Effect of rare-earth element modification on the performance of Cu/ZnAl catalysts derived from hydrotalcite precursor in methanol steam reforming

-

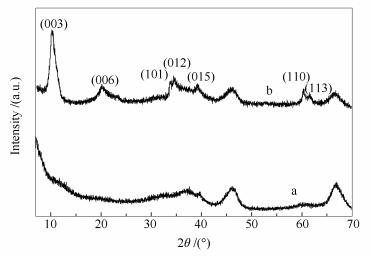

摘要: 采用原位合成法在γ-Al2O3表面合成了锌铝水滑石,再通过顺次浸渍法制备了一系列掺杂稀土改性的M(M=Y、La、Ce、Sm、Gd)/Cu/ZnAl催化材料,并将其应用于甲醇水蒸气重整制氢反应。探讨了稀土掺杂改性对Cu/ZnAl催化剂催化性能的影响,并采用XRD、SEM-EDS、BET、H2-TPR、XPS和N2O滴定等手段对催化剂进行了表征。结果表明,催化剂的活性与Cu比表面积和催化剂的还原性质密切相关,Cu比表面积越大,还原温度越低,催化活性越高。稀土Ce、Sm、Gd的引入能改善活性组分Cu的分散度、Cu比表面积以及催化剂的还原性质,进而提高催化剂的催化活性。其中,Ce/Cu/ZnAl催化剂表现出最佳的催化活性,在反应温度为250 ℃时,甲醇转化率达到100%,CO含量为0.39%,相比Cu/ZnAl催化剂,甲醇转化率提高了近40%。Abstract: Zn-Al layered double hydroxides (ZnAl-LDHs) were prepared on γ-Al2O3 by an in-situ synthesis method; with ZnAl-LDHs as the supports, a series of rare-earth element M (M=Y, La, Ce, Sm and Gd) doped M/Cu/ZnAl catalysts were then obtained through sequential wet impregnation method and used in the methanol steam reforming to produce hydrogen. The M/Cu/ZnAl catalysts were characterized by XRD, SEM-EDS, N2 sorption, H2-TPR, XPS and N2O titration and the effect of rare-earth metal doping on their catalytic performance in the methanol steam reforming was then investigated. The results showed that the activity of Cu/ZnAl catalyst is closely related to the copper surface area and the reducibility; larger copper surface area and lower reduction temperature lead to a higher catalytic activity in methanol steam reforming. The addition of rare-earth elements including Ce, Sm and Gd can improve the copper dispersion, surface copper area and the catalyst reducibility, which is helpful to enhance the activity of M/Cu/ZnAl catalysts. Especially, the Ce/Cu/ZnAl catalyst exhibits the highest activity; over it, the methanol conversion is 100% (about 40% higher than that over the Cu/ZnAl catalyst) and the CO concentration in the product is only 0.39%, for the methanol steam reforming at 250℃.

-

Key words:

- rare-earth /

- hydrotalcite /

- Cu/ZnAl /

- methanol steam reforming /

- hydrogen /

- carbon monoxide

-

图 12 反应温度对催化剂CO浓度的影响

Figure 12 CO molar concentrations in the gaseous products as a function of the reaction temperature for the methanol steam reforming at a water/methanol molar ratio of 1.2 and GHSV of 800 h-1

a: Cu/ZnAl; b: Y/Cu/ZnAl; c: La/Cu/ZnAl; d: Ce/Cu/ZnAl; e: Sm/Cu/ZnAl; f: Gd/Cu/ZnAl; g: equil

表 1 催化剂的物化性质及其催化甲醇水蒸气重整反应中氢气产率

Table 1 Textural properties of the M/Cn/ZnAl catalysts modified with various rare earth elements and their hydrogen production rate in the methanol steam reforming

Catalyst ABET

/(m2·g-1)Pore volume

v/(cm3·g-1)CuO crystallite

size d/nmCu surface area

A/(m2·g-1)Cu dispersion

/%YcH2/

(mL·kgcat-1·s-1)Cu/ZnAl 147.0 0.47 34 5.9 10.32 446.2 Y/Cu/ZnAl 101.9 0.39 25 5.3 10.15 414.8 La/Cu/ZnAl 105.5 0.37 24 5.3 10.05 424.4 Ce/Cu/ZnAl 109.6 0.41 23 6.3 11.49 810.7 Sm/Cu/ZnAl 106.0 0.37 25 6.1 11.53 568.5 Gd/Cu/ZnAl 107.6 0.40 24 5.9 11.15 457.3 note: the Cu surface area was measured by N2O chemisorption and Cu dispersion was determined as the ratio of the surface copper amount to the total copper content in the catalysts; The hydrogen production rate (YH2) was obtained by methanol steam reforming under atmospheric pressure, 240 ℃, water methanol molar ratio of 1.2 and GHSV of 800 h-1; no carrier gas was used 表 2 高斯拟合后还原峰位置

Table 2 Positions of the reduction peak by a Gauss fit of the H2-TPR profiles

Catalyst Peak position t/ ℃ peak 1 peak 2 peak 3 Cu/ZnAl 266 324 - Y/Cu/ZnAl 293 305 315 La/Cu/ZnAl 279 297 309 Ce/Cu/ZnAl 242 266 281 Sm/Cu/ZnAl 266 297 - Gd/Cu/ZnAl 266 297 - 表 3 CO的选择性

Table 3 Selectivity to CO over various catalysts

Catalyst Methanol conversion

x/%Selectivity to CO

s/%Temperature

t/ ℃Cu/ZnAl 79 1.6 260 Y/Cu/ZnAl 76 1.1 260 La/Cu/ZnAl 77 1.2 260 Ce/Cu/ZnAl 92 0.9 240 Sm/Cu/ZnAl 83 1.0 250 Gd/Cu/ZnAl 81 0 260 -

[1] JACOBSON M Z, COLELLA W G, GOLDEN D. Cleaning the air and improving health with hydrogen fuel-cell vehicles[J]. Science, 2005, 308(5730):1901-1905. doi: 10.1126/science.1109157 [2] FIHRI A, ARTERO V, RAZAVET M, BAFFERT C, LEIBL W, FONTECAVE M. Cobaloxime-based photocatalytic devices for hydrogen production[J]. Angew Chem Int Ed, 2008, 47(3):564-567. [3] KUC J, NEUMANN M, ARMBRUSTER M, YOON S, ZHANG Y, ERNI R, WEIDENKAFF A, MATAM S K. Methanol steam reforming catalysts derived by reduction of perovskite-type oxides LaCo1-x-yPdx ZnyO3±δ[J]. Catal Sci Technol, 2016, 6:1455-1468. doi: 10.1039/C5CY01410G [4] MA Y, GUAN G, PHANTHONG P, LI X, CAO J, HAO X, WANG Z, ABUDULA A. Steam reforming of methanol for hydrogen production over nanostructured wire-like molybdenum carbide catalyst[J]. Int J Hydrogen Energy, 2014, 39(33):18803-18811. doi: 10.1016/j.ijhydene.2014.09.062 [5] SA S, SILVA H, BRANDAO L, SOUSA J M, MENDES A. Catalysts for methanol steam reforming-A review[J]. Appl Catal B:Environ, 2010, 99(1/2):43-57. https://www.sciencedirect.com/science/article/pii/S0926337310002584 [6] 张磊, 潘立卫, 倪长军, 赵生生, 王树东, 胡永康, 王安杰, 蒋凯.甲醇水蒸气重整制氢反应条件的优化[J].燃料化学学报, 2013, 41(1):116-122. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18110.shtmlZHANG Lei, PAN Li-wei, NI Chang-jun, ZHAO Sheng-sheng, WANG Shu-dong, HU Yong-kang, WANG An-jie, JIANG Kai. Optimization of methanol steam reforming for hydrogen[J]. J Fuel Chem Technol, 2013, 41(1):116-122. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18110.shtml [7] KIM W, MOHAIDEEN K K, SEO D J, YOON L Y. Methanol-steam reforming reaction over Cu-Al-based catalysts derived from layered double hydroxides[J]. Int J Hydrogen Energy, 2017, 42(4):2081-2087. doi: 10.1016/j.ijhydene.2016.11.014 [8] ZHOU J J, ZHANG Y, WU G S, MAO D S, LU G Z. Influence of the component interaction over Cu/ZrO2 catalysts induced with fractionated precipitation method on the catalytic performance for methanol steam reforming[J]. RSC Adv, 2016, 6:30176-30183. doi: 10.1039/C5RA24163D [9] DAS D, LLORCA J, DOMINGUEZ M, COLUSSI S, TROVARELLI A, GAYEN A. Methanol steam reforming behavior of copper impregnated over CeO2-ZrO2 derived from a surfactant assisted coprecipitation route[J]. Int J Hydrogen Energy, 2015, 40(33):10463-10479. doi: 10.1016/j.ijhydene.2015.06.130 [10] LYTKINA A A, ZHILYAEVA N A, ERMILOVA M M, OREKHOVA N V, YAROSLAVTSEO A B. Influence of the support structure and composition of Ni-Cu-based catalysts on hydrogen production by methanol steam reforming[J]. Int J Hydrogen Energy, 2015, 40(31):9677-9684. doi: 10.1016/j.ijhydene.2015.05.094 [11] HUANG Y H, WANG S F, TSAI A P, KAMEOKA S. Catalysts prepared from copper-nickel ferrites for the steam reforming of methanol[J]. J Power Sources, 2015, 281:138-145. https://www.sciencedirect.com/science/article/pii/S0378775315001962 [12] BUSCA G, COSTANTINO U, MARMOTTINI F, MONTANARI T, PATRONO P, PINZARI F, RAMIS G. Methanol steam reforming over ex-hydrotalcite Cu-Zn-Al catalysts[J]. Appl Catal A:Gen, 2006, 310:70-78. doi: 10.1016/j.apcata.2006.05.028 [13] YAO C Z, WANG L C, LIU Y M, WU G S, CAO Y, DAI W L, FAN K N. Effect of preparation method on the hydrogen production from methanol steam reforming over binary Cu/ZrO2 catalysts[J]. Appl Catal A:Gen, 2006, 297(2):151-158. doi: 10.1016/j.apcata.2005.09.002 [14] PATEL S, PANT K K. Influence of preparation method on performance of Cu(Zn)(Zr) -alumina catalysts for the hydrogen production via steam reforming of methanol[J]. Porous Mater, 2006, 13(3):373-378. https://www.sciencedirect.com/science/article/pii/S0360319911004186 [15] SHEN J P, SONG C S. Influence of preparation method on performance of Cu/Zn-based catalysts for low-temperature steam reforming and oxidative steam reforming of methanol for H2 production for fuel cells[J]. Catal Today, 2002, 77(1):89-98. https://www.sciencedirect.com/science/article/pii/S0920586102002353 [16] HAMMOUD D, GENNEQUIN C, ABOUKAIS A, AAD E A. Steam reforming of methanol over x% Cu/Zn-Al 400500 based catalysts for production of hydrogen:Preparation by adopting memory effect of hydrotalcite and behavior evaluation[J]. Int J Hydrogen Energy, 2015, 40(2):1283-1297. doi: 10.1016/j.ijhydene.2014.09.080 [17] CAI Y C, LIU S W, XU X L, LI S B. team reforming of methanol over CuO-ZnO-La2O3-Al2O3 catalyst[J]. Mol Catal, 2002, 2(15):152-154. [18] PATEL S, PANT K K. Activity and stability enhancement of copper-alumina catalysts using cerium and zinc promoters for the selective production of hydrogen via steam reforming of methanol[J]. J Power Sources, 2006, 159(1):139-143. doi: 10.1016/j.jpowsour.2006.04.008 [19] TROVARELLI A. Catalytic properties of ceria and CeO2-containing materials[J]. Catal Rev Sci Eng, 1996, 38(4):439-520. doi: 10.1080/01614949608006464 [20] HE J P, YANG Z X, ZHANG L, LI Y, PAN L W. Cu supported on ZnAl-LDHs precursor prepared by in-situ synthesis method on γ-Al2O3 as catalytic material with high catalytic activity for methanol steam reforming[J]. Int J Hydrogen Energy, 2017, 42(15):9930-9937. doi: 10.1016/j.ijhydene.2017.01.229 [21] XIE R F, FAN G L, YANG L, LI F. Solvent-free oxidation of ethylbenzene over hierarchical flower-like core-shell structured Co-based mixed metal oxides with significantly enhanced catalytic performance[J]. Catal Sci Technol, 2015, 5(1):540-548. https://www.sciencedirect.com/science/article/pii/S1385894715016617 [22] AGARWAL V, PATEL S, PANT K K. H2 production by steam reforming of methanol over Cu/ZnO/Al2O3 catalysts:Transient deactivation kinetics modeling[J]. Appl Catal A:Gen, 2005, 279(1):155-164. http://www.doc88.com/p-4754410122489.html [23] ZHANG L, PAN L W, NI C J, SUN T J, ZHAO S S, WANG S D, WANG A J, HU Y K. CeO2-ZrO2-promoted CuO/ZnO catalyst for methanol steam reforming[J]. Int J Hydrogen Energy, 2013, 38(11):4397-4406. doi: 10.1016/j.ijhydene.2013.01.053 [24] ZHANG L, PAN L W, NI C J, SUN T J, WANG S D, WANG A J, HU Y K, ZHAO S S. Effect of precipitation aging time on the performance of CuO/ZnO/CeO2-ZrO2 for methanol steam reforming[J]. J Fuel Chem Technol, 2013, 41(7):883-888. doi: 10.1016/S1872-5813(13)60038-9 [25] HURST N W, GENTRY S J, JONES A, MCNICOL B D. Temperature programmed reduction[J]. Catal Rev Sci Eng, 1982, 24(2):233-309. doi: 10.1080/03602458208079654 [26] SHIM J O, NA H S, JHA A, JANG W J, JEONG D W, NAH I W, JEON B H, ROH H S. Effect of preparation method on the oxygen vacancy concentration of CeO2-promoted Cu/γ-Al2O3 catalysts for HTS reactions[J]. Chem Eng J, 2016, 306:908-915. doi: 10.1016/j.cej.2016.08.030 [27] WANG C, CHENG Q P, WANG X L, MA K, BAI X Q, TAN S R, TIAN Y, TONG D, ZHENG L R, ZHANG J, LI X G. Enhanced catalytic performance for CO preferential oxidation over CuO catalysts supported on highly defective CeO2 nanocrystals[J]. Appl Surf Sci, 2017, 422:932-943. doi: 10.1016/j.apsusc.2017.06.017 [28] 张磊, 雷俊腾, 田园, 胡鑫, 白金, 刘丹, 杨义, 潘立卫.前驱体和沉淀剂浓度对CuO/ZnO/CeO2-ZrO2甲醇水蒸气重整制氢催化剂性能的影响[J].燃料化学学报, 2015, 43(11):1366-1374. doi: 10.3969/j.issn.0253-2409.2015.11.012ZHANG Lei, LEI Jun-teng, TIAN Yuan, HU Xin, BAI Jin, LIU Dan, YANG Yi, PAN Li-wei. Effect of precursor and precipitant concentration on the performance of CuO/ZnO/CeO2-ZrO2 catalyst for methanol steam reforming[J]. J Fuel Chem Technol, 2015, 43(11):1366-1374. doi: 10.3969/j.issn.0253-2409.2015.11.012 [29] DAS D, LLORCA J, DOMINGUEZ M, COLUSSI S, TROVARELLI A, GAYEN A. Methanol steam reforming behavior of copper impregnated over CeO2-ZrO2 derived from a surfactant assisted coprecipitation route[J]. Int J Hydrogen Energy, 2015, 40(33):10463-10479. https://www.sciencedirect.com/science/article/pii/S0360319916326787 [30] 张国强, 郭天玉, 郑华艳, 李忠.焙烧温度对CuCe/Ac催化剂甲醇氧化羰基化性能的影响[J].燃料化学学报, 2016, 44(6):674-679. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18844.shtmlZHANG Guo-qiang, GUO Tian-yu, ZHENG Hua-yan, LI Zhong. Effect of calcination temperature on catalytic performance of CuCe/Ac catalysts for oxidative carbonylation of methanol[J]. J Fuel Chem Technol, 2016, 44(6):674-679. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18844.shtml [31] XIAO S, ZHANG Y F, GAO P, ZHONG L S, LI X P, ZHANG Z Z, WANG H, WEI W, SUN Y H. Highly efficient cu-based catalysts via hydrotalcite-like precursors for CO2 hydrogenation to methanol[J]. Catal Today, 2017, 281:327-336. doi: 10.1016/j.cattod.2016.02.004 [32] LIU L J, YAO Z J, DENG Y, GAO F, LIU B, DONG L. Nanoscale ceria on the activity of CuO/CeO2 for NO reduction by CO[J]. ChemCatChem, 2011, 3(6):978-989. https://www.sciencedirect.com/science/article/pii/S0926337309001039 [33] LIANG F L, YU Y, ZHOU W, XU X Y, ZHU Z H. Highly defective CeO2 as a promoter for efficient and stable water oxidation[J]. J Mater Chem A, 2015, 3(2):634-640. doi: 10.1039/C4TA05770H -

下载:

下载: