Evolution of carbon microstructure and gasification activity during rice husk gasification

-

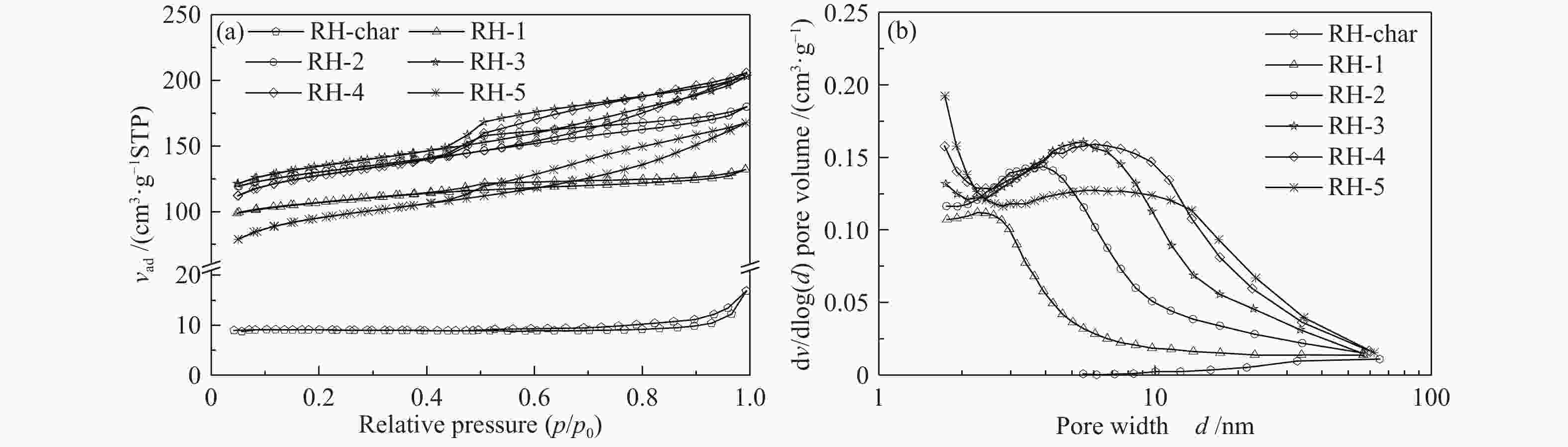

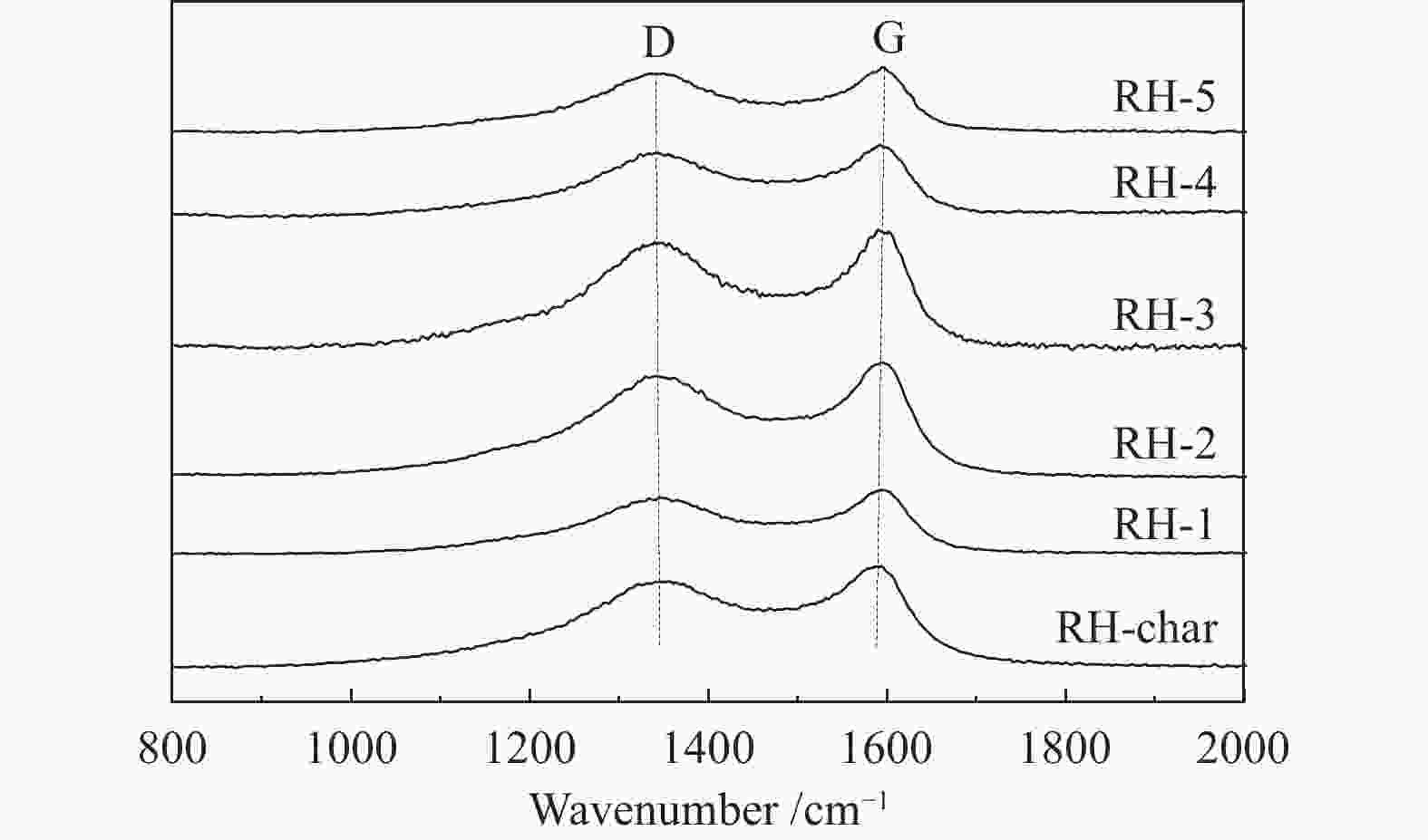

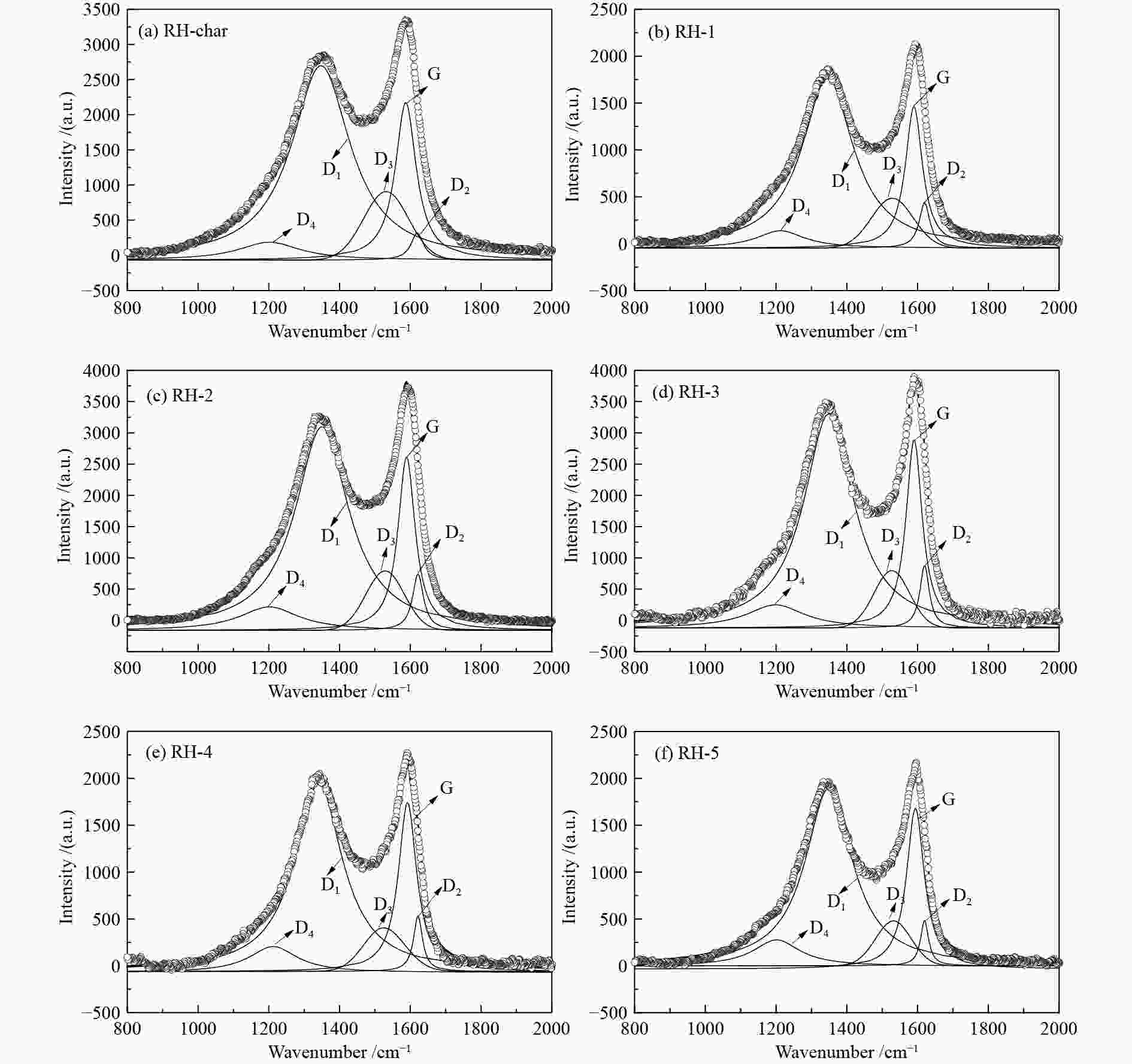

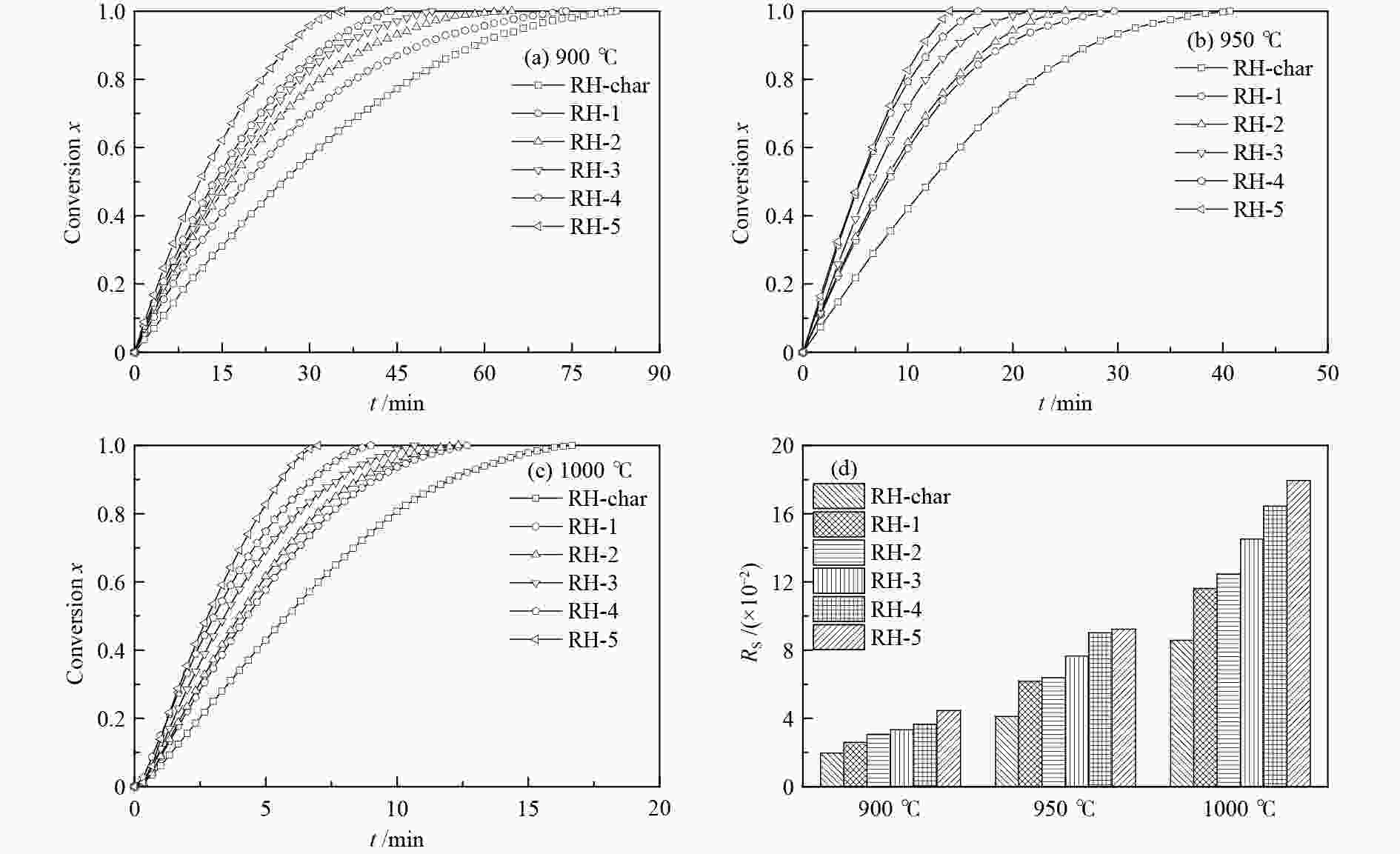

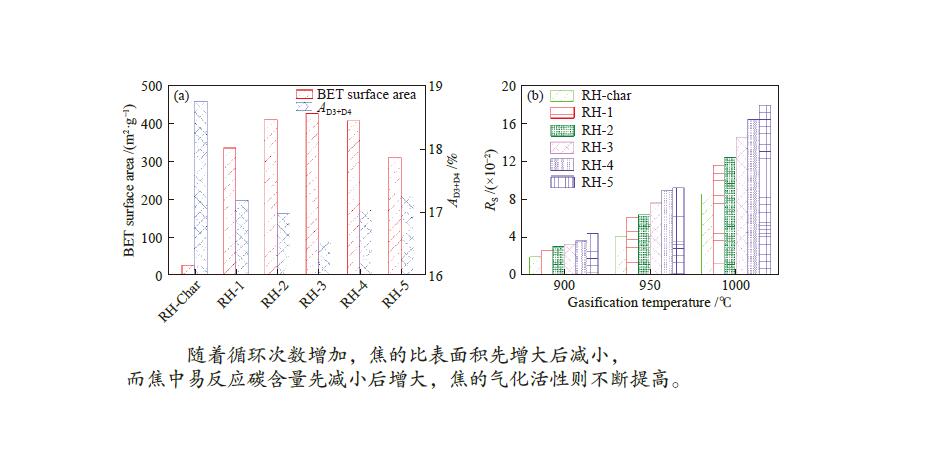

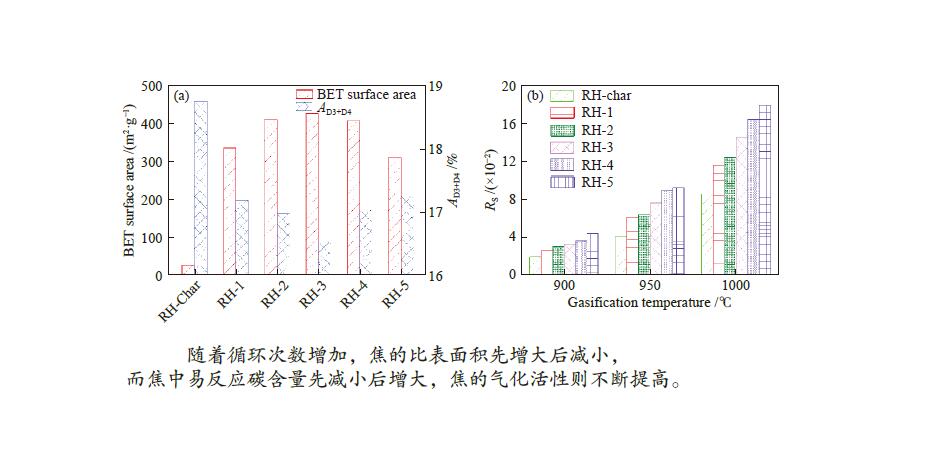

摘要: 为探究高倍率循环流化床气化过程中生物质中碳微观结构及气化活性演变规律,在实验室固定床反应装置上对稻壳进行了高循环倍率气化过程模拟,并对稻壳热解焦及其不同次数循环气化后样品的孔隙结构、碳微观结构及气化活性进行了研究。结果表明,随着循环次数的增加,焦的比表面积呈现先增大后减小的趋势,但不同次数循环后焦的BET比表面积均明显高于稻壳热解焦。随着循环气化过程的进行,焦中碳的ID1/IG不断减小,即焦中碳结构有序程度不断提高,而AD3+D4相对含量则先减小后稍有增加,但与热解焦相比均有所减小。在实验条件下不同次数循环后焦的气化活性均优于其热解焦,且随着循环次数的增加,焦的CO2气化反应活性不断提高。Abstract: In order to investigate the evolution of carbon microstructure and gasification activity during circulating fluidized bed gasification, the simulated circulating gasification of a rice husk was carried out in a laboratory fixed bed reactor, and the pore structure, carbon microstructure and gasification activity of char during gasification were investigated. The results show that the BET surface area of char increases firstly and then decreases with an increase in gasification cycle times, and the surface areas of rice husk chars obtained from circulating gasification process are much higher than that of original char. The ID1/IG values of char decrease monotonously with an increase in gasification cycle times, indicating that the graphitization degree of carbon structure in char increases. Meanwhile, the relative content of AD3+D4 of char decreases firstly and then increases slightly with the progress of circulating gasification, and the relative contents of AD3+D4 of all chars obtained from a circulating gasification process are lower than that of original char. Moreover, the gasification activity of char increases gradually with an increase in gasification cycle times, and the gasification activity of all chars obtained from a circulating gasification process are higher than that of original char.

-

表 1 稻壳的工业分析和元素分析

Table 1 Proximate and ultimate analyses of a rice husk

Proximate analysis w/% Ultimate analysis wd/% Mar Ad Vd FCd C H N $ {\rm{O}}^* $ St 9.15 15.44 69.28 15.28 43.53 4.67 0.44 35.89 0.03 ar-as received;d-dry basis;*-by difference 表 2 稻壳的灰分组成

Table 2 Chemical compositions of ash in rice husk at a temperature of 823 K

Sample Content w/% SiO2 K2O CaO MgO Na2O Al2O3 Fe2O3 TiO2 P2O5 SO3 RH 91.84 3.33 0.71 0.57 0.05 0.20 0.75 0.01 0.87 0.35 表 3 稻壳不同次数循环后焦的基本性质

Table 3 Preliminary properties of samples

Sample Proximate analysis w/% Ultimate analysis wd/% x/% Mad Ad Vd FCd C H N O St RH-char 3.49 40.70 3.51 55.79 57.89 0.42 0.51 0.36 0.12 49.55 RH-1 2.24 48.26 3.01 48.73 50.38 0.54 0.42 0.3 0.09 62.97 RH-2 2.31 57.55 2.79 39.66 41.11 0.51 0.47 0.28 0.08 74.66 RH-3 2.69 65.25 2.67 32.08 33.41 0.52 0.46 0.27 0.10 81.84 RH-4 2.31 72.50 2.58 24.92 26.24 0.51 0.39 0.25 0.11 87.16 RH-5 2.07 82.47 2.48 15.05 16.22 0.55 0.39 0.22 0.14 93.02 表 4 样品的孔结构参数

Table 4 Parameters of pore structure of samples

Sample A/

(m2·g−1)v/

(cm3·g−1)d/nm RH-char 27.01 0.01 35.37 RH-1 335.55 0.07 3.12 RH-2 410.16 0.12 3.81 RH-3 426.82 0.16 4.22 RH-4 407.81 0.18 4.43 RH-5 309.61 0.17 4.46 表 5 样品拉曼光谱的碳结构参数

Table 5 Carbon structural parameters of samples

Parameters RH-char RH-1 RH-2 RH-3 RH-4 RH-5 D1-FWHM/cm−1 198.00 173.84 180.91 168.78 163.14 159.14 G-FWHM/cm−1 71.49 58.55 58.86 55.67 62.69 61.11 G-D separation/cm−1 245.17 249.42 251.55 252.08 253.68 255.82 ID1/IG 1.21 1.18 1.15 1.12 1.10 1.09 AD3+D4/AAll (%) 18.75 17.19 16.97 16.52 17.03 17.25 -

[1] 陈冠益, 高文学, 颜蓓蓓. 生物质气化技术研究现状与发展[J]. 煤气与热力,2006,26(7):20−26.CHEN Guan-yi, GAO Wen-xue, YAN Bei-bei. Present research status and development of biomass gasification technologies[J]. Gas Heat,2006,26(7):20−26. [2] RAGNAR W. Gasification of biomass: Comparison of fixed bed and fluized bed gasifier[J]. Biomass Bioenergy,2000,18:489−497. doi: 10.1016/S0961-9534(00)00009-X [3] 樊红莉, 李风海, 黄戒介. 神木煤焦与流化床气化带出细粉的CO2气化特性[J]. 洁净煤技术,2019,25(1):98−102.FAN Hong-li, LI Feng-hai, HUANG Jie-jie. CO2 gasification properties of coal chars and fine chars from fluidized bed gasification of Shenmu coal[J]. Clean Coal Technol,2019,25(1):98−102. [4] 景旭亮, 王志青, 余钟亮, 房倚天. 半焦的多循环气化活性及微观结构分析[J]. 燃料化学学报,2013,41(8):917−921.JING Xu-liang, WANG Zhi-qing, YU Zhong-liang, FANG Yi-tian. Multi-circulated gasification reactivity of coal char and its microstructure analysis[J]. J Fuel Chem Technol,2013,41(8):917−921. [5] 向银花, 王洋, 张建民, 张守玉, 房倚天, 董众兵. 部分气化焦的水蒸气气化动力学[J]. 化工学报,2003,54(3):368−373.XIANG Yin-hua, WANG Yang, ZHANG Jian-min, ZHANG Shou-yu, FANG Yi-tian, DONG Zhong-bing. Kinetic on steam gasification of partially gasified char[J]. J Chem Ind Eng,2003,54(3):368−373. [6] 易秋明, 刘华财, 阴秀丽, 吴创之. 生物质新生半焦与冷态半焦CO2气化活性差异分析[J]. 新能源进展,2015,3(3):169−176.YI Qiu-ming, LIU Hua-cai, YIN Xiu-li, WU Chuang-zhi. Comparative investigation of the CO2 gasification characteristics of biomass In-situ char and Ex-situ char[J]. Adv New Renew Eng,2015,3(3):169−176. [7] 赵丽萍, 王鑫, 张彪, 吴斯侃, 邓桂春. 不同热解温度下落叶松半焦特性的演变规律[J]. 可再生能源,2019,37(7):972−977.ZHAO Li-ping, WANG Xin, ZHANG Biao, WU Si-kan, DENG Gui-chun. Effect of pyrolysis temperature on characteristics evolution of larch char[J]. Renewable Energy Resour,2019,37(7):972−977. [8] BRECH Y L, RAYA J, DELMOTTE L, BROSSE N, GADIOU R, DUFOUR A. Characterization of biomass char formation investigated by advanced solid state NMR[J]. Carbon,2016,108:165−177. doi: 10.1016/j.carbon.2016.06.033 [9] WANG G W, ZHANG J L, SHAO J G, LIU Z J, WANG H Y, LI X Y, ZHANG P C, GENG W W, ZHANG G H. Experimental and modeling studies on CO2 gasification of biomass chars[J]. Energy,2016,114:143−154. doi: 10.1016/j.energy.2016.08.002 [10] HUANG S, WU S Y, WU Y Q, GAO J S. Structure characteristics and gasification activity of residual carbon from updraft fixed bed biomass gasification ash[J]. Energy Convers Manange,2017,136:108−118. doi: 10.1016/j.enconman.2016.12.091 [11] SING K S W, EVERETT D H, HAUL R A W, MOSCOU L, PIEROTTI R A, ROUQUEROL J, SIEMIENIEWSKA T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity[J]. Pure Appl Chem,1985,57:603−619. doi: 10.1351/pac198557040603 [12] 尹艳山, 王泽忠, 田红, 张巍, 何金桥, 刘亮, 鄢晓忠. 木质纤维类生活垃圾热解过程矿物质和碳结构的演化规律[J]. 燃料化学学报,2015,43(2):160−166.YIN Yan-shan, WANG Ze-zhong, TIAN Hong, ZHANG Wei, HE Jin-qiao, LIU Liang, YAN Xiao-zhong. Evolution of mineral matter and carbonaceous structure during lignocellulosic municipal solid waste pyrolysis[J]. J Fuel Chem Technol,2015,43(2):160−166. [13] ZICKLER G A, SMARSLY B, GIERLINGER N, PETRLIK H, PARIS O. A reconsideration of the relationship between the crystallite size La of carbons determined by X-ray diffraction and Raman spectroscopy[J]. Carbon,2006,44(15):3239−3246. doi: 10.1016/j.carbon.2006.06.029 [14] MIAO Z K, GUO F H, ZHAO X, GUO Z K, GUO Y, ZHANG Y X, WU J J. Effects of acid treatment on physicochemical properties and gasificationreactivity of fine slag from Texaco gasifier[J]. Chem Eng Res Des,2021,169:1−8. doi: 10.1016/j.cherd.2021.01.020 [15] WU S Y, HUANG S, JI L Y, WU Y Q, GAO J S. Structure characteristics and gasification activity of residual carbon from entrained-flow coal gasification slag[J]. Fuel,2014,122:67−75. doi: 10.1016/j.fuel.2014.01.011 [16] WANG J, KONG L X, BAI J, XUE K, ZHU X L, LUO Y D, ZHAO X P, LI H Z, GUO Z X, BAI Z Q, LI W. Characterization of slag from anthracite gasification in moving bed slagging gasifier[J]. Fuel,2021,292:120390. doi: 10.1016/j.fuel.2021.120390 [17] XU S Q, ZHOU Z J, GAO X X, YU G S, GONG X. The gasification reactivity of unburned carbon present in gasification slag from entrained-flow gasifier[J]. Fuel Process Technol,2009,90:1062−1070. doi: 10.1016/j.fuproc.2009.04.006 [18] 李庆峰, 房倚天, 张建民, 王洋, 时铭显, 孙国刚. 气化活性与孔比表面积的关系[J]. 煤炭转化,2003,26(3):45−48.LI Qing-feng, FANG Yi-tian, ZHANG Jian-min, WANG Yang, SHI Ming-xian, SUN Guo-gang. Relationship of gasification activity and pore structure[J]. Coal Convers,2003,26(3):45−48. -

下载:

下载: