Cracking of F-T refined wax for producing linear α-olefin

-

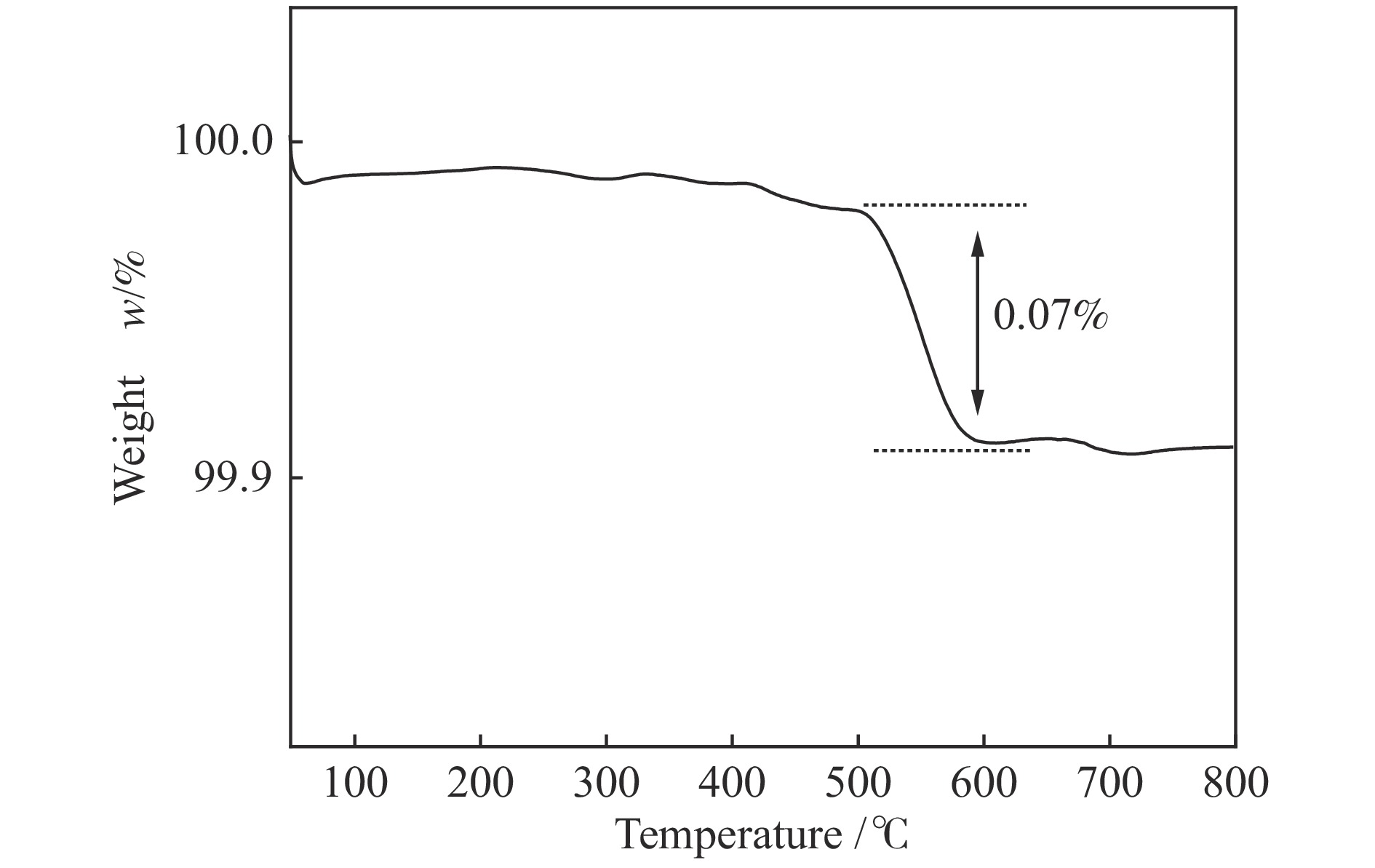

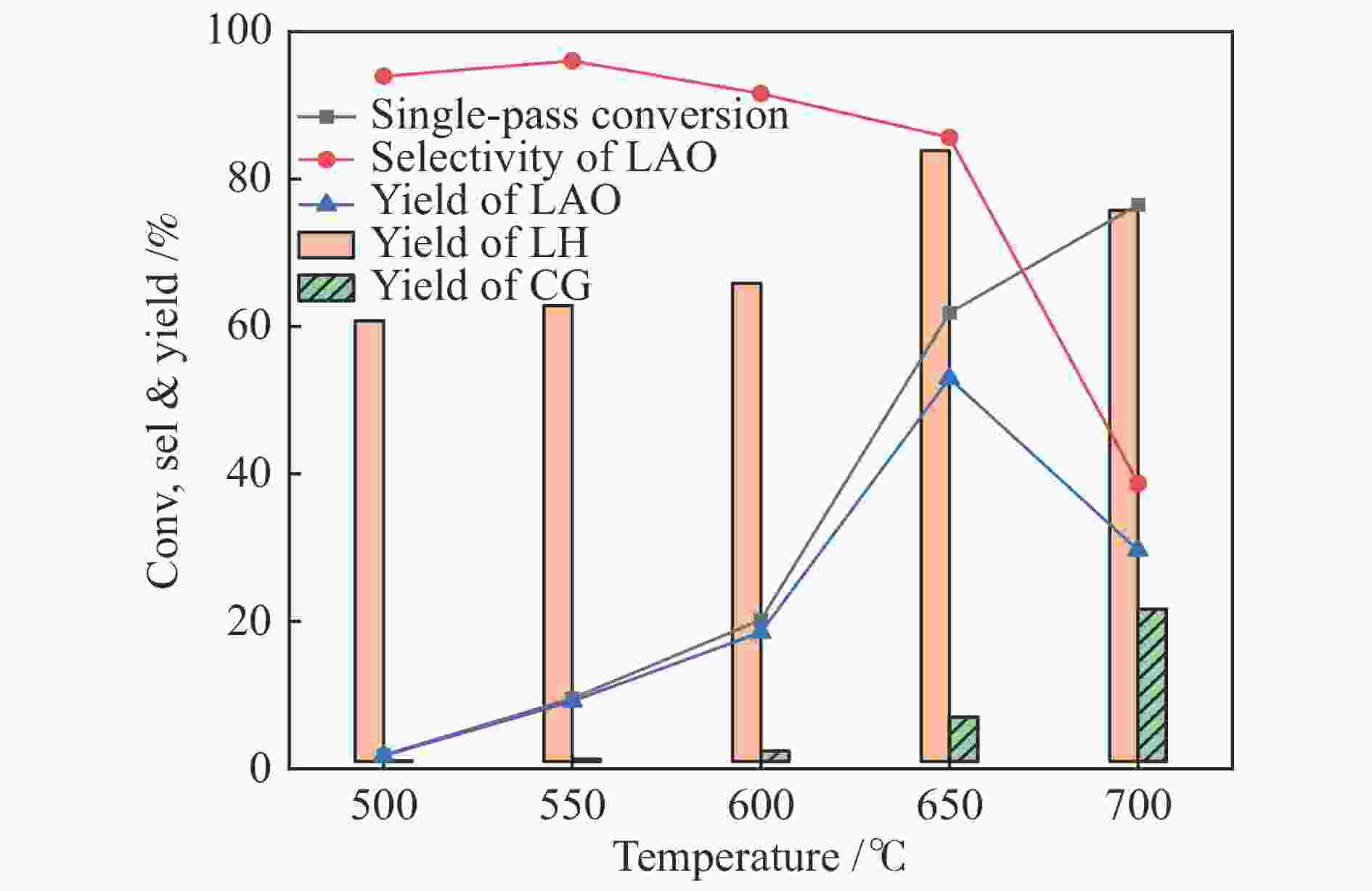

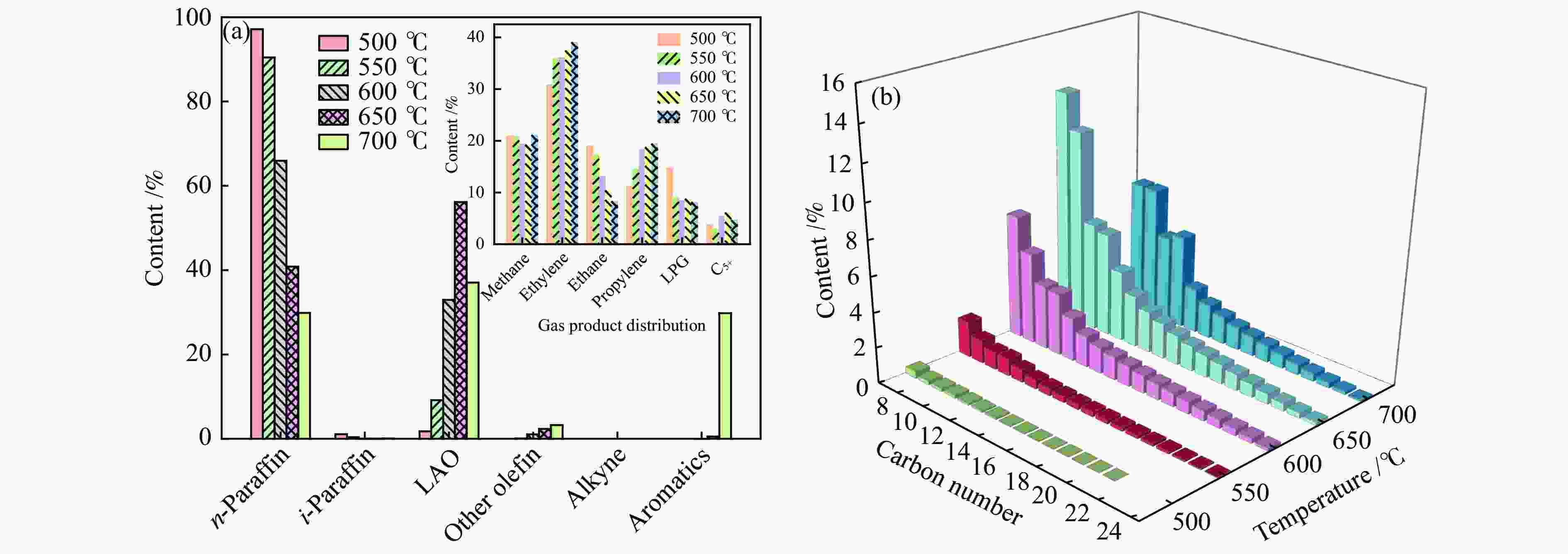

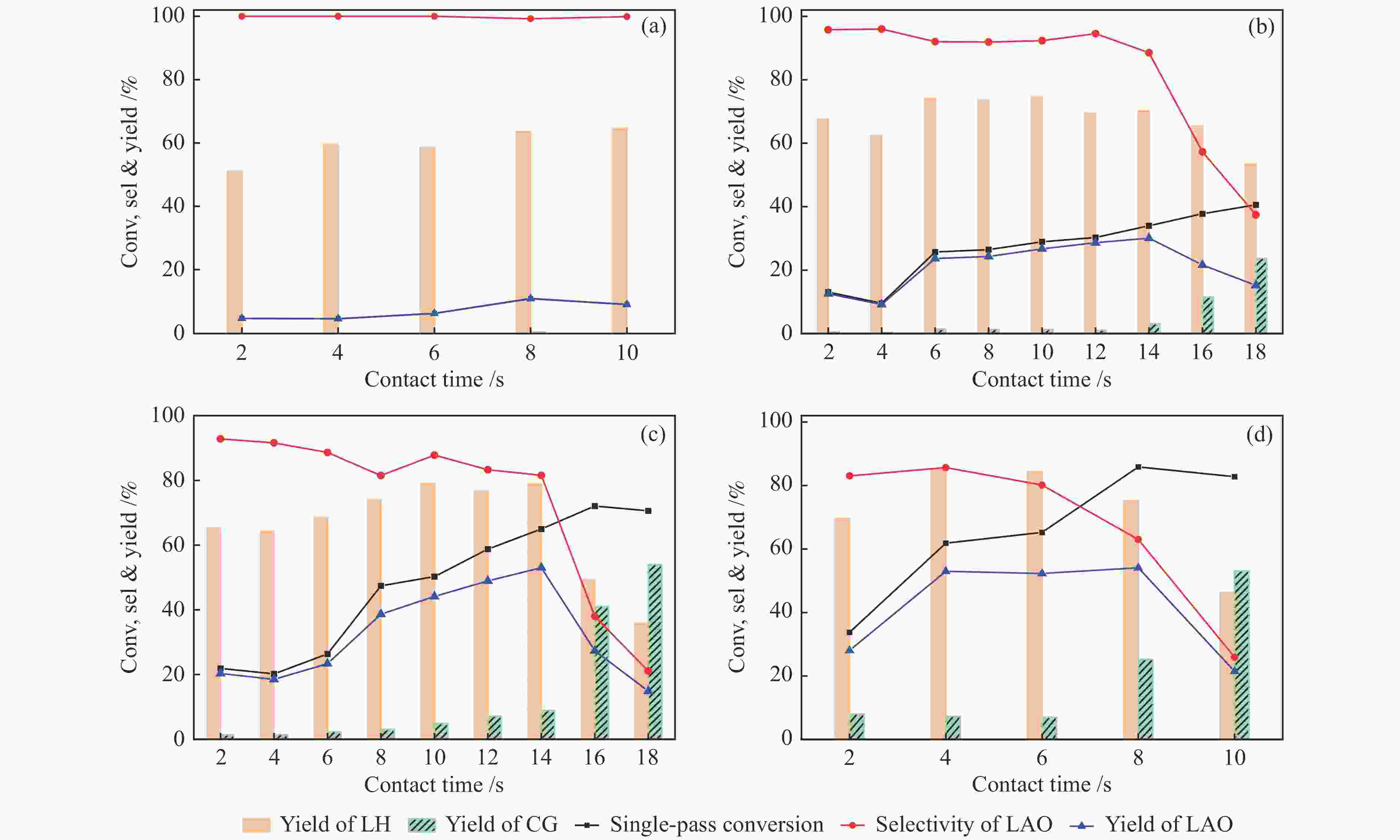

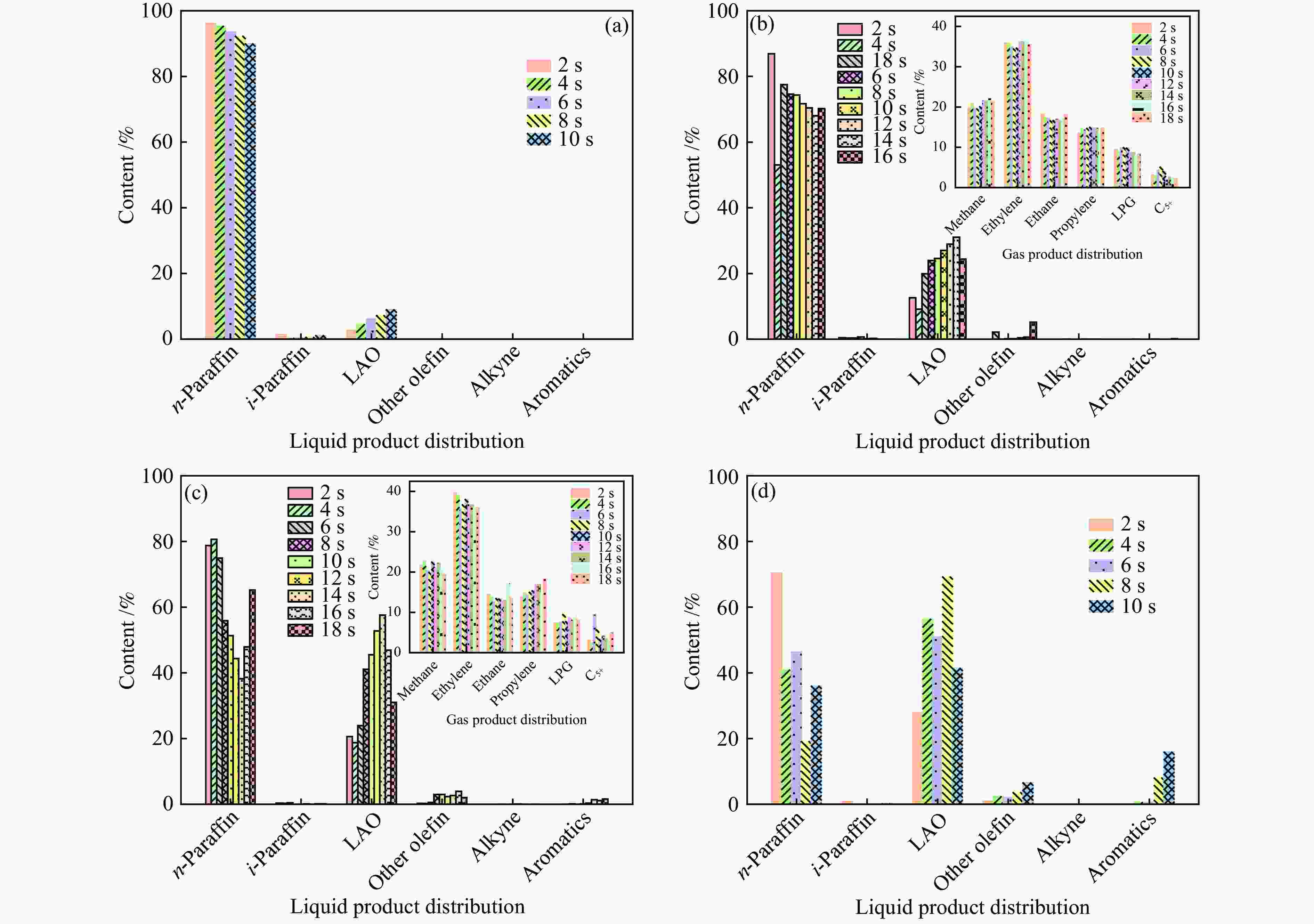

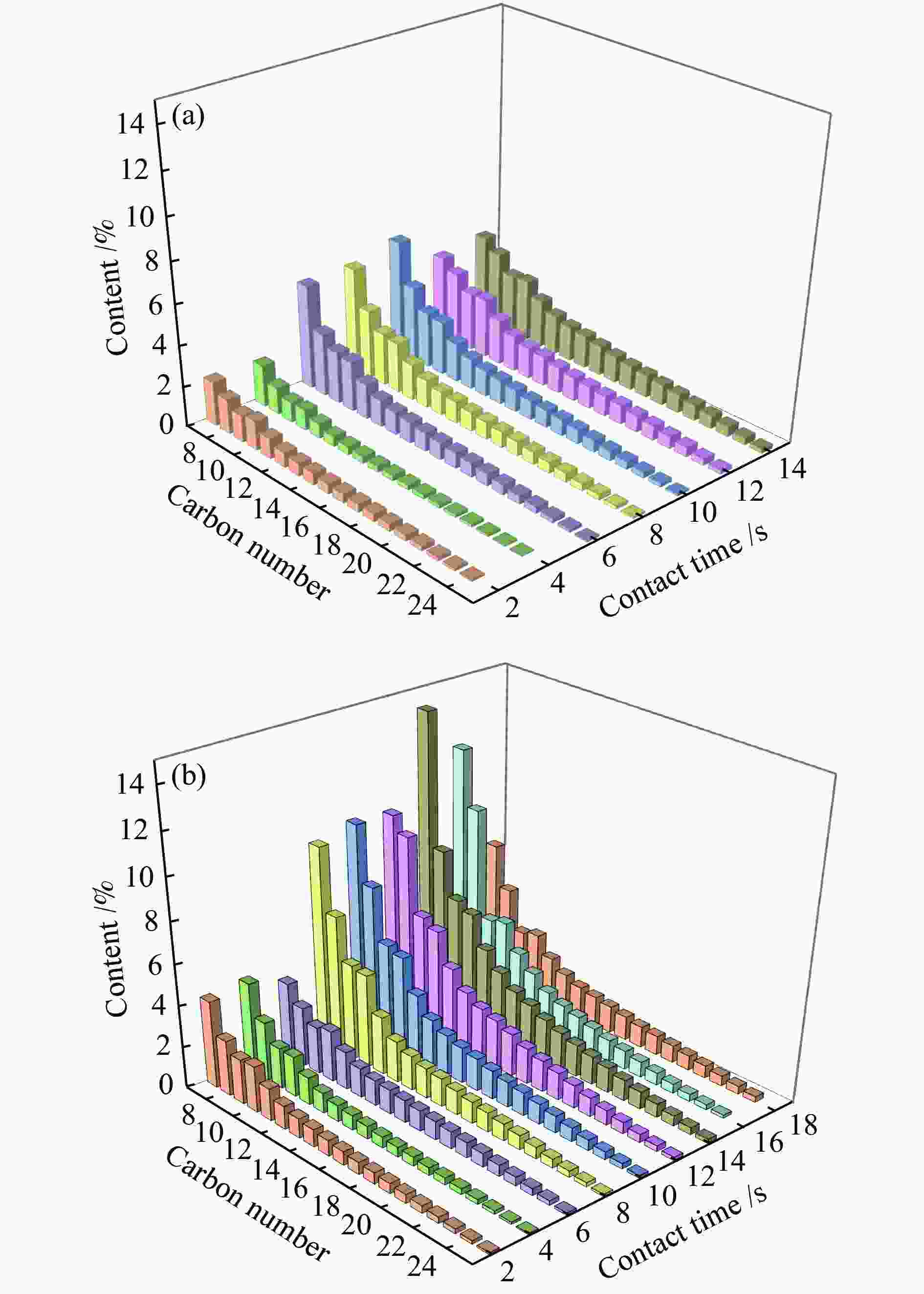

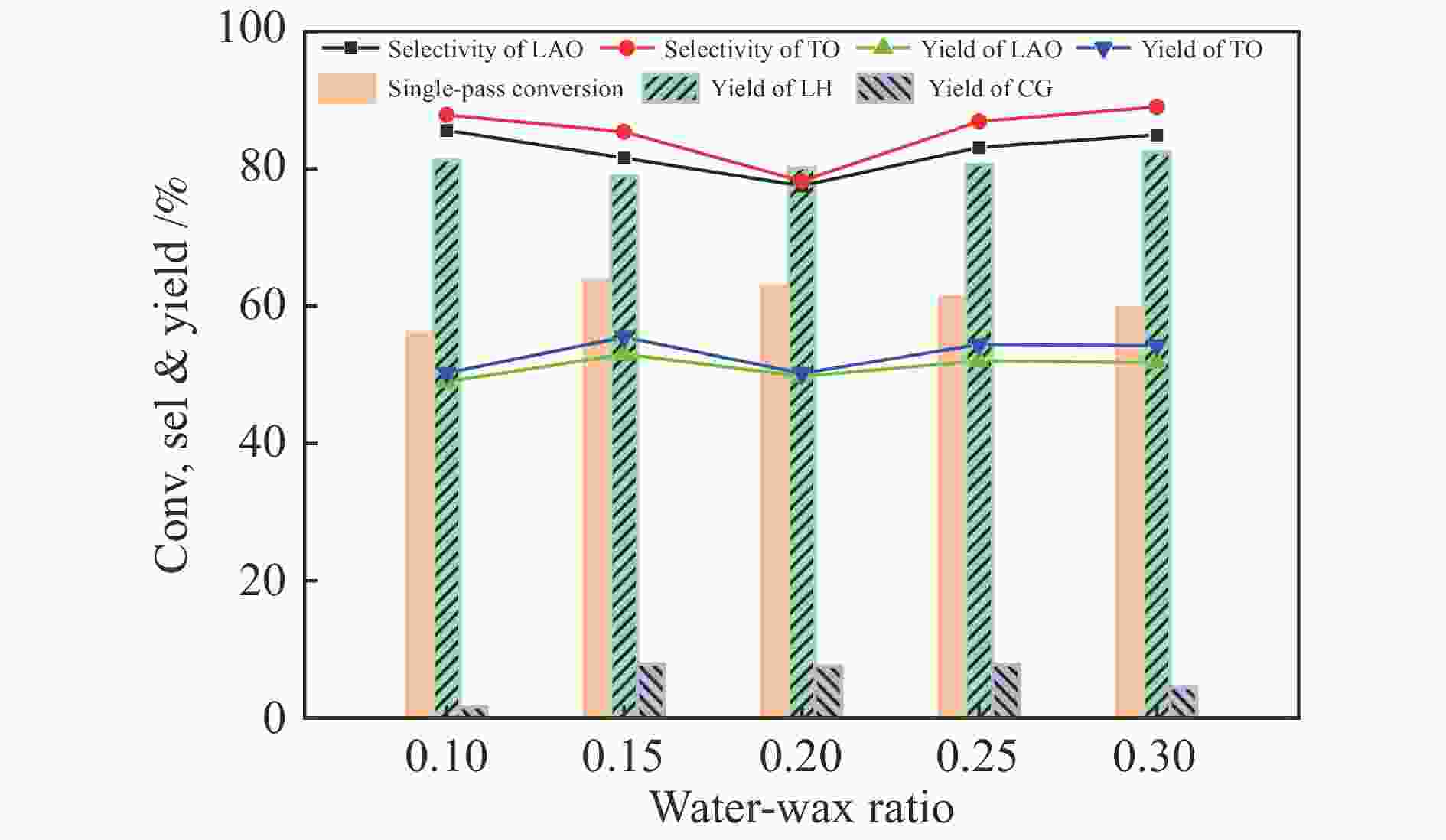

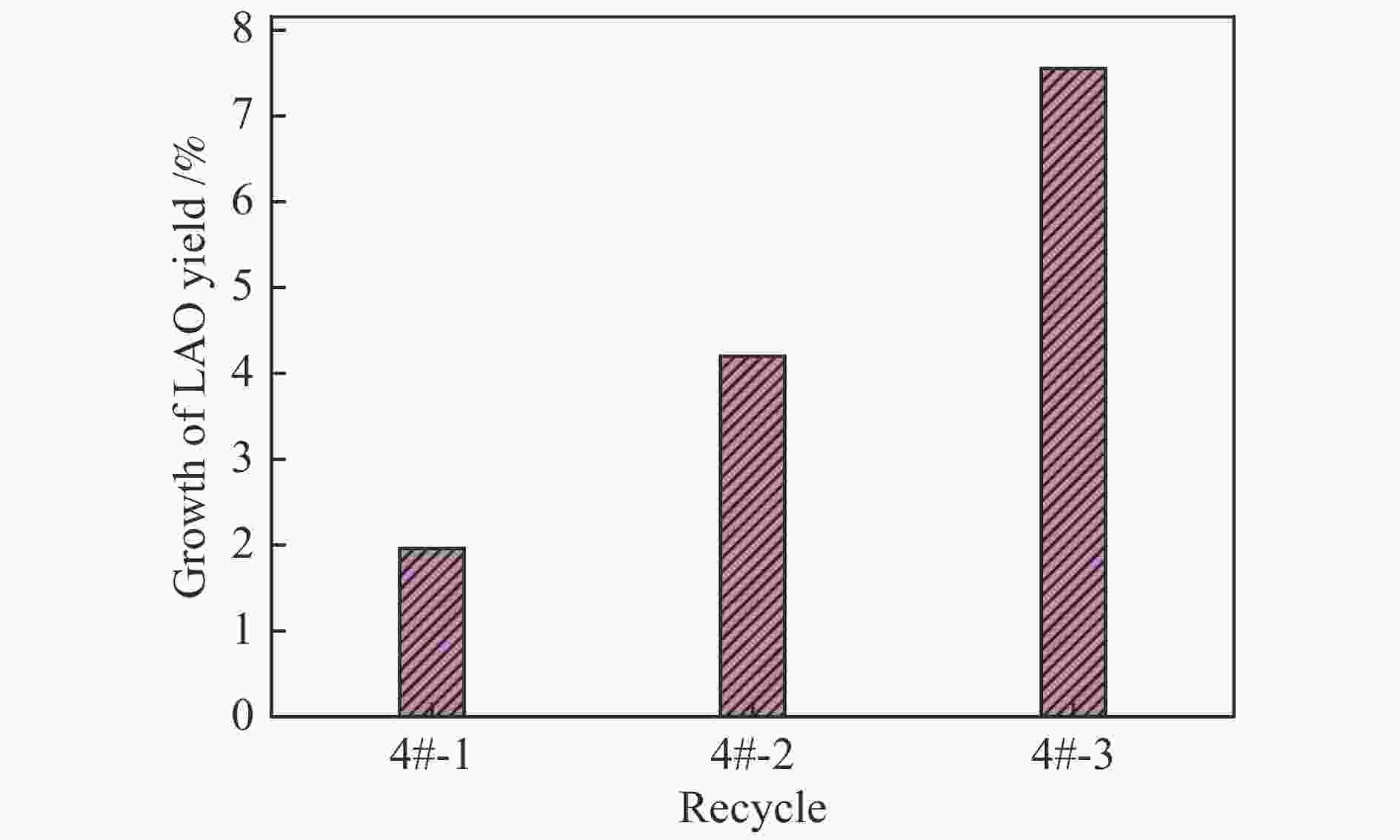

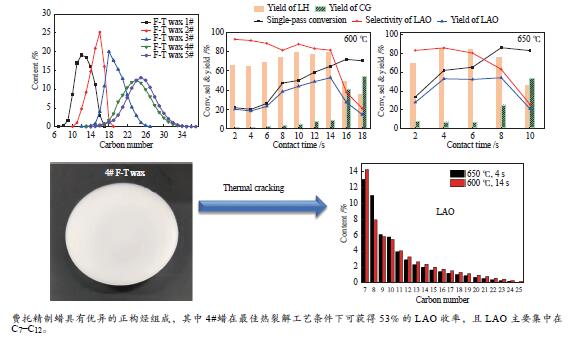

摘要: 以煤制油工艺费托精制蜡为原料,在固定床反应器上进行了热裂解制线性α-烯烃(LAO)的实验,考察了原料组成、裂解温度、停留时间、水蜡比及循环工艺对转化率及裂解产物分布的影响,优化了工艺条件。结果表明,裂解温度及停留时间对原料转化率及LAO收率有显著影响,循环工艺可进一步提高LAO收率。过高的裂解温度或过长的停留时间均会导致生成的LAO的二次反应,对反应不利。在适合的工艺条件下可获得53%的LAO收率。Abstract: The steam cracking of Fischer-Tropsch refined wax from the coal-to-oil process for producing linear α-olefin (LAO) was carried out on a fixed bed reactor. The effects of feedstock composition, cracking temperature, contact time, water-to-wax ratio and cyclic process on the feed conversion and products distribution were investigated and optimized. The factors such as cracking temperature and contact time have significant influence on conversion and LAO yield, and cyclic process can further improve the LAO yield. However, excess high cracking temperature and longer contact time result in the second reactions, which are unfavorable for the LAO production. Under the suitable process conditions 53% of LAO yield are obtained.

-

Key words:

- Fischer-Tropsch refined wax /

- thermal cracking /

- linear α-olefin /

- liquid hydrocarbon /

- optimization

1) # These authors contributed equally to this work -

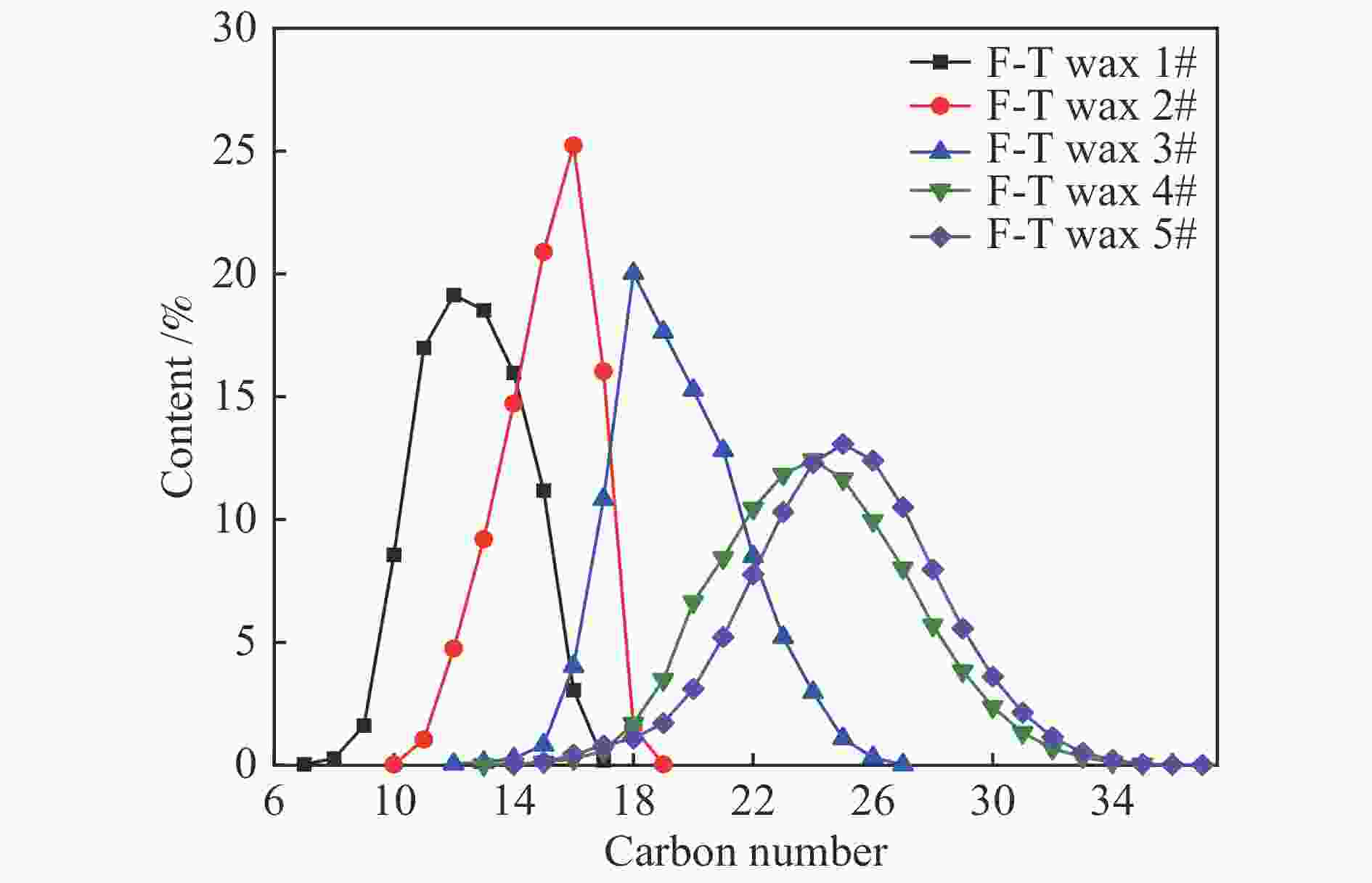

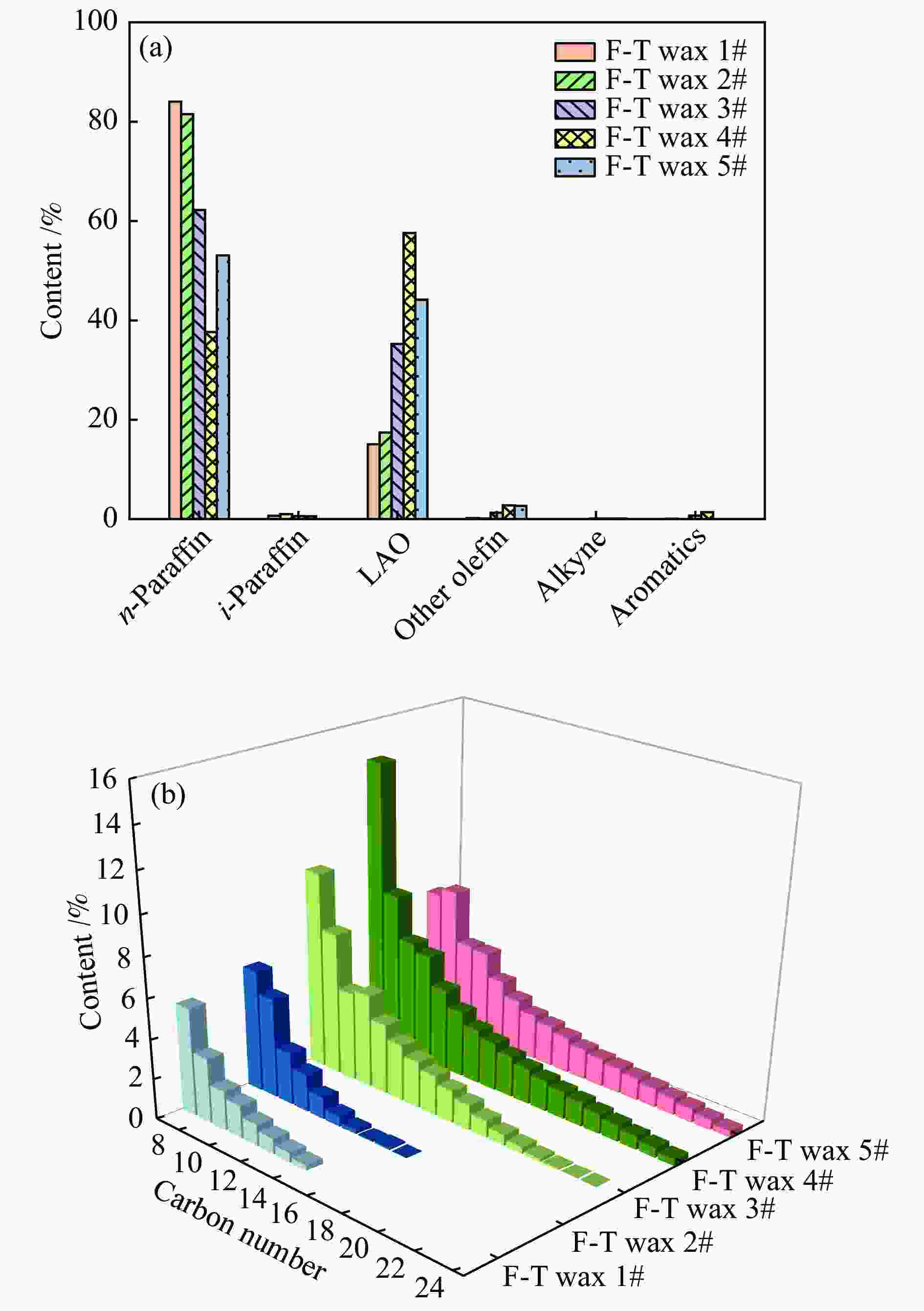

表 1 费托蜡基本组成

Table 1 Composition of F-T wax

Fischer-Tropsch

refined wax1# 2# 3# 4# 5# Composition

w/%n-paraffin 95.56 93.49 87.96 95.11 99.11 i-paraffin 4.44 6.51 12.04 4.89 0.89 other 0 0 0 0 0 heavy hydrocarbon

(>C25)− − 0.34 32.34 44.10 表 2 不同原料蜡的裂解气组成

Table 2 Composition of cracking gas for different wax

Feedstock 1# 2# 3# 4# 5# Yield /% 2.3 3.1 4.9 10.1 7.4 Selectivity

/%methane 24.2 24.0 22.2 22.4 22.5 ethane 14.8 14.8 13.6 13.3 11.3 ethylene 39.3 39.2 36.1 38.0 39.8 propylene 14.4 14.6 17.1 15.3 15.4 propane 1.3 1.2 1.5 1.5 1.0 isobutene 0.0 0.0 0.0 3.8 0.0 n-butene 3.2 3.4 4.0 1.6 3.6 n-butane 1.0 1.0 2.0 0.5 1.9 maleic 0.1 0.1 0.3 0.3 0.3 C5+ 1.6 1.7 3.2 3.3 4.1 表 3 不同循环原料的基本组成

Table 3 Composition of cyclic feedstock

Composition

/%Feedstock 4# 4#-1 4#-2 4#-3 n -paraffin 95.1 95.2 91.8 90.6 iso-paraffin 4.9 3.0 3.5 3.4 LAO 0 1.7 4.6 5.8 Total olefins 0 1.7 4.8 6.0 Heavy hydrocarbon(C25+) 32.3 30.8 29.9 30.9 -

[1] 李东胜, 孙朝霞, 孙桂大, 刘四运. 我国蜡裂解α-烯烃的综合利用[J]. 辽宁石油化工大学学报,1999,19(3):4−8. doi: 10.3969/j.issn.1672-6952.1999.03.002LI Dong-sheng, SUN Zhao-xia, SUN Gui-da, LIU Si-yun. The appropriate using of domestic wax cracking α-olefins[J]. J Liaoning Petrochem Univ,1999,19(3):4−8. doi: 10.3969/j.issn.1672-6952.1999.03.002 [2] PATEL R M, KARJALA T P, SAVARGAONKAR N R, SALIBI P, LIU L Z. Fundamentals of structure-property relationships in blown films of linear low density polyethylene/low density polyethylene blends[J]. J Plast Film Sheet,2019,35(4):401−421. doi: 10.1177/8756087919844303 [3] 刘素丽, 袁炜, 罗春桃. α-烯烃的生产及应用[J]. 合成材料老化与应用,2016,45(3):132−135. doi: 10.3969/j.issn.1671-5381.2016.03.031LIU Su-li, YUAN Wei, LUO Chun-tao. The production and application of α-olefin[J]. Synth Mater Aging Appl,2016,45(3):132−135. doi: 10.3969/j.issn.1671-5381.2016.03.031 [4] 乔瑞平. α-烯烃磺酸盐的新生产工艺研究[D]. 天津: 天津大学, 1999.QIAO Rui-ping. The study on new process for production of α-olefin sulfonate[D]. Tianjin: Tianjin University, 1999. [5] DONG W D, ZHU H J, DING Y J, PEI Y P, DU H, WANG T. Effect of trace amounts of Li doping on performance of Co/AC catalysts for syntheses of mixed linear alpha-alcohols[J]. Acta Phys-Chim Sin,2014,30(9):1745−1751. doi: 10.3866/PKU.WHXB201405301 [6] 蔡力宏, 梁雪美. 高碳醇的市场应用及煤基费托合成高碳醇的生产工艺[J]. 合成材料老化与应用,2017,46(6):123−127. doi: 10.16584/j.cnki.issn1671-5381.2017.06.026CAI Li-hong, LIANG Xue-mei. Application of higher alcohol and technology of Fishcher-Tropsch higher alcohol[J]. Synth Mater Aging Appl,2017,46(6):123−127. doi: 10.16584/j.cnki.issn1671-5381.2017.06.026 [7] 于玥, 陈华磊, 侯殿志, 朱延光, 黄双霞, 蓝蔚冰, 王帅静, 陈山. 二十八烷醇的应用与安全性研究[J]. 广西糖业,2016,(6):30−35. doi: 10.3969/j.issn.1007-4732.2016.06.007YU Yue, CHEN Hua-lei, HOU Dian-zhi, ZHU Yan-guang, HUANG Shuang-xia, LAN Wei-bing, WANG Shuai-jing, CHEN Shan. Application and safety research of octacosanol[J]. Guangxi Sugar Ind,2016,(6):30−35. doi: 10.3969/j.issn.1007-4732.2016.06.007 [8] YU X, SHEN B, SUN H, YANG L, LIU L, LIU J. Synthesis of poly alpha olefins using alpha olefins obtained from the steam cracking process of coal liquefaction wax[J]. Energy Source Part A,2015,37(11):1195−1201. doi: 10.1080/15567036.2012.678960 [9] CHEN X D, YAN Y J. Study on the technology of thermal cracking of paraffin to alpha olefins[J]. J Anal Appl Pyrolysis,2008,81(1):106−112. doi: 10.1016/j.jaap.2007.09.009 [10] JONATHAN A, EAGAN N M, BRUNS D L, STAHL S S, LANCI M P, DUMESIC J A, HUBER G W. Ethylene oligomerization into linear olefins over cobalt oxide on carbon catalyst[J]. Catal Sci Technol,2021,11:3599−3608. doi: 10.1039/D1CY00207D [11] 陈新德. 石蜡裂解制α-烯烃及其综合应用技术研究[D]. 上海: 华东理工大学, 2008.CHEN Xin-de. Study on the technology of thermal cracking of paraffin to alpha olefins and their comprehensive utilization[D]. Shanghai: East China University of Science and Technology, 2008. [12] YU X Q, SHEN B X, LIU J C, LIU L. Preparation of α-olefins through the steam cracking process of wax from coal liquefaction[J]. Pet Sci Technol,2014,32(11):1291−1299. doi: 10.1080/10916466.2011.651235 [13] 刘磊. 煤蜡蒸汽裂解制α-烯烃工艺技术研究[D]. 上海: 华东理工大学, 2012.LIU Lei. Study on the technology of coal wax cracking to alpha olefins[D]. Shanghai: East China University of Science and Technology, 2012. [14] 刘东阳, 曹祖宾, 石薇薇, 李洪梅, 曹传洋. 费-托蜡裂解混合α-烯烃齐聚制备润滑油基础油[J]. 石油化工,2019,48(6):575−582. doi: 10.3969/j.issn.1000-8144.2019.06.008LIU Dong-yang, CAO Zu-bin, SHI Wei-wei, LI Hong-mei, CAO Chuan-yang. Preparation of lubricating base oil by oligomerization of Fischer-Tropsch wax cracking mixed α-olefins[J]. Petrochem Technol,2019,48(6):575−582. doi: 10.3969/j.issn.1000-8144.2019.06.008 [15] 李先锋, 冯威, 杨志远. 中熔点费托蜡市场前景分析[J]. 石化技术,2019,26(7):347−349. doi: 10.3969/j.issn.1006-0235.2019.07.208LI Xian-feng, FENG Wei, YANG Zhi-yuan. Market prospect analysis of medium melting point Fischer-Tropsch wax[J]. Petrochem Ind Technol,2019,26(7):347−349. doi: 10.3969/j.issn.1006-0235.2019.07.208 [16] 王立荣, 安良成. 费托蜡市场分析与展望[J]. 合成材料老化与应用,2019,48(6):132−136. doi: 10.16584/j.cnki.issn1671-5381.2019.06.034WANG Li-rong, AN Liang-cheng. Analysis and prospect of Fischer-Tropsch wax market[J]. Synth Mater Aging Appl,2019,48(6):132−136. doi: 10.16584/j.cnki.issn1671-5381.2019.06.034 [17] 于小桥. 煤蜡裂解α-烯烃合成润滑油基础油新技术研究[D]. 上海: 华东理工大学, 2013.YU Xiao-qiao. Study on novel technology for synthesis of polyalphaolefins lubricant base oil using alpha olefins obtained from steam cracking process of coal liquefaction wax[D]. Shanghai: East China University of Science and Technology, 2013. [18] 林世雄. 石油炼制工程 [M]. 第三版. 北京: 石油工业出版社, 2000.LIN Shi-xiong. Petroleum Refining Engineering[M]. 3rd ed. Beijing: Petroleum Industry, 2000. [19] DE KLERK A. Thermal cracking of Fischer-tropsch waxes[J]. Ind Eng Chem Res,2007,46(17):5516−5521. doi: 10.1021/ie070155g [20] RICE F O, HERZFELD K F. The thermal decomposition of organic compounds from the standpoint of free radicals. VI. The mechanism of some chain reactions[J]. J Am Chem Soc,1934,56(2):284−289. doi: 10.1021/ja01317a006 [21] WATANABE M, ADSCHIRI T, ARAI K. Overall rate constant of pyrolysis of n-alkanes at a low conversion level[J]. Ind Eng Chem Res,2001,40(9):2027−2036. doi: 10.1021/ie000796a [22] IKURA M, STANCIULESCU M, KELLY J F. Short contact time thermal cracking of carbonaceous wastes to alpha olefins[J]. J Anal Appl Pyrolysis,1999,51(1/2):89−105. doi: 10.1016/S0165-2370(99)00010-8 -

下载:

下载: