Corrosion behavior of co-gasification slag of furfural residue and coal on alumina-silica refractories

-

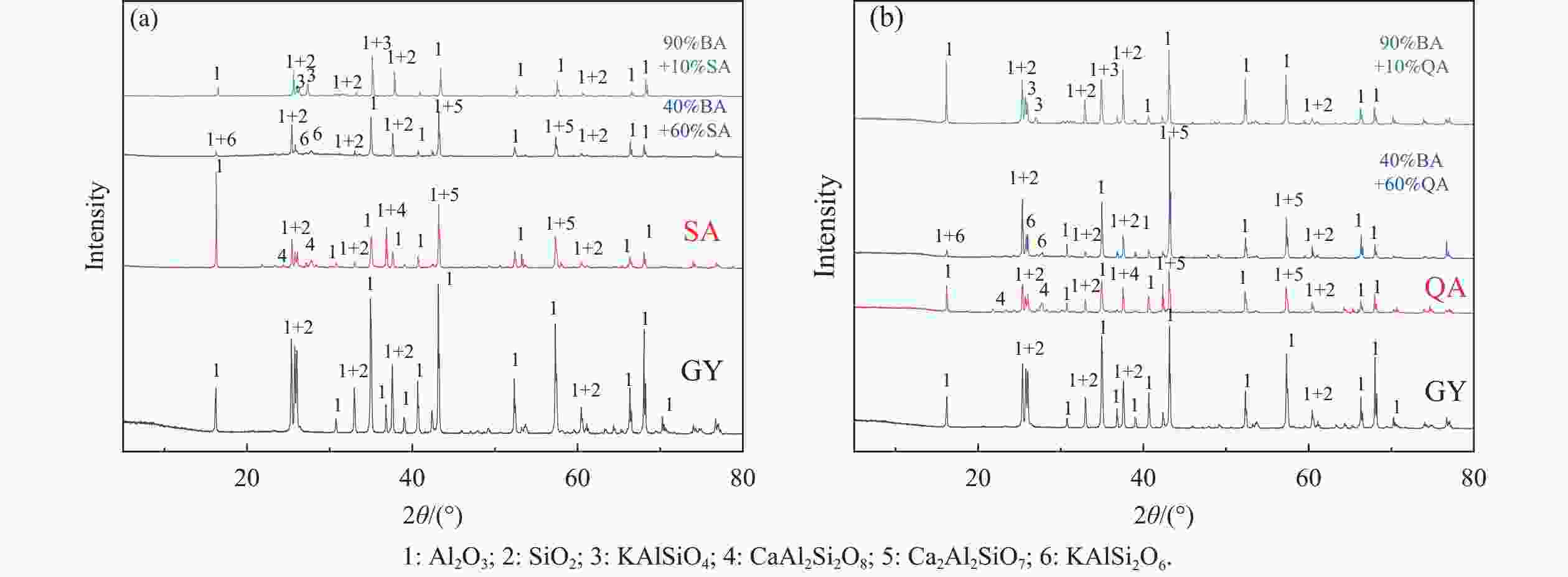

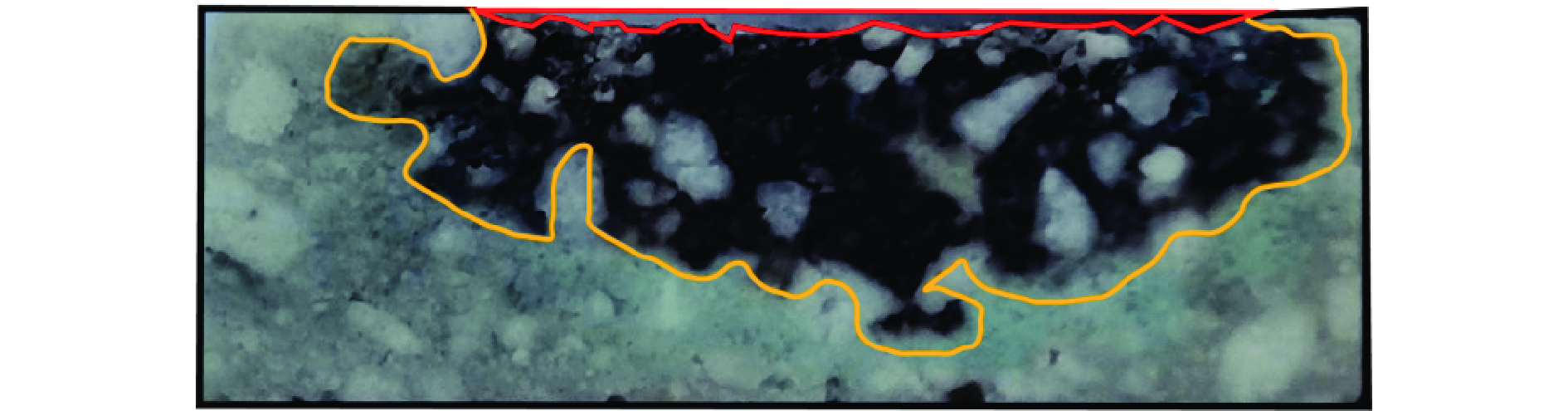

摘要: 糠醛渣与煤共气化是实现其清洁高效利用的可行路径,但煤中配入碱金属含量高的糠醛渣易造成气化炉耐火材料的腐蚀。本研究选用两种不同硅铝比(Si/Al)的气化煤和一种糠醛渣,利用X射线衍射仪(XRD)、扫描电镜(SEM-EDS)和FactSage热力学计算软件研究了配入糠醛渣的共气化灰渣对硅砖、刚玉砖、高铝砖和莫来石砖四种硅铝质耐火材料侵蚀的影响,分析了灰渣侵蚀耐火材料的机理。随着糠醛渣配比的增加,共气化灰渣对刚玉砖、高铝砖和莫来石砖三种铝质耐火材料的渗透率均呈先降低后增加的趋势,硅砖的渗透率呈逐渐降低的趋势。配入糠醛渣的灰渣中K2O、SiO2与铝质耐火材料中Al2O3反应生成的难熔矿物质白榴石(KAlSi2O6),阻碍灰渣在耐火材料的渗透。随着糠醛渣配比的增加,灰渣中K2O含量增加,形成低熔点矿物质钾霞石(KAlSiO4),加剧了灰渣在耐火材料的渗透。灰渣与硅砖间发生明显的矿物酸碱反应,随着糠醛渣配比的增加,更多的灰渣与硅砖中SiO2在表面发生反应,渗入硅砖内的灰渣量降低。硅砖的侵蚀主要由矿物酸碱反应引起,而铝质耐火材料的腐蚀主要由灰渣渗透决定的。氧化铝为主的耐火材料的渗透率能与灰渣黏度建立线性关系,其渗透率随灰渣黏度的降低而增加,这也导致低黏度的高Si/Al渣比高黏度的低Si/Al渣表现出更强的渗透性。Abstract: Gasifition of furfural residue with coal can realize its efficient and clean utilization. But the high alkali metal content in furfural slag is easy to cause the corrosion of gasifier refractory. Two gasification coals with different silica alumina ratio and a furfural residue were selected in the study. The effects of furfural residue additions on corrosion of silica brick, corundum brick, high alumina brick and mullite brick were investigated by using XRD, SEM-EDS and Factsage Software, and the corrosion mechanism was analyzed. With increasing furfural residue addition, the permeability of the slags to high-aluminium-bearing refractories first decreases and then increases, while the permeability on silica brick shows a slight decrease trend. Leucite (KAlSi2O6) with high-melting temperature is generated from the reaction of K2O and SiO2 in slag with Al2O3 in refractories after furfural residue is added, which hinders the infiltration of slag in refractories. Kaliophilite(KAlSiO4) of low-melting point is formed when K2O content increases, and this contributes to the infiltration of slag in refractories. The acid-base reaction between slag and silica brick is distinctly occurred, more slag reacts with SiO2 in the silicon brick, resulting in a decrease in the amount of slag infiltrating into the silicon brick as furfural residue is added. The corrosion of silica brick is mainly caused by the acid-base reaction, while the corrosion of three alumina based refractory bricks of corundum, mullite and high alumina brick is determined by slag infiltration. A linear correlation between the percolation rate and slag viscosity is established, the slag permeability increase with decreasing viscosity, resutling in stronger permeability for the high Si/Al slag with lower viscosity.

-

Key words:

- furfural residue /

- co-gasification /

- slag /

- refractory /

- corrosion

-

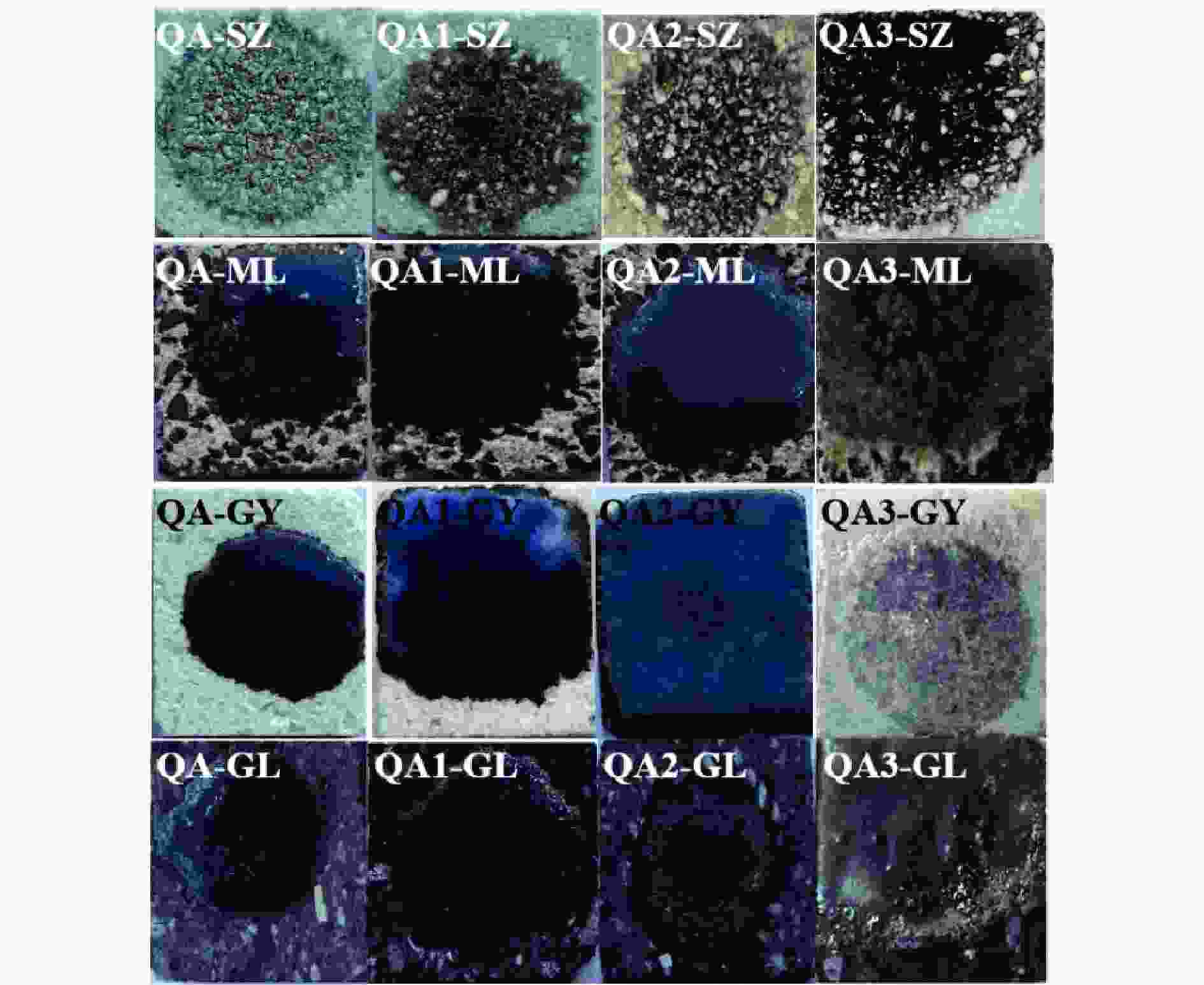

Figure 4 Percolation rate and corrosion ratio of slag on refratory

(a): SZ brick after the SA slag corrosion; (b): SZ brick after the QA slag corrosion; (c): ML brick after the SA slag corrosion;(d): ML brick after the QA slag corrosion; (e): GY brick after the SA slag corrosion; (f): GY brick after the QA slag corrosion;(g): GL brick after the SA slag corrosion; (h): GL brick after the QA slag corrosion.

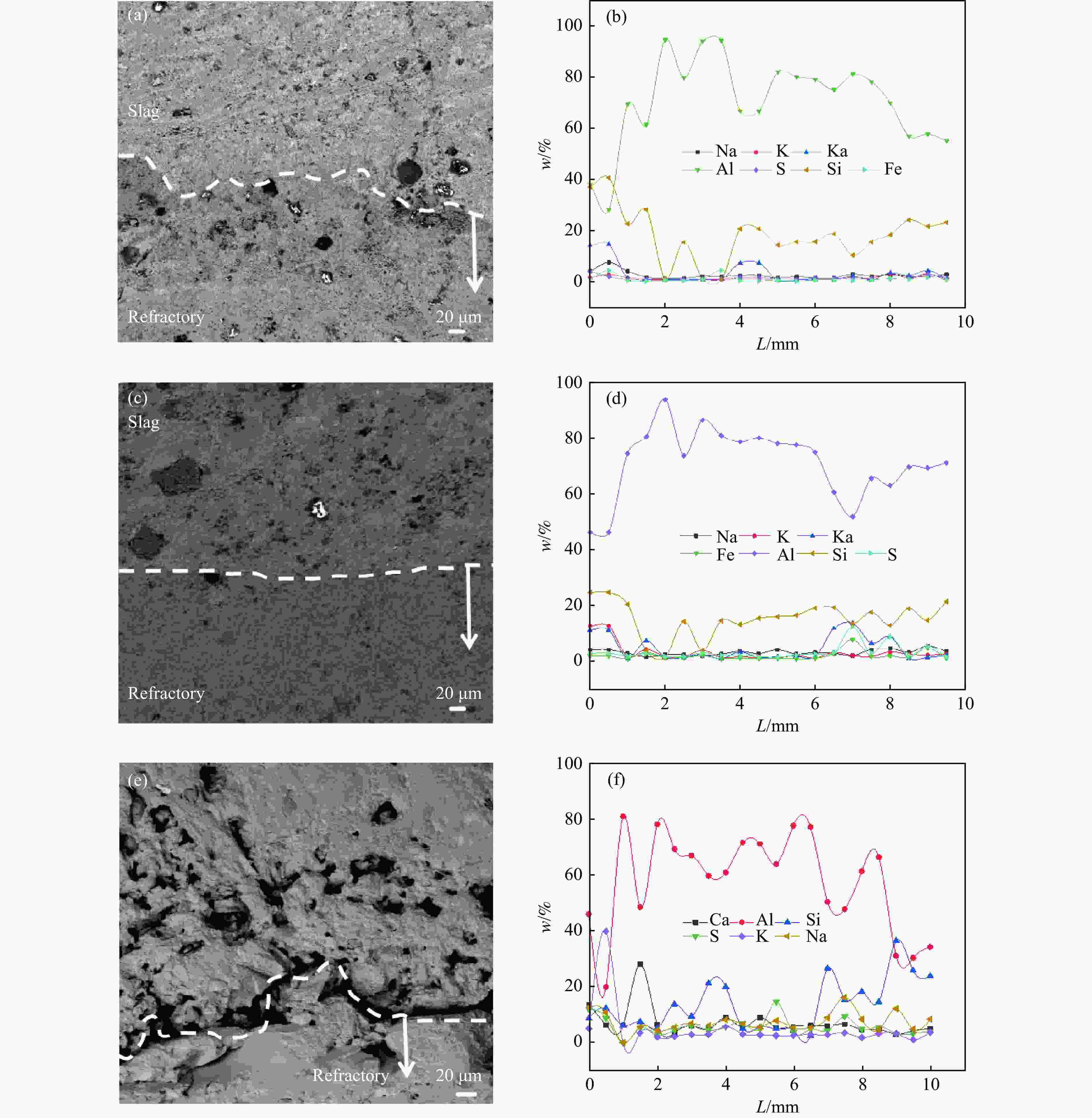

Figure 10 Thermodynamic calculation of interaction of slag with GY bricks

(a) :Slag composition of QA and GY; (b): Solid phase composition of QA and GY; (c): Slag composition of QA2 and GY; (d): Solid phase composition of QA2 and GY; (e): Slag composition of QA3 and GY; (f): Solid phase composition of QA3 and GY.

Table 1 Chemical composition of refractory materials

Sample Content w/% MgO CaO SiO2 Al2O3 Fe2O3 SZ 0.38 3.14 94.16 1.55 0.77 ML 0.28 0.00 30.93 67.83 0.96 GY 0.00 0.23 19.60 80.06 0.11 GL 1.92 0.26 17.16 79.39 1.27 Table 2 Porosity and bulk density of refractory materials

Porosity/% Bulk density/(g·cm−3 ) SZ 20.82 2.18 ML 11.54 2.90 GY 11.21 3.27 GL 18.16 3.16 -

[1] ZHU X Z, ZHANG B F, ZHU Y H, et al. Development application and optimization of biomass (furfural residue) circulating fluidized bed boiler[J]. M-Sized Nitro Fer Prog,2020,(1):56−58+62. [2] BI S X, LIU W Y, WANG C H, et al. A versatile approach to the synthesis of biomass derived from furfural residues as a potential adsorbent[J]. J Environ Chem Eng,2018,6(4):5049−5052. doi: 10.1016/j.jece.2018.07.038 [3] FENG T J, ZHANG J, ZHANG S Y. Progress of furfural production technology and market analysis in China [J]. Henan Chem Ind, 2019, 36(9): 7−10. [4] ZHOU T, ZHANG W, YUAN S F, et al. Progress in the change of ash melting behavior and slagging characteristics of co-gasification of biomass and coal: A review[J]. J Energy Inst,2023,111:101414. doi: 10.1016/j.joei.2023.101414 [5] NAKANO J, SRIDHAR S, BENNETT J, et al. Interaction of refractory materials with molten gasifier slags[J]. Int J Hydrog Energ,2011,36(7):4595−4604. doi: 10.1016/j.ijhydene.2010.04.117 [6] CAI B L, LI H X, ZHAO S X, et al. Corrosion of high chromia refractory materials by basic coal slag under simulated coal gasification atmosphere [J]. Ceram Int, 2018, 44(5): 4592-4602. [7] YU G S, ZHU Q R, CHI G Z, et al. Study on slag composition and flow property in a bench-scale OMB gasifier[J]. Fuel Process Technol,2012,104:136−143. doi: 10.1016/j.fuproc.2012.05.001 [8] MEDRALA A M, MAGDZIARZ A, REC I K, et al. The influence of potassium-richbiomass ashes on steel corrosion above 550 ℃[J]. Energ Convers Manage,2019,187:15−28. doi: 10.1016/j.enconman.2019.02.074 [9] ZHANG X, HUANG C, TANG A. S. Effect of chemical composition on corrosion resistance to cryolite of refractory[J]. Bull Chin Ceram Soc,2020,39(7):2302−2307. [10] ZHANG G. J Study on high temperature corrosion characteristics of refractory materials by coal and biomass slag[J]. Coal quality technol,2017,(6):68−72. [11] SI Y C, LI H X, SUN H G, et al. High temperature corrosion of SiC-CaAl12O19 composite refractory by coal slag[J]. Corros Sci,2022,206:110506. doi: 10.1016/j.corsci.2022.110506 [12] REINMOLLER M, KLINGER M, THIEME E, et al. Analysis and prediction of slag-induced corrosion of chromium oxide-free refractory materials during fusion of coal and biomass ash under simulated gasification conditions[J]. Fuel Process Technol,2016,149:218−230. doi: 10.1016/j.fuproc.2016.04.022 [13] CHEN D L, DU Y, ZHOU C, et al. Slagging characteristics of coal ash with different alkali-acid ratios on corundum refractories[J]. J Chin Soc Power Eng,2013,33(4):256−260. [14] WANG H, SHEN R L, WANG H M, et al. Effect of crystal phase composition on alkali corrosion resistance of silica refractories[J]. Bull Chin Ceram Soc,2023,42(3):1130−1136. [15] DANG L X. Corrosion behavior of potassium sodium alkali metals on refractories [D]. Beijing, China: China University of Petroleum, 2019. [16] QI Y. Research on viscosity-temperature characteristics of Shenhua bituminous coal and straw mixed gasification ash [D]. Jiangsu, China: Jiangsu University, 2019. [17] KANEKO T K, ZHU J X, HOWELL N, et al. The effects of gasification feedstock chemistries on the infiltration of slag into the porous high chromia refractory and their reaction products[J]. Fuel,2014,115:248−263. doi: 10.1016/j.fuel.2013.06.052 [18] MAO E L, BAI X S, LI Y, et al. Chromium-free alkaline refractories for cement kilns[J]. China Cem,2013,(9):57−59. [19] ILYUSHECHKIN A Y, HLA S S, CHEN X, et al. Effect of sodium in brown coal ash transformations and slagging behavior under gasification conditions[J]. Fuel Process Technol,2018,(179):86−98. [20] GEHRE P, ANEZIRIS C G. Investigation of slag containing refractory materials for gasification processes[J]. J Eur Ceram Soc,2012,32(16):4051−4062. doi: 10.1016/j.jeurceramsoc.2012.06.014 [21] MA X T, WANG Z G, LU H, et al. Study on the effect of furfural residue on the melting characteristics of gasified coal ash[J]. J Fuel Chem Technol,2023,51(10):1373−1382. doi: 10.1016/S1872-5813(23)60355-X -

下载:

下载: