Facile preparation of pitch-derived carbon for high electrically conductive composites via carbon nanotube template

-

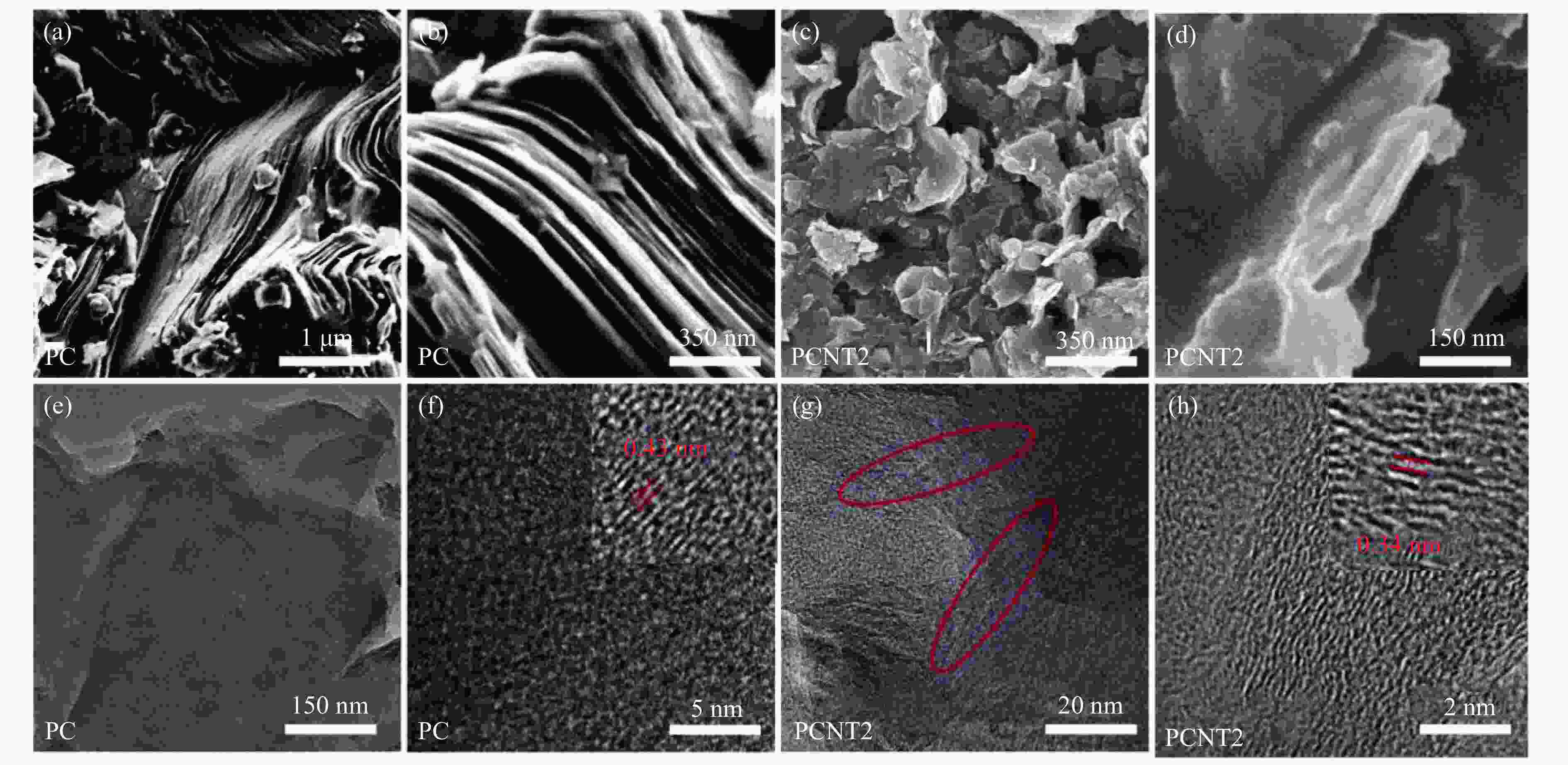

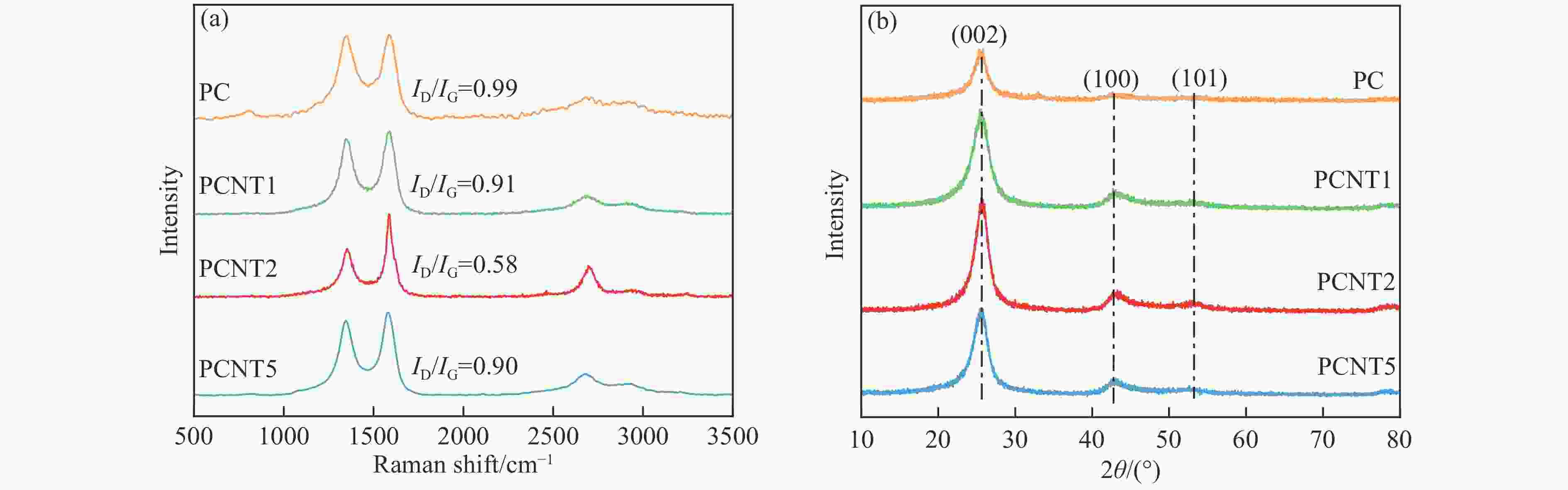

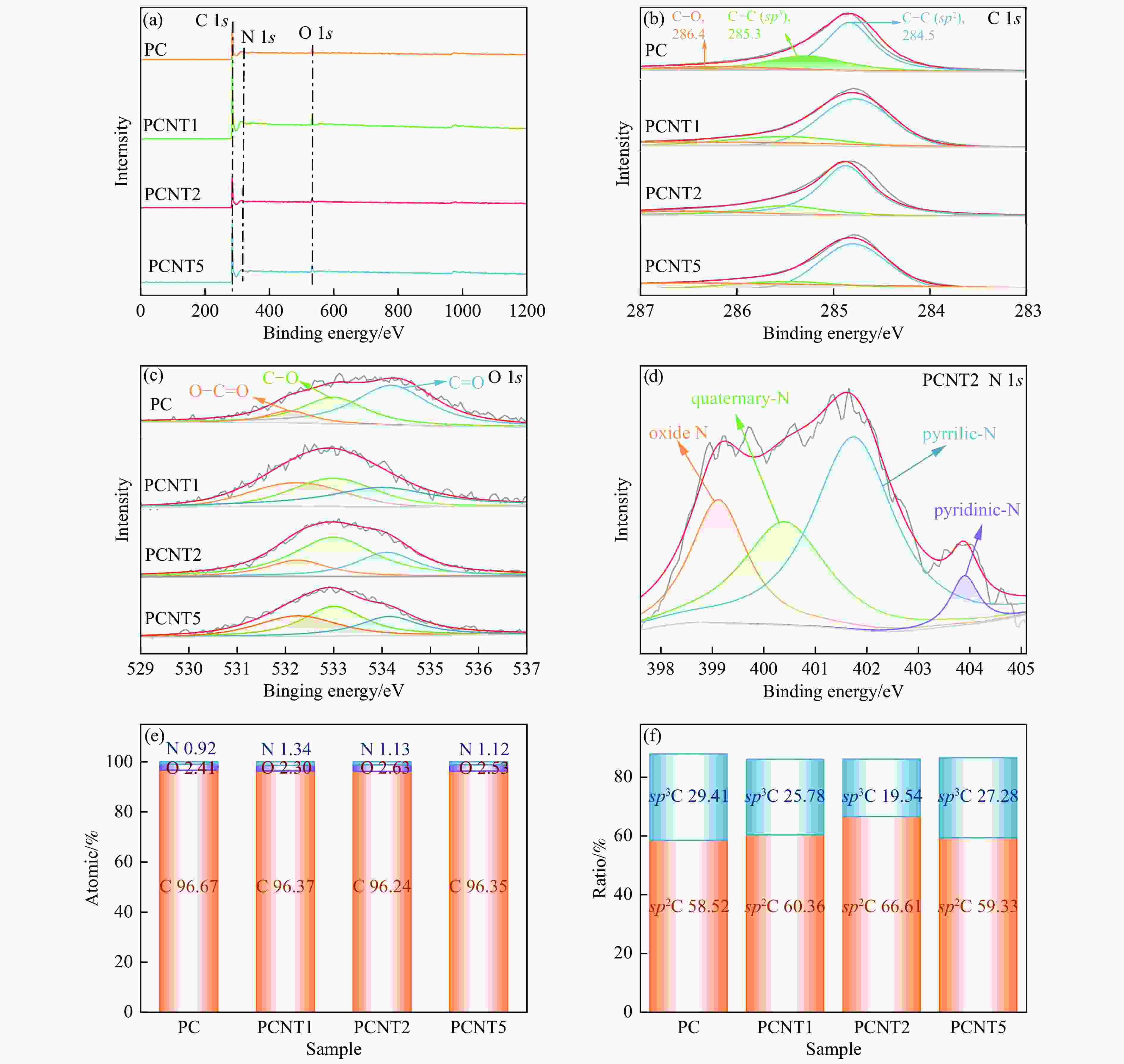

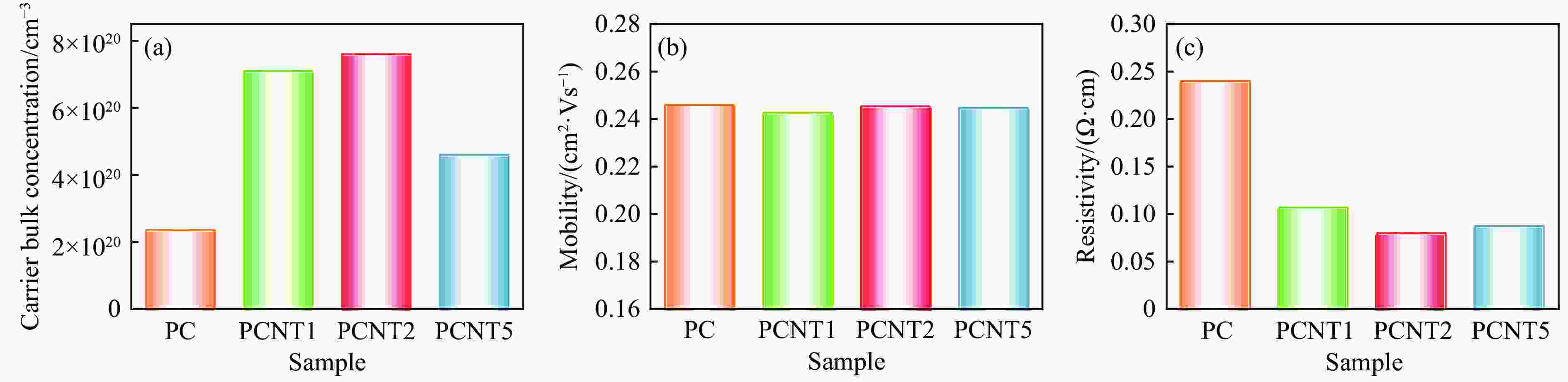

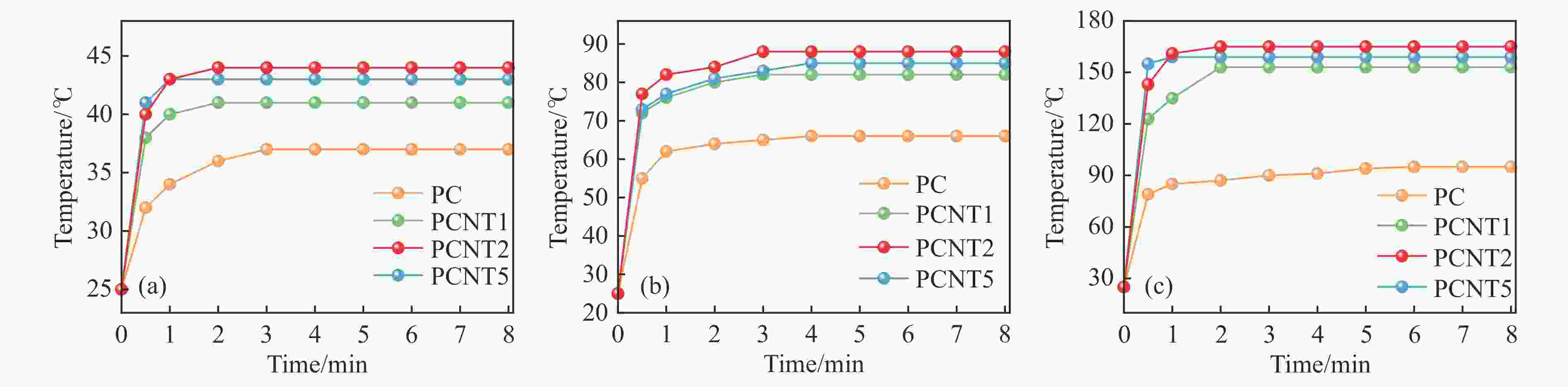

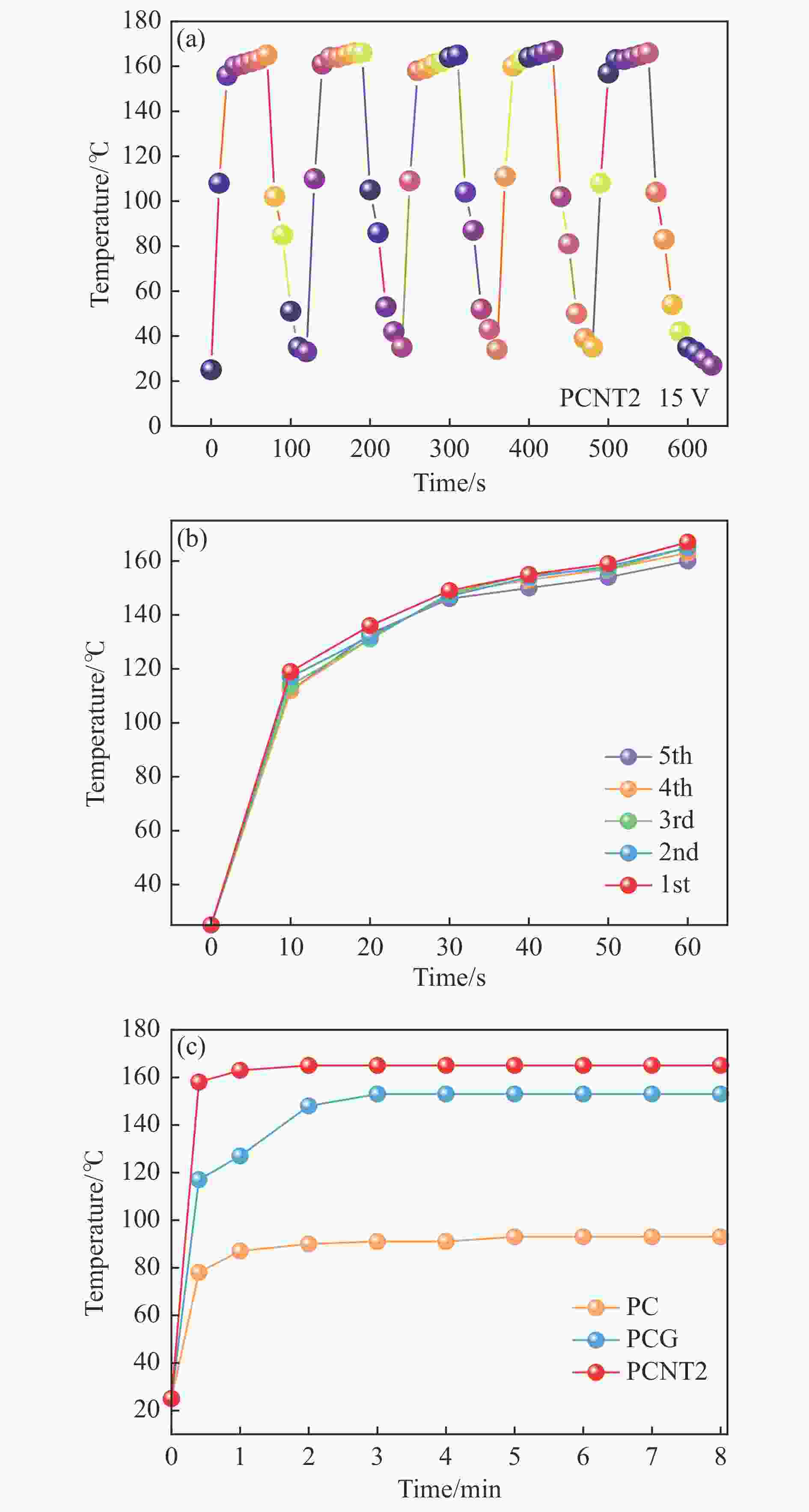

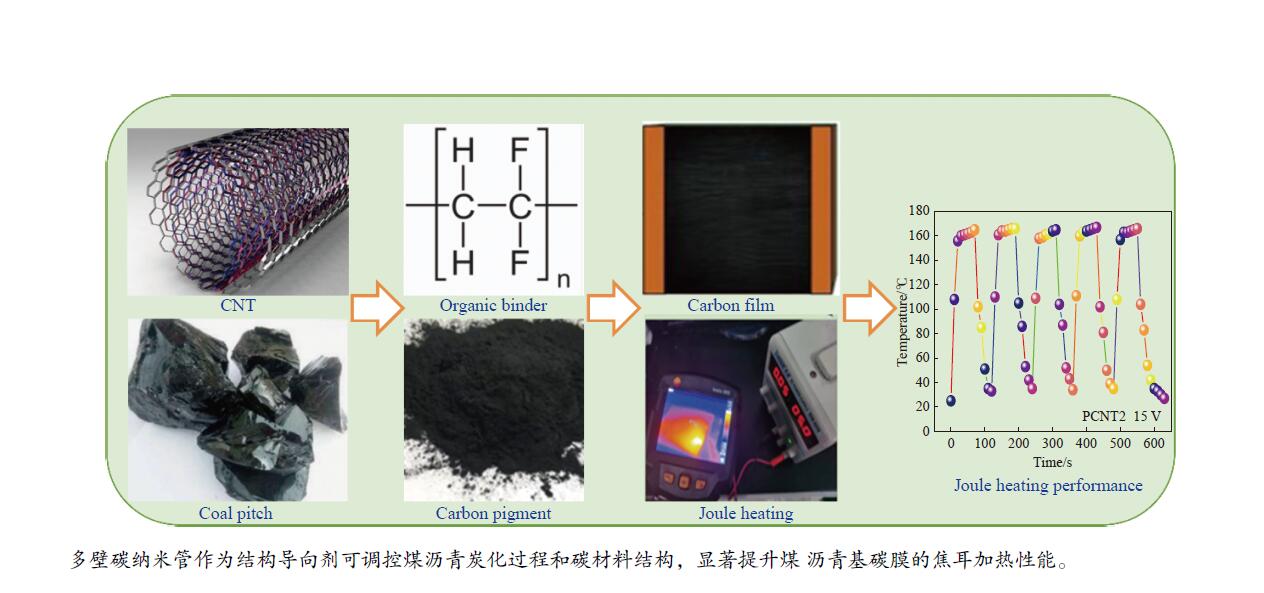

摘要: 本研究以煤沥青为原料、多壁碳纳米管为结构导向剂,通过炭化制备了形貌和结构可控的煤沥青基碳膜,考察了多壁碳纳米管对导电填料结构及碳膜电热性能的影响规律。研究发现,多壁碳纳米管掺杂导致导电填料的晶格排列有序度增加、晶格间距减小和石墨化程度提高;多壁碳纳米管的引入提高了碳膜的载流子浓度,进而显著提高了其导电性。掺杂2%碳纳米管,可使煤沥青基碳膜的载流子浓度提高3.2倍、电阻降低67%;在5、10和15 V电压下,煤沥青基碳膜的发热温度分别可达44、88和165 ℃,相对未掺杂碳膜分别提高了7、22和70 ℃,显示出极大的应用前景。Abstract: Coal pitch, a byproduct of coal coking, is an ideal precursor for preparing conductive carbon fillers because of its rich aromatics and high yield of carbonization products. In this paper, coal pitch-based carbon materials with controllable morphology and structure were prepared by carbonization using coal pitch and multi-walled carbon nanotubes as raw material and structure-directing agent, respectively. The effect of carbon nanotubes on the structure and electrothermal properties of carbon materials was investigated. The results show that the doping of multi-walled carbon nanotubes results in an increase in the lattice arrangement order, a decrease in lattice spacing, and an increase in graphitization degree of conductive fillers, which leads to a significant increase in the carrier concentration of the carbon film and thus its conductivity. The doping of 2% carbon nanotubes can increase the carrier concentration of coal pitch-based carbon film by 3.2 times and reduce the resistance of coal pitch-based carbon film by 67%. At 5, 10 and 15 V, the heating temperature of the coal pitch-based carbon film can reach 44, 88 and 165 ℃, respectively, which is enhanced 7, 22 and 70 ℃ compared with the undoped carbon film, showing great application prospect.

-

Key words:

- coal pitch /

- carbon film /

- carbon nanotube template /

- Joule heating

-

表 1 煤沥青基碳膜的附着性能

Table 1 Adhesion performance of coal pitch-derived carbon films

Sample Adhesion grade PC 2 B PCNT1 3 B PCNT2 3 B PCNT5 2 B SBR-PCNT2 5 B MMA-PCNT2 5 B 5B: Smooth of the edge of the incision and no peeling at the edge of the grid area; 4B: Small pieces peeling off at the intersection of the incision and the actual damage in the grid area not exceed 5%; 3B: Exfoliation of the edge of the incision with area greater than 5% but less than 15%; 2B: Exfoliation of the edge of the incision with area greater than 15% but less than 35%. 表 2 煤沥青基碳膜的防腐性能

Table 2 Anticorrosion performance of coal pitch-derived carbon films

PC PCNT1 PCNT2 PCNT5 H2O NO NO NO NO Ethanol NO NO NO NO 1M NaCl NO NO NO NO 1M H2SO4 NO NO NO NO 1M HCl NO NO NO NO 1M NaOH NO NO NO NO -

[1] YANG P, GHOSH S, XIA T, et al. Joule Heating and mechanical properties of epoxy/graphene based aerogel composite[J]. Compost Sci Technol,2022,218:109199. doi: 10.1016/j.compscitech.2021.109199 [2] ZHANG Q, YU Y, YANG K, et al. Mechanically robust and electrically conductive graphene-paper/glass-fibers/epoxy composites for stimuli-responsive sensors and Joule heating deicers[J]. Carbon,2017,124:296−307. doi: 10.1016/j.carbon.2017.09.001 [3] BA H, TRUONG-PHUOC L, ROMERO T, et al. Lightweight, few-layer graphene composites with improved electro-thermal properties as efficient heating devices for de-icing applications[J]. Carbon,2021,182:655−668. [4] MA J, JIANG H, HU S, et al. Ultraviolet light crosslinked graphene/multi-walled carbon nanotube hybrid films for highly robust, efficient and flexible electrothermal heaters[J]. Compost Sci Technol,2022,221:109183. doi: 10.1016/j.compscitech.2021.109183 [5] IMAI M, AKIYAMA K, TANAKA T, et al. Highly strong and conductive carbon nanotube/cellulose composite paper[J]. Compost Sci Technol,2010,70(10):1564−1570. doi: 10.1016/j.compscitech.2010.05.023 [6] RAJI A R, VARADHACHARY T, NAN K, et al. Composites of graphene nanoribbon stacks and epoxy for Joule heating and deicing of surfaces[J]. ACS Appl Mater Interfaces,2016,8(5):3551−3556. doi: 10.1021/acsami.5b11131 [7] JIANG M, SUN N, ALI SOOMRO R, et al. The recent progress of pitch-based carbon anodes in sodium-ion batteries[J]. J Energy Chem,2021,55:34−47. doi: 10.1016/j.jechem.2020.07.002 [8] LIU C, ZHENG H, WANG Y, et al. Microstructure regulation of pitch-based soft carbon anodes by iodine treatment towards high-performance potassium-ion batteries[J]. J Colloid Interface Sci,2022,615:485−493. doi: 10.1016/j.jcis.2022.01.178 [9] ZHANG G, GUAN T, QIAO J, et al. Free-radical-initiated strategy aiming for pitch-based dual-doped carbon nanosheets engaged into high-energy asymmetric supercapacitors[J]. Energy Storage Mater,2020,26:119−128. doi: 10.1016/j.ensm.2019.12.038 [10] LI Y, LEI Z, YANG X, et al. Coal tar-derived conductive pigment/polyvinylidene fluoride composite for Joule heating[J]. Prog Organ Coat,2023,174:107288. doi: 10.1016/j.porgcoat.2022.107288 [11] FERRARI A C, BASKO D M. Raman spectroscopy as a versatile tool for studying the properties of graphene[J]. Nat Nanotechnol,2013,8(4):235−246. doi: 10.1038/nnano.2013.46 [12] LEE W J, CLANCY A J, FERNÁNDEZ-TORIBIO J C, et al. Interfacially-grafted single-walled carbon nanotube/poly(vinyl alcohol) composite fibers[J]. Carbon,2019,146:162−171. doi: 10.1016/j.carbon.2019.01.075 [13] LEI Z, LI Y, LEI Z, et al. Enhanced electrical conductivity of pitch-derived carbon via graphene template effects for high electrically conductive composites[J]. J Ind Eng Chem,2023,117:394−401. doi: 10.1016/j.jiec.2022.10.027 [14] MINUS M L, CHAE H G, KUMAR S. Interfacial crystallization in gel-spun poly(vinyl alcohol)/single-wall carbon nanotube composite fibers[J]. Macromol Chem Phys,2009,210(21):1799−1808. doi: 10.1002/macp.200900223 [15] CUNNING B V, WANG B, SHIN T J, et al. Structure-directing effect of single crystal graphene film on polymer carbonization and graphitization[J]. Mater Horiz,2019,6(4):796−801. doi: 10.1039/C8MH01507D [16] TORRES-CANAS F, BENTALEB A, FӦLLMER M, et al. Improved structure and highly conductive lignin-carbon fibers through graphene oxide liquid crystal[J]. Carbon,2020,163:120−127. doi: 10.1016/j.carbon.2020.02.077 -

下载:

下载: