Enhanced electro-catalytic activity of TNTs/SnO2-Sb electrode through the effect mechanism of TNTs architecture

-

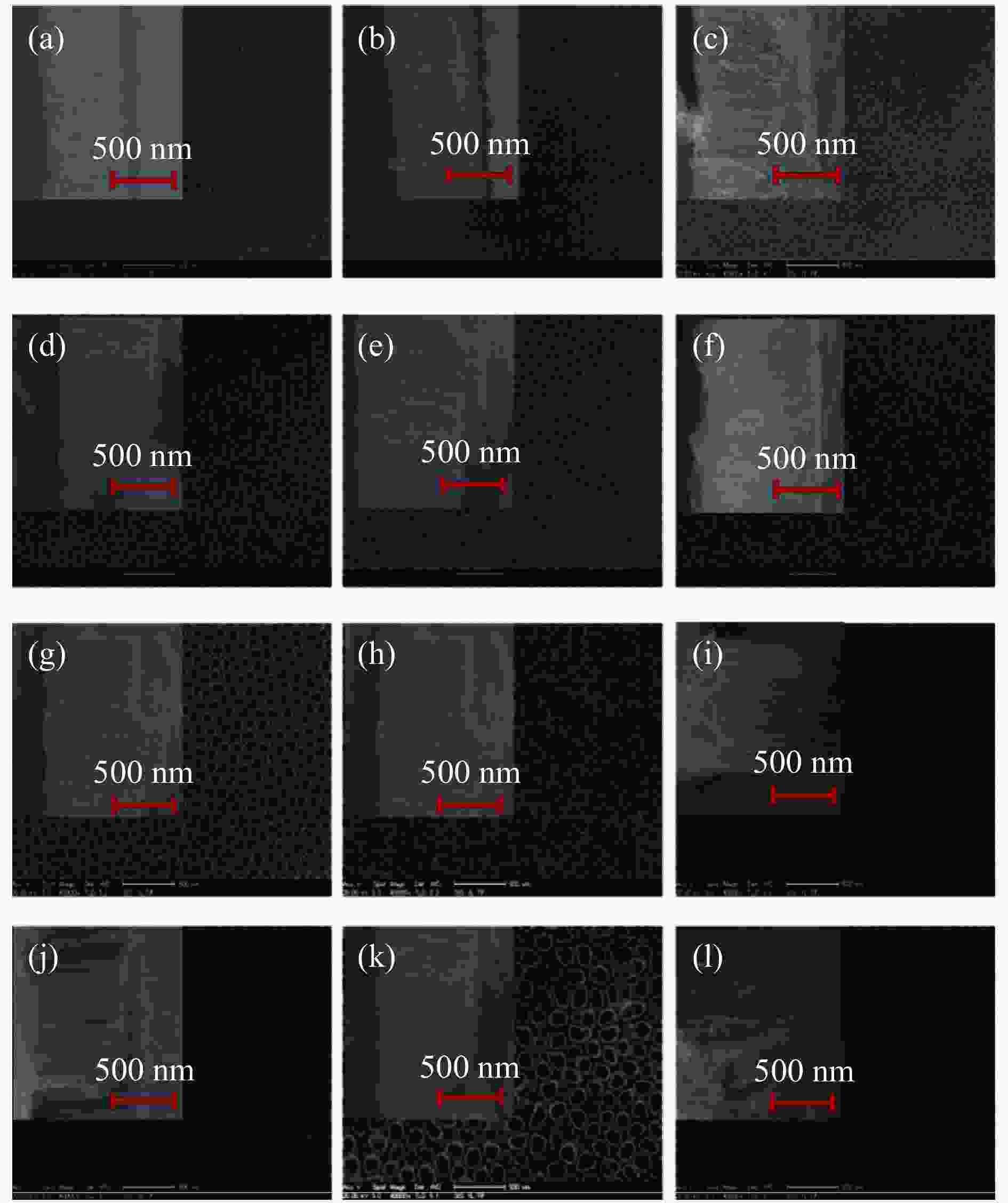

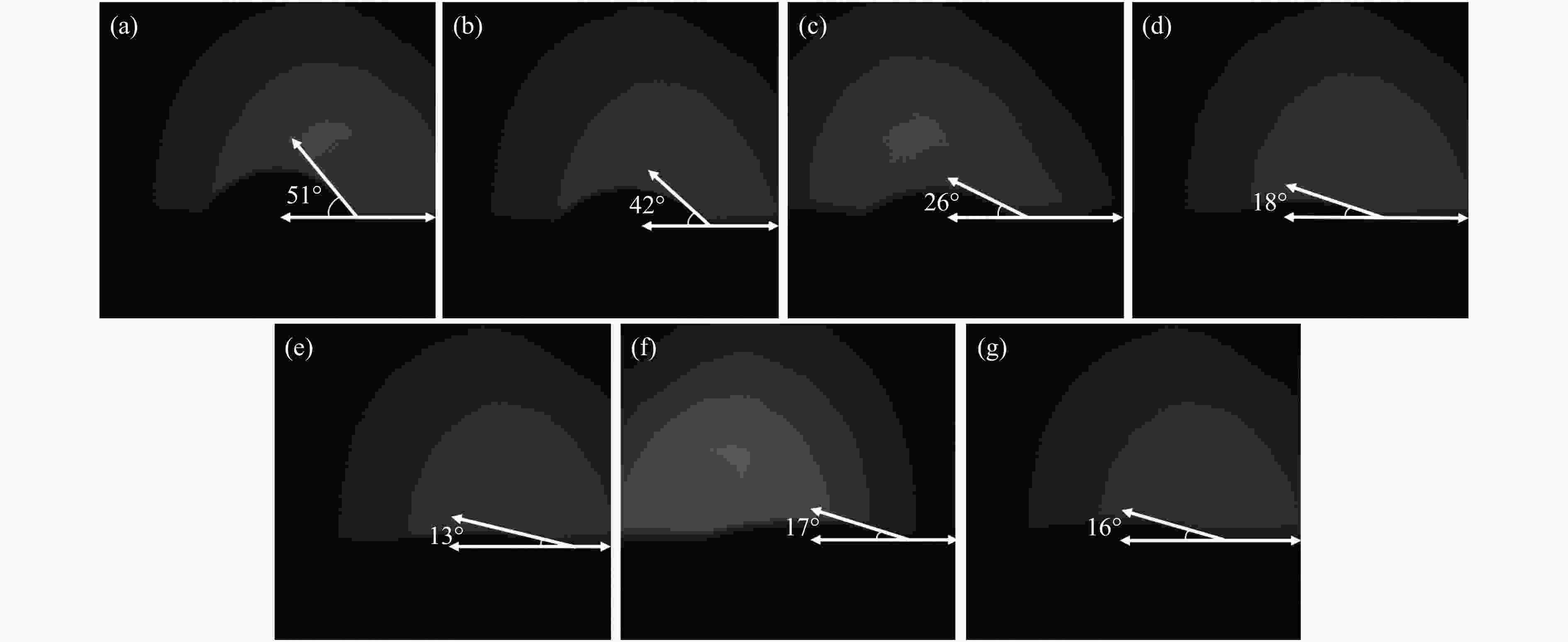

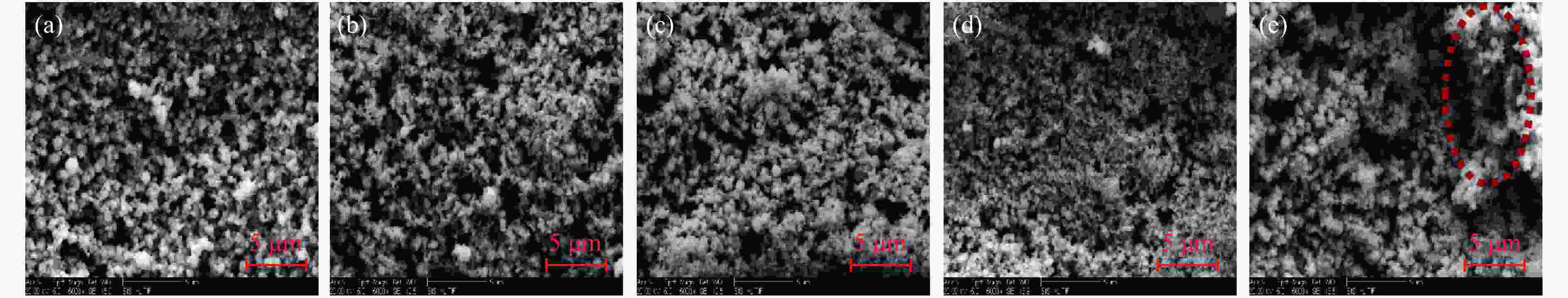

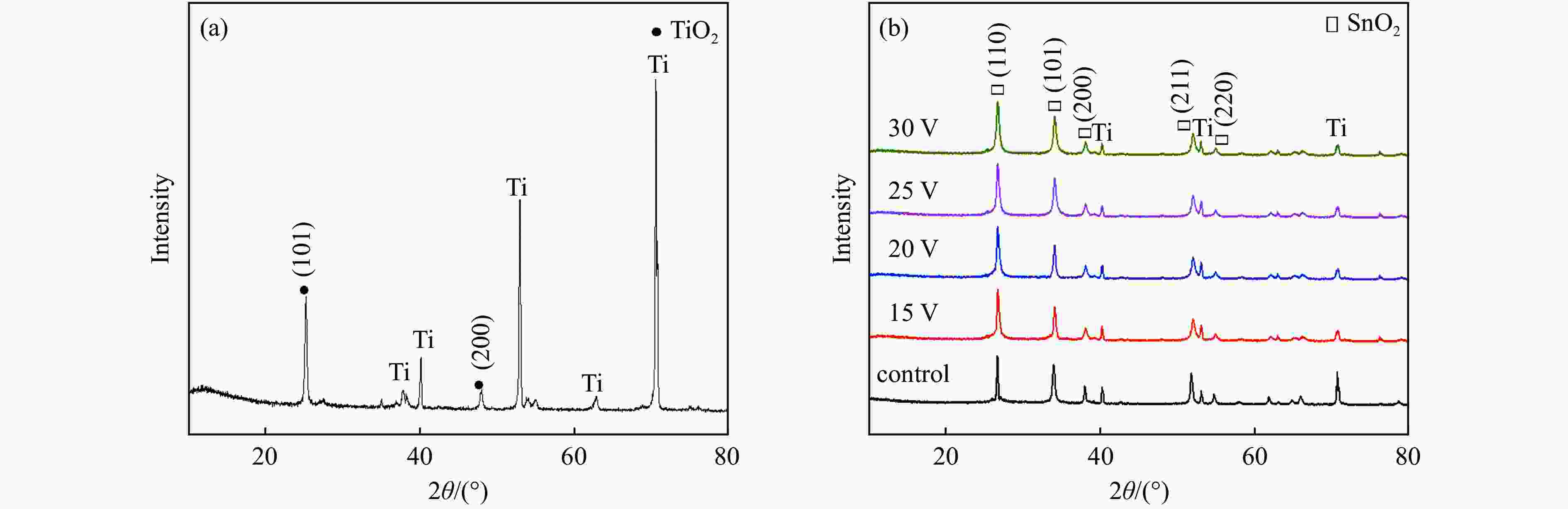

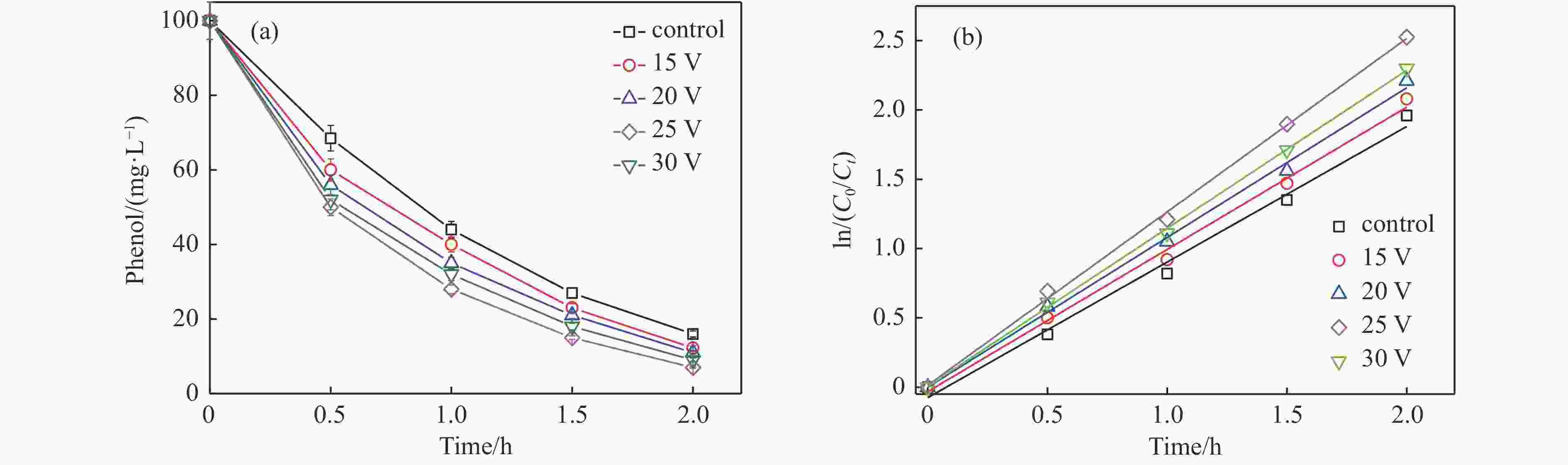

摘要: 采用溶剂热法制备了TNTs/SnO2-Sb电极,通过调整氧化电压和氧化时间构建出不同结构的二氧化钛纳米管(TNTs)阵列,以探究其对电极结构和电化学性能的影响。SEM和接触角测试表明,相较于阳极氧化时间,阳极氧化电压是影响TNTs阵列形貌和表面亲水性的主要因素。SEM、XRD、LSV和EIS结果表明,TNTs阵列孔径的大小影响了催化涂层的形貌、晶粒尺寸以及电极的析氧电位。XPS、EPR和羟基自由基(·OH)生成测试表明,涂层表面致密且粒径较小有利于电极表面获得更多的氧空位,且氧空位浓度越高,吸附氧物种越多,从而增强了活性自由基的形成以及对有机物的降解。以长度950 nm,孔径100 nm 的TNTs 阵列层为基底时,所制备的电极TNTs (25 V) / SnO2-Sb展现出了最佳的苯酚处理效果(92%±4.6%,2 h)。

-

关键词:

- TNTs 结构 /

- SnO2-Sb 电极 /

- 溶剂热 /

- 氧空位 /

- 电催化氧化

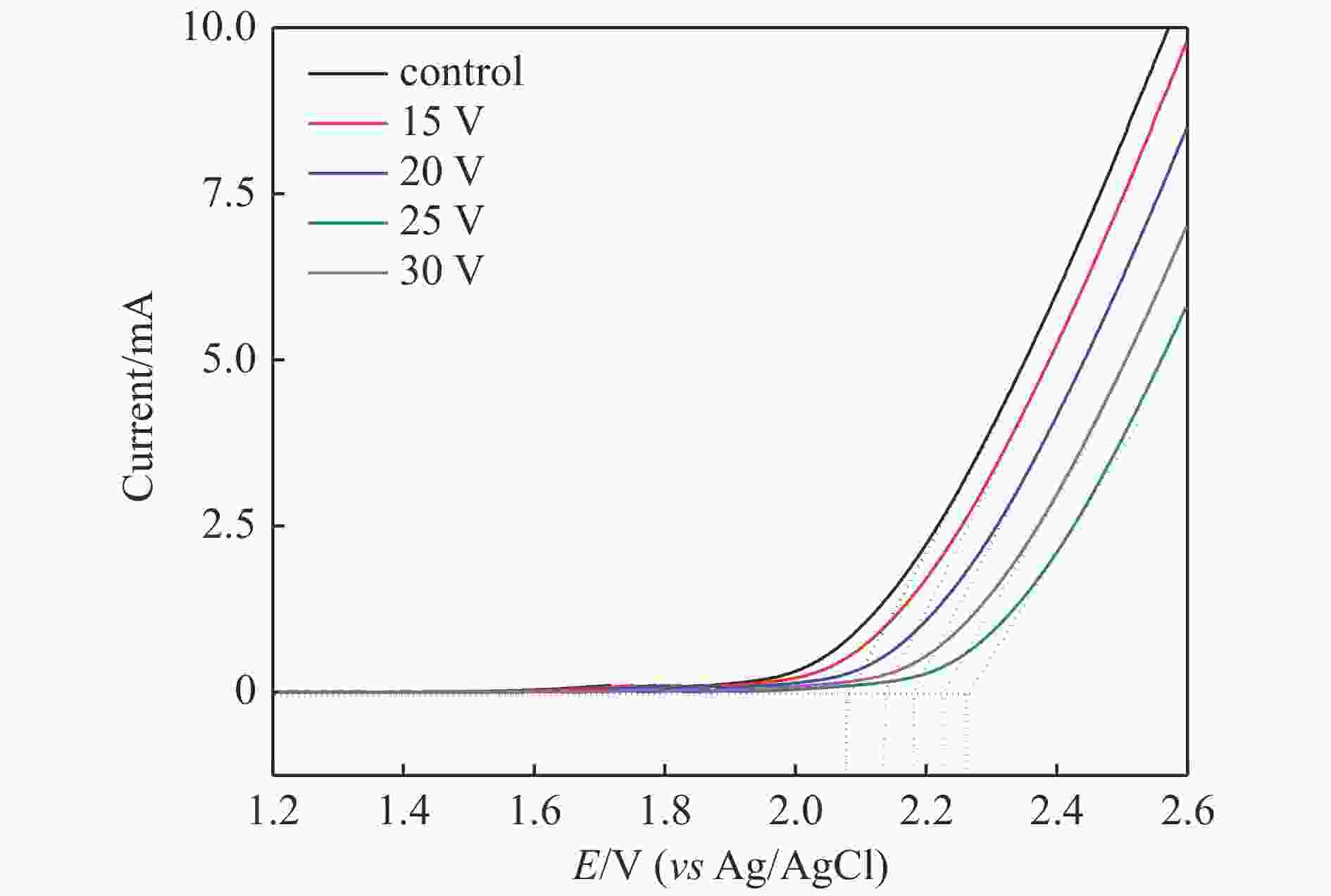

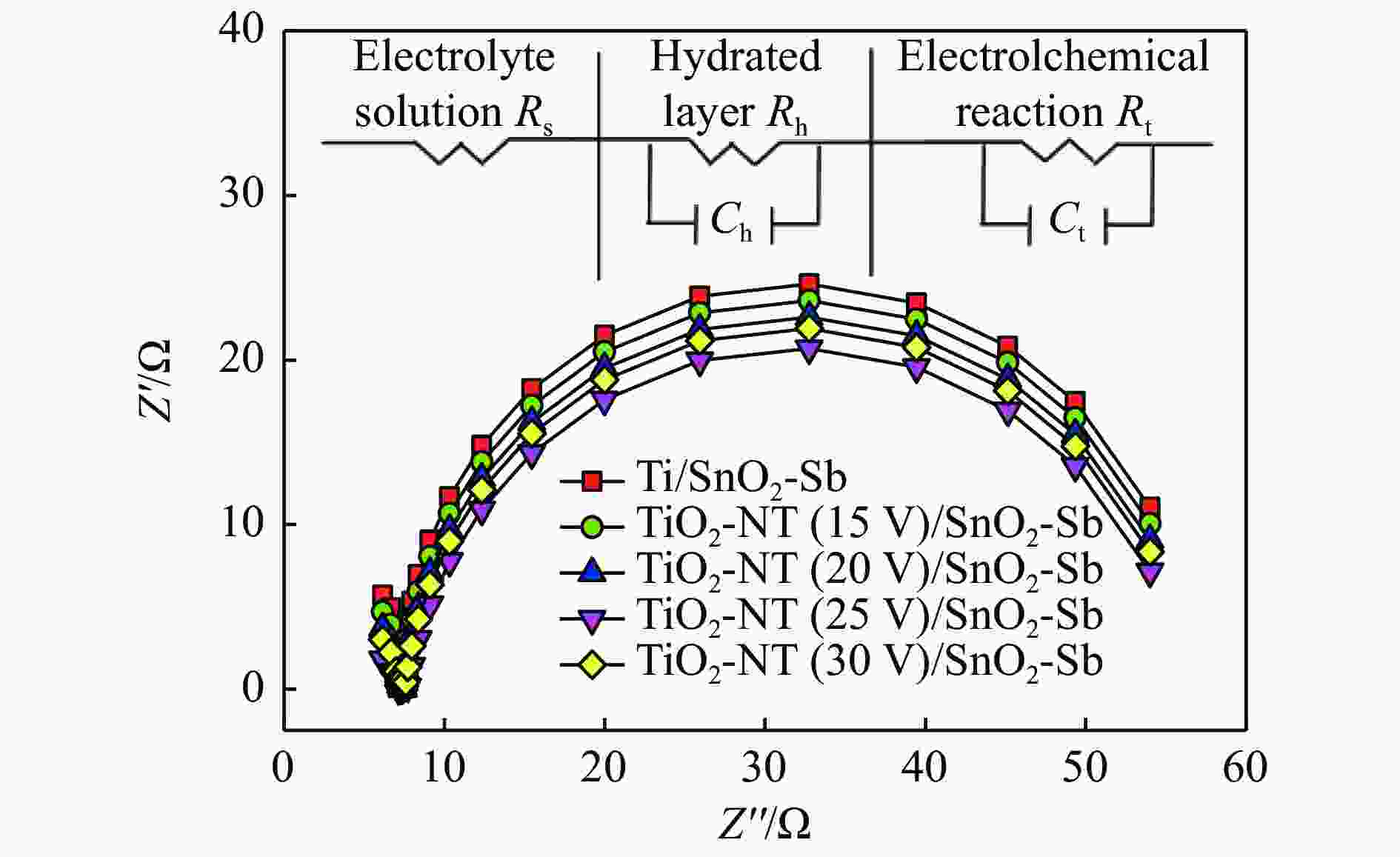

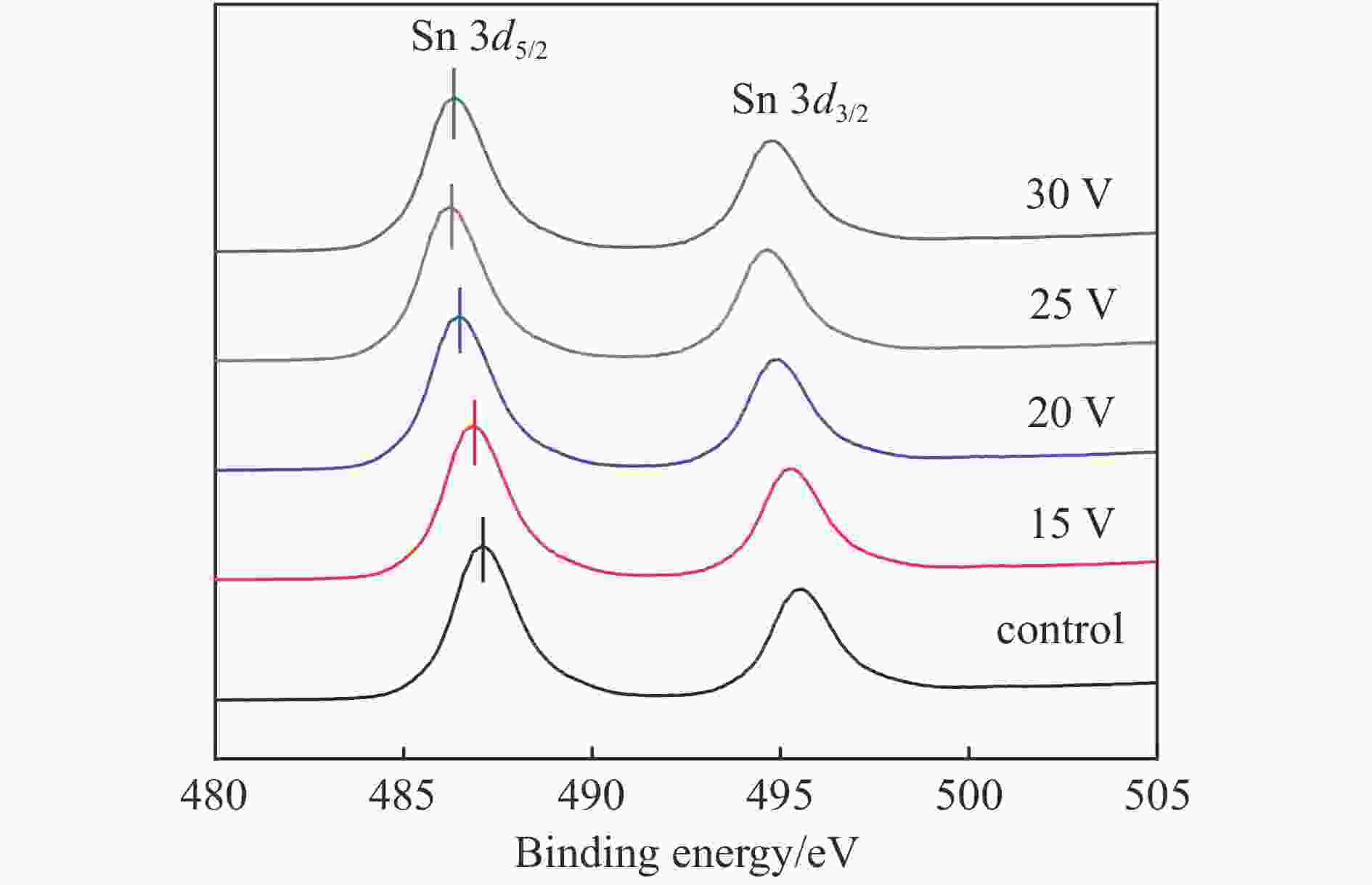

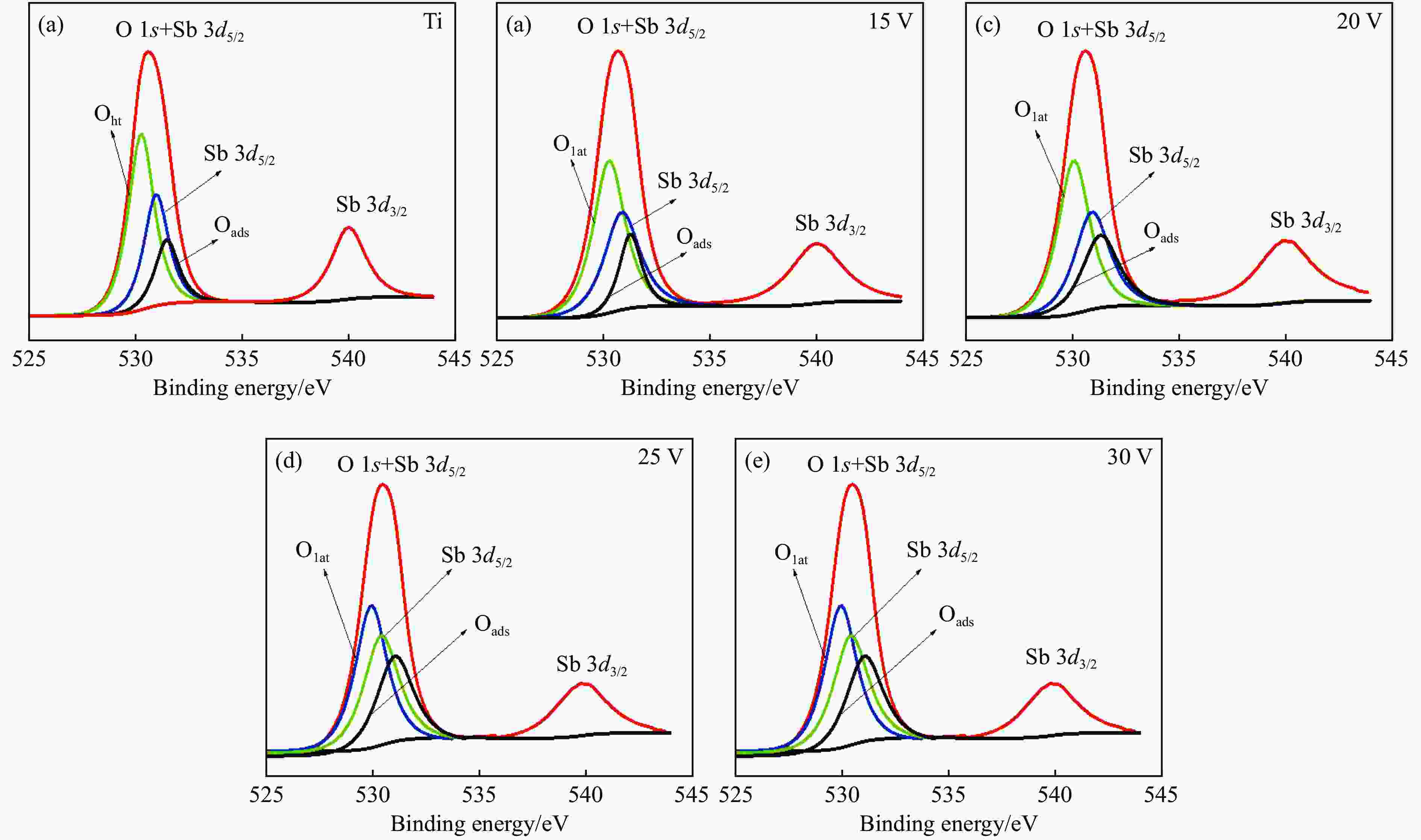

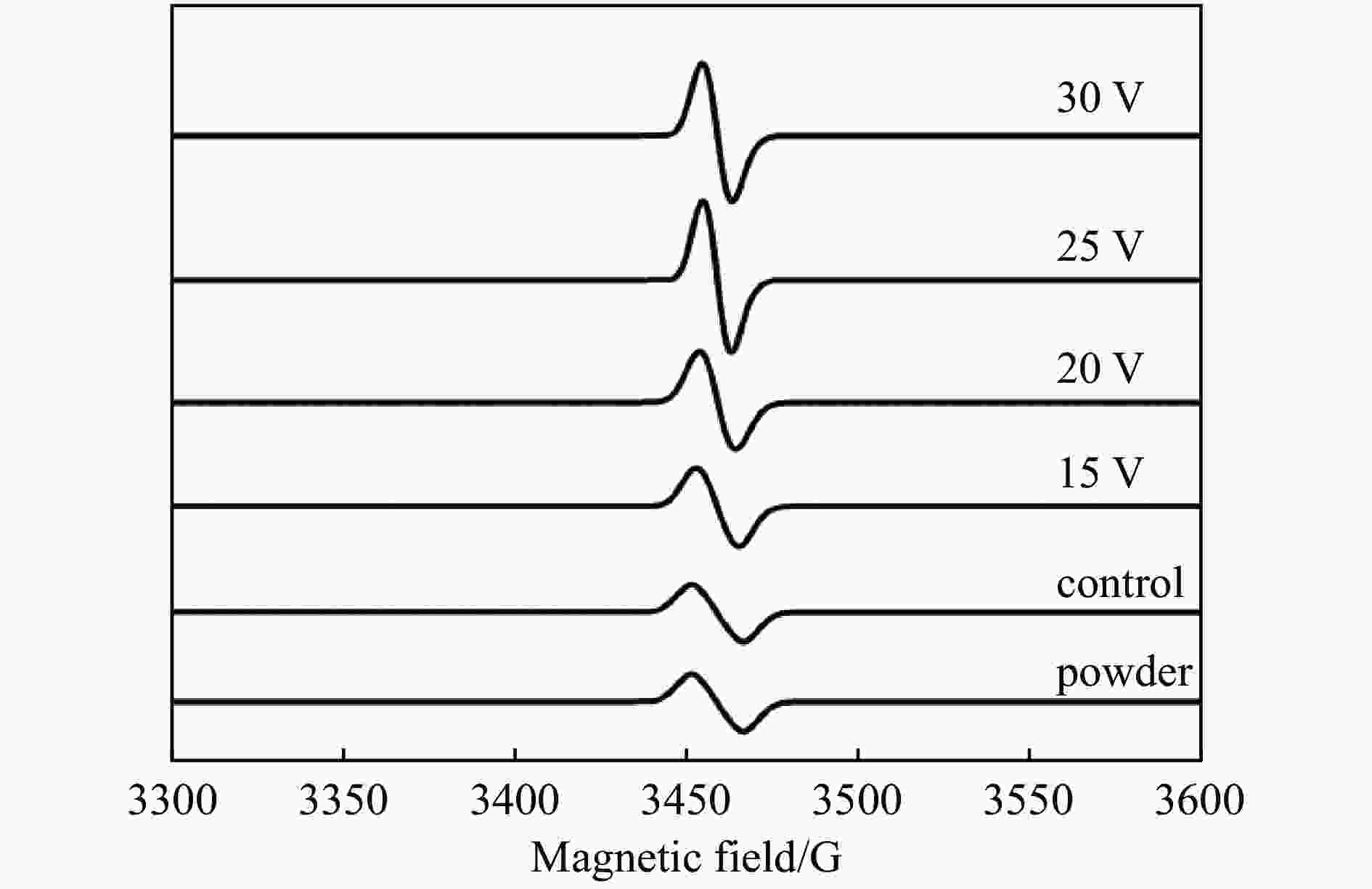

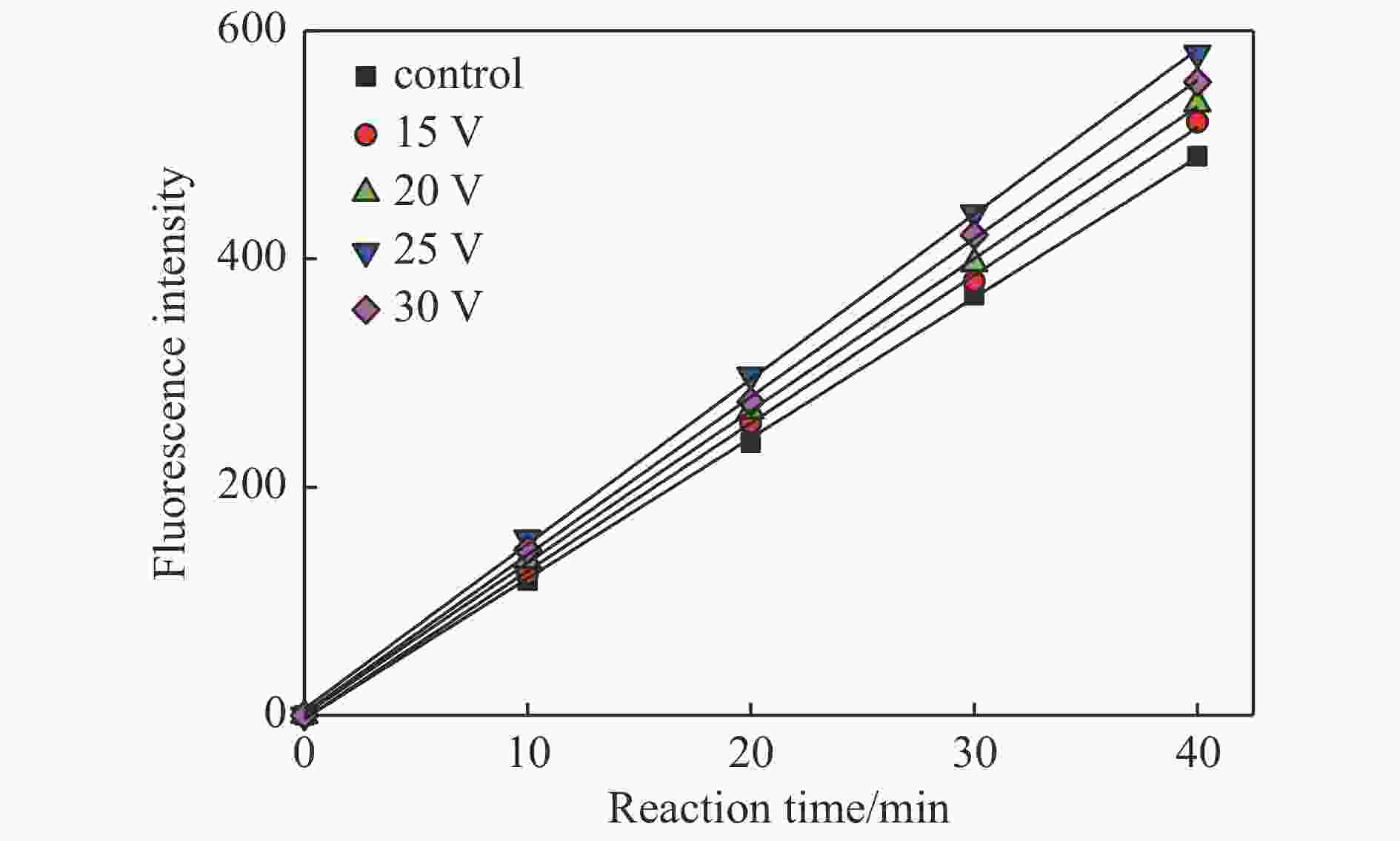

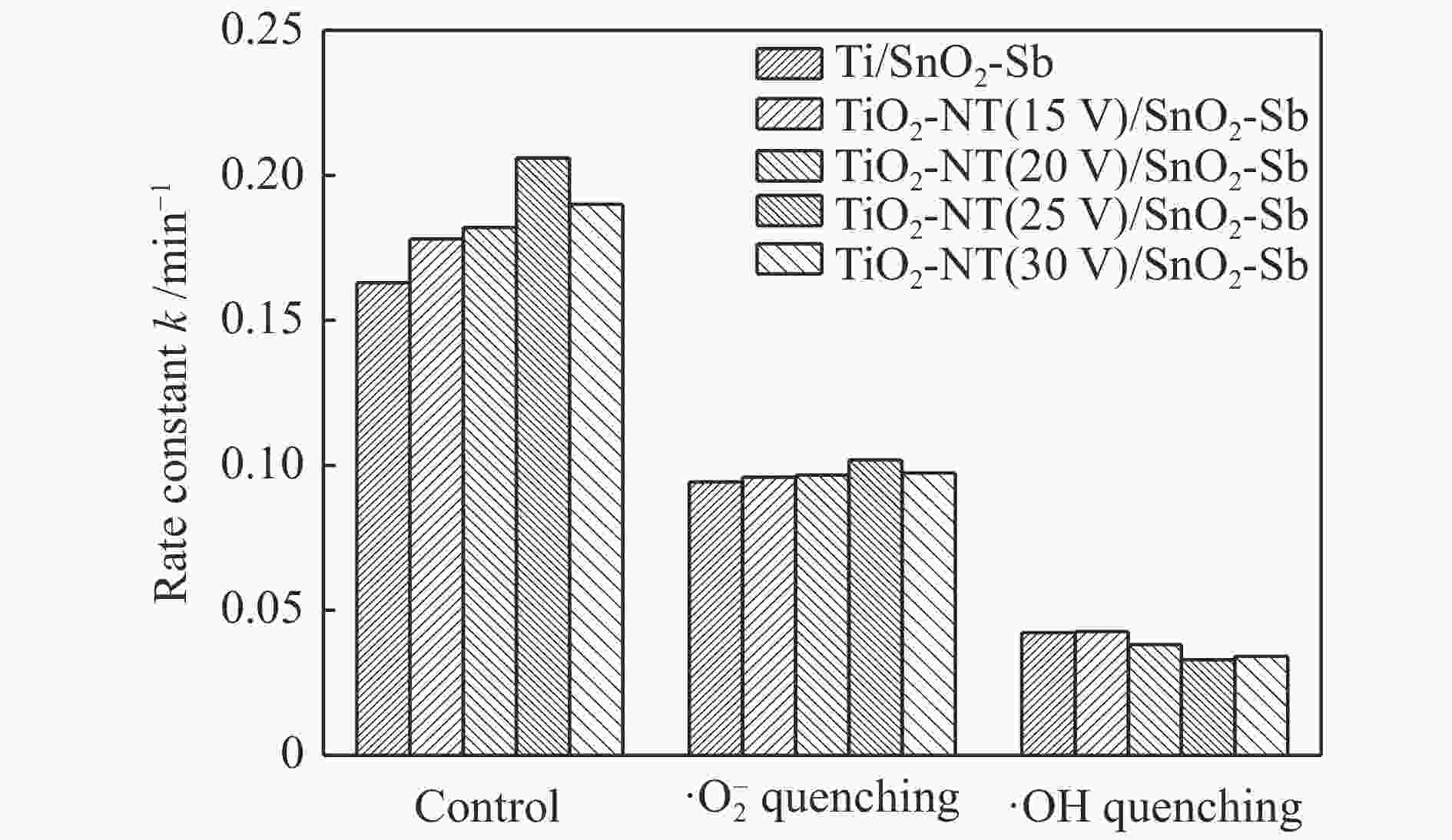

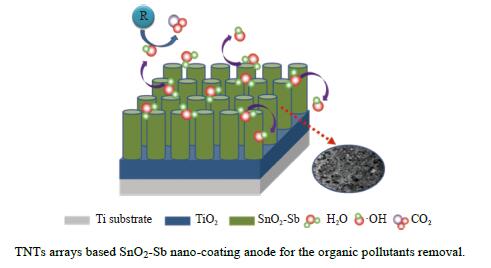

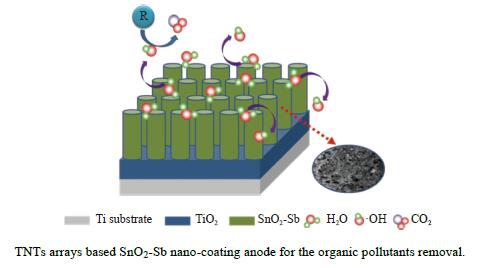

Abstract: The TiO2 nanotubes arrays/SnO2-Sb (TNTs/SnO2-Sb) electrode is successfully fabricated using the solvothermal synthesis technique. Various architectures of TNTs are constructed by varying the anodization voltage and time, aiming to investigate their impact on the structural and electrochemical properties of the SnO2-Sb electrode. The anodization voltage is identified as the primary influencing factor on the morphology and surface hydrophilia of TNTs arrays, which is evidenced by scanning electron microscopy (SEM) and contact angle testing. In contrast, the effect of anodization time is relatively small. SEM, X-ray diffraction (XRD), linear sweep voltammograms (LSV), and electrochemical impedance spectroscopy (EIS) results indicate that the morphology and crystal size of the catalytic coating, as well as the oxygen evolution potential of the electrode, are influenced by the pore size of TNTs arrays. The influencing mechanism of enhanced electrochemical activity by adjusting the architecture of TNTs arrays is investigated using X-ray photoelectron spectroscopy (XPS), electron paramagnetic resonance (EPR), and hydroxyl radicals (·OH) generation test. The results reveal a higher concentration of oxygen vacancies on the sample with a compact and smaller particle coating, indicating the presence of more adsorbed oxygen species. Consequently, this enhances the generation capacity of active radicals for organic matter degradation. The electrode featuring TNTs arrays with a length of 950 nm and a pore diameter of 100 nm exhibits the most effective remediation of phenol-containing wastewater, achieving approximately 92% ± 4.6% removal after a duration of 2 h. -

Table 1 Effect of preparation conditions for TNTs arrays on the average crystal size of SnO2-Sb calculated by Scherrer formula

Sample Crystallite size/nm Ti/SnO2-Sb 23±0.3 TNTs (15 V)/SnO2-Sb 20±0.3 TNTs (20 V)/SnO2-Sb 17±0.4 TNTs (25 V)/SnO2-Sb 15±0.3 TNTs (30 V)/SnO2-Sb 13±0.4 Scherrer formula: D=kλ/(βcosθ), where D is the crystallite size, k is the Scherrer constant (0.89), λ is the wavelength of incident ray, β is the full width at half maximum of the peak, and θ is the position of plane peak[30]. Table 2 EIS fitting results of TNTs/SnO2-Sb electrodes with different substrate preparation voltages

Sample Rs/Ω Ch/F Rh/Ω Ct/F Rt/Ω Ti/SnO2-Sb 4.72 5.33×10−8 49.3 2.02×10−5 49 TNTs (15 V)/SnO2-Sb 4.71 5.62×10−8 47.6 2.06×10−5 48 TNTs (20 V)/SnO2-Sb 4.69 5.84×10−8 46.9 2.11×10−5 47 TNTs (25 V)/SnO2-Sb 4.67 6.33×10−8 44.3 2.20×10−5 45 TNTs (30 V)/SnO2-Sb 4.74 6.12×10−8 45.4 2.16×10−5 46 Table 3 Effect of preparation voltage of TNTs arrays on the contact angle of substrate surface and loading amount of SnO2-Sb

Sample Contact angle/(°) Loading amount/(mg·cm−2) Ti 52 2.05±0.05 TNTs (15 V-2 h) 43 2.15±0.04 TNTs (20 V-2 h) 34 2.24±0.04 TNTs (25 V-2 h) 13 2.36±0.03 TNTs (30 V-2 h) 10 2.42±0.02 Table 4 XPS analysis of TNTs/SnO2-Sb electrodes with different substrate preparation voltages

Sample Binding energy/eV Oads

(at% = $\dfrac{\rm{O}_{\mathrm{a}\mathrm{d}\mathrm{s} }}{\mathrm{S}\mathrm{n} + \mathrm{S}\mathrm{b} + \mathrm{O}_{\mathrm{a}\mathrm{d}\mathrm{s}} + \mathrm{O}_{\mathrm{l}\mathrm{a}\mathrm{t} }}$ × 100% )Atom ratio of Olat/(Sn + Sb) Sn 3d5/2 Sb 3d5/2 Oads Olat Control 486.91 530.89 532.03 530.73 14.6 2.65 15 V 486.84 530.90 531.98 530.69 17.9 2.41 20 V 486.46 531.19 531.96 530.64 19.8 2.18 25 V 486.21 531.12 531.89 530.55 25.6 1.88 30 V 486.35 530.94 531.91 530.59 23.2 1.97 Table 5 The computed result from the quenching experiment

Sample The contribution to phenol degradation/% ·O2 − ·OH Control 42.1 74 15 V 45.7 76.3 20 V 47 79 25 V 50.5 84 30 V 48.6 81 -

[1] FENG Y J, YANG L S, LIU J F, et al. Electrochemical technologies for wastewater treatment and resource reclamation[J]. Environ Sci: Water Res Technol,2016,2(5):800−831. doi: 10.1039/C5EW00289C [2] DBIRA S, BENSALAH N, AHMAD M I, et al. Electrochemical oxidation/disinfection of urine wastewaters with different anode materials[J]. Materials,2019,12(8):1254. doi: 10.3390/ma12081254 [3] NIDHEESH P V, KUMAR A, BABU D S, et al. Treatment of mixed industrial wastewater by electrocoagulation and indirect electrochemical oxidation[J]. Chemosphere,2020,251:126437. doi: 10.1016/j.chemosphere.2020.126437 [4] SUMAN H, SANGAL V K, VASHISHTHA M. Treatment of tannery industry effluent by electrochemical methods: A review[J]. Mater Today: Proc,2021,47:1438−1444. doi: 10.1016/j.matpr.2021.03.300 [5] RAI D, SINHA S. Research trends in the development of anodes for electrochemical oxidation of wastewater[J]. Rev Chem Eng.,2023,39(5):807−855. doi: 10.1515/revce-2021-0067 [6] PATEL P S, BANDRE N, SARAF A, et al. Electro-catalytic materials (electrode materials) in electrochemical wastewater treatment[J]. Proc Eng,2013,51:430−435. doi: 10.1016/j.proeng.2013.01.060 [7] WU W, HUANG Z H, LIM T T. Recent development of mixed metal oxide anodes for electrochemical oxidation of organic pollutants in water[J]. Appl Catal A: Gen,2014,480:58−78. doi: 10.1016/j.apcata.2014.04.035 [8] TOLBA R, TIAN M, WEN J, et al. Electrochemical oxidation of lignin at IrO2-based oxide electrodes[J]. J Electroanal Chem,2010,649(1/2):9−15. doi: 10.1016/j.jelechem.2009.12.013 [9] ZHU X, HU W W, FENG C P, et al. Electrochemical oxidation of aniline in sodium chloride solution using a Ti/RuO2 anode[J]. Int J Electrochem Sci,2019,14(8):7516−7528. doi: 10.20964/2019.08.36 [10] ZHANG Z T, YI G Y, LI P, et al. Electrochemical oxidation of hydroquinone using Eu-doped PbO2 electrodes: Electrode characterization, influencing factors and degradation pathways[J]. J Electroanal Chem,2021,895:115493. doi: 10.1016/j.jelechem.2021.115493 [11] CAO F, TAN J, ZHANG S, et al. Preparation and recent developments of Ti/SnO2-Sb electrodes[J]. J Chem,2021,12:1−13. [12] GATTRELL M, KIRK D W. A study of electrode passivation during aqueous phenol electrolysis[J]. J Electrochem Soc,1993,140(4):903. doi: 10.1149/1.2056225 [13] SARHAN JAWAD S, H ABBAR A. Treatment of petroleum refinery wastewater by electrochemical oxidation using graphite anodes[J]. QJES,2019,12(3):144−150. [14] ZHUO Q, WANG J, NIU J, et al. Electrochemical oxidation of perfluorooctane sulfonate (PFOS) substitute by modified boron doped diamond (BDD) anodes[J]. Chem Eng J,2020,379:122280. doi: 10.1016/j.cej.2019.122280 [15] GAO G, VECITIS C D. Electrochemical carbon nanotube filter oxidative performance as a function of surface chemistry[J]. Environ Sci Technol,2011,45(22):9726−9734. doi: 10.1021/es202271z [16] CUI Y H, FENG Y J, LIU Z Q. Influence of rare earths doping on the structure and electro-catalytic performance of Ti/Sb-SnO2 electrodes[J]. Electrochim Acta,2009,54(21):4903−4909. doi: 10.1016/j.electacta.2009.04.041 [17] NHAN N T, LE LUU T. Fabrication of novel Ti/SnO2-Nb2O5 electrode in comparison with traditional doping metal oxides for electrochemical textile wastewater treatment[J]. Environ Technol Innov,2023,32:103292. doi: 10.1016/j.eti.2023.103292 [18] LI X, SHAO D, XU H, et al. Fabrication of a stable Ti/TiOxHy/Sb-SnO2 anode for aniline degradation in different electrolytes[J]. Chem Eng J,2016,285:1−10. doi: 10.1016/j.cej.2015.09.089 [19] BRAVO-YUMI N, PACHECO-ÁLVAREZ M, BANDALA E R, et al. Studying the influence of different parameters on the electrochemical oxidation of tannery dyes using a Ti/IrO2-SnO2-Sb2O5 anode[J]. Chem Eng Process,2022,181:109173. doi: 10.1016/j.cep.2022.109173 [20] SHAO M Y, HU B, GE S Y, et al. Fabrication of Ti/TiO2/SnO2-Sb-Ir/SnO2-Sb-Ni using three kinds of TiO2 interlayer and an optimized TiO2-nanotube interlayer-based anode for electrochemical treatment of wastewater[J]. J Electron Mater,2023,52(2):907−916. doi: 10.1007/s11664-022-10070-6 [21] CHEN D Y, ZHAO L, CHEN D N, et al. Fabrication of a SnO2-Sb electrode with TiO2 nanotube array as the middle layer for efficient electrochemical oxidation of amaranth dye[J]. Chemosphere,2023,325:138380. doi: 10.1016/j.chemosphere.2023.138380 [22] MOR G K, VARGHESE O K, PAULOSE M, et al. Transparent highly ordered TiO2 nanotube arrays via anodization of titanium thin films[J]. Adv Funct Mater,2005,15(8):1291−1296. doi: 10.1002/adfm.200500096 [23] XU L, YI Y, LIANG G, et al. Antimony doped tin oxide nanoparticles deposited onto Nb-TiO2 nanotubes for electrochemical degradation of bio-refractory pollutions[J]. Electroanalysis,2020,32(6):1370−1378. doi: 10.1002/elan.201900775 [24] WANG G X, ZHANG H L, WANG W Z, et al. Fabrication of Fe-TiO2-NTs/SnO2-Sb-Ce electrode for electrochemical degradation of aniline[J]. Sep Purif Technol,2021,268:118591. doi: 10.1016/j.seppur.2021.118591 [25] ZHANG Z, LIU J, AI H, et al. Construction of the multi-layer TiO2-NTs/Sb-SnO2/PbO2 electrode for the highly efficient and selective oxidation of ammonia in aqueous solution: Characterization, performance and mechanism[J]. J Environ Chem Eng,2023,11(3):109834. doi: 10.1016/j.jece.2023.109834 [26] CHEN Y, HONG L, XUE H, et al. Preparation and characterization of TiO2-NTs/SnO2-Sb electrodes by electrodeposition[J]. J Electroanal Chem,2010,648(2):119−127. doi: 10.1016/j.jelechem.2010.08.004 [27] XU H, ZHANG Q, YAN W, et al. A composite Sb-doped SnO2 electrode based on the TiO2 nanotubes prepared by hydrothermal synthesis[J]. Int J Electrochem Sci,2011,6(12):6639−6652. doi: 10.1016/S1452-3981(23)19708-2 [28] GUO Y, DUAN T, CHEN Y, et al. Solvothermal fabrication of three-dimensionally sphere-stacking Sb-SnO2 electrode based on TiO2 nanotube arrays[J]. Ceram Int,2015,41(7):8723−8729. doi: 10.1016/j.ceramint.2015.03.092 [29] WANG Q, JIN T, HU Z, et al. TiO2-NTs/SnO2-Sb anode for efficient electrocatalytic degradation of organic pollutants: effect of TiO2-NTs architecture[J]. Sep Purif Technol,2013,102:180−186. doi: 10.1016/j.seppur.2012.10.006 [30] YANG L S, ZHANG Z H, LIU J F, et al. Influence of Gd doping on the structure and electrocatalytic performance of TiO2 nanotube/SnO2-Sb nano‐coated electrode[J]. Chem Electro Chem,2018,5(22):3451−3459. doi: 10.1002/celc.201801079 [31] YANG L S, LIU J F, HUANG L L, et al. Fabrication of nano-structured stacked sphere SnO2-Sb electrode with enhanced performance using a situ solvothermal synthesis method[J]. J Electrochem Soc,2018,165(5):E208. doi: 10.1149/2.0711805jes [32] BARAN E, YAZICI B. Fabrication of TiO2-NTs and TiO2-NTs covered honeycomb lattice and investigation of carrier densities in I−/I3− electrolyte by electrochemical impedance spectroscopy[J]. Appl Surf Sci,2015,357:2206−2216. doi: 10.1016/j.apsusc.2015.09.212 [33] LIU J F. Investigation on preparation and performance of Ti-base tin dioxide nanocoating electrode doped by antimony[D]. Harbin: University of Harbin Institute of Technology, 2008. [34] ZHAO G H, CUI X, LIU M C, et al. Electrochemical degradation of refractory pollutant using a novel microstructured TiO2 nanotubes/Sb-doped SnO2 electrode[J]. Environ Sci Technol,2009,43(5):1480−1486. doi: 10.1021/es802155p [35] CUI X, ZHAO G H, LEI Y Z, et al. Novel vertically aligned TiO2 nanotubes embedded with Sb-doped SnO2 electrode with high oxygen evolution potential and long service time[J]. Mater Chem Phys,2009,113(1):314−321. doi: 10.1016/j.matchemphys.2008.07.087 [36] CUI Y H, FENG Y J. EPR study on Sb doped Ti-base SnO2 electrodes[J]. J Mater Sci,2005,40(17):4695−4697. doi: 10.1007/s10853-005-3930-3 -

下载:

下载: