021-27699-2 [61] YAN B, LIN X, CHEN Z, et al. Selective production of phenolic monomers via high efficient lignin depolymerization with a carbon based nickel-iron-molybdenum carbide catalyst under mild conditions[J]. Bioresour Technol,2021,321:1−8. [62] XIAO L-P, WANG S, LI H, et al. Catalytic hydrogenolysis of lignins into phenolic compounds over carbon nanotube supported molybdenum oxide[J]. ACS Catal,2017,7(11):7535−7542. doi: 10.1021/acscatal.7b02563 [63] KUMAR M M, PRABHUDESAI V S, VINU R. Lignin depolymerization to guaiacol and vanillin derivatives via catalytic transfer hydrogenolysis using Pd-Lewis metal oxide supported on activated carbon catalysts[J]. Mol Catal,2023,549:1−13. [64] PARK J, OH S, KIM J-Y, et al. Comparison of degradation features of lignin to phenols over Pt catalysts prepared with various forms of carbon supports[J]. RSC Adv,2016,6(21):16917−16924. doi: 10.1039/C5RA21875F [65] WAHYUDIONO, SASAKI M, GOTO M. Recovery of phenolic compounds through the decomposition of lignin in near and supercritical water[J]. Chem Eng Process Int,2008,47(9−10):1609−1619. doi: 10.1016/j.cep.2007.09.001 [66] WANG D, WANG Y, LI X, et al. Lignin Valorization: A novel in situ catalytic hydrogenolysis method in alkaline aqueous solution[J]. Energy Fuels,2018,32(7):7643−7651. doi: 10.1021/acs.energyfuels.8b01032 [67] WANG H, ZHANG L, DENG T, et al. ZnCl2 induced catalytic conversion of softwood lignin to aromatics and hydrocarbons[J]. Green Chem,2016,18(9):2802−2810. doi: 10.1039/C5GC02967H [68] KHUDOSHIN A G, LUNIN V V, BOGDAN V I. Conversion of veratrole and sodium lignosulfonate in the sub- and supercritical water[J]. J Phys Chem B,2011,5(7):1069−1075. [69] SONG Q, WANG F, CAI J, et al. Lignin depolymerization (LDP) in alcohol over nickel-based catalysts via a fragmentation–hydrogenolysis process[J]. Energy Environ Sci,2013,6(3):994−1007. doi: 10.1039/c2ee23741e [70] MCVEIGH A, BOUXIN F P, JARVIS M C, et al. Catalytic depolymerisation of isolated lignin to fine chemicals: part 2-process optimisation[J]. Catal Sci Technol,2016,6(12):4142−4150. doi: 10.1039/C5CY01896J [71] BARTA K, MATSON T D, FETTIG M L, et al. Catalytic disassembly of an organosolv lignin via hydrogen transfer from supercritical methanol[J]. Green Chem,2010,12(9):1640−1647. doi: 10.1039/c0gc00181c [72] SONG Q, WANG F, CAI J, et al. Lignin depolymerization (LDP) in alcohol over nickel-based catalysts via a fragmentation–hydrogenolysis process[J]. Energy Environ Sci,2013,6(3):994−1007. doi: 10.1039/c2ee23741e [73] BRAND S, SUSANTI R F, KIM S K, et al. Supercritical ethanol as an enhanced medium for lignocellulosic biomass liquefaction: Influence of physical process parameters[J]. Energy,2013,59:173−82. doi: 10.1016/j.energy.2013.06.049 [74] HUANG X M, KORáNYI T I, BOOT M D, et al. Catalytic Depolymerization of Lignin in Supercritical Ethanol[J]. Chemsuschem,2014,7(8):2276−2288. doi: 10.1002/cssc.201402094 [75] LEE H-S, JAE J, HA J-M, et al. Hydro-and solvothermolysis of kraft lignin for maximizing production of monomeric aromatic chemicals[J]. Bioresour Technol,2016,203:142−149. doi: 10.1016/j.biortech.2015.12.022 [76] KONG X, LIU C, XU W, et al. Catalytic hydroprocessing of stubborn lignin in supercritical methanol with Cu/CuMgAlOx catalyst[J]. Fuel Process Technol,2021,218:1−11. [77] KUMAR M M, PRABHUDESAI V S, VINU R. Lignin depolymerization to guaiacol and vanillin derivatives via catalytic transfer hydrogenolysis using Pd-Lewis metal oxide supported on activated carbon catalysts[J]. Mol Catal,2023,549:1−11. [78] MCVEIGH A, BOUXIN F P, JARVIS M C, et al. Catalytic depolymerisation of isolated lignin to fine chemicals: part 2 – process optimisation[J]. Catal Sci Technol,2016,6(12):4142−4150. doi: 10.1039/C5CY01896J [79] CHEN J, WANG D, LU X, et al. Effect of cobalt(II) on acid-modified attapulgite-supported catalysts on the depolymerization of Alkali lignin[J]. Ind Eng Chem Res,2022,61(4):1675−1683. doi: 10.1021/acs.iecr.1c04695 [80] YANG Z, FENG J, CHENG H, et al. Directional depolymerization of lignin into high added-value chemical with synergistic effect of binary solvents[J]. Bioresour Technol,2021,321:1−7. [81] ZAKZESKI J, JONGERIUS A L, BRUIJNINCX P C A, et al. Catalytic lignin valorization process for the production of aromatic chemicals and hydrogen[J]. Chemsuschem,2012,5(8):1602−1609. doi: 10.1002/cssc.201100699 [82] WU Y, DANG Q, WU T, et al. Efficient lignin depolymerization process for phenolic products with lignin-based catalysts and mixed solvents[J]. Energy Fuels,2023,37(7):5206−5219 doi: 10.1021/acs.energyfuels.3c00063 [83] QIN Y, WANG D, CHEN J, et al. Selective depolymerization of lignin into phenolic products over Ni xZn1- x/ZrO2-MgO [J]. Biomass Conver Bioref, 2022, 1−17. [84] SHEN C, LI W, ZHANG B, et al. Valorization of lignin in native corn stover via fractionation-hydrogenolysis process over cobalt-supported catalyst without external hydrogen[J]. Mol Catal,2021,514:1−11. [85] GUVENATAM B, HEERES E H J, PIDKO E A, et al. Lewis acid-catalyzed depolymerization of soda lignin in supercritical ethanol/water mixtures[J]. Catal Today,2016,269:9−20. doi: 10.1016/j.cattod.2015.08.039 [86] JOFFRES B, NGUYEN M T, LAURENTI D, et al. Lignin hydroconversion on MoS2-based supported catalyst: comprehensive analysis of products and reaction scheme[J]. Appl Catal B-Environ,2016,184:153−162. doi: 10.1016/j.apcatb.2015.11.005 [87] SHAO Y, XIA Q, DONG L, et al. Selective production of arenes via direct lignin upgrading over a niobium-based catalyst[J]. Nat Commun,2017,8:1−9. doi: 10.1038/s41467-016-0009-6 [88] LONG J, ZHANG Q, WANG T, et al. An efficient and economical process for lignin depolymerization in biomass-derived solvent tetrahydrofuran[J]. Bioresour Technol,2014,154:10−17. doi: 10.1016/j.biortech.2013.12.020 [89] THI DIEU HUYEN N, MASCHIETTI M, AMAND L-E, et al. The effect of temperature on the catalytic conversion of Kraft lignin using near-critical water[J]. Bioresour Technol,2014,170:196−203. doi: 10.1016/j.biortech.2014.06.051 [90] SONG W, LAI W, LIAN Y, et al. Sulfated ZrO2 supported CoMo sulfide catalyst by surface exsolution for enhanced hydrodeoxygenation of lignin-derived ethers to aromatics[J]. Fuel,2020,263:1−10. [91] HUANG Y-B, ZHANG J-L, ZHANG X, et al. Catalytic depolymerization of lignin via transfer hydrogenation strategy over skeletal CuZnAl catalyst[J]. Fuel Process Technol,2022,237:1−13. [92] LI Y W, CAI Z P, LIAO M C, et al. Catalytic depolymerization of organosolv sugarcane bagasse lignin in cooperative ionic liquid pairs[J]. Catal Today,2017,298:168−174. doi: 10.1016/j.cattod.2017.04.059 [93] DIAS R M, PETRIN L C G, H. B. SOSA F, et al. Investigation of Kraft lignin solubility in protic ionic liquids and their aqueous solutions[J]. Ind Eng Chem Res,2020,59(40):18193−18202. doi: 10.1021/acs.iecr.0c02605 [94] PENG M M, NAKABAYASHI M, KIM K, et al. Lignin depolymerization with alkaline ionic liquids and ethylene glycol in a continuous flow reactor[J]. Fuel,2023,335:1−10. [95] LI W, WANG Y, LI D, et al. 1-Ethyl-3-methylimidazolium acetate ionic liquid as simple and efficient catalytic system for the oxidative depolymerization of alkali lignin[J]. Int J Biol Macro,2021,183:285−294. doi: 10.1016/j.ijbiomac.2021.04.118 [96] GAO H, WANG J, LIU M, et al. Enhanced oxidative depolymerization of lignin in cooperative imidazolium-based ionic liquid binary mixtures[J]. Bioresour Technol,2022,357:1−9. [97] JI Q, YU X, CHEN L, et al. Comprehensive depolymerization of lignin from lignocellulosic biomass: A review[J]. Crit Rev Environ Sci Technol,2023,53(21):1866−1887. doi: 10.1080/10643389.2023.2190314 [98] LI P H, LI X Y, JIANG Z W, et al. Mild depolymerization of alkaline lignin in a formic acid-choline chloride type deep eutectic solvent system[J]. Holzforschung,2023,77(3):149−158. doi: 10.1515/hf-2022-0145 [99] SOSA F H B, BJELIC A, COUTINHO J A P, et al. Conversion of organosolv and Kraft lignins into value-added compounds assisted by an acidic deep eutectic solvent[J]. Sustain Energy Fuels,2022,6(20):4800−4815. doi: 10.1039/D2SE00859A [100] HONG S, SHEN X-J, PANG B, et al. In-depth interpretation of the structural changes of lignin and formation of diketones during acidic deep eutectic solvent pretreatment[J]. Green Chem,2020,22(6):1851−1858. doi: 10.1039/D0GC00006J [101] LI Z M, LONG J X, ZENG Q, et al. Production of methyl-hydroxycinnamate by selective tailoring of herbaceous lignin using metal-based deep eutectic solvents (DES) as catalyst[J]. Ind Eng Chem Res,2020,59(39):17328−17337. doi: 10.1021/acs.iecr.0c01307 [102] YU Q, SONG Z L, CHEN X Y, et al. A methanol-choline chloride based deep eutectic solvent enhances the catalytic oxidation of lignin into acetovanillone and acetic acid[J]. Green Chem,2020,22(19):6415−6423. doi: 10.1039/D0GC02189J -

下载:

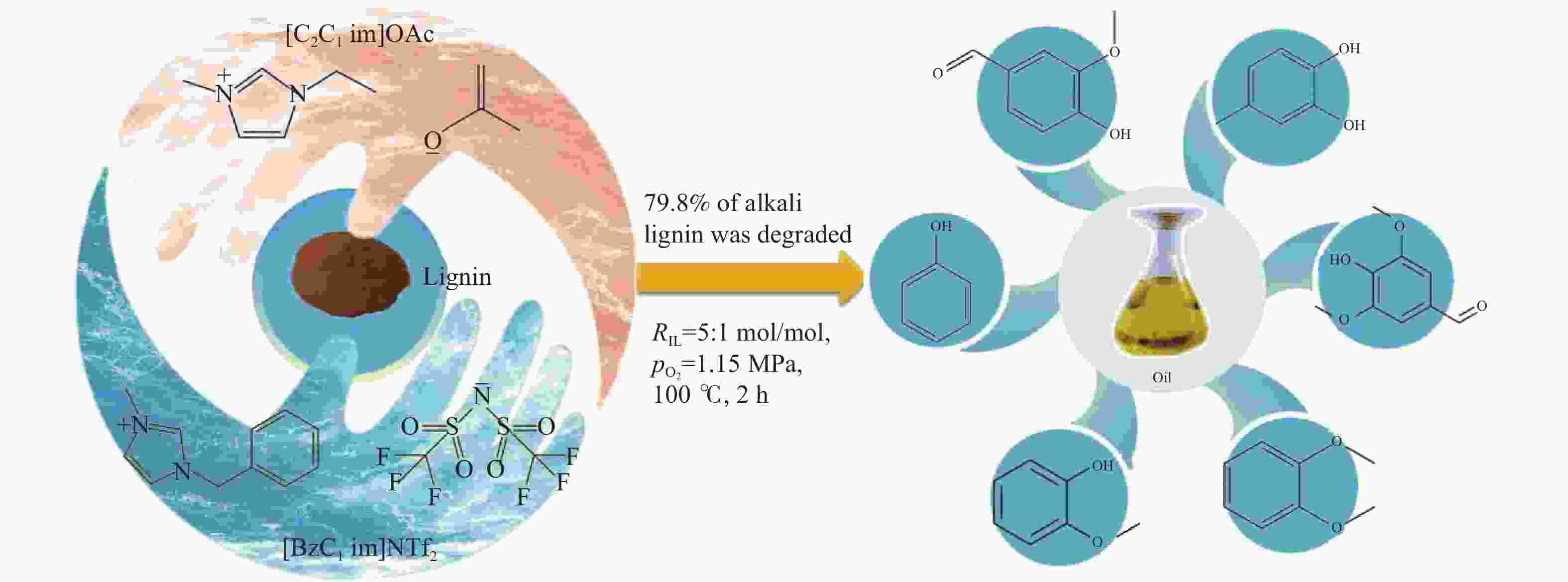

下载: